Industrail Training PPT SAURABH SRIVASTAVA

2 likes339 views

The document discusses the benefits of an industrial training program at Action Construction Equipment (ACE). It provides details about ACE and its manufacturing facilities. The author lists their reasons for choosing ACE for training, which included interests in the automobile and construction sectors. During the training, the author learned about various engineering and manufacturing processes, including fabrication, welding, assembly, quality testing, inventory control, and design software. They gained knowledge in areas like tower cranes, forklifts, and tractors. Overall, the training program provided valuable hands-on experience of industrial practices that complemented the author's engineering education.

1 of 28

Downloaded 15 times

Ad

Recommended

Bsm profile automotive

Bsm profile automotiveHuy Bui Van

Ěý

BSM Group, a global manufacturing company, specializes in tooling and injection molding with operations spanning multiple countries and a diverse product portfolio. They focus on R&D for automotive components, utilizing advanced technologies and maintaining rigorous quality and management systems. Future expansions include a new industrial city dedicated to enhancing molding capabilities and automation.Automotive molds - BSM Group (Shenzhen)

Automotive molds - BSM Group (Shenzhen) BlueStar Technology (Shenzhen) Co., Ltd

Ěý

BSM Group is a manufacturing company with a primary focus on automotive components, electronics, and appliances, operating globally with significant facilities in Shenzhen and a workforce of 550 employees. The company emphasizes research and development, particularly in automotive trimming technologies and precision tooling, engaging in dedicated project management for clients like Ford, GM, and Honda. Future plans include expanding manufacturing capacities and establishing the Bluestar Industrial City, targeting advanced tooling design and injection molding.Ibraheem CV - final

Ibraheem CV - finalibraheem Osman

Ěý

Ibrahim Abd El-Moniem is an electrical maintenance engineer with over 14 years of experience in the pharmaceutical industry. He currently works as the Electrical Maintenance Section Head at Egyptian International Pharmaceutical Industries Co, where he manages commissioning, installation, and maintenance of production machines and utilities. Ibrahim has strong technical, communication, and managerial skills, and has completed extensive factory training and testing in countries like Italy, India, and Germany. He holds an engineering degree in electrical engineering and is fluent in Arabic and proficient in English.Resume 1

Resume 1 vishal singh

Ěý

Rambishal K. Singh is seeking a position that allows him to work in a challenging and creative environment. He has over 15 years of experience in production engineering and quality control roles. He has expertise in CNC turning and machining centers. His experience includes planning and scheduling production, ensuring quality standards, training staff, and implementing improvements to increase efficiency. He is looking for a senior production role where he can utilize his skills and experience.Faisal Mehmood CV

Faisal Mehmood CVFaisal Mehmood

Ěý

This document provides information about an individual's education and work experience. It lists that they have a Diploma of Associate Engineering from Sindh Board of Technical Education in Karachi and studied Hifz-ul-Quran. For work experience, it details positions at several companies in sheet metal fabrication, auto parts manufacturing and quality control, tool and die manufacturing, and as a technical manager for auto parts.VARUN WAGHMARE

VARUN WAGHMAREVarun Waghmare

Ěý

Varun Suresh Waghmare is seeking a position that stimulates creativity and learning. He has over 2 years of experience servicing Volvo construction equipment including excavators, motor graders, and wheel loaders. His responsibilities included troubleshooting, maintenance, training subordinates, and completing documentation. He holds a Bachelor's degree in Mechanical Engineering and has experience with CAD software. He is looking for an opportunity to contribute to a company's growth through hard work and smart techniques.Tech.Eng PE CV 2015

Tech.Eng PE CV 2015zaid zulfiqar

Ěý

This document contains a summary of Zaid Zulfiqar's work experience and qualifications. He has over 5 years of experience in mechanical engineering roles, including maintenance engineering, project management, and proposal engineering. Currently he works as a Technical Engineer and Proposal Engineer for Al jaber group of companies in Abu Dhabi, where he is responsible for maintenance planning, tender preparation, and facility management. He has a Bachelor's degree in Mechanical Engineering from NED University of Engineering and Technology in Pakistan.ASHOK CV

ASHOK CVAshok Kumar

Ěý

Ashok Kumar is an Assistant Manager with over 10 years of experience. He currently works for Natasha Enterprises, an ISO-certified company that deals in industrial machinery. In his role, he prepares technical proposals, negotiates costs, provides customer support, and helps with sales and marketing activities. Previously, he worked as a Production Engineer for an automotive components manufacturer, where he programmed CNC machines and ensured quality of manufactured cutting tools. He holds a Bachelor's degree in Mechanical Engineering.Eng. Omar Yousry CV_2016.11

Eng. Omar Yousry CV_2016.11Omar Yousry

Ěý

This document contains the resume of Omar Yousry, a senior automation engineer with over 11 years of experience in steel plant automation. It summarizes his roles and responsibilities in automation system design, commissioning, technical support, and sales. It also lists his professional accomplishments, including doubling sales and acquiring new customers in his current role providing customer service and technical support in Egypt. His work experience includes positions in Italy and Egypt with automation system supplier Danieli Automation, as well as with other companies in Egypt.CV

