International distributorpres. jan2013

- 1. International Distributor Presentation for On-Site Analysis, Inc. Will Willis, Jr. 2013 President & CEO On-Site Analysis, Inc. 7108 Fairway Drive, Suite 130 Palm Beach Gardens, FL 33418 561.775.5756, ext. 226 www.on-siteanalysis.com wwillis007@aol.com

- 2. Company ŌĆó On-Site Analysis, Inc. (OSA) was Incorporated in 1986 and has become the global leader in on-site fluids analysis instrumentation. Corporate Headquarters- Palm Beach Gardens, FL Manufacturing & Technical Center- Marlborough, MA LubeTrak┬« web-based Data storage and mining - Salt Lake City, UT ŌĆó OSA manufactures state of the art analyzers that provide ŌĆ£Lab-QualityŌĆØ results, in minutes not days, yet are as easy to use as an ATM. ŌĆó ASTM Designation D7417-10, and & ╔Č Approved 2

- 3. 3

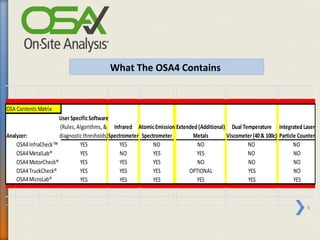

- 4. What The OSA4 Contains OSA Contents Matrix User Specific Software (Rules, Algorithms, & Infrared Atomic Emission Extended (Additional) Dual Temperature Integrated Laser Analyzer: diagnostic thresholds)Spectrometer Spectrometer Metals Viscometer (40 & 100c) Particle Counter OSA4 InfraCheckŌäó YES YES NO NO NO NO OSA4 MetalLab┬« YES NO YES YES NO NO OSA4 MotorCheck┬« YES YES YES NO NO NO OSA4 TruckCheck┬« YES YES YES OPTIONAL YES NO OSA4 MicroLab┬« YES YES YES YES YES YES 4

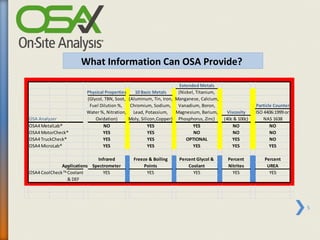

- 5. What Information Can OSA Provide? Extended Metals Physical Properties 10 Basic Metals (Nickel, Titanium, (Glycol, TBN, Soot, (Aluminum, Tin, Iron, Manganese, Calcium, Fuel Dilution %, Chromium, Sodium, Vanadium, Boron, Particle Counter Water %, Nitration, Lead, Potassium, Magnesium, Barium, Viscosity ISO 4406:1999 or OSA Analyzer Oxidation) Moly, Silicon,Copper) Phosphorus, Zinc) (40c & 100c) NAS 1638 OSA4 MetalLab┬« NO YES YES NO NO OSA4 MotorCheck┬« YES YES NO NO NO OSA4 TruckCheck┬« YES YES OPTIONAL YES NO OSA4 MicroLab┬« YES YES YES YES YES Infrared Freeze & Boiling Percent Glycol & Percent Percent Applications Spectrometer Points Coolant Nitrites UREA OSA4 CoolCheckŌäóCoolant YES YES YES YES YES & DEF 5

- 6. The OSA4 is a Comprehensive Diagnostic Tool ŌĆó Engine Oils ŌĆó Transmission Fluids ŌĆó Hydraulic Fluids ŌĆó Generator Lubricants ŌĆó Power Steering Fluids ŌĆó Gear Box Lubricants 6

- 7. Fire Dept. School Bus OSA4 Applications Police Dept. Solid Waste Public Works Transit Heavy 7 Equipment

- 8. Why Are Immediate Test Results Important ? ŌĆó Test results are available while vehicles are in the shop. ŌĆó Needed repairs can be addressed and corrective action determined. ŌĆó Vehicles are not taking up yard space while waiting for test results. ŌĆó Replacement parts can be ordered prior to tearing down an engine. ŌĆó Vehicles are not sent into the shop with unknown problems. ŌĆó Scheduling of repairs can be planned before they become critical. ŌĆó No loss of productivity due to lack of information. 8 ŌĆó Identify needed repairs before they become catastrophic.

