independentinquiry

Download as pptx, pdf1 like206 views

Bulk metallic glasses (BMGs) are strong, corrosion resistant materials that lack a crystalline microstructure. While BMGs offer advantages like high strength and formability, they are also brittle and expensive to produce. Current applications are limited to niche uses where properties like biocompatibility or magnetism are valuable. However, research continues on utilizing BMGs in composites or developing new alloys to improve ductility and toughness for applications in aerospace, precision tools, and more. Challenges remain in reducing cost and brittleness for widespread structural use.

1 of 16

Downloaded 19 times

Ad

Recommended

Metallic glass

Metallic glassnwzjck

Ěý

Metallic glasses are metal alloys that solidify into an amorphous, non-crystalline structure rather than a crystalline structure. They have properties of both metals and glasses, such as strength and corrosion resistance. Metallic glasses are prepared through rapid cooling of molten metal alloys to prevent crystallization. They have applications in transformer cores, sensors, and nuclear waste disposal due to their magnetic and electrical properties.Metallic glasses

Metallic glassesMoxit Khandhar

Ěý

Metallic glass, an amorphous material with properties of both metals and glasses, has high strength, corrosion resistance, and good magnetic properties. It is produced by rapidly cooling molten metal, which prevents crystallization and allows for unique structural characteristics. Applications range from transformers and sensors to nuclear waste containers and surgical instruments, with potential future uses in personal electronics.Metallic Glasses(Physics)

Metallic Glasses(Physics)Dipesh Rafaliya

Ěý

Metallic glasses, also known as amorphous metals or metglasses, are materials that have the properties of both metals and glasses. They have high strength, good magnetic properties, and better corrosion resistance compared to traditional metals. Common metallic glass compositions include combinations of iron, cobalt, or nickel with boron, silicon, sulfur, or phosphorus. Metallic glasses have a non-crystalline, tetrahedrally close-packed structure without grain boundaries or dislocations which gives them high strength and corrosion resistance. They also exhibit useful electrical, magnetic, and chemical properties such as high resistivity, soft or hard magnetism, and stability. Due to these properties, metallic glasses have applications as transformer cores, sensors, computerMetallic glasses ppt

Metallic glasses pptManish Mor

Ěý

Metallic glasses are metal alloys that are amorphous, meaning they lack long-range atomic order and have a glass-like structure. They can be produced through rapid cooling techniques that solidify the molten metal before crystallization occurs. Metallic glasses have strong, corrosion-resistant, and homogeneous properties due to their amorphous structure. They also exhibit a reversible glass-liquid transition when heated instead of melting. Potential applications of metallic glasses include use in transformer cores, sensors, surgical instruments, and electronic devices due to their electrical and magnetic properties.Advanced material

Advanced material Bhavin Gadhiya

Ěý

Metallic glasses, also known as amorphous metals or glassy metals, have an atomic structure that is non-crystalline and disordered like liquids. They are produced by rapidly cooling molten metal alloys to below the glass transition temperature before crystals can form. This gives metallic glasses properties unlike conventional metals, such as high strength and elasticity. Some key applications of metallic glasses include use in sports equipment due to their formability and in electronic device casings due to their corrosion resistance.Application of metallic glasses

Application of metallic glassesAnuj Dave

Ěý

Metallic glasses are materials that have properties of both metals and glasses. They are strong, ductile, malleable, opaque, and brittle. There are two main types of metallic glasses: metal-metal metallic glasses formed from combinations of metals, and metal-metalloid metallic glasses formed from combinations of metals and metalloids like boron or silicon. Metallic glasses have applications in electrical devices due to their high electrical resistance, in medical implants due to corrosion resistance, and in nuclear reactors due to magnetic properties unaffected by irradiation.Advanced Engineering Materials

Advanced Engineering Materialskishan619

Ěý

This document discusses various advanced engineering materials. It begins by introducing metallic glasses, including their types, preparation methods, properties, and applications. It then discusses shape memory alloys, including temperature-induced transformation, stress-induced transformation, shape memory effect, super elasticity, types, applications, advantages, and disadvantages. Finally, it briefly introduces biomaterials and ultracapacitors, including their principles and types. Advanced Materilas

Advanced Materilas Liton Ahmed

Ěý

The document outlines advanced materials, which are engineered materials with specialized properties used in manufacturing across industries like aerospace and automotive. It discusses the benefits and examples of advanced materials such as magnesium, titanium, carbon fiber, and nano composites, highlighting their superior properties compared to traditional materials. The content emphasizes the importance of these materials in improving product performance, fuel efficiency, and reducing environmental impact.Alloys

AlloysMANJUNATH N

Ěý

This document discusses the classification and properties of engineering materials. It describes 8 categories of material properties - mechanical, thermal, electrical, magnetic, chemical, optical, physical and technological. Mechanical properties include strength, elasticity, plasticity, rigidity, ductility, malleability, resilience and hardness. Alloys are formed by combining metals for improved strength or corrosion resistance. Examples of alloys discussed are aluminum alloys like aluminum-silicon and aluminum-copper, copper alloys like copper-tin, and stainless steel. Common applications of these alloys are also mentioned.Emil negoita

Emil negoitaMarta MartĂn

Ěý

Gold is commonly used in home appliances as it is an excellent conductor of electricity, allowing circuits and conductors to efficiently transmit power. Gold is also used as a pigment in some specialty glasses to provide an attractive finish to glass pieces by imparting color. Gold's conductive and aesthetic properties make it a valuable material for use in electrical and glass industries.Classification of materials

