Indigo dyeing

- 1. INDIGO DYEING PREPARED BY- RAJDEEP SINGH B-Tech 4th Sem.

- 2. CONTENTS ïIntroduction To Indigo Dye ïChemical Property And Synthesis Of Indigo ïWhy Indigo ? ïIndigo Dyeing Briefing ïIndigo Dyeing Methods ïRecent Developments In Indigo Dyeing ïReferences

- 3. Indigo dye is an organic compound with a distinctive blue colour. Historically, indigo was a natural dye extracted from plants, and this process was important economically because blue dyes were once rare. Nearly all indigo dye produced today several thousand tons each year is synthetic. It is the blue of blue jeans. The primary use for indigo is as a dye for cotton yarn, which is mainly for the production of denim cloth for blue jeans. On average, a pair of blue jean trousers requires 3 â 12 g of indigo. INTRODUCTION

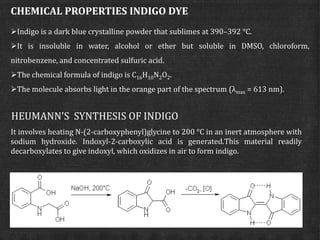

- 4. CHEMICAL PROPERTIES INDIGO DYE ïIndigo is a dark blue crystalline powder that sublimes at 390â392 °C. ïIt is insoluble in water, alcohol or ether but soluble in DMSO, chloroform, nitrobenzene, and concentrated sulfuric acid. ïThe chemical formula of indigo is C16H10N2O2. ïThe molecule absorbs light in the orange part of the spectrum (Îŧmax = 613 nm). HEUMANN'S SYNTHESIS OF INDIGO It involves heating N-(2-carboxyphenyl)glycine to 200 °C in an inert atmosphere with sodium hydroxide. Indoxyl-2-carboxylic acid is generated.This material readily decarboxylates to give indoxyl, which oxidizes in air to form indigo.

- 5. WHY INDIGO ? âĒIt supplies favoured shades from black to navy to sky blue. âĒ Pleasant colour shade. âĒPossibility to dye cotton in cold dye bath. âĒCompetitive in price. âĒGives acceptable colour fastness and the exceptional advantage by repeated washing of fading colour, to keep the colour shade that always a clear, pleasant blue shade result. âĒItâs soluble form is not sensitive to water hardness and this allows the dyeing of greige or minimum pretreated cotton.

- 6. The warp yarn in denim jeans is traditionally dyed with INDIGO, whereas the weft yarn is white. In indigo dyeing there is symbolic built-up of dye stuff on the yarn according to the multi-deep process. Indigo sticks to the surface of the cotton yarn, resulting in a blue surface, while the interior of the yarn will remains white. INDIGO DYEING

- 7. DIFFERENT INDIGO DYEING METHODS ïIndigo rope dyeing process ïIndigo-Slasher-or Sheet-dyeing ïLoop dye 1 for 6 (continuous dye slashing) ïLoop dye 1 for 6 with dyemer (continuous mercerization dyeing and sizing).

- 8. INDIGO ROPE DYEING WITH SUBSEQUENT SIZING PROCESS Step 1: Ball Warper Step 2: Rope Dyeing Step 3: Long Chain Beamer Step 4: Sizing

- 9. ïYarn from the ring spinning machine is wound into suitable package,assembled into a rope and wound into a ball. ïUsually 18 â 24 ropes are simultaneously processed. ïPrior to dyeing, the ropes are boiled out and treated with caustic-soda and wetting agent. ïThe ropes are immersed into the dye-bath. ïImmersion time 30 â 60 seconds . ïOxidation time 60 â 180 seconds for uniform dyeing. ïFor deep shade 5 â 6 times the ropes are immersed in a sequence of dye boxes. ïAfter dyeing and oxidation range the ropes are guided through 2 or 3 washing boxes to wash off excessive dye. ïThey are dried in a series of cans and deposited into large coilers. ïAfter this rebeaming and opening of the ropes takes place for sizing operation. Processing -An overviewâĶâĶâĶâĶ

- 11. Processing of single sheet slasher dyeingâĶâĶ.. ïIn continuous slasher dyeing and sizing back beams are used. ïHere the total number of ends required for a weavers beam are dyed, dried, sized and dried simultaneously. ïNumber of ends are pretreated (washed),dyed in 4 dye boxes and oxidized, no softener are used in the last wash box. ïThe squeezing effect here is lower and therefore the danger of streakiness and shade variation from centre to out side is also higher. ïThe immersion time in the dye boxes is approx. 10 â 15 seconds ïTime for oxidation 30 â 60 second. ïThis system allows the installation of less expensive dye range and less additional preparatory machinery.

