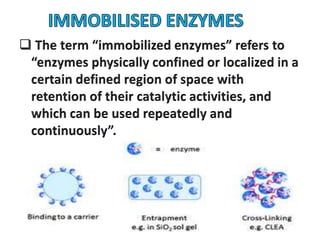

Immobilised enzymes

- 7. •

- 10. • The Occlusion Of An Enzyme Within A Polymeric Network That Allows The Substrate And Products To Pass Through But Retains The Enzyme. • Entrapping Can Be Done Through Gels And Fibers. • Organics: Polysaccharides, Proteins, Carbon, Vinyl And Allyl Polymers, And Polyamides. E.G. Ca-alginate, Agar, K-carrageenin, Collagen. • Inorganic: Activated Carbon, Porous Ceramic.

- 11. CHALLENGES: • Enzyme Leakage Into Solution • Diffusional Limitation • Reduced Enzyme Activity And Stability • Lack Of Control Micro-environmental Conditions.

- 16. Industrial enzymes are immobilized using the modified gels to produce low-cost foods and drugs:- • The use of immobilized glucose isomerase (from Streptomyces or Bacillus coagulans) for the production of high-fructose corn syrup. In this process, the enzyme is bound to an insoluble carrier such as dimethyl amino ethyl cellulose or a slurry of the fixed enzyme coated onto a pressure-leaf filter. The filter then serves as the continuous reactor through which the corn syrup flows. The product obtained by this process is a syrup with 71% solids that contains about 42% fructose and 50% glucose.  It has high sweetening power.  High fermentability  High humectancy  Reduced tendency to crystallize  Low viscosity  Good flavour.

- 17. IMMOBILIZED ENZYMES CAN BE YSED IN TWO BASIC TYPES OF REACTOR SYSTEM: • STIRRED TANK REACTOR SYSTEM • CONTINUOUS FLOW REACTOR SYSTEM

- 18. STIRRED TANK REACTOR SYSTEM (BATCH SYSTEM) • Simplest type of reactor. • The immobilized enzyme is stirred with the substrate solution. • After the completion of reaction, the immobilized enzyme is separated from the product. • Composed of a reactor and a mixer such as a stirrer, a turbine wing or a propeller. • This reactor is useful for substrate solutions of high viscosity and for immobilized enzymes with relatively low activity. A problem that arises is that an immobilized enzyme tends to decompose upon physical stirring. The batch system is generally suitable for the production of rather small amounts of chemicals.

- 19. • A problem that arises is that an immobilized enzyme tends to decompose upon physical stirring. • The batch system is generally suitable for the production of rather small amounts of chemicals.

- 20. CONTINUOUS FLOW SYSTEM • This system includes continuous flow columns in which the substrate flows through the immobilized enzyme contained in a column. • The continuous stirred tank reactor is more efficient than a batch stirred tank reactor but the equipment is slightly more complicated.

- 22. EFFECT OF Immobilization ON pH AND TEMPERATURE

- 23. Optimum pH The pH optimum can be shifted. The optimum pH value of the immobilized enzyme was more acidic than that of the free enzyme.

- 24. Optimumtemperature The optimum temperature of the immobilized enzyme exceeded that of the free state as the optimum temperature of the free enzyme

- 25. Temperature stability Immobilizing result in increased thermal stability.

- 26. FIELD ENZYMES USES Industrial Penicillinase In production of semi-synthetic antibiotics such as penicillin, amoxycillin, ampicillin. Inulinase and glucose isomerase • Production of fructose and high fructose corn syrup • 4 times sweeter than glucose (used in high fructose syrups) • Has the advantage of being recommended to people on a diet and diabetics. Lipase Hydrolyses lipids in food industries. β-galactosidase • Hydrolyses lactose to glucose and galactose. • solve 70% of the worldwide population suffering from lactose intolerance in milk and dairy products • protecting the environment by converting wastes, as whey, to lactose free syrup. Chymosin In the production of cheese.

- 27. FIELD ENZYMES USES INDUSTRIAL Pectinase and cellulase In fruit juice industries (to hydrolyse pectin and cellulose). Xylanase / phytase In animal feeds, to improve their nutritional value. Detergent enzymes 70 – 80 % of purified enzymes are used in detergent industries. Aspartase(from Escherichia coli ) used for the production of L-aspartic acid. Fumarase (from Brevibacterium ammoniagenes ) Used for the production of L-malic acid.

- 28. REFRENCE • FOOD CHEMISTRY DEEMAN • FOOD CHEMISTRY FENEMMA • http://www.rpi.edu/dept/chem-eng/Biotech- Environ/IMMOB/batch-st.gif • http://openi.nlm.nih.gov/imgs/512/165/3212977/321297 7_1472-6750-11-63-5.png?keywords= • http://www.epj.eg.net/articles/2015/14/2/images/Egypt PharmaceutJ_2015_14_2_87_161268_f6.jpg

Editor's Notes

- #2: Xylanase enzyme immobilised by sodium alginate.