Classification of materialskumarraman351

Ěý

Materials can be classified into plastics, wood, composites, ceramics, metals, and fabrics. Each category can be further divided: plastics into thermoplastics, thermosets, and elastomers; wood into hardwood, softwood, and manufactured board; composites include reinforced plastics, ceramic-matrix, metal-matrix, and laminates. Ceramics include oxides, carbides, and nitrides. Metals are ferrous such as steels or non-ferrous like aluminum and copper. Fabrics are natural like cotton or synthetic like nylon. Smart materials have useful responses to external stimuli and include shape memory alloys, smart fluids, piezoelectric materials, andReplacement of lead Free Cutting Steel - 2018 research paper

Replacement of lead Free Cutting Steel - 2018 research paperMukesh Karnik

Ěý

This document discusses free cutting steels, focusing on their machinability properties and the development of lead-free grades. It details the chemical composition and alloying elements that enhance machinability, such as sulfur and manganese, while also addressing the harmful effects of lead. Furthermore, it highlights ongoing research to replace lead with safer alternatives like graphite to maintain performance while improving environmental safety.Engineering materials part 1

Engineering materials part 1KRIPA SHNAKAR TIWARI

Ěý

Engineering materials is a science focusing on the study of materials, their properties, and uses, categorized into metals and non-metallic materials. Metals can be ferrous (containing iron) or non-ferrous, with various classifications for both types, while non-metallic materials include synthetic and natural forms such as plastics and ceramics. The document provides an overview of material types and their classifications, highlighting their applications and characteristics.Stick welding an ultimate guide for beginners

Stick welding an ultimate guide for beginnersSophia Lorenn

Ěý

Stick welding is a common and versatile arc welding technique that uses an electrode and electric current to join metals like steel and aluminum. The process, also known as shielded metal arc welding, involves a flux-coated electrode that creates a protective gas cloud during welding. While both AC and DC current can be used, DC is generally preferred for its flexibility and safety in various projects.Microstructure and Hardness observation of HEAT AFFECTED ZONE of low carbon s...

Microstructure and Hardness observation of HEAT AFFECTED ZONE of low carbon s...Mukesh Karnik

Ěý

The document details a project investigating the microstructure changes and mechanical properties of mild steel due to welding and heat-affected zones. It outlines the methodology for specimen preparation and observation, including hardness testing before and after welding. The findings indicate changes in microstructure and increased hardness in different zones resulting from heat and cooling time during the welding process.Shrink dip socket

Shrink dip socketNalin Sheth

Ěý

An integrated circuit socket is designed for shrink ICs with a 1.778mm contact pitch. The sockets have precision-machined receptacles with multi-finger contact clips housed in high temperature thermoplastic insulators. Each receptacle has a brass alloy shell and a press-fit four-finger beryllium copper contact clip that forms electrical and mechanical connections. The multi-finger clips provide better power distribution than stamped pins. Receptacle shells and clips can have different plating combinations for optimum conductivity and solderability. The sockets protect ICs, are easy to handle, reduce assembly lead time, and are cost-effective for industrial and commercial applications.Electrical and Hydraulic Tools

Electrical and Hydraulic ToolsDyanara Pernia

Ěý

This document discusses electrical power tools used in construction. It begins by listing advantages of using proper electrical tools like efficiency, quality, speed, accuracy, and less stress on users. However, these advantages depend on availability of materials, worker experience, and tool quality. It then lists common types of construction tools for different trades like carpentry, masonry, plumbing, and electrical work. The document provides safety rules for using power equipment and describes portable drills, grinders, hammer drills, core drills, and power threaders. It identifies common defects in electrical power tools and assigns performance tasks to label tool parts and functions.Basic metallurgy

Basic metallurgySEVUGARAJAN KARUPPAIAH, BE,MS.

Ěý

This document provides an overview of basic metallurgy. It discusses the classification of materials, including metals and alloys, ceramics, polymers, and composites. The key metallurgy processes of casting, forming, welding, and powder metallurgy are described. Advanced materials like electronic materials, biomaterials, and nanomaterials are also introduced. The document is authored by K. Sevugarajan of Metz Lab Pvt. Ltd and provides their contact information.Engineering materials

Engineering materials Usman Shah

Ěý

The document discusses advanced materials used in high-tech applications, including semiconductors, biomaterials, smart materials, and nanoengineered materials, detailing their properties and uses. It highlights the importance of developing new materials that are high-performance, cost-effective, and environmentally friendly, especially for energy conversion and pollution control. Challenges remain in materials science related to sustainability, energy efficiency, and the lifecycle impact of materials.Welding defects

Welding defectspremkumar1862

Ěý

This document discusses common welding defects such as blow holes and worm holes, their causes, and how to prevent them. Blow holes can be caused by an unclean base metal surface, rusty wire or wet flux, improper spot welding or wire size, excessively long arc length or insufficient gas shielding, or welding in windy conditions without a shield. Worm holes are caused by a wet, unclean, or damaged electrode, base metal covered in oil or rust, over traveling speed, over currents, excessively long or short arc length, or a base metal that is too thick or cools too quickly. To prevent these defects, welders should properly clean the base metal, maintain equipment, use proper currentsAnodic protection for corrosion prevention

Anodic protection for corrosion preventionBapi Mondal

Ěý

Anodic protection is a corrosion prevention technique that works by making a metal the anode of an electrochemical cell and controlling its electrode potential to maintain passivity. It involves using a potentiostat to apply a constant potential to the metal relative to a reference electrode, keeping the metal in the passive region of its polarization curve where corrosion rates are low. This technique is effective for metals that exhibit active-passive behavior like steel, and is commonly used to protect tanks containing highly corrosive chemicals where cathodic protection would require too much current.Stainless steel alloys

