Introduction to construction mortar.pptx

- 1. MORTAR

- 2. Content :- ŌĆó Introduction ŌĆó Constituents ŌĆó Properties ŌĆó Types of mortar ŌĆó Selection of mortar ŌĆó Tests ŌĆó Grouting ŌĆó Guniting ŌĆó Application ŌĆó Site visit

- 3. What is mortar ? ŌĆó It is a workable paste which hardens to bind building blocks. ŌĆó It is used to fill and seal the irregular gaps between stones, bricks and concrete masonry units, spread the weight of them evenly. ŌĆó In its broadest sense mortar include pitch, asphalt and soft mud or clay as used between mud bricks. ŌĆó The word Mortar comes from Latin mortarium meaning crushed. ŌĆó mortar is a mixture of sand a Binder such as cement, lime and water is supplied as a paste which then sets hard.

- 4. Constituents of mortar:- Basic composition of mortar requires three main constituents i.e. 1. Fine aggregate, Sand is most commonly used for this purpose. 2. Binding material, e.g. Cement, Lime, Gypsum etc. Can be a compound material by mixture of two or more of these. 3. Water. These are mixed in different ratios for different purposes of construction. A coarse aggregate is also mixed sometime for various reasons, mostly for development of concrete.

- 5. PROPERTIES OF MORTAR:- ŌĆó workability ŌĆó Strength ŌĆó water retentivity ŌĆó rate of stiffening ŌĆó resistance to rain penetration

- 6. WORKABILITY:- ŌĆó Workability is the property of mortar which enables it to be spread and applied to masonry unit with ease. ŌĆó It also facilitates proper filling of joints in masonry. ŌĆó This property of mortar depends on properties of various ingredients used for making mortar and on the method of mixing adopted

- 7. STRENGTH:- ŌĆó A mortar is said to be good in strength only after its hardening ŌĆó From structural considerations it is necessary that masonry should attain the requisite strength by the time loads are imposed on it. With that in view, 28-day strength of a mortar is taken into consideration. ŌĆó Strength of masonry depends on strength of mortar. ŌĆó When it comes to preparation of good strength mortar, the sufficient cement content should be used. Well graded fine aggregate should be used. Water content should not be more than required amount.

- 8. WATER RETENTIVITY:- ŌĆó Most of the masonry units have normally appreciable suction, depending on their porosity and moisture content and they begin to suck moisture from mortar as soon as these come in contact with mortar. ŌĆó If units draw out too much moisture from the mortar rapidly, the latter is unable to gain adequate strength, when gain of strength is dependent on the process of hydration in mortar. ŌĆó Water retentivity of mortar is improved by the addition of hydrated lime or finely ground limestone or chemical compounds known as plasticizers. Generally speaking, mortars having good workability have also good water retentivity.

- 9. RATE OF STIFFENING:- ŌĆó Stiffening of mortar in masonry is caused either by loss of moisture or by the setting action of binder used in the mortar or by both. ŌĆó Most of the moisture lost is absorbed into the masonry unit but some evaporates into the atmosphere. ŌĆó Some stiffen early whereas some take too much time or it. ŌĆó time rate of stiffening must be sufficient.

- 10. RESISTANCE TO RAIN PENETRATION:- ŌĆó Rain water penetrates a masonry wall through - pores of masonry units - pores of mortar - cracks between units and mortar ŌĆó main source of rain penetration is through cracks in masonry. ŌĆó from the point of rain penetration, bonding property of mortar is of great importance.

- 11. REQUIREMENTS OF ideal MORTAR :- ŌĆó The following are the important general ŌĆó requirements of mortar: ŌĆó Strength: It must have the required strength. ŌĆó Workability: It must be workable ŌĆó (lime mortars are more workable) ŌĆó Durability: It must be durable. ŌĆó It should stiffen early. ŌĆó (Time rate of stiffening must be sufficient.) ŌĆó It must have good bond with bricks. ŌĆó It should prevent seepage of rain water. ŌĆó (Resistance to rain penetration should be high.) ŌĆó It should have water retentivity.

