Industrial Excursion ( Yangon Division, Myanmar)

- 1. 6/26/2016 1 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 2. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 2 1. Production of Tungsten Steel 2. Production of Steel Billets 3. Production of Bolts, Nuts and Washers 4. Production of Steel Blade 5. Production of wire coils

- 3. To No.3 Steel Mill (Myaung Taka) 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 3

- 4. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 4

- 5. • Raw Material, Iron ore or recycled iron cutting pieces are started to melt at 1538˚C •Oxygen, Nitrogen, Argon are released as a by product • Calcium carbonate is precipitated Formation of steel billets 6/26/2016 5 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 6. PROCESS OF MANUFACTURING STEEL BILLETS 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 6 1. Collecting Raw Materials in an electric arc furnace 2. Melting 3. Tapping in the ladle and refining the furnace 4. Transfer 5. Continuous Casting 6. Cutting 7. Cooling

- 7.  Raw Material: Scrap metal (by means of a bucket or magnet)  Scrap metal are put systematically and methodically unless the furnace is destroyed. 1. COLLECTING RAW MATERIALS IN AN ELECTRIC ARC FURNACE 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 7

- 8. 2. MELTING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 8  Oxidation process  Melting point at 1538˚C  Need to heat till the temperature of 1620˚C  Molten to get a liquid steel  An electrical current is combined with chemical energy to heat the scrap to a near molten state.  Forming slag as bubbles on top of the molten steel is removed

- 9. 3. REFINING THE FURNACE 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 9  When the molten steel is reached to 1620˚C, the molten steel is poured into the ladle.  The temperature and the chemistry are adjusted not to freeze the molten steel.  The gas, nitrogen and argon, and carbon, silicon is inserted for its chemistry and quality control.

- 10. What is Ladle? 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 10  Burnt magnesium carbon is the main ingredient.  The bricks need to seal with two layers.  Between the bricks and the ladle, there must be the poly.  The molten liquid is very secretive through the bricks it can harm the harm the ladle.  Two holes at the bottom: one for the gases and one for flowing the molten.  Can use the one ladle for 30 times.

- 11. 6/26/2016 11 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) Lateral View Top View

- 12. 4. TRANSFER 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 12  The molten liquid steel in the ladle is carried along by the crane to the continuous casting machine.

- 13. 5. CONTINUOUS CASTING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 13  the ladle gate is opened and the molten steel is allowed flow in a controlled matter into a tundish.  The tundish must be preheated between 900-1000˚C  This steel flows into three billet moulds. The steel billets are formed.

- 14. 6. CUTTING AND COOLING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 14  Molten hot steel billets are cut and cooled to get the steel billets with the desired lengths by the customers.  It is cooled with chemical and water bath as semi-product.  125mmx125mmx12m(or)6m  1.5 ton per billet

- 15. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 15

- 16. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 16 Process of Manufacturingsteel billets

- 17.  Raw materials from steel billets Usually diameter form between 5.5 mm to 8mm Two kinds of wire: raw hard wire, galvanized wire Need to be descaled the billets before the billets be ductile Manufacturing wire and wire drawing 6/26/2016 17 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 18. PROCESS OF MANUFACTURING WIRE 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 18 1. Wire Drawing 2. Cleaning 3. Patenting 4. Galvanising

- 19. 1. WIRE DRAWING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 19  The billets are put through the wire drawing machines  Desired customized diameter is being compressed through dies.

- 20. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 20

- 21. 2. CLEANING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 21  Not the wire be corroded

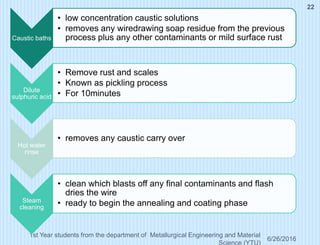

- 22. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) Caustic baths • low concentration caustic solutions • removes any wiredrawing soap residue from the previous process plus any other contaminants or mild surface rust Dilute sulphuric acid • Remove rust and scales • Known as pickling process • For 10minutes Hot water rinse • removes any caustic carry over Steam cleaning • clean which blasts off any final contaminants and flash dries the wire • ready to begin the annealing and coating phase 22

- 23. 4. GALVANIZING 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 23  To be galvanized, the cooled wire is passes through the molten zinc bath between 430- 470°C.  It passes through the ammonium chloride, charcoal oil, engine oil solution for best adhesion property.  the excess zinc is removed by air blowing.  Then they are coiled for each wire.

- 24. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 24

- 25. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 25

- 26. WIRES DRAWN FROM GALVANIZING PROCESS 6/26/2016 26 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) RealismCartoon Picture

- 27. 5. Shaping 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 27

- 28. 6/26/2016 28 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 29. 6/26/2016 29 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 30. 6/26/2016 30 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 31. 6/26/2016 31 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 32. 6/26/2016 32 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 33. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 33

- 34. 6/26/20161st Year students from the department of Metallurgical Engineering and Material Science 34

- 35. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 35 Four stages in one machine 1. Cutting 2. Threading 3. Heading 4. Trimming

- 36. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 36

- 37. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 37

- 38. To prevent corrosion 6/26/2016 38 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) Machine Sand

- 39. two kinds of bolts: HSB, High tension bolt and TSB, Torque shear bolt  There two kinds of forming: cold forming and hot forming Washer be obtained from 35% of the raw materials 6/26/2016 39 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 40. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 40  There are four stages in hot and cold forming of bolts: 1. Cutting 2. Forming 3. Heading 4. Marking 5. Trimming 40

- 41. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 41

- 42. Formation of bolts 6/26/2016 42 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) Machine’s description Machine

- 43. Residual Chips 6/26/2016 43 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 44. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 44

- 45. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 45

- 46. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 46

- 47. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 47

- 48. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 48

- 49. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 49

- 50. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 50  The stages 1. Cutting off 2. Forming 1 3. Forming 2 4. Forming 3 5. Forming 4 6. Forming 5 7. Before/ After Nut tapping

- 51. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 51

- 52. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 52

- 53. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 53

- 54. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 54

- 55. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 55

- 56. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 56

- 57. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 57

- 58. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 58

- 59. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 59

- 60. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 60  dfdff

- 61. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 61

- 62. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 62

- 63. Galvanizing 6/26/2016 63 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 64. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 64

- 65. Formation of steel plates 6/26/2016 65 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 66. 6/26/2016 66 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 67.  Chemical Composition  Shape and Design  Dimension  Hardness  Tensile Strength  Torque Testing  Stress Vs. Strain  Corrosion  Wave  Shearness, Crack Quality Control 6/26/2016 67 1st Year students from the department of Metallurgical Engineering and Material Science (YTU)

- 68. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 68

- 69. Special Thanks To 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 69

- 70. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 70 References  www.pacificsteel.com  www.tenaris-steel.com  www.madehow.com

- 71. 6/26/2016 1st Year students from the department of Metallurgical Engineering and Material Science (YTU) 71  May Pwint Phyu  May Myat Thu  Hsu Hsu Htet  May Zin Thu  Phue Myat Thaw  Chaw Su Thet Htar  Htet Thazin Zaw  Cherry Wint  Hlaing Yamin Oo  Mya Phu Pwint Thit

Editor's Notes

- #8: In 15 ton pot we need to put 18 ton of scratch to get a 15 tons of molten iron. Carbon % ------^ Manganese inversely proportional C, S,Mn depends on QC