Stainless steel alloysLakshita Sood

Ěý

Stainless steel alloys are used widely in orthodontics. They contain 12-30% chromium which gives corrosion resistance. There are three main types - ferritic, austenitic and martensitic - depending on crystal structure. Austenitic stainless steel like 18-8 is most common due to good ductility. It can be work hardened or hardened by rapid cooling to form martensite. Heat treatments like annealing can relieve stresses from work hardening. Stainless steel is joined by silver soldering or spot welding in orthodontics.Welding

WeldingAnasMirza10

Ěý

Welding is a process that joins two or more metal pieces together by applying heat, pressure, or both. It is the primary way to join metal parts into a single piece. Some key equipment needed for gas welding includes oxygen and acetylene cylinders/valves, hoses, safety gear like gloves and goggles, and tools for cleaning and prepping the metal. There are different types of fusion welding that melt and fuse the base metal, and may add a filler metal, using heat sources like gas flames, electric arcs, plasma arcs, or lasers. A welding torch is used to direct the electrode, conduct welding power, and provide shielding of the arc during automatic welding.Ceramics for structural applications

Ceramics for structural applicationsJAPHETHENRIQUEZ

Ěý

The document discusses the use of various ceramics, particularly aluminum oxide, silicon carbide, silicon nitride, and zirconium oxide, in structural applications and manufacturing processes. It highlights the differences in porosity, mechanical properties, and applications of these materials in industries such as automotive and abrasive products. Additionally, it touches on the electrical properties of ceramics and the use of magnetic ceramics for applications requiring rapid magnetization.junker_2015nurfprojectsummary

junker_2015nurfprojectsummaryMichael Junker

Ěý

This project summary describes research conducted on synthesizing nanoparticles for fabricating solid-state batteries. The student learned how to synthesize powders, mill materials, operate furnaces, and characterize samples using XRD and XRF. The goal was to develop a solid oxide electrolyte with sufficient ionic conductivity for batteries by reducing the sintering temperature of Li7La3Zr2O12 below 900°C to prevent lithium loss. Experiments showed milling to 50nm and adding Al2O3 and Li3BO3 glass reduced the sintering temperature by 300°C to 890°C. Further research is needed to increase density for higher ionic conductivity. Progress was also made tape-casting thin electrolyBasic metallurgy for welding & fabricaton professionals

Basic metallurgy for welding & fabricaton professionalsPuneet Sharma

Ěý

This document outlines a comprehensive course on basic metallurgy for welding and fabricating professionals, covering metal properties, types of steels, heat treatment processes, and various applications of metals and non-metals. It discusses fundamental concepts like the iron carbide diagram, classification of steels, and the effects of alloying elements on mechanical properties. Additionally, it delves into specific steels' characteristics, including low alloy and stainless steels, and their usage in various industrial applications.Daad presentation

Daad presentationMrak13

Ěý

This document discusses the application of superplasticity and creepage effects for aircraft component production using sheet metal and plates made of titanium. It first provides background on the Aircraft Faculty at Novosibirsk State Technical University and properties of titanium. It then explains superplasticity, the mechanisms that provide it, and relevant technological processes. The document outlines issues with the current forming equipment used at a local aircraft production enterprise and objectives to improve uniform heating and the forming system to achieve the required accuracy for titanium panels. It concludes with future plans to conduct finite element analysis and determine optimal forming conditions.Types of stainless steel and commonly used stainless

Types of stainless steel and commonly used stainlessJayDhamecha3

Ěý

This document discusses types of stainless steel and commonly used grades. It describes the five main types - ferritic, austenitic, martensitic, duplex, and precipitation hardened - and their key properties. Common grades discussed include 301, 302, 304, 309, and 316. Applications where stainless steel is used are also summarized, such as architecture, automotive, medical, and energy/heavy industries due to its corrosion resistance, strength and low maintenance.“Metallic glasses from''alchemy''to pure science: Present and future of desig...

“Metallic glasses from''alchemy''to pure science: Present and future of desig...Eugen Axinte

Ěý

The document reviews the history, properties, and applications of bulk metallic glasses (BMGs), highlighting their transformation from metals into glass-like materials through rapid cooling processes. It discusses structural models, mechanical properties, and potential engineering applications in microdevices and other industries. Future developments and ongoing research in this field are acknowledged, with thanks to various contributors and institutions.BULK METALLIC GLASS

BULK METALLIC GLASSManjinder Singh

Ěý

The document discusses bulk metallic glasses (BMGs), detailing their properties, preparation methods, and applications. BMGs, composed of amorphous alloys, exhibit unique characteristics such as high strength, ductility, and corrosion resistance, making them suitable for various engineering applications. Historical milestones in the development of BMGs and different processing techniques like melt-spinning and selective laser melting are also highlighted.More Related Content

What's hot (20)

Alloys

AlloysMANJUNATH N

Ěý

This document discusses the classification and properties of engineering materials. It describes 8 categories of material properties - mechanical, thermal, electrical, magnetic, chemical, optical, physical and technological. Mechanical properties include strength, elasticity, plasticity, rigidity, ductility, malleability, resilience and hardness. Alloys are formed by combining metals for improved strength or corrosion resistance. Examples of alloys discussed are aluminum alloys like aluminum-silicon and aluminum-copper, copper alloys like copper-tin, and stainless steel. Common applications of these alloys are also mentioned.Emil negoita