CVVikas Pal

Ěý

This document provides a summary of Vikash Hanslal Pal's qualifications and experience. It includes his contact information, career objective, educational background including a BE in Mechanical Engineering from University of Mumbai with 65% and an automotive engineering project. His work history includes an internship at Larsen & Toubro and a final year project at VE Commercial Vehicles. Personal details like date of birth, address and languages known are also provided.Arpit cv

Arpit cvARPIT PATEL

Ěý

This curriculum vitae is for Arpit M. Patel, an engineer with experience in mechanical design, product development, simulation, and project documentation. He received a Bachelor of Engineering degree in Mechanical Engineering in 2010. His current role is as a Senior Engineer at Moflex Suspension Pvt Ltd since 2015, where he works on 3D modeling, drawings, material selection, cost analysis and more for automotive clients. Previously he held engineering roles at Jyoti Ltd from 2012-2015 and Krystal Steel Manufacturing from 2011 where he contributed to various industrial projects.RESUME Production - Automobile

RESUME Production - Automobilesivaraman s

Ěý

S.Sivaraman is a mechanical engineer seeking a position in the automobile industry. He has over 9.5 years of experience in production, planning, quality control, and manufacturing at various automobile parts suppliers. His experience includes assembling brake parts and manufacturing plastic and rubber injection molded parts. He holds a B.Tech in mechanical engineering and various other qualifications including a diploma in computer applications. He is looking for a full-time, permanent position utilizing his skills in production, quality control, and project management.Resume

Resumesingaram dharmaraj

Ěý

S. Dharmaraj is an experienced production manager with 15 years in manufacturing, focusing on production planning and control, quality management, and team leadership. He has held various positions in several companies, demonstrating expertise in machine scheduling, process optimization, and resource management, with significant accomplishments in enhancing operational effectiveness. Dharmaraj possesses a diploma in mechanical engineering and is skilled in relevant software and quality standards.Amii Marketing Services Presentation 1

Amii Marketing Services Presentation 1compositesjoe

Ěý

Aero Mechanical Industries, Inc. is a certified repair station that specializes in repairs and modifications of flight controls and engine nacelles for various aircraft. It has expertise in working with advanced composite materials like graphite, Kevlar, and carbon fiber. The company is approved by the FAA, EASA, and CAAC and ensures the highest quality workmanship and customer service throughout the repair process.juned cv

juned cvJuned Hawa

Ěý

This curriculum vitae is for Hawa Juned Hasan, who is seeking a position as a QA/QC Inspector, Supervisor, or Production Supervisor. He has an education background that includes completing SSC and HSC, as well as technical qualifications in welding/turning and as a fitter from ITI. He has several professional certificates in quality control, management, calibration, ISO standards, and non-destructive testing. His work experience includes positions in quality control inspection and as a fitter instructor in India, as well as roles in quality control labs and departments in Dubai and India. His job profile involves inspecting and testing parts and equipment, maintaining quality records, operating measuring instruments, minimizing nonconformUMAPATHY RES

UMAPATHY RESUmapathy Dsa

Ěý

Umapathy is seeking a position in maintenance with 10 years of experience troubleshooting various sheet metal machines including presses, spot welders, and robots. He has maintained documentation for maintenance plans, machine histories, and critical spare parts. Currently he works as an Engineer of Maintenance and Utility at Thai Summit Auto Parts India Pvt monitoring subordinates, attending breakdowns, and improving maintenance processes.Satheesh resume

Satheesh resumeSatheesh Badrajalam

Ěý

Satheesh B provides his curriculum vitae, including contact information, objective, work experience in sales and marketing roles for solar companies and CNC machine companies, education qualifications including a mechanical engineering degree and tool design post-diploma, skills in CAD tools, overseas experience in Saudi Arabia, and personal details. He has over 10 years of work experience in sales and marketing of solar panels, inverters, and CNC machines, with achievements including projects in India, Qatar, and Saudi Arabia totaling over $500,000 in orders.Ali Esmail ElShazly

Ali Esmail ElShazlyAli El-Shazly

Ěý

Ali Esmail ElShazly is seeking a position as a section head in a dynamic organization that encourages continuous learning. He has a bachelor's degree in mechanical design and production from Cairo University, with experience as a senior industrial engineer and mechanical design engineer. His objective is to work in fields like production management, quality, and production planning.RESUME- BALA SEP 2015

RESUME- BALA SEP 2015Bala Bala

Ěý

This curriculum vitae summarizes the educational and professional experience of P. BALAMURUGAN S. PUSHPARAJ. He has an MBA in International Project Management from Belgium and studied Aeronautical Engineering. His work experience includes over 8 years as a Product Development Engineer using CAD software at Ford India and other roles in design, quality control, and project management. He is proficient in mechanical CAD software programs and has experience designing automobile and other mechanical components.karthik New

karthik NewKarthik Mohanraj

Ěý

M. Karthik is seeking a production role with an automotive organization. He has over 10 years of experience in automotive, electrical components, and battery industries. Currently he is an Assistant Manager of Maintenance at Exide Industries, leading production and maintenance of pasting and expander shops. He aims to increase efficiency and productivity through process improvement, problem solving, and team leadership.CV