- 12. Types of mortar :- ŌĆó Based on bulk density ŌĆó Based on Nature of application ŌĆó Based on strength ŌĆó Based on binding material used ŌĆó Special purpose mortars

- 13. Bulk density :- heavy weight mortar ŌĆó mortar have bulk density of 15 KN/ 3 ØæÜ or more then it ŌĆó heavy quartzes are used as adulterants in this mortar Light weight mortar ŌĆó mortar have bulk density of less than 15 KN/ 3 ØæÜ ŌĆó light porous sands, soft sands are used as adulterants in this mortar

- 14. Based on nature of applications:- ŌĆó Brick laying or stone laying mortar ŌĆó Finishing mortar

- 15. BRICK LAYING OR STONE LAYING MORTAR:- ŌĆó In masonry walls the structural units such as stones or bricks are bonded together using mortar. ŌĆó The proportions of ingredients for this purpose is decided with respect to the kind of binding material used

- 16. FINISHING MORTAR:- ŌĆó It should have great strength, mobility and resistance against atmospheric action like rain, wind, etc ŌĆó The mortar is used for ornamental finishing ŌĆó Finishing mortar is used for pointing and plastering works

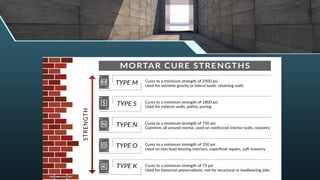

- 17. Based on strength ŌĆó Type m ŌĆó Type s ŌĆó Type n ŌĆó Type o ŌĆó Type k

- 19. Based on binding material used:- ŌĆó Cement mortar ŌĆó Lime mortar ŌĆó Surkhi mortar ŌĆó Mud mortar ŌĆó Gypsum mortar

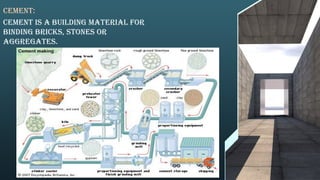

- 20. Cement is a building material for binding bricks, stones or aggregates. CEMENT:

- 21. Cement mortar :- ŌĆó The paste is prepared by mixing cement and sand in suitable proportions in addition to water. ŌĆó The general proportion is 1 part of cement to 2-8 parts clean sand. ŌĆó These mortars must be use within half an hour, i.e. before initial setting time of the cement. ŌĆó This type is used for all engineering works where high strength is desired such as load bearing walls, deep foundations, flooring etc.

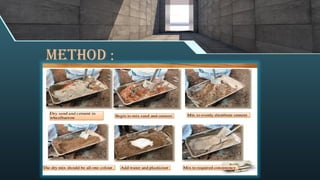

- 22. PREPARATION OF cement MORTAR ŌĆó When mixing by hand, the sand cement are helped up on a mixing board or in a wheel barrow and repeatedly turned over and over until thoroughly mixed. ŌĆó The colour of the dry mix will change as the cement is distributed throughout - there should be no ŌĆśstreakingŌĆÖ of cement, and no clumps of pure sand or pure cement. ŌĆó Once the dry ingredient are mixed, the water can be added.

- 23. PREPARATION PROCESS ŌĆó When using a mechanical mixer, add half a bucket (2 or 3 litres) of clean cold water to the empty drum before adding the dry ingredients in sequence. ŌĆó Add 4 measures of sand then 1 of cement, followed by 4 sand, then another cement and so until the required quantity is in the mixer. ŌĆó This ensure a more through mix than adding, say, 20 measures of sand then 5 measures of cement. ŌĆó Again, the water is added to the revolving dump once the dry ingredient are thoroughly blended.

- 24. METHOD :

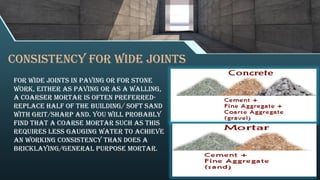

- 25. CONSISTENCY FOR WIDE JOINTS For wide joints in paving or for stone work, either as paving or as a walling, a coarser mortar is often preferred- replace half of the building/ soft sand with grit/sharp and. You will probably find that a coarse mortar such as this requires less gauging water to achieve an working consistency than does a bricklaying/general purpose mortar.

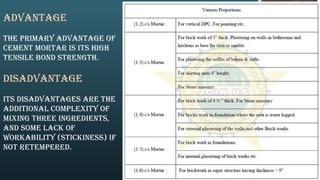

- 26. advantage The primary advantage of cement mortar is its high tensile bond strength. disadvantage its disadvantages are the additional complexity of mixing three ingredients, and some lack of workability (stickiness) if not retempered.

