IDE (I) West Bengal

- 2. Advantages of weeding Periodic management of weeds has been one of the major factors contributing towards the higher productivity of paddy under SRI – 1. Promotes healthy growth of roots and consequently the plant 2. Enhances the utilisation of biomass 3. Facilitates proper aeration in the soil 4. Increase in yields as a result of more productive tillers, large panicle size, more number of grains per panicle & increased grain weight

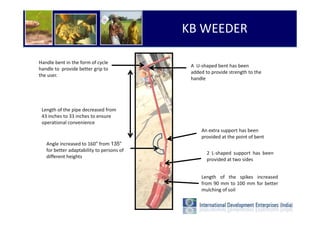

- 3. KB WEEDER Handle bent in the form of cycle A U-shaped bent has been handle to provide better grip to added to provide strength to the the user. handle Length of the pipe decreased from 43 inches to 33 inches to ensure operational convenience An extra support has been provided at the point of bent Angle increased to 160° from 135° for better adaptability to persons of 2 L-shaped support has been different heights provided at two sides Length of the spikes increased from 90 mm to 100 mm for better mulching of soil

- 4. Manufacturing Units To provide the SRI adopters with easy to use, low cost weeder, IDEI has identified and developed manufacturers in West Bengal. Contai Engineering Works in Contai, East Midnapore has the capacity to produce 100 weeders. Jaber Engineering Works in Raiganj, North Dinajpur has the capacity to produce 100 weeders. Modern Engineering works in Coochbehar also has the capacity to produce 100 weeders.

- 5. Supply Chain The Weeders fabricated by the potential manufacturers are then passed on to dealers for sale in remote rural areas. We are currently using the existing KB supply chain for weeder marketing.

- 6. Quality and Production Quality control during Production: Strict quality control measures are taken at manufacturing unit through Quality Assurance Manager Plan: Warranty of one year Each weeder will have unique punch plate numbers Weeders will be sold under the Brand name KB Production: Production just enough to meet IDEIs requirement of weeder Interested organization can make a visit to the manufacturing units to understand the process

- 7. And in Closing... Farmer Speak… “The KB Weeder is an efficient device in its function and easy to use so as to reduce the drudgery on labour. Adding organic matter to the soil by mixing weeds with the soil has helped in increasing the yield of rice. It is really wonderful and stirring to see such a robust growth in rice”, says Asgar Ali, North Dinajpur, West Bengal. “I found that the stirring effect of the weeder has positive impact on the grain yield. I also found that the weeder use has a sort of earthing up effect and the plants produce new roots which probably help in additional nutrient uptake. Today I am a happy man as there is regular supply of rice for my family”, says a cheerful Ramhari Panda, Contai, West Bengal.

- 8. THANK YOU