Igara case

- 1. IGARA GROWERS TEA FACTORY LIMITED,UGANDA Arthur Babu Muguzi – Chairman Igara Board of Directors 2nd Briefing for Africa July 2014

- 2. 2 Outline 1. Background 2. Igara’s journey to success 3. Production Trend 4. Achievements of Igara Growers Tea Factory as a farmer-led business 5. Challenges faced by Igara Growers Tea Factory 6. Replication of the Business Model

- 3. 3 Background … • 1970s: Tea as 4th highest foreign income earner for Uganda. • Decline in Sector starting 1973 , and near Collapse by 1981. • During the period of economic recovery after the Amin regime. • Uganda Tea Growers designed the Smallholder Tea Development Programme. • The Green Leaf Project • The Tea Factory Project (4 tea factories) • The objectives of the programme were as follows: • Assist smallholder farmers to take control of the factories to which they delivered their green leaf • Create an attractive investment environment for the medium and large scale farmers • Improve extension services • Improve the technical efficiency and capacity of the tea factories

- 4. 4 Background … • Igara Tea Growers Factory Limited was incorporated in 1995. • It is a public company in which ownership is restricted to bona fide tea farmers with a signed green leaf supply contract. • Shares are allotted during the production season on the basis of one share for every 500 kg of green leaf delivered. • The principal goal of the company is to buy green leaf tea, process it into black tea and sell the black tea on the local and export markets. • As part of the programme, a management company was established to manage all the tea factories. • At the end of the project the other tea factories opted to carry out their own management. • Igara and Kayonza opted to create the Uganda Tea Development Agency Limited (UTDAL).

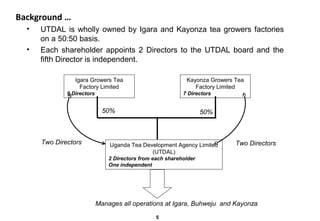

- 5. 5 Background … • UTDAL is wholly owned by Igara and Kayonza tea growers factories on a 50:50 basis. • Each shareholder appoints 2 Directors to the UTDAL board and the fifth Director is independent. Uganda Tea Development Agency Limited (UTDAL) 2 Directors from each shareholder One independent Igara Growers Tea Factory Limited 9 Directors Kayonza Growers Tea Factory Limited 7 Directors 50%50% Two DirectorsTwo Directors Manages all operations at Igara, Buhweju and Kayonza

- 6. 6 Igara’s Journey to Success … • Igara Growers Tea Factory Limited has a board of 9 elected members. • The board is managed on a rotational system for continuity. • Board members are elected to represent specific areas within which they farm. • Maintain relationship with the farmers through regular engagement ie quarterly meetings • Igara lobbied and attracted Government support. • During 2008 Igara obtained government support for the Buhweju factory in the form of a grant to cover all the buildings valued at US$ 2.4 million.

- 7. 7 Igara’s Journey to Success … • Igara provides a credit facility to the farmers for inputs such as fertilizer, herbicides,prunning knives and spray pumps. • Igara has seen its farmer membership increase from about 4,000 farmers to 6,880 farmers between 1995 and 2013. • This has been attributed to the recognition given to the farmers, both new and old farmer, and in some instances some farmers are recognised posthumously. • Igara currently has a green leaf production of about 34 million kg per annum valued at approximately US$ 7.2 million in the local economy. • This is driven by the US$ 21 cent per kg of green leaf paid to the farmers which is influenced by the prices attained for the made tea and overall management of the production and marketing costs.

- 9. 9 Achievements of Igara Growers Tea Factory as a farmer-led business … • High level of accountability to the farmers • Emphasis is on adding value to what is already in place • Made significant improvements to the business such as improved internal control systems • Payments to the farmers are significantly high. This includes the first, second and bonus payments, In addition to dividends. • The turnover and profitability of the factory is increasing. • Increased the capacity of the factory from 86,000 kg in 1995 to the current 100,000 kg per day • Established and invested in a subsidiary tea factory, the Buhweju Growers Tea Factory,with the withering capacity of 70,000kg per day

- 10. 10 Challenges faced by Igara Growers Tea Factory … • Poor road infrastructure • Labour costs for the farmer and the factory. • Delays in services that should be provided by government. • Lack of regulation of the tea sector. • Timely activities and reward of the farmers • Expensive capital costs(high interest rates) • Lack of research capacities within the country • Dependency on international markets,which we don’t control • Low prices facing the tea industry.

- 11. 11 Replication of the Business Model … • Gives Farmer Organisations an option to attract business and management skills not available within the farmer environment. • The farmers have the opportunity to remain in control of their destiny. • Having a management company allows the combining farmer organisations in different activities under one management company. • The opportunity to share some services and thus lower fixed costs.