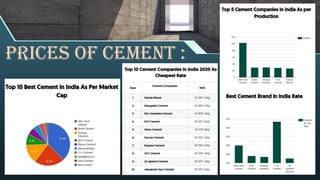

- 27. prices of cement :

- 28. Mud mortar :- ŌĆó The paste is prepared by mixing suitable clay, soil with water. ŌĆó The soil which is used for preparing mud mortar should be free from grass, pebbles etc. ŌĆó These are the cheapest mortars but weakest in strength ŌĆó These mortars are used for brickwork of ordinary buildings and for plastering walls in rural areas.

- 29. Mud mortar without waterproofing:- ŌĆó The earth for the mud mortar should be of tenacious nature and specially selected. ŌĆó Sand is added to this earth in such quantity that when a sample of the mixture is mixed well with water and made into a ball which is allowed to get dry it should show no sign of cracking up. ŌĆó This mixture of mud and sand is well trodden and worked into the consistency of a thick paste by adding sufficient water. ŌĆó All the clods and stones are removed in the process. It is then allowed to get mature for a week with water standing on top of the mud in a shallow pool. ŌĆó It is then kneaded well by treading on it to the suitable consistency to be used for brickwork in mud.

- 30. Mud mortar with waterproofing:- ŌĆó The soil to be used for mud mortar shall be such that 100 per cent will pass through 2.36 mm sieve and not less than 75 per cent pass through 850 microns sieve. The clay content shall not exceed 10 per cent. ŌĆó Loamy soil has better adhesion to the sun-dried brick walls than granular soil. Lime and bitumen are added to this soil as specified below to improve the waterproofing qualities of the mix. Hydrated lime 3 per cent by weight is added first and then 2 per cent by weight bitumen of penetration 80/100. ŌĆó Water is then added to the above soil mix and the whole mass thoroughly mixed by trodding bring it to a workable consistency.

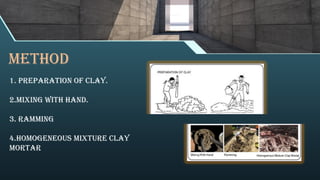

- 31. METHOD 1. PREPARATION OF CLAY. 2.MIXING WITH HAND. 3. RAMMING 4.HOMOGENEOUS MIXTURE CLAY MORTAR

- 32. USES:

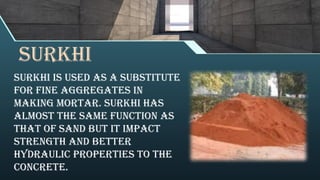

- 33. surkhi Surkhi is used as a substitute for fine aggregates in making mortar. Surkhi has almost the same function as that of sand but it impact strength and better hydraulic properties to the concrete.

- 34. Strength characteristics of surkhi :- ŌĆó The physical and chemical composition of lime or cement or surkhi. ŌĆó Mineral logical composition of surkhi. ŌĆó Degree of the burning of lime or cement or surkhi. ŌĆó Fineness of surkhi ŌĆó Mix proportion

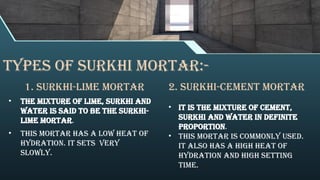

- 35. Types of surkhi mortar:- 1. Surkhi-Lime Mortar ŌĆó The mixture of lime, surkhi and water is said to be the surkhi- lime mortar. ŌĆó This mortar has a low heat of hydration. It sets very slowly. 2. Surkhi-Cement Mortar ŌĆó It is the mixture of cement, surkhi and water in definite proportion. ŌĆó This mortar is commonly used. It also has a high heat of hydration and high setting time.

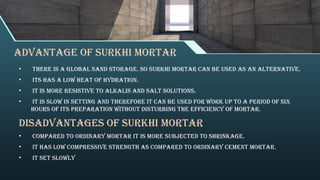

- 36. Advantage of surkhi Mortar ŌĆó There is a global sand storage. So surkhi mortar can be used as an alternative. ŌĆó Its has a low heat of hydration. ŌĆó It is more resistive to alkalis and salt solutions. ŌĆó It is slow in setting and therefore it can be used for work up to a period of six hours of its preparation without disturbing the efficiency of mortar. Disadvantages of surkhi Mortar ŌĆó Compared to ordinary mortar it is more subjected to shrinkage. ŌĆó It has low compressive strength as compared to ordinary cement mortar. ŌĆó It set slowly