- 12. ïIn this system dyeing, sizing is done in 2 operations. ïThe main reason for dyeing of 2 sheet simultaneously is that it gives more even dyed sheet . ïThese beams are dyed, oxidized and dried. ïThese beams are transported to the sizing machine and the yarn sheet sized in double size boxes. ïImmersion time and oxidation time is the same as with continuous slasher dyeing. ïWith double sheet dyeing the linear warp thread density is doubled which have following additions: âĒ Squeezing effect is increased. âĒ An even squeezing over the whole width is achieved. âĒThere is no colour strips formation, streakiness or shading in the finished fabric. âĒThe production out put of the dyeing is increased by 75%. Processing of double sheet dyeingâĶâĶ.

- 13. COMPARISION ON SLASHER DYEING ROPE DYEING Required Space Less More Mercerizing Easy Difficult Manpower Less More Dye bath Less capacity More Yarn Can use Ne 1-30 without major change Can use Ne 1-16 without major change Flexibility Flexibility to produce denim in different colors and small quantities Less flexible. Difficult to change colours. Cost Cost of production is lesser compared to Rope Dyeing Cost of production is more compared to Sheet Dyeing SLASHER DYEING VS ROPE DYEING- A COMPARISON

- 14. LOOP DYE 1 FOR 6 (CONTINUOUS DYE SLASHING) ïIn this system 10 â 16 warper beams with the total number of ends required for the weaver beams are used. ïThe warper beams are placed in a moveable warp creel of which one can be loaded while other one set is in rotation. ïThe yarn sheet is guided to the soaking bath through a feed-in system ïThe soaking bath has the task to prepare the yarn for the following dyeing operation.

- 15. ïThere is only a single Indigo dye box through which the yarn passes 4-5 times. ïThe yarn sheet after having been immersed into a single indigo dye instead of moving forward runs into a long loop where oxidation takes place. ïOne of the advantages is ideal, utilization of hydrosulphite through squeezing 4 â 6 layers simultaneously and oxidation of yarn in a comparatively long oxidation loop. ï After the oxidation the yarn sheet is guided through 2 washing boxes ,finally on to a series of drying cans. ïAfter that yarn is immersed into size boxes, dried and wound onto a weavers beam. ContinuedâĶâĶâĶ

- 16. ïThere is growing demand for dark shades specially dark marine blue for super blue denims. ïFor this new indigo dyeing ranges which have increased the number of dye boxes between 8-15 with corresponding oxidation ranges. ïIn some cases hydroxyaceton is used which gives a darker shade with the desire greenish touch . ïIn order to achieve ring dyeing, mercerized yarn has also been used. Mercerizing gives an optical blue effect and superior colour fastness and behaviour in washing. Mercerizing is very costly, therefore new ways in continuous mercerizing and indigo dyeing was found.And so dyemer was introduced. DYEMER The dyemer range is integrated. For impregnation;padder for hot caustic solution is placed after the heating system . The yarn is guided over cold cylinders and with an adjustable roller the tension of the yarn sheet can be adjusted according to the required tension prior to the scouring in 2 more boxes. After having passed this, the yarn sheet is immersed into the dye box and the same process as with the loop dye method is repeated. LOOP DYE 1 FOR 6 COMBINED WITH DYEMER

- 17. PARAMETER EFFECT IN CASE THE REFERRING PARAMETER IS INCREASED,SUPPOSED ALL THE OTHERS ARE KEPT THE SAME 1. Indigo concentration -deeper shade -higher degree of penetration -in extreme cases: inferior fastness level 2. pH (alkali concentration) -higher degree of penetration -clearer, more reddish shade -increased indigo concentration due to inferior affinity 3. Hydrosulphite concentration - higher degree of penetration -clearer, more bluish shade -- bronzing shade in absence of hydrosulphite and high indigo concentration 4. Temperature - higher degree of penetration - higher indigo concentration due to inferior affinity - higher demand for hydrosulphite - higher demand for caustic soda IMPORTANT INDIGO DYEING PARAMETERS

- 18. RECENT DEVELOPMENTS IN INDIGO DYEING ïLatest loop dye machines are equipped with nitrogen units which use nitrogen gas as protective blanket over the surface of the Indigo dye. The nitrogen gas prevents oxygen in the air from attacking sodium hydrosulphite resulting in more consistent dyeing and reducing consumption of hydrosulphite,which lowers the costs and pollution. There are other claimed advantages such as higher speeds and darker Indigo colour. ïDyStar and RedElec in regard of global awareness of environmental issues have decided to use join forces to develop electrochemical dyeing of Indigo, a sustainable solution that will eliminate harmful substances in dyeing and waste water. The team will use its patented products, DyStar IndigoÂŪ Vat 40% Solution and RedElec's electrochemical technologies, throughout the development process.