Emil negoitaMarta MartĂn

Ěý

Gold is commonly used in home appliances as it is an excellent conductor of electricity, allowing circuits and conductors to efficiently transmit power. Gold is also used as a pigment in some specialty glasses to provide an attractive finish to glass pieces by imparting color. Gold's conductive and aesthetic properties make it a valuable material for use in electrical and glass industries.Classification of materials

Classification of materialskumarraman351

Ěý

Materials can be classified into plastics, wood, composites, ceramics, metals, and fabrics. Each category can be further divided: plastics into thermoplastics, thermosets, and elastomers; wood into hardwood, softwood, and manufactured board; composites include reinforced plastics, ceramic-matrix, metal-matrix, and laminates. Ceramics include oxides, carbides, and nitrides. Metals are ferrous such as steels or non-ferrous like aluminum and copper. Fabrics are natural like cotton or synthetic like nylon. Smart materials have useful responses to external stimuli and include shape memory alloys, smart fluids, piezoelectric materials, andReplacement of lead Free Cutting Steel - 2018 research paper

Replacement of lead Free Cutting Steel - 2018 research paperMukesh Karnik

Ěý

This document discusses free cutting steels, focusing on their machinability properties and the development of lead-free grades. It details the chemical composition and alloying elements that enhance machinability, such as sulfur and manganese, while also addressing the harmful effects of lead. Furthermore, it highlights ongoing research to replace lead with safer alternatives like graphite to maintain performance while improving environmental safety.Engineering materials part 1

Engineering materials part 1KRIPA SHNAKAR TIWARI

Ěý

Engineering materials is a science focusing on the study of materials, their properties, and uses, categorized into metals and non-metallic materials. Metals can be ferrous (containing iron) or non-ferrous, with various classifications for both types, while non-metallic materials include synthetic and natural forms such as plastics and ceramics. The document provides an overview of material types and their classifications, highlighting their applications and characteristics.Stick welding an ultimate guide for beginners

Stick welding an ultimate guide for beginnersSophia Lorenn

Ěý

Stick welding is a common and versatile arc welding technique that uses an electrode and electric current to join metals like steel and aluminum. The process, also known as shielded metal arc welding, involves a flux-coated electrode that creates a protective gas cloud during welding. While both AC and DC current can be used, DC is generally preferred for its flexibility and safety in various projects.Microstructure and Hardness observation of HEAT AFFECTED ZONE of low carbon s...

Microstructure and Hardness observation of HEAT AFFECTED ZONE of low carbon s...Mukesh Karnik

Ěý

The document details a project investigating the microstructure changes and mechanical properties of mild steel due to welding and heat-affected zones. It outlines the methodology for specimen preparation and observation, including hardness testing before and after welding. The findings indicate changes in microstructure and increased hardness in different zones resulting from heat and cooling time during the welding process.Shrink dip socket

Shrink dip socketNalin Sheth

Ěý

An integrated circuit socket is designed for shrink ICs with a 1.778mm contact pitch. The sockets have precision-machined receptacles with multi-finger contact clips housed in high temperature thermoplastic insulators. Each receptacle has a brass alloy shell and a press-fit four-finger beryllium copper contact clip that forms electrical and mechanical connections. The multi-finger clips provide better power distribution than stamped pins. Receptacle shells and clips can have different plating combinations for optimum conductivity and solderability. The sockets protect ICs, are easy to handle, reduce assembly lead time, and are cost-effective for industrial and commercial applications.Electrical and Hydraulic Tools

Electrical and Hydraulic ToolsDyanara Pernia

Ěý

This document discusses electrical power tools used in construction. It begins by listing advantages of using proper electrical tools like efficiency, quality, speed, accuracy, and less stress on users. However, these advantages depend on availability of materials, worker experience, and tool quality. It then lists common types of construction tools for different trades like carpentry, masonry, plumbing, and electrical work. The document provides safety rules for using power equipment and describes portable drills, grinders, hammer drills, core drills, and power threaders. It identifies common defects in electrical power tools and assigns performance tasks to label tool parts and functions.Basic metallurgy

Basic metallurgySEVUGARAJAN KARUPPAIAH, BE,MS.

Ěý

This document provides an overview of basic metallurgy. It discusses the classification of materials, including metals and alloys, ceramics, polymers, and composites. The key metallurgy processes of casting, forming, welding, and powder metallurgy are described. Advanced materials like electronic materials, biomaterials, and nanomaterials are also introduced. The document is authored by K. Sevugarajan of Metz Lab Pvt. Ltd and provides their contact information.Engineering materials

Engineering materials Usman Shah

Ěý

The document discusses advanced materials used in high-tech applications, including semiconductors, biomaterials, smart materials, and nanoengineered materials, detailing their properties and uses. It highlights the importance of developing new materials that are high-performance, cost-effective, and environmentally friendly, especially for energy conversion and pollution control. Challenges remain in materials science related to sustainability, energy efficiency, and the lifecycle impact of materials.Welding defects

Welding defectspremkumar1862

Ěý

This document discusses common welding defects such as blow holes and worm holes, their causes, and how to prevent them. Blow holes can be caused by an unclean base metal surface, rusty wire or wet flux, improper spot welding or wire size, excessively long arc length or insufficient gas shielding, or welding in windy conditions without a shield. Worm holes are caused by a wet, unclean, or damaged electrode, base metal covered in oil or rust, over traveling speed, over currents, excessively long or short arc length, or a base metal that is too thick or cools too quickly. To prevent these defects, welders should properly clean the base metal, maintain equipment, use proper currentsAnodic protection for corrosion prevention