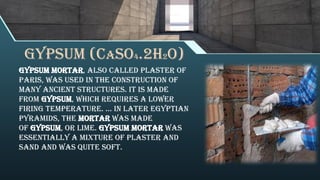

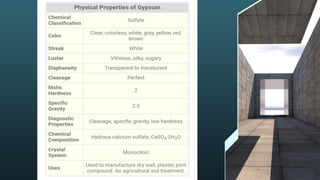

- 37. GYPsum (CaSO4.2h2o) Gypsum mortar, also called plaster of Paris, was used in the construction of many ancient structures. It is made from gypsum, which requires a lower firing temperature. ... In later Egyptian pyramids, the mortar was made of gypsum, or lime. Gypsum mortar was essentially a mixture of plaster and sand and was quite soft.

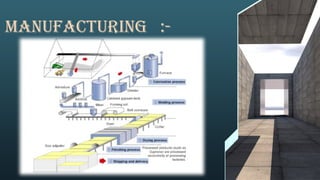

- 39. Manufacturing :-

- 40. Uses of gypsum ŌĆó Decorative Plaster ŌĆó Building plaster ŌĆó Plaster Walls ŌĆó Gypsum fibreboards 140rs/25kg

- 41. Lime mortar :- ŌĆó The paste is prepared by mixing lime and sand or surkhi in suitable proportions in addition to water. ŌĆó If surkhi is to be added in lime mortar the equal proportions of sand and surkhi should be mixed with lime. ŌĆó These mortars are inferior to cement mortars in strength as well as water tightness. ŌĆó These mortars should not be used for underground works as they set in the presence of carbon dioxide and break up in damp conditions. ŌĆó This type is used for construction work above ground level i.e. exposed positions.

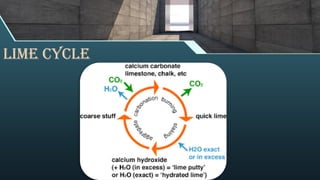

- 42. Lime cycle

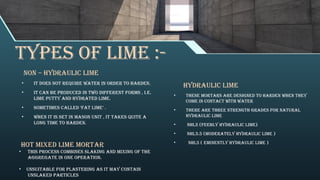

- 43. Types of lime :- NON ŌĆō HYDRAULIC LIME ŌĆó It does not require water in order to harden. ŌĆó It can be produced in two different forms , i.e. lime putty and hydrated lime. ŌĆó Sometimes called ŌĆśfat limeŌĆÖ . ŌĆó When it is set in mason unit , it takes quite a long time to harden. HYDRAULIC LIME ŌĆó These Mortars are designed to harden when they come in contact with water ŌĆó There are three strength grades for natural hydraulic lime ŌĆó NHL2 (Feebly Hydraulic Lime) ŌĆó NHL3.5 (Moderately Hydraulic Lime ) ŌĆó NHL5 ( Eminently Hydraulic Lime ) HOT MIXED LIME MORTAR ŌĆó This process combines slaking and mixing of the aggregate in one operation. ŌĆó Unsuitable for plastering as it may contain unslaked particles

- 44. Special purpose mortars:- ŌĆó Fire resistance mortar ŌĆó Packing mortar ŌĆó Sound absorbing mortar ŌĆó Chemical resistant mortar ŌĆó Lightweight mortar ŌĆó X-ray shielding mortar

- 45. Fire Resistant Mortar:- ŌĆó When there are fire warnings or similar dangers to a building structure in a particular zone, then fire resistant mortar is used as these acts as a fireproofing shield. ŌĆó Mortar attains fire resistance properties when aluminous cement is added to the fine powder of fire bricks.

- 46. Packing Mortar:- ŌĆó The main ingredients of packing mortars are normally cement-loam, cement-sand or sometimes even cement-sand-loam. ŌĆó This kind of mortar is commonly used in the packing of oil wells. Packing mortar needs to be of high homogeneity and strength, and also should be resistant to water. ŌĆó Dry pack mortar also known as deck mud or floor mud, is formed by blending sand, cement, and water. ItŌĆÖs application is found in repairing small spots, developing thick bed mortar for tile and brick placement, and bed shower setting up.

- 47. Sound Absorbing Mortar:- ŌĆó Just as the name suggests, this kind of mortar helps in reducing noise levels by acting as a soundproofing layer. ŌĆó The mortar mixture contains cement, lime, slag, gypsum, etc. as binding materials and cinders and pumice as adulterants.