CVOmar Mekky

Ěý

Omar Muhammad Abdel-Maksoud Abdel-Aal is a mechanical engineer from Alexandria, Egypt seeking a challenging position utilizing his experience. He has over 5 years of experience in project management and site engineering for petroleum maintenance companies. He holds a B.Sc. in Mechanical Power Engineering and additional technical and computer certifications.Resume

ResumeAbdul Nabi

Ěý

Abdul Nabi is seeking a challenging career that utilizes his 12 years of experience in mechanical engineering and CNC machining. He has a diploma in mechanical engineering and certificates in various STCW courses. Nabi has experience programming and operating CNC lathes and mills, manufacturing components for automotive and other industries. His previous roles include machine shop supervisor and CNC setter. He is proficient in AutoCAD, MS Office, and other software.Viman Multiplug Private Limited

Viman Multiplug Private LimitedMayankRohatgi

Ěý

Viman Multiplug Pvt. Ltd. is a Bangalore-based manufacturer and exporter of precision sheet metal products since 1989. It has over 25,000 square feet of infrastructure including CNC machines and finishing facilities. Key customers include Hindustan Aeronauticals Ltd. and TATA BP Solar Ltd. The company is ISO 9001 certified and working towards environmental certification. It is part of the C.M. Pai Group of companies and has future plans to expand facilities and automation.Hasan GSME

Hasan GSMEmohamed hasan

Ěý

S.S. Mohamed Hasan is applying for a position as a foreman in machine shop industry. He has over 19 years of experience as a skilled machinist and 5 years of experience as a foreman. Most recently, he worked as a foreman for GSME in Abu Dhabi from 2014 to present, where he was responsible for overseeing machine shop departments and production. Previously, he worked as a foreman for Al-Fanar Moulds in Riyadh, Saudi Arabia from 2011 to 2013 with similar responsibilities. He has extensive technical skills operating various machines and experience developing tools. He is looking for a new opportunity to utilize his education and skills.Ram resume

Ram resumeRamaiyan Kannusamy

Ěý

This document is a curriculum vitae for Kannusamy Ramaiyan that summarizes his professional experience and qualifications. It outlines his 7 years of experience as a CNC programmer, setter, and operator on machines like Makino and Fanuc. It also lists his educational background, including an NTC in turning from an Industrial Training Institute in India and a Precision Machining (Milling) qualification from ITE Skills Level II in Singapore. The CV indicates he is seeking a challenging career in CNC programming and operating to further his machining knowledge and support company growth.Rajj P K Resume

Rajj P K ResumeRajaprasannakumar D Pillai

Ěý

Raja Prasanna Kumar D has over 13 years of experience in managing operations and maintenance, customer service, sales, and production planning roles in various industries. He currently works as a Customer Service Manager for NDTS India Private Limited, a leading global NDT service provider, where he ensures installation, commissioning, repair services, and calibration of NDT equipment for customers. Prior to this, he held roles as a Shift Engineer at a glass manufacturing company and a Service/Sales Engineer at a plastic welding machine supplier where he provided technical support, commissioning, and service of industrial equipment. He holds a Diploma in Electrical and Electronics Engineering as well as a Bachelor's degree in the same field and is currently pursuing an MBAKec presentions

Kec presentions DRx Rajveer Prajapati

Ěý

A student named Raju Prajapati from the Mechanical Engineering department at Poornima Group of Institutions gave an industrial training seminar presentation at KEC International Ltd. in Jaipur from May 28th to July 9th. The training was guided by Mr. Sunil Kumar from the Mechanical Engineering department.Industrial training report

Industrial training reportRohit Kumar

Ěý

The document appears to be an industrial training report submitted by Shubham Chakraborty after completing a 15-day training at AMTEK AUTO LIMITED. It provides an overview of AMTEK AUTO LTD, including its various divisions and product range. The report also includes sections on the raw material grading, tool and die shop, metallurgical lab, billet yard processes, forge shop processes, heat treatment processes, end control checks and dispatch procedures at AMTEK AUTO LTD.Centre For Hands-On Engineering Training by Verdure Infrastructure Solutions

Centre For Hands-On Engineering Training by Verdure Infrastructure SolutionsSurabhi5

Ěý

The document outlines the establishment of a hands-on engineering training center aimed at bridging the gap between fresh engineering graduates and industry requirements. It highlights the importance of practical training, communication skills, and technical knowledge in increasing employability, given that a significant percentage of graduates are deemed unemployable. The center offers a comprehensive training program across various engineering specializations with a strong track record of successful placements for its trainees.E10_ISE_Lecture.ppt