Anodic protection for corrosion preventionBapi Mondal

Ěý

Anodic protection is a corrosion prevention technique that works by making a metal the anode of an electrochemical cell and controlling its electrode potential to maintain passivity. It involves using a potentiostat to apply a constant potential to the metal relative to a reference electrode, keeping the metal in the passive region of its polarization curve where corrosion rates are low. This technique is effective for metals that exhibit active-passive behavior like steel, and is commonly used to protect tanks containing highly corrosive chemicals where cathodic protection would require too much current.Stainless steel alloys

Stainless steel alloysLakshita Sood

Ěý

Stainless steel alloys are used widely in orthodontics. They contain 12-30% chromium which gives corrosion resistance. There are three main types - ferritic, austenitic and martensitic - depending on crystal structure. Austenitic stainless steel like 18-8 is most common due to good ductility. It can be work hardened or hardened by rapid cooling to form martensite. Heat treatments like annealing can relieve stresses from work hardening. Stainless steel is joined by silver soldering or spot welding in orthodontics.Welding

WeldingAnasMirza10

Ěý

Welding is a process that joins two or more metal pieces together by applying heat, pressure, or both. It is the primary way to join metal parts into a single piece. Some key equipment needed for gas welding includes oxygen and acetylene cylinders/valves, hoses, safety gear like gloves and goggles, and tools for cleaning and prepping the metal. There are different types of fusion welding that melt and fuse the base metal, and may add a filler metal, using heat sources like gas flames, electric arcs, plasma arcs, or lasers. A welding torch is used to direct the electrode, conduct welding power, and provide shielding of the arc during automatic welding.Ceramics for structural applications

Ceramics for structural applicationsJAPHETHENRIQUEZ

Ěý

The document discusses the use of various ceramics, particularly aluminum oxide, silicon carbide, silicon nitride, and zirconium oxide, in structural applications and manufacturing processes. It highlights the differences in porosity, mechanical properties, and applications of these materials in industries such as automotive and abrasive products. Additionally, it touches on the electrical properties of ceramics and the use of magnetic ceramics for applications requiring rapid magnetization.junker_2015nurfprojectsummary

junker_2015nurfprojectsummaryMichael Junker

Ěý

This project summary describes research conducted on synthesizing nanoparticles for fabricating solid-state batteries. The student learned how to synthesize powders, mill materials, operate furnaces, and characterize samples using XRD and XRF. The goal was to develop a solid oxide electrolyte with sufficient ionic conductivity for batteries by reducing the sintering temperature of Li7La3Zr2O12 below 900°C to prevent lithium loss. Experiments showed milling to 50nm and adding Al2O3 and Li3BO3 glass reduced the sintering temperature by 300°C to 890°C. Further research is needed to increase density for higher ionic conductivity. Progress was also made tape-casting thin electrolyBasic metallurgy for welding & fabricaton professionals

Basic metallurgy for welding & fabricaton professionalsPuneet Sharma

Ěý

This document outlines a comprehensive course on basic metallurgy for welding and fabricating professionals, covering metal properties, types of steels, heat treatment processes, and various applications of metals and non-metals. It discusses fundamental concepts like the iron carbide diagram, classification of steels, and the effects of alloying elements on mechanical properties. Additionally, it delves into specific steels' characteristics, including low alloy and stainless steels, and their usage in various industrial applications.Daad presentation

Daad presentationMrak13

Ěý

This document discusses the application of superplasticity and creepage effects for aircraft component production using sheet metal and plates made of titanium. It first provides background on the Aircraft Faculty at Novosibirsk State Technical University and properties of titanium. It then explains superplasticity, the mechanisms that provide it, and relevant technological processes. The document outlines issues with the current forming equipment used at a local aircraft production enterprise and objectives to improve uniform heating and the forming system to achieve the required accuracy for titanium panels. It concludes with future plans to conduct finite element analysis and determine optimal forming conditions.Types of stainless steel and commonly used stainless

Types of stainless steel and commonly used stainlessJayDhamecha3

Ěý

This document discusses types of stainless steel and commonly used grades. It describes the five main types - ferritic, austenitic, martensitic, duplex, and precipitation hardened - and their key properties. Common grades discussed include 301, 302, 304, 309, and 316. Applications where stainless steel is used are also summarized, such as architecture, automotive, medical, and energy/heavy industries due to its corrosion resistance, strength and low maintenance.Similar to independentinquiry (20)

“Metallic glasses from''alchemy''to pure science: Present and future of desig...

“Metallic glasses from''alchemy''to pure science: Present and future of desig...Eugen Axinte

Ěý

The document reviews the history, properties, and applications of bulk metallic glasses (BMGs), highlighting their transformation from metals into glass-like materials through rapid cooling processes. It discusses structural models, mechanical properties, and potential engineering applications in microdevices and other industries. Future developments and ongoing research in this field are acknowledged, with thanks to various contributors and institutions.BULK METALLIC GLASS

BULK METALLIC GLASSManjinder Singh

Ěý

The document discusses bulk metallic glasses (BMGs), detailing their properties, preparation methods, and applications. BMGs, composed of amorphous alloys, exhibit unique characteristics such as high strength, ductility, and corrosion resistance, making them suitable for various engineering applications. Historical milestones in the development of BMGs and different processing techniques like melt-spinning and selective laser melting are also highlighted.EP PPT 3.pptx