- 9. The OSA4 is Easy to Operate & Maintain ŌĆó The OSA4 is as simple to operate as an ATM. ŌĆó User friendly prompts guide technicians through the menu. ŌĆó Vehicle data is entered (or pre-entered) and stored in the OSA4 and retained for future use. ŌĆó Once the information is entered into the data base, sample tests results are stored for immediate trending and future tracking. ŌĆó Technicians enter the model, engine, sump capacity, mileage or hours. ŌĆó In minutes, the OSA4 will interpret the test results based on the data entered and make diagnostic recommendations of parts that need to be checked if abnormal test results occur. ŌĆó Maintenance is minimal. 9

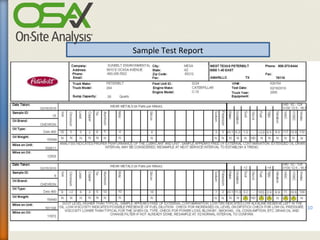

- 10. Sample Test Report 10

- 11. Data Storage and Networking ŌĆó The OSA4 has the ability to store vehicle information and test data and: - Shows results on the touch screen - Prints a hard copy of test reports - Downloads to a password protected data trending, monitoring, and sorting website: www.LubeTrak.com - Provides instant email ŌĆ£AlertsŌĆØ if an abnormal test result is found anywhere within your system - LubeTrak┬« gives you the ability to spot trends, track down poor maintenance practices and graph any unit or component condition. 11

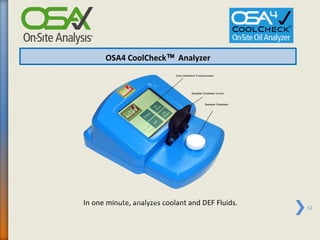

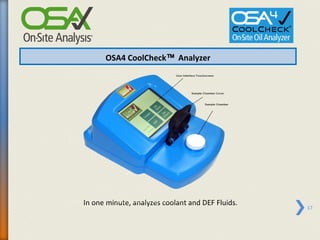

- 12. OSA4 CoolCheckŌäó Analyzer In one minute, analyzes coolant and DEF Fluids. 12

- 13. The November/December 2011 Edition of Grading & Excavation Contractor Magazine reported: ŌĆ£A recent Industry Study confirmed that 40% of ALL Engine breakdowns can be attributed to the Cooling SystemŌĆØ 13

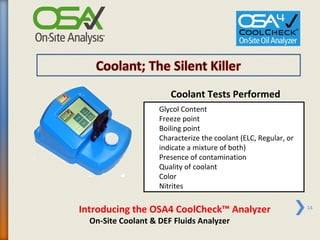

- 14. Coolant Tests Performed Glycol Content Freeze point Boiling point Characterize the coolant (ELC, Regular, or indicate a mixture of both) Presence of contamination Quality of coolant Color Nitrites Introducing the OSA4 CoolCheckŌäó Analyzer 14 On-Site Coolant & DEF Fluids Analyzer

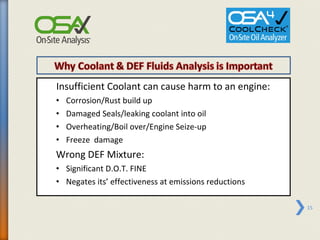

- 15. Insufficient Coolant can cause harm to an engine: ŌĆó Corrosion/Rust build up ŌĆó Damaged Seals/leaking coolant into oil ŌĆó Overheating/Boil over/Engine Seize-up ŌĆó Freeze damage Wrong DEF Mixture: ŌĆó Significant D.O.T. FINE ŌĆó Negates itsŌĆÖ effectiveness at emissions reductions 15

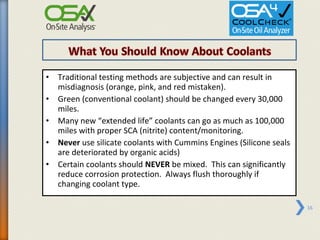

- 16. ŌĆó Traditional testing methods are subjective and can result in misdiagnosis (orange, pink, and red mistaken). ŌĆó Green (conventional coolant) should be changed every 30,000 miles. ŌĆó Many new ŌĆ£extended lifeŌĆØ coolants can go as much as 100,000 miles with proper SCA (nitrite) content/monitoring. ŌĆó Never use silicate coolants with Cummins Engines (Silicone seals are deteriorated by organic acids) ŌĆó Certain coolants should NEVER be mixed. This can significantly reduce corrosion protection. Always flush thoroughly if changing coolant type. 16

- 17. OSA4 CoolCheckŌäó Analyzer In one minute, analyzes coolant and DEF Fluids. 17

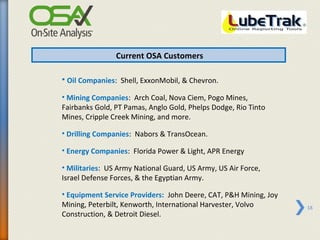

- 18. Current OSA Customers ŌĆó Oil Companies: Shell, ExxonMobil, & Chevron. ŌĆó Mining Companies: Arch Coal, Nova Ciem, Pogo Mines, Fairbanks Gold, PT Pamas, Anglo Gold, Phelps Dodge, Rio Tinto Mines, Cripple Creek Mining, and more. ŌĆó Drilling Companies: Nabors & TransOcean. ŌĆó Energy Companies: Florida Power & Light, APR Energy ŌĆó Militaries: US Army National Guard, US Army, US Air Force, Israel Defense Forces, & the Egyptian Army. ŌĆó Equipment Service Providers: John Deere, CAT, P&H Mining, Joy Mining, Peterbilt, Kenworth, International Harvester, Volvo 18 Construction, & Detroit Diesel.