E10_ISE_Lecture.pptNeelGamers

Ěý

This document provides an introduction to industrial and systems engineering. It discusses what industrial engineering and systems engineering are, providing examples related to manufacturing like car assembly lines and the Toyota Production System. It also gives an example of systems engineering applied to the service industry through Disneyland's FastPass system. The document outlines the industrial and systems engineering curriculum at SJSU and current multidisciplinary research into improving efficiency and safety in large truck freight operations.More Related Content

What's hot (19)

Eng. Omar Yousry CV_2016.11

Eng. Omar Yousry CV_2016.11Omar Yousry

Ěý

This document contains the resume of Omar Yousry, a senior automation engineer with over 11 years of experience in steel plant automation. It summarizes his roles and responsibilities in automation system design, commissioning, technical support, and sales. It also lists his professional accomplishments, including doubling sales and acquiring new customers in his current role providing customer service and technical support in Egypt. His work experience includes positions in Italy and Egypt with automation system supplier Danieli Automation, as well as with other companies in Egypt.CV

CVVikas Pal

Ěý

This document provides a summary of Vikash Hanslal Pal's qualifications and experience. It includes his contact information, career objective, educational background including a BE in Mechanical Engineering from University of Mumbai with 65% and an automotive engineering project. His work history includes an internship at Larsen & Toubro and a final year project at VE Commercial Vehicles. Personal details like date of birth, address and languages known are also provided.Arpit cv

Arpit cvARPIT PATEL

Ěý

This curriculum vitae is for Arpit M. Patel, an engineer with experience in mechanical design, product development, simulation, and project documentation. He received a Bachelor of Engineering degree in Mechanical Engineering in 2010. His current role is as a Senior Engineer at Moflex Suspension Pvt Ltd since 2015, where he works on 3D modeling, drawings, material selection, cost analysis and more for automotive clients. Previously he held engineering roles at Jyoti Ltd from 2012-2015 and Krystal Steel Manufacturing from 2011 where he contributed to various industrial projects.RESUME Production - Automobile

RESUME Production - Automobilesivaraman s

Ěý

S.Sivaraman is a mechanical engineer seeking a position in the automobile industry. He has over 9.5 years of experience in production, planning, quality control, and manufacturing at various automobile parts suppliers. His experience includes assembling brake parts and manufacturing plastic and rubber injection molded parts. He holds a B.Tech in mechanical engineering and various other qualifications including a diploma in computer applications. He is looking for a full-time, permanent position utilizing his skills in production, quality control, and project management.Resume

Resumesingaram dharmaraj

Ěý

S. Dharmaraj is an experienced production manager with 15 years in manufacturing, focusing on production planning and control, quality management, and team leadership. He has held various positions in several companies, demonstrating expertise in machine scheduling, process optimization, and resource management, with significant accomplishments in enhancing operational effectiveness. Dharmaraj possesses a diploma in mechanical engineering and is skilled in relevant software and quality standards.Amii Marketing Services Presentation 1

Amii Marketing Services Presentation 1compositesjoe

Ěý

Aero Mechanical Industries, Inc. is a certified repair station that specializes in repairs and modifications of flight controls and engine nacelles for various aircraft. It has expertise in working with advanced composite materials like graphite, Kevlar, and carbon fiber. The company is approved by the FAA, EASA, and CAAC and ensures the highest quality workmanship and customer service throughout the repair process.juned cv

juned cvJuned Hawa

Ěý

This curriculum vitae is for Hawa Juned Hasan, who is seeking a position as a QA/QC Inspector, Supervisor, or Production Supervisor. He has an education background that includes completing SSC and HSC, as well as technical qualifications in welding/turning and as a fitter from ITI. He has several professional certificates in quality control, management, calibration, ISO standards, and non-destructive testing. His work experience includes positions in quality control inspection and as a fitter instructor in India, as well as roles in quality control labs and departments in Dubai and India. His job profile involves inspecting and testing parts and equipment, maintaining quality records, operating measuring instruments, minimizing nonconformUMAPATHY RES

UMAPATHY RESUmapathy Dsa

Ěý

Umapathy is seeking a position in maintenance with 10 years of experience troubleshooting various sheet metal machines including presses, spot welders, and robots. He has maintained documentation for maintenance plans, machine histories, and critical spare parts. Currently he works as an Engineer of Maintenance and Utility at Thai Summit Auto Parts India Pvt monitoring subordinates, attending breakdowns, and improving maintenance processes.Satheesh resume

Satheesh resumeSatheesh Badrajalam

Ěý

Satheesh B provides his curriculum vitae, including contact information, objective, work experience in sales and marketing roles for solar companies and CNC machine companies, education qualifications including a mechanical engineering degree and tool design post-diploma, skills in CAD tools, overseas experience in Saudi Arabia, and personal details. He has over 10 years of work experience in sales and marketing of solar panels, inverters, and CNC machines, with achievements including projects in India, Qatar, and Saudi Arabia totaling over $500,000 in orders.Ali Esmail ElShazly