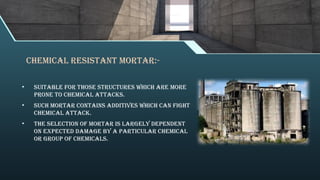

- 48. Chemical Resistant Mortar:- ŌĆó suitable for those structures which are more prone to chemical attacks. ŌĆó Such mortar contains additives which can fight chemical attack. ŌĆó The selection of mortar is largely dependent on expected damage by a particular chemical or group of chemicals.

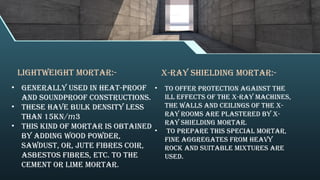

- 49. ŌĆó To offer protection against the ill effects of the X-ray machines, the walls and ceilings of the X- ray rooms are plastered by X- ray shielding mortar. ŌĆó To prepare this special mortar, fine aggregates from heavy rock and suitable mixtures are used. X-ray Shielding Mortar:- Lightweight Mortar:- ŌĆó Generally used in heat-proof and soundproof constructions. ŌĆó these Have bulk density less than 15KN/ 3 ØæÜ ŌĆó This kind of mortar is obtained by adding wood powder, sawdust, or, jute fibres coir, asbestos fibres, etc. to the cement or lime mortar.

- 52. What is the purp0se of tests on mortar? ŌĆó The purpose of the testing is to determine whether a mortar mixed with construction materials to specified proportions conforms with physical property requirements listed within the standard. ŌĆó Field testing and sampling of mortar is used to verify consistency of materials and procedures, not for mortar strength.

- 53. Tests:- Crushing strength - ŌĆó Sample of mortar is taken and is gradually loaded in a compression testing machine till failure occurs due to crushing. ŌĆó The ultimate crushing strength is obtained by dividing maximum load with cross sectional area Tensile strength ŌĆō ŌĆó Mortar to be tested is placed in the briquette molds. ŌĆó The briquette are then tested in a tension testing machine ŌĆó The cross sectional are of central portion is 38mm x 38mm or 144 mm2 ŌĆó The ultimate tensile stress per mm2 is obtained by dividing failing load with 1444

- 55. data and results Comparison between determined and standard value

- 56. adhesive strength test ŌĆó The two bricks are placed at right angles to each other ŌĆó The mortar is placed to join them so as to form a horizontal joint of 90x90 = 810 mm2 will form size of bricks ŌĆó The upper brick is suspended from an overhead support and the weights are attached to the lower brick ŌĆó The weights are gradually increases till separation of brick occurs ŌĆó The ultimate adhesive strength of mortar/mm2 area is obtained by diving maximum load with 810 mm2 .

- 57. grouting ŌĆó Grout is usually a mixture of cement, sand, and water or chemicals that are used to fill gaps. ŌĆó Give additional strength to the foundations of load- bearing structures

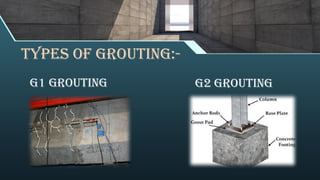

- 58. Types of grouting:- G1 GROUTING G2 Grouting

- 59. Applications of grouting:- :- Filling and sealing cavities, gaps or voids Post fixing Concrete repairs

- 60. Under grouting base plates Paving joints Fixing street furniture and traffic

- 61. Guniting:- Application of mortar or concrete under pneumatic pressure through a cement gun is known as guniting, concrete becomes extremely strong & a high bond is achieved. Composed of cement & sand conveyed through gun. Water is added at high velocity & the mix strikes the surface.

- 62. Brick Masonry Construction Preparation- ŌĆó Check the level of the ground using level, theodolite or transparent hose level. ŌĆó Set the layout of the structure. ŌĆó Trace of building axis and wall alignment using gypsum powder, chalk, or similar, marking the trenches for foundation. ŌĆó After that, install foundation wall, cure foundation for minimum two days before beginning of brick masonry construction. ŌĆó Distribute bricks in several stacks along project site to cut time and effort later. ŌĆó Wet bricks few hours prior to the work. Not only does this avoid absorbing too much water from mortar but also improve adherence of bricks and mortar.