- 19. Target Markets & Applications ŌĆó Truck Fleet Operators: Include in PM service to reduce operating cost by extending oil drain interval, identifying needed repairs, reducing down time and extending the useful life of equipment. ŌĆó Truck Fleet Service Providers: Identifies needed repairs while vehicle in service bay. Increases parts and repair service revenue. Increases customer retention. ŌĆó Military Fleet Readiness: Reduces potentially catastrophic breakdowns. Extends the useful life of equipment. ŌĆó Mines: Increases equipment utilization and reduces unscheduled down time. Extend the useful life of equipment. ŌĆó Oil Companies: Provide instruments to large customers in exchange for lubricants business. Improve customer acquisition/retention. ŌĆó Municipalities: Improved Bus, Off Road, Emergency Equipment, and police vehicle maintenance. Extends useful life. 19

- 20. Oil Company Case Study A major oil company in Canada identified 100 of their top target accounts. We agreed to a program whereby the oil company would offer a FREE OSA in exchange for the customer signing a five year commitment to purchase all of their lubricants from them, at a competitive price. ŌĆóDuring the first 18 months of operation, they closed 52 of their top 100 accounts. ŌĆóDuring the next 12 months, they closed 24 of their top 100 target accounts. ŌĆóDuring the last 18 months, they closed an additional 13 of their top 100. ŌĆóTotal of 89 placements. Commissions during rollout was $834,019 20

- 21. Fleet Service Provider Case Study A major US Truck Service Provider, with 82 locations, was having difficulty attaining national fleet accounts, while their parts & repair service revenue was suffering. We placed Five TruckCheck┬« units in locations to measure their impact on their Parts and Repair Service revenue. ŌĆóDuring the 120 day test, they closed an average of three major fleet accounts in each of the five locations. ŌĆóOf the 2,614 oil analysis conducted during the initial 120 days, 26% were found to be over extended fluids, 7% showed early stages of coolant leaks, and 4% had fuel dilution. Over 50% of the identified problems were converted to a repair service. ŌĆóParts and Repair Revenue increased 14% for the test location as compared to the non- test locations for the same time period. ŌĆóDuring the following 20 months, they populated all 82 locations. 21 ŌĆóCommission was $570,310 for the 20 months rollout.

- 22. Heavy Equipment Distributor Case Study A globally recognized agriculture and heavy equipment Distributor was having difficulty competing with Caterpillar (CAT in-house fluids labs were providing unmatchable customer support). The problem was exacerbated by the fact that the DistributorŌĆÖs independent dealerships refused to invest $300,000+ for a lab and staff it with trained lab technicians. OSA put together a Private Label MicroLab┬« Dealership program in August, 2010. ŌĆó To date, 12 Distributors have purchased units and many more have committed for 2012. ŌĆó Commission for the initial 12 placements $112,452. 22

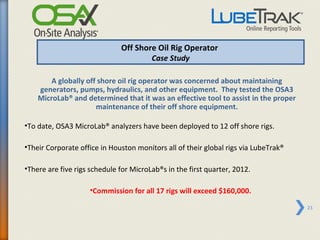

- 23. Off Shore Oil Rig Operator Case Study A globally off shore oil rig operator was concerned about maintaining generators, pumps, hydraulics, and other equipment. They tested the OSA3 MicroLab┬« and determined that it was an effective tool to assist in the proper maintenance of their off shore equipment. ŌĆóTo date, OSA3 MicroLab┬« analyzers have been deployed to 12 off shore rigs. ŌĆóTheir Corporate office in Houston monitors all of their global rigs via LubeTrak┬« ŌĆóThere are five rigs schedule for MicroLab┬«s in the first quarter, 2012. ŌĆóCommission for all 17 rigs will exceed $160,000. 23