Ali Esmail ElShazlyAli El-Shazly

Ěý

Ali Esmail ElShazly is seeking a position as a section head in a dynamic organization that encourages continuous learning. He has a bachelor's degree in mechanical design and production from Cairo University, with experience as a senior industrial engineer and mechanical design engineer. His objective is to work in fields like production management, quality, and production planning.RESUME- BALA SEP 2015

RESUME- BALA SEP 2015Bala Bala

Ěý

This curriculum vitae summarizes the educational and professional experience of P. BALAMURUGAN S. PUSHPARAJ. He has an MBA in International Project Management from Belgium and studied Aeronautical Engineering. His work experience includes over 8 years as a Product Development Engineer using CAD software at Ford India and other roles in design, quality control, and project management. He is proficient in mechanical CAD software programs and has experience designing automobile and other mechanical components.karthik New

karthik NewKarthik Mohanraj

Ěý

M. Karthik is seeking a production role with an automotive organization. He has over 10 years of experience in automotive, electrical components, and battery industries. Currently he is an Assistant Manager of Maintenance at Exide Industries, leading production and maintenance of pasting and expander shops. He aims to increase efficiency and productivity through process improvement, problem solving, and team leadership.CV

CVOmar Mekky

Ěý

Omar Muhammad Abdel-Maksoud Abdel-Aal is a mechanical engineer from Alexandria, Egypt seeking a challenging position utilizing his experience. He has over 5 years of experience in project management and site engineering for petroleum maintenance companies. He holds a B.Sc. in Mechanical Power Engineering and additional technical and computer certifications.Resume

ResumeAbdul Nabi

Ěý

Abdul Nabi is seeking a challenging career that utilizes his 12 years of experience in mechanical engineering and CNC machining. He has a diploma in mechanical engineering and certificates in various STCW courses. Nabi has experience programming and operating CNC lathes and mills, manufacturing components for automotive and other industries. His previous roles include machine shop supervisor and CNC setter. He is proficient in AutoCAD, MS Office, and other software.Viman Multiplug Private Limited

Viman Multiplug Private LimitedMayankRohatgi

Ěý

Viman Multiplug Pvt. Ltd. is a Bangalore-based manufacturer and exporter of precision sheet metal products since 1989. It has over 25,000 square feet of infrastructure including CNC machines and finishing facilities. Key customers include Hindustan Aeronauticals Ltd. and TATA BP Solar Ltd. The company is ISO 9001 certified and working towards environmental certification. It is part of the C.M. Pai Group of companies and has future plans to expand facilities and automation.Hasan GSME

Hasan GSMEmohamed hasan

Ěý

S.S. Mohamed Hasan is applying for a position as a foreman in machine shop industry. He has over 19 years of experience as a skilled machinist and 5 years of experience as a foreman. Most recently, he worked as a foreman for GSME in Abu Dhabi from 2014 to present, where he was responsible for overseeing machine shop departments and production. Previously, he worked as a foreman for Al-Fanar Moulds in Riyadh, Saudi Arabia from 2011 to 2013 with similar responsibilities. He has extensive technical skills operating various machines and experience developing tools. He is looking for a new opportunity to utilize his education and skills.Ram resume

Ram resumeRamaiyan Kannusamy

Ěý

This document is a curriculum vitae for Kannusamy Ramaiyan that summarizes his professional experience and qualifications. It outlines his 7 years of experience as a CNC programmer, setter, and operator on machines like Makino and Fanuc. It also lists his educational background, including an NTC in turning from an Industrial Training Institute in India and a Precision Machining (Milling) qualification from ITE Skills Level II in Singapore. The CV indicates he is seeking a challenging career in CNC programming and operating to further his machining knowledge and support company growth.Rajj P K Resume

Rajj P K ResumeRajaprasannakumar D Pillai

Ěý

Raja Prasanna Kumar D has over 13 years of experience in managing operations and maintenance, customer service, sales, and production planning roles in various industries. He currently works as a Customer Service Manager for NDTS India Private Limited, a leading global NDT service provider, where he ensures installation, commissioning, repair services, and calibration of NDT equipment for customers. Prior to this, he held roles as a Shift Engineer at a glass manufacturing company and a Service/Sales Engineer at a plastic welding machine supplier where he provided technical support, commissioning, and service of industrial equipment. He holds a Diploma in Electrical and Electronics Engineering as well as a Bachelor's degree in the same field and is currently pursuing an MBAKec presentions

Kec presentions DRx Rajveer Prajapati

Ěý

A student named Raju Prajapati from the Mechanical Engineering department at Poornima Group of Institutions gave an industrial training seminar presentation at KEC International Ltd. in Jaipur from May 28th to July 9th. The training was guided by Mr. Sunil Kumar from the Mechanical Engineering department.Similar to Industrail Training PPT SAURABH SRIVASTAVA (20)

Industrial training report

Industrial training reportRohit Kumar

Ěý

The document appears to be an industrial training report submitted by Shubham Chakraborty after completing a 15-day training at AMTEK AUTO LIMITED. It provides an overview of AMTEK AUTO LTD, including its various divisions and product range. The report also includes sections on the raw material grading, tool and die shop, metallurgical lab, billet yard processes, forge shop processes, heat treatment processes, end control checks and dispatch procedures at AMTEK AUTO LTD.Centre For Hands-On Engineering Training by Verdure Infrastructure Solutions