EP PPT 3.pptxDeveshSingh608809

Ěý

Metallic glasses are amorphous alloys that are prepared through rapid quenching of molten alloys to prevent crystallization. They have properties of both metals and glasses such as high strength, elasticity, ductility, corrosion resistance, and good magnetic properties. Common preparation methods include spinning, spraying, and deposition which involve rapidly cooling the molten alloy. Metallic glasses find applications as reinforcing elements, razor blades, springs, transformer cores, electrical and electronics components, nuclear reactors, and biomedical implants due to their unique combination of properties.Atul msme

Atul msmeAtul Patel

Ěý

Bulk metallic glasses are metallic alloys that lack long-range atomic order and behave like liquids in their supercooled liquid region. They can be formed through rapid quenching of alloys with proper alloying additions to improve glass-forming ability. This document discusses experiments adding elements like Si, Au, Ag, Cu, and P to Pd- and Ni-based alloys to enhance thermal stability and glass formation, enabling the production of bulk metallic glass samples. Alloying additions were found to improve properties like plasticity by stabilizing the liquid phase and destabilizing crystalline phases. Potential applications of bulk metallic glasses include aerospace and military materials, biomedical implants, and electronics due to their strength, elasticity,Metallic Glasses (Type of Metallic Materials)

Metallic Glasses (Type of Metallic Materials)Dhaval Shukla

Ěý

The document discusses metallic glasses, which are metal alloys that lack long-range atomic order and crystallinity. Metallic glasses have properties of both metals and alloys, such as strength and corrosion resistance. They are produced through rapid cooling techniques to prevent crystal nucleation. Potential applications include use as transformer cores due to low hysteresis loss, in sensors due to resistance properties, and in medical implants due to corrosion resistance. Metallic glasses offer advantages over crystalline metals like fewer defects and potential for new applications.Metallic glass

Metallic glassGanapathy ThayammalMurugesan

Ěý

Metallic glass, also known as amorphous metal or metglass, has properties of both metals and glasses. It is prepared by rapidly cooling a metallic liquid to prevent crystallization. Metallic glass has a glass transition temperature between 20-300°C and is typically produced using melt spinning, which involves ejecting a molten alloy through a nozzle onto a spinning copper wheel where it rapidly solidifies into an amorphous solid. Metallic glasses have many applications due to their high strength, corrosion resistance, and magnetic properties and are used in transformers, surgical instruments, and marine cables.METALLIC GLASS Akshat Metallic+Glasses (15 files merged).pptx

METALLIC GLASS Akshat Metallic+Glasses (15 files merged).pptxVishalKumar847614

Ěý

METALLIC GLASS Akshat.pptxHifkljjjjkkjjhfddj jhhjj dyjkkjnb ijggjk

Hifkljjjjkkjjhfddj jhhjj dyjkkjnb ijggjkPRAKASHC62

Ěý

This document summarizes an M.Tech research project on fabrication and analysis of aluminium metal matrix composites. The project will be presented on May 2nd, 2013 under the guidance of Dr. B. Anand Ronald. The presentation will cover an introduction to composites, properties and applications of composites and magnesium matrix composites. It will discuss processing techniques like stir casting for synthesizing and characterizing magnesium matrix composites. The proposed research work aims to enhance mechanical properties of magnesium composites by incorporating graphite and similar particulates using stir casting. It will investigate mechanical properties, microstructure, and analyze the composites using techniques like X-ray diffraction.Il Magnesio E Le Sue Leghe Convegno Modena En 14102009

Il Magnesio E Le Sue Leghe Convegno Modena En 14102009Montevenda Engineering Interantional Association

Ěý

Magnesium is a lightweight metal that could have widespread applications in the 21st century engineering industry. Although it was discovered in the early 19th century, difficulties in working with the highly reactive metal limited its use. However, advances in alloying and production techniques now make magnesium alloys comparable in strength and corrosion resistance to aluminum. Magnesium's high strength-to-weight ratio and ability to absorb vibrations could enable significant energy savings through reduced vehicle and aircraft weights. Its use is growing rapidly and expected to expand further if production challenges are overcome.New engineering materials

New engineering materialsTanuj Parikh

Ěý

The document discusses new engineering materials called metallic glasses. Metallic glasses are metal alloys that are non-crystalline, or amorphous, meaning they lack long-range atomic order. They can be produced by rapidly cooling molten metals to rates of over 2 million degrees Celsius per second. This prevents crystal nucleation and results in a glassy solid. Metallic glasses have advantages like strength and corrosion resistance. Applications include use in transformers, sensors, and as surgical instruments. Shape memory alloys that can revert to their original shape after deformation are also discussed.Stress-Strain curve for a ex-situ prepared Zr based metallic glass composite

Stress-Strain curve for a ex-situ prepared Zr based metallic glass composite Piyush Verma

Ěý

This document summarizes research on a zirconium-based bulk metallic glass composite reinforced with tungsten fibers. The composite was created with 31% tungsten fiber volume fraction. Testing showed the composite had a slightly lower compressive fracture stress than the unreinforced bulk metallic glass but its fracture strain was over 10 times higher. This is because the tungsten wires interact with shear bands in the glass, generating multiple shear bands in the tungsten and allowing for substantial plastic deformation. The increased toughness makes these composites promising for applications requiring energy absorption like armor.Glass

GlassGAURAV. H .TANDON

Ěý

Glass is an amorphous solid formed by rapidly cooling molten materials containing silica. The most common type of glass, soda lime glass, is made from silica, sodium oxide and calcium oxide. Glass is manufactured by melting raw materials in furnaces then shaping the molten glass through various processes like pressing, blowing or drawing. Glass has high strength and hardness but is brittle, with properties that can be altered by adding materials like lead, boron or fiberglass. It has various industrial and architectural uses due to its strength, durability and optical properties.Lecture alloys 2014

Lecture alloys 2014Gopal5757

Ěý

This document discusses metal alloys, including their classifications, properties, fabrication techniques, and applications. It begins by outlining key issues to address, such as how alloys are classified and how properties can be modified by heat treatment. It then provides details on various alloy systems, including:

- Ferrous alloys like steels and cast irons, describing their compositions and applications.