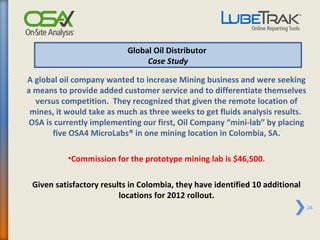

- 24. Global Oil Distributor Case Study A global oil company wanted to increase Mining business and were seeking a means to provide added customer service and to differentiate themselves versus competition. They recognized that given the remote location of mines, it would take as much as three weeks to get fluids analysis results. OSA is currently implementing our first, Oil Company ŌĆ£mini-labŌĆØ by placing five OSA4 MicroLabs┬« in one mining location in Colombia, SA. ŌĆóCommission for the prototype mining lab is $46,500. Given satisfactory results in Colombia, they have identified 10 additional locations for 2012 rollout. 24

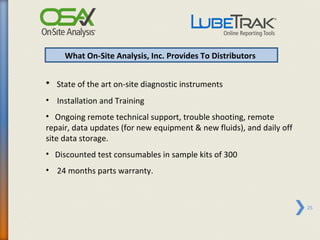

- 25. What On-Site Analysis, Inc. Provides To Distributors ŌĆó State of the art on-site diagnostic instruments ŌĆó Installation and Training ŌĆó Ongoing remote technical support, trouble shooting, remote repair, data updates (for new equipment & new fluids), and daily off site data storage. ŌĆó Discounted test consumables in sample kits of 300 ŌĆó 24 months parts warranty. 25

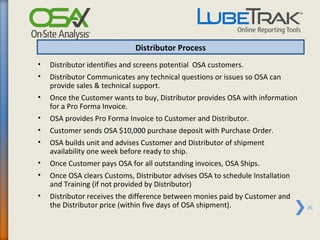

- 26. Distributor Process ŌĆó Distributor identifies and screens potential OSA customers. ŌĆó Distributor Communicates any technical questions or issues so OSA can provide sales & technical support. ŌĆó Once the Customer wants to buy, Distributor provides OSA with information for a Pro Forma Invoice. ŌĆó OSA provides Pro Forma Invoice to Customer and Distributor. ŌĆó Customer sends OSA $10,000 purchase deposit with Purchase Order. ŌĆó OSA builds unit and advises Customer and Distributor of shipment availability one week before ready to ship. ŌĆó Once Customer pays OSA for all outstanding invoices, OSA Ships. ŌĆó Once OSA clears Customs, Distributor advises OSA to schedule Installation and Training (if not provided by Distributor) ŌĆó Distributor receives the difference between monies paid by Customer and the Distributor price (within five days of OSA shipment). 26

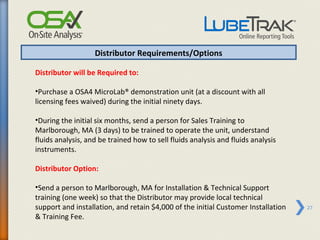

- 27. Distributor Requirements/Options Distributor will be Required to: ŌĆóPurchase a OSA4 MicroLab┬« demonstration unit (at a discount with all licensing fees waived) during the initial ninety days. ŌĆóDuring the initial six months, send a person for Sales Training to Marlborough, MA (3 days) to be trained to operate the unit, understand fluids analysis, and be trained how to sell fluids analysis and fluids analysis instruments. Distributor Option: ŌĆóSend a person to Marlborough, MA for Installation & Technical Support training (one week) so that the Distributor may provide local technical support and installation, and retain $4,000 of the initial Customer Installation 27 & Training Fee.

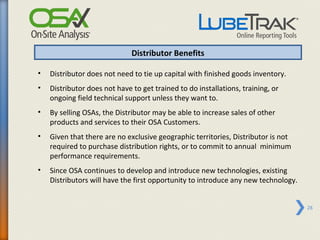

- 28. Distributor Benefits ŌĆó Distributor does not need to tie up capital with finished goods inventory. ŌĆó Distributor does not have to get trained to do installations, training, or ongoing field technical support unless they want to. ŌĆó By selling OSAs, the Distributor may be able to increase sales of other products and services to their OSA Customers. ŌĆó Given that there are no exclusive geographic territories, Distributor is not required to purchase distribution rights, or to commit to annual minimum performance requirements. ŌĆó Since OSA continues to develop and introduce new technologies, existing Distributors will have the first opportunity to introduce any new technology. 28

- 29. Headquarters 7108 Fairway Drive, Suite 130 Palm Beach Gardens, FL 33418 Phone: 561.775.5756 International Manufacturing & Technical Support Representation 72 Cedar Hill Street Russia Marlborough, MA 01752 Egypt Phone: 508-460-7778 United Kingdom China LubeTrak Sales & Service Australia 9469 S. 550 West South Africa Sandy, UT 84070 Indonesia Central America Phone: 866-582-3872 Brazil 29 India