- 63. Brick Masonry Construction Procedure ŌĆó Initially, mix the mortar with water and blend it until a smooth and plastic mortar is produced. ŌĆó After that, place the mortar on foundation line evenly using trowel (25mm thickness and one brick wide is recommended for laid mortar). ŌĆó Then, lay the first course of stretcher bricks in the mortar. Start with second brick, apply mortar to the head joint end of each brick, After that shove the bricks into place firmly so that the mortar is squeezed out of all side of the joints. ŌĆó Utilize a level to examine the course for correct height. ensure that bricks are plumb and level. ŌĆó Place another mortar line alongside the first course, then begin laying the second course.

- 64. ŌĆó Use the two half bricks to begin the second to ensure that the first two courses are staggered for structural purposes. ŌĆó To finish the second course of the lead, lay three header bricks and make sure that they are plumb and level. ŌĆó The third and fifth courses consists of stretchers similar to the first course. The fourth course begins with single header, ŌĆó followed by stretchers. Use the level to make sure that the lead is true on each course. Lastly, this pattern of brick laying is used till the target height is reached.

- 65. BRICK MASONRY:- 1.BRICKS: Building units of masonry. 2.MORTAR:- Binding the building units and providing strength to act as a single unit. 3.BRICK MASONRY: Construction of building units bonded together with mortar.

- 66. PLASTERING : ŌĆó To protect external surfaces against atmospheric agencies. ŌĆó To give smooth surface in which dust and dirt cannot lodge. ŌĆó To protect surfaces against vermin ŌĆó To conceal inferior materials or defective workmanship. ŌĆó Mortar used for plastering are: a. Cement Mortar b. Lime Mortar c. Gypsum Mortar d. Gauged Mortar e. Surkhi Mortar f. Aerated Cement Mortar

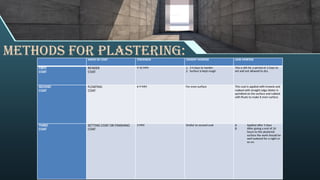

- 67. METHODS FOR PLASTERING: NAME OF COAT THICKNESS CEMENT MORTAR LIME MORTAR FIRST COAT RENDER COAT 9-10 MM 1. 3-4 days to harden 2. Surface is kept rough This is left for a period of 2 Days to set and not allowed to dry. SECOND COAT FLOATING COAT 6-9 MM For even surface This coat is applied with trowels and rubbed with straight edge.Water is sprinkled on the surface and rubbed with floats to make it even surface. THIRD COAT SETTING COAT OR FINISHING COAT 3 MM Similar to second coat A. Applied after 5 days B. After giving a rest of 24 hours to the plastered surface the work should be well watered for a night or so on.

- 68. Defects in plastering:- 3.PEELING 4.FLAKING 1.BLISTERING OF PLASTER SURFACE: 2.EFFLORESCENCE

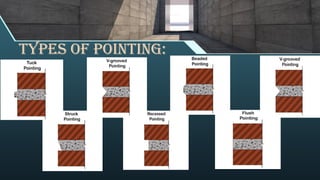

- 69. POINTING: The term pointing is used to denote the finishing of mortar in either stone masonry or brick masonry. Pointing involves raking out of joints which are constructed with good mortar and filling the joints with mortar which, in many cases is not sufficiently watered.

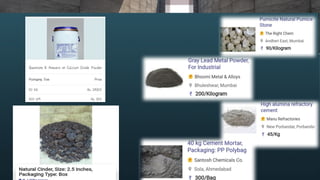

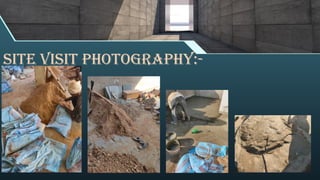

- 71. Market survey

- 72. SAND aggregates

- 73. cement 50 KG bag

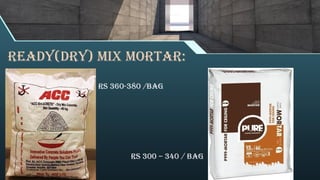

- 74. READY(DRY) MIX MORTAR: RS 360-380 /bag RS 300 ŌĆō 340 / bag

- 76. 50 KG bag

- 80. Shivangini singh Saumya singh Shambhavi Srivastava Shailesh Kunwar Shivam srivastava A presentation by: Shreya singh Shreya Chandra Saurabh rana Shivam keshari thankyou