- Nonferrous alloys such as aluminum, copper, magnesium, and titanium alloys.

- Fabrication techniques for forming and shaping metals, including casting, powder processing, forming methods like forging, extrusion, and rolling.

- How properties vary based on factors like cooling rate during solidification or quenching.smart memory

smart memorySathees Physics

Ěý

Shape memory alloys have the ability to return to their original shape after deformation through heating or cooling. They exist in martensite and austenite phases and undergo a phase change between the two. Common shape memory alloys include nickel-titanium alloys. Applications include medical devices, toys, and aerospace components.

Metallic glasses are amorphous metal alloys produced through rapid cooling that prevents crystallization. They can be fabricated using melt spinning or other techniques. Metallic glasses have high strength and corrosion resistance due to their non-crystalline structure. Potential applications include reinforced composites, pressure vessels, and medical instruments.Bt1 metals

Bt1 metalsLizette Pedroso

Ěý

This document provides an overview of metals and metal by-products. It discusses the extraction of metals from ores through processes like pyrometallurgy and hydrometallurgy. It then describes various physical and mechanical properties of metals like hardness, conductivity, strength. Ferrous metals like iron and steel are explained in detail, along with common alloys. Non-ferrous metals discussed include aluminium, noting its use in modern construction for properties like durability, design flexibility, and surface finish options.Building Metal

Building MetalTricia Jardin

Ěý

This document provides an overview of metals and metal by-products. It discusses the extraction of metals from ores through processes like pyrometallurgy and hydrometallurgy. Various properties of metals are outlined, including physical properties like conductivity and mechanical properties like strength. Common metals like iron, steel, aluminum and tin are described in terms of their composition, production, properties and uses. Potential defects in metal structures like dislocations and corrosion are also mentioned.2-2013-refractory-raw-materials-presentation.pdf

2-2013-refractory-raw-materials-presentation.pdfsiddharthsingh829453

Ěý

Refractory materials are primarily metal oxides produced from natural and synthetic raw materials, characterized by high melting points essential for steelmaking environments. Key natural raw materials include silica, clays, and graphite, while semi-synthetic and synthetic options, like calcined bauxite and tabular alumina, undergo industrial processing to enhance their properties. These materials are crucial in fabricating various refractory products due to their specific thermal and mechanical properties.Module - 2.1 mechanical 1st year

Module - 2.1 mechanical 1st yearRockyKannadiga

Ěý

This document provides information on various engineering materials. It begins by defining engineering materials as solid substances used for engineering applications and notes that material selection depends on a material's properties. The document then classifies materials into polymers, metals, ceramics, composites, and smart materials. Details are provided on plastics, metals like steel and aluminum, ceramics like glass and optical fibers, and composites. Key properties and applications of different material types are outlined.What is Toughened glass !

What is Toughened glass !DavidDaixiGlass

Ěý

Zouping Daixi Glass Co., Ltd., established in 2002, specializes in manufacturing and supplying various glass products including toughened glass, which is known for its strength and safety features. The document outlines the properties, manufacturing steps, specifications, and applications of toughened glass, emphasizing its safety characteristics when broken, as well as the benefits and distinctions between toughened and laminated glass. Additionally, the company aims to meet international quality standards and seeks to establish successful business relationships with clients worldwide.Presentaion on GLASS (properties of glass) by Luqman

Presentaion on GLASS (properties of glass) by LuqmanEngr MUHAMMAD LUQMAN

Ěý

Glass is a hard, brittle material primarily made from sand, soda ash, and limestone, used in various applications such as windows and containers. The history of glassmaking dates back to around 3500 BCE, believed to have originated in Egypt or coastal North Syria, evolving through various cultures including the Roman Empire and the Anglo-Saxons. Modern advancements in glass technology include innovative designs and applications in building facades, reflecting evolving aesthetic and functional demands.Il Magnesio E Le Sue Leghe Convegno Modena En 14102009

Il Magnesio E Le Sue Leghe Convegno Modena En 14102009Montevenda Engineering Interantional Association

Ěý

Ad

independentinquiry

- 1. BULK METALLIC GLASSES MATE 310/350 Independent Inquiry Cal Poly Materials Engineering RHYS GILMORE

- 2. MATERIALS SCIENCE BACKGROUND Theoretical strength of a material is significantly higher than what is observed in reality.  Why?  Dislocations and grain boundaries provide zones for a material to fracture  Theoretical strength is exclusively a property of atomic bonding

- 3. BACKGROUND What if engineers could take advantage of the inherent strength and ductility of metals, without weakening the material with grain boundaries and dislocations?

- 4. WHAT IS A BULK METALLIC GLASS? BULK: Material that can be manufactured to a thickness of at least one millimeter. METALLIC: Composed of at least one metallic element. GLASS: The microstructure of the material is amorphous, rather than crystalline.