Centre For Hands-On Engineering Training by Verdure Infrastructure SolutionsSurabhi5

Ěý

The document outlines the establishment of a hands-on engineering training center aimed at bridging the gap between fresh engineering graduates and industry requirements. It highlights the importance of practical training, communication skills, and technical knowledge in increasing employability, given that a significant percentage of graduates are deemed unemployable. The center offers a comprehensive training program across various engineering specializations with a strong track record of successful placements for its trainees.E10_ISE_Lecture.ppt

E10_ISE_Lecture.pptNeelGamers

Ěý

This document provides an introduction to industrial and systems engineering. It discusses what industrial engineering and systems engineering are, providing examples related to manufacturing like car assembly lines and the Toyota Production System. It also gives an example of systems engineering applied to the service industry through Disneyland's FastPass system. The document outlines the industrial and systems engineering curriculum at SJSU and current multidisciplinary research into improving efficiency and safety in large truck freight operations.Training catalog rve 2015

Training catalog rve 2015Vinod Nayak

Ěý

Rishi Vocational Education Pvt. Ltd. offers specialized training for welding and skill development to create an employable workforce, focusing on practical and theoretical instruction. The program includes various courses in welding techniques, soft skills training, and vocational education, aiming to bridge the skills gap in industries like manufacturing and construction. The organization also supports job placements and corporate social responsibility initiatives to benefit society and ensure career advancement for its students.Report on hydra assembly

Report on hydra assemblyPushpendra Bansi

Ěý

ACE is India's leading manufacturer of material handling and construction equipment. It has a majority market share in mobile and tower cranes. ACE manufactures various types of cranes, loaders, backhoes, rollers, forklifts, tractors, and other equipment. It has six manufacturing plants and focuses on quality, infrastructure, and developing new technology through R&D. The document provides an overview of ACE and descriptions of its various products.Industry 4.0 Walk Through - Accialini Training & Consulting

Industry 4.0 Walk Through - Accialini Training & ConsultingNicola Accialini

Ěý

The document outlines the concept of Industry 4.0, emphasizing the integration of digital technologies to enhance productivity, efficiency, and product customization in manufacturing. It discusses the methodologies for assessing and implementing these technologies through on-site evaluations, identifying hidden opportunities, and providing actionable recommendations. The proposal also highlights the importance of using advanced technologies like IoT, additive manufacturing, and big data analytics, alongside the necessity of cybersecurity measures.Lecture 1 final.pdf

Lecture 1 final.pdfmppooniamech

Ěý

The document outlines the vision and mission of the Malaviya National Institute of Technology (MNIT), emphasizing the creation of technical manpower and research to meet industry demands. It discusses various challenges faced by engineering students, including a lack of practical skills and a preference for IT jobs over core engineering fields. Additionally, the course curriculum for mechanical engineering includes diverse topics such as machining operations, power generation systems, and material properties, aiming to equip students with the necessary knowledge and skills for the workforce.Final PMT 2 Research Chart

Final PMT 2 Research ChartJan Kennerknecht

Ěý

This document summarizes the results of a DACUM (Developing A Curriculum) workshop with a panel of industry experts in precision machining. The panel identified key worker behaviors, general knowledge and skills, current trends, future directions, concerns, recommended certifications, adult education training needs, and advice for students in the precision machining field. The top three priorities for precision machining according to the panel are safety, quality, and cost.kamlesh cv

kamlesh cvkamlesh singh

Ěý

This document is a resume for Kamlesh Kumar Singh. The summary provides:

1) Kamlesh Kumar Singh is a mechanical design professional with over 6 years of experience in product development, 3D modeling, and validation.

2) He is currently a Senior Engineer at Action Construction Equipment Limited working on design and development of cranes and backhoe loaders.

3) Previously he has worked as a Design Engineer and Assistant Manager on mechanical design, prototyping, and cost saving projects.Intership Seminar

Intership SeminarBharat Joshi

Ěý

This document provides an overview of an internship completed at L&T Construction Equipment Ltd. It discusses the company, various manufacturing processes used including shot blasting, honing and induction hardening. It also describes quality control measures, types of compressors and CNC machines. Robots used for welding are discussed. The document concludes with notes on energy conservation efforts like solar power and programmable timers.Final report

Final reportAMSADO

Ěý

This document provides an overview and summary of an industrial training report. It includes chapters on the company background of FEHM Group, a weekly activity summary, a technical report, results and conclusions. The first chapter introduces the industrial training and outlines its importance for exposing students to real-world work experiences. It also discusses the objectives of the training and report. The second chapter describes FEHM Group's vision, mission, key management personnel, and their solutions in search and rescue technologies and intelligence/surveillance systems.Foundations of Technology

Foundations of Technologyjnordtvedt

Ěý

The document provides an overview of the ActionLAB program for students. It describes the program as consisting of 22 instructional units over 10 days, where students work in pairs on hands-on activities covering various topics delivered through online content. The document lists the topic areas covered in the program, including transportation, manufacturing, and bio-related fields. It also provides details on some of the specific instructional units, such as virtual architecture, structural engineering, and robotics technology.Abhishek mishra Cv

Abhishek mishra CvAbhishek Mishra

Ěý

Abhishek Kumar Mishra is seeking a position in a result-oriented company where he can utilize his skills in design engineering, quality assurance, and mechatronics. He has over 3 years of experience as a Design Engineer where he conceptualized furniture designs and handled projects from initial design to final assembly. Previously, he worked as a Quality Assurance Engineer ensuring product quality and compliance with ISO standards. Mishra has a Bachelor's degree in Mechatronics and his technical skills include SolidWorks, CATIA V5, ANSYS, C and C++. He has undergone training in machine tool design and has experience with internship projects involving autonomous vehicle control and a wireless car racing game.Industry 4.0 Training Centre at Bangalore - Scaling to PAN India Level

Industry 4.0 Training Centre at Bangalore - Scaling to PAN India LevelNagesh Setty K S

Ěý

JLUTechnologies offers a residential training program focused on industrial skills for engineering graduates and professionals, with hands-on experience, a team-based learning model, and placement assurance. The rigorous 6-month course includes various topics in Industry 4.0 and additional extracurricular activities for practical exposure. Trainees can choose between employment options post-internship, including guaranteed placement in the industry or positions within the organization.Training catalog 2014

Training catalog 2014Prolific Systems And Technologies Pvt. Ltd.

Ěý

Prolific Systems & Technologies offers a comprehensive workforce development program that includes technical training in various fields such as electrical, mechanical, automation, and management. The training includes both in-plant and public courses with international accreditation, ensuring high standards and practical learning experiences. With over 500 training programs executed globally, Prolific aims to cater to the professional development needs of organizations and individuals.The New Partnership Concept for Inspiring CNC Education

The New Partnership Concept for Inspiring CNC EducationBert Maes

Ěý

The document discusses the manufacturing skills shortage and the need for advanced technical education to equip young workers with CNC manufacturing skills. It emphasizes the importance of the HTEC network, which aims to transform training centers into technology-rich environments that support collaboration between schools and industry. By addressing both educational and employment opportunities, the initiative seeks to inspire future generations and strengthen the manufacturing sector's competitiveness.ROBOTIC WELDING Presentation to show2

ROBOTIC WELDING Presentation to show2Prateek Sood

Ěý

Prateek Sood completed an industrial training at VEEGEE KAUSHICKO ENGINEERING PVT. LTD. The training focused on learning about robotic welding through teaching programming, installations, cell design, and hands-on work. During the training, Prateek learned robotic functionality, welding machine basics, robot teaching, PLC programming, and production calculations. The training helped develop practical skills and confidence needed to work in the robotics and manufacturing field.Internship presentation.pptx

Internship presentation.pptxkirannayakar1

Ěý

Kiran Nayakar A/L Supramaniam completed a 6-month industrial training program at Semiconductor Assembler and Manufacturer Sdn. Bhd. to gain exposure to real-world engineering. The training objectives were to expose students to engineering professions, facilitate knowledge sharing between students and industry staff, and develop creative/positive thinking for overcoming engineering problems. Kiran learned about the company's semiconductor packaging processes like die preparation, die attach, wire bonding, and encapsulation. His training scope involved machine operation like pick and place, die bonding, wire bonding, and capping. Through the training, Kiran understood the roles of technicians and engineers better and gained skills in time management, goal setting,Ad

Industrail Training PPT SAURABH SRIVASTAVA

- 2. To provide an opportunity to undergraduates to identify, observe and practice how engineering is applicable in the real industry. To get experience on technical practices but also to observe management practices and to interact with fellow workers& Officers.

- 3. ABOUT ACE ACTION CONSTRUCTION EQUIPMENT LIMITED (ACE) is India’s leading material handling and construction equipment manufacturing company with a majority market share in Mobile Cranes and Tower Cranes segment. It was established in the year 1995, today ACE has full-fledged state of the art production facilities based at industrial townships of Faridabad (Haryana), It has its other manufacturing units in different states of India

- 5. Why Action Construction Equipment for Training Interest in Automobile sector . Ace is mechanical company for construction field. New and wide area for gaining knowledge. Wanted to improve my knowledge for electric trucks . Opportunity to learn industrial engineering. To learn the basic industrial practices and ethics. Opportunity to learn Engineering designing

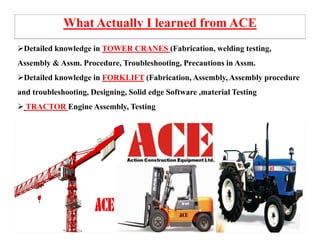

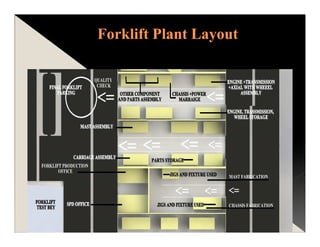

- 6. Detailed knowledge in TOWER CRANES (Fabrication, welding testing, Assembly & Assm. Procedure, Troubleshooting, Precautions in Assm. Detailed knowledge in FORKLIFT (Fabrication, Assembly, Assembly procedure and troubleshooting, Designing, Solid edge Software ,material Testing TRACTOR Engine Assembly, Testing What Actually I learned from ACE