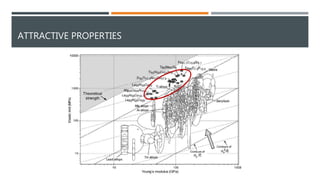

- 5. ATTRACTIVE PROPERTIES  High hardness, yield strength  Lack of microstructural features gives good corrosion resistance  Glass Transition Temperatures allows for thermoplastic forming capabilities  Magnetism, Resistivity independent of temperature Significant Advantages:  BMGs are strong, corrosion resistant materials that are easily formable.  Some alloys have unique magnetic, polish, or biocompatible properties that allow for use in niche markets.

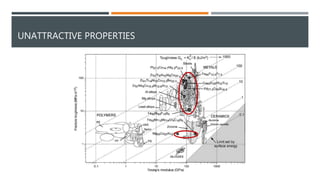

- 7. UNATTRACTIVE PROPERTIES  Current high cost of material and processing limits applications.  Severe localization of plastic flow produces zero ductility in tension.  Unstable at high temperatures due to crystallization or low viscosity.  Fracture toughness can be very low. Significant Disadvantages:  BMGs are expensive and difficult to manufacture.  Brittle failure is a significant concern, especially for large parts.

- 9. PROCESSING Common Production Methods  Extremely fast cooling  Vapor Deposition  Solid-state Reactions  Ion Irradiation  Mechanical Allloying

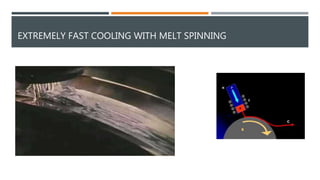

- 10. EXTREMELY FAST COOLING WITH MELT SPINNING

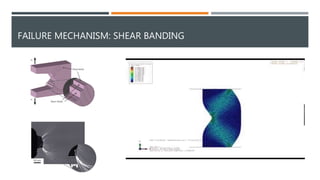

- 11. FAILURE MECHANISM: SHEAR BANDING

- 12. CURRENT APPLICATIONS Most are niche applications, focusing on biocompatibility, springiness, or magnetic properties.  Transformers  Electronic Article Surveillance  Sports Equipment  Biomedical Implants

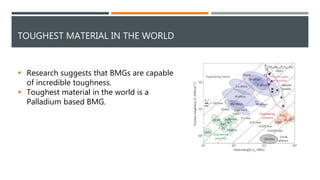

- 13. TOUGHEST MATERIAL IN THE WORLD  Research suggests that BMGs are capable of incredible toughness.  Toughest material in the world is a Palladium based BMG.

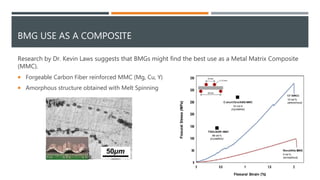

- 14. BMG USE AS A COMPOSITE Research by Dr. Kevin Laws suggests that BMGs might find the best use as a Metal Matrix Composite (MMC).  Forgeable Carbon Fiber reinforced MMC (Mg, Cu, Y)  Amorphous structure obtained with Melt Spinning

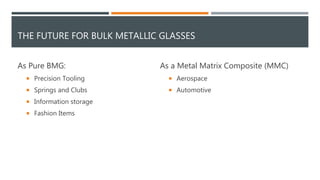

- 15. THE FUTURE FOR BULK METALLIC GLASSES As Pure BMG:  Precision Tooling  Springs and Clubs  Information storage  Fashion Items As a Metal Matrix Composite (MMC)  Aerospace  Automotive

- 16. REFERENCES Ashby, M.F. Metallic glasses as structural materials Scripta Materialia, 2005 Demetrious, Marios D. A damage-tolerant glass Nature Materials, 2011 Laws, Kevin J. Supercooled liquid fusion of carbon fibre-bulk metallic glass composites with superplastic forming properties Scripta Materialia, 2015

Editor's Notes

- #3: Theoretical strength of a material is significantly higher than what is observed in reality. Dislocations Grain Boundaries

- #4: What if engineers could take advantage of the inherent strength and ductility of metals, without weakening the material with grain boundaries and dislocations?

- #5: Bulk: thickness Metallic: Metals Glass: Amorphous

- #6: High hardness, yield strength Lack of microstructural features gives good corrosion resistance Glass Transition Temperatures allows for thermoplastic forming capabilities Magnetism, Resistivity independent of temperature

- #7: Close to theoretical strength, higher than other alloys, ashby plot/paper

- #8: Materials, processing is expensive Unstable at high temperatures Fracture toughness tends to be low Biggest issue: brittle-- Severe localization of plastic flow produces zero ductility in tension

- #9: Low fracture toughness… but wait… HUGE range

- #10: Extremely fast cooling Vapor Deposition Solid-state Reactions Ion Irradiation Mechanical Allloying

- #11: Molten metal, spinning copper wheel, liquid nitrogen cooled. Near infinite cooling rates prohibits crystallization from occurring.

- #12: Shear Band: A narrow zone of intense shearing strain that occurs during deformation of ductile materials. New research suggests that this occurs in brittle materials too, just much more rapid (shear band is much more narrow). In fact, depends on the type of atomic bonding, NOT exclusively crystal structure (or lack thereof). Ceramic covalent bonding vs Metallic bonding in metals.

- #13: Unique properties, niche applications: Transformers, Electronic tags, sports equipment, dissolvable bone screws

- #14: Cal Tech research suggests that a palladium based BMG is capable of shielding crack propagation, thereby producing high toughness. In fact, it is the toughest material in the world.

- #15: Dr. Laws from UNSW suggests that BMGs might find best use as an MMC. Forgeable composite, first of its kind. Superplastic forming.

- #16: As a pure BMG: precision tooling, sports, information storage, fashion As MMC: high performance, low weight, high strength scenarios: aerospace and automotive.