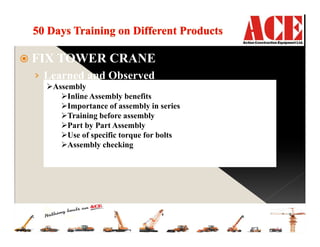

- 8. FIX TOWER CRANE › Learned and Observed Inventory control Raw material handling Raw material localization Parts and sub assembly categorization Providing parts Information & parts to production Purchase of new parts on time Data and parts handling Fabrication Plasma cutting Gas Cutting Mig welding Radial Drill machine Pipe bender Quality test MPT (magnetic particle testing) UVT(ultra violet testing) Speed test Load test Assembly Inline Assembly benefits Importance of assembly in series Training before assembly Part by Part Assembly Use of specific torque for bolts Assembly checking

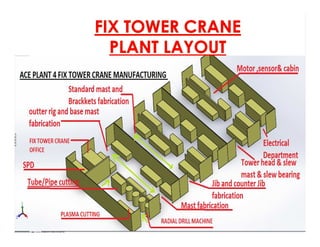

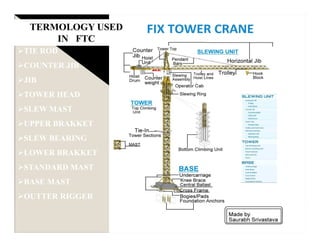

- 11. TERMOLOGY USED IN FTC TIE ROD COUNTER JIB JIB TOWER HEAD SLEW MAST UPPER BRAKKET SLEW BEARING LOWER BRAKKET STANDARD MAST BASE MAST OUTTER RIGGER

- 12. FORKLIFT › Learned and Observed DESIGNING Solid edge software Got designing Tips from officers Basics of Designing Design according to Standard Tools ,Nut and Bolts While Designing must know about Machine and its process and details of machine Must know about technology you going design

- 13. FORKLIFT › Learned and Observed Inventory control Raw material handling Raw material localization Parts and sub assembly categorization Providing parts Information & parts to production Purchase of new parts on time Data and parts handling

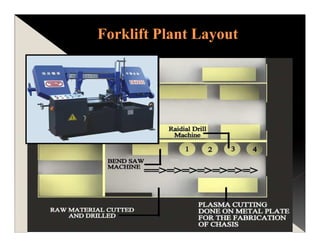

- 14. FORKLIFT › Learned and Observed Fabrication Plasma cutting Gas Cutting Mig welding Radial Drill machine Pipe bender Pipe Cutter Air Hammer AIR Drill Air Sander Air Blow Gun Impact Wrench Air Ratchet

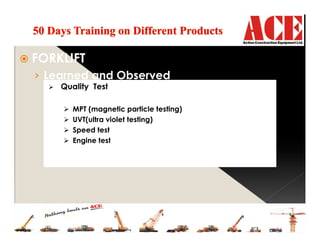

- 15. FORKLIFT › Learned and Observed Quality Test MPT (magnetic particle testing) UVT(ultra violet testing) Speed test Engine test

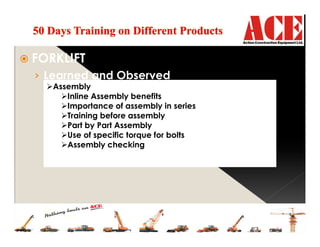

- 16. FORKLIFT › Learned and Observed Assembly Inline Assembly benefits Importance of assembly in series Training before assembly Part by Part Assembly Use of specific torque for bolts Assembly checking

- 19. Few Snapshots

- 20. Few Snapshots

- 21. Few Snapshots

- 22. Few Snapshots

- 23. Few Snapshots

- 24. Few Snapshots

- 25. Few Snapshots

- 26. JOB in Designing › FTC › FORKLIFT › TRACTOR › CRAWLER CRANE › ROAD EQIPMENTS ……….ETC Job in Quality Job in Maintenance Job in Production Job in Assembly

- 27. Industrial training program is an excellent opportunity for us to get to the ground level experience of Machines and Industry It is easy to work with sophisticated machines, but not with people. I learnt the way of work in an organization, the importance of being technical person, the importance of maximum commitment, and the importance of team spirit. The training program having three destinations was a lot more useful than staying at one place throughout the whole 8 weeks . I have gained lots of knowledge and experience needed to be successful in a great engineering challenge, as in my opinion, I personally felt that education in University is providing me is actually very much relevant to real industrial practices and after 2 months of industrial training I am serious about studies as with basic knowledge no one values in industry I am grateful to the Poornima university for giving us this wonderful opportunity.