Introduction to Metal Forming Processes – A detailed exploration of key metal forming techniques, focusing on deformation principles, material properties, and industrial applications.

- 1. Background • The word manufacturing is centuries old and derived from two Latin words. • “Manus” means “hand” and “factus” means “make”. • Hence the combination of two words literally means “made by hand”. • Manufacturing can be defined in two ways, one technologic and the other economic. • In technology, manufacturing is the application of physical/chemical to alter geometry or properties of material. • In economy, manufacturing is the transformation of materials into items of greater value.

- 2. Classification of Manufacturing Process

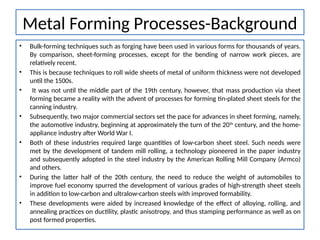

- 3. Metal Forming Processes-Background • Bulk-forming techniques such as forging have been used in various forms for thousands of years. By comparison, sheet-forming processes, except for the bending of narrow work pieces, are relatively recent. • This is because techniques to roll wide sheets of metal of uniform thickness were not developed until the 1500s. • It was not until the middle part of the 19th century, however, that mass production via sheet forming became a reality with the advent of processes for forming tin-plated sheet steels for the canning industry. • Subsequently, two major commercial sectors set the pace for advances in sheet forming, namely, the automotive industry, beginning at approximately the turn of the 20th century, and the home- appliance industry after World War I. • Both of these industries required large quantities of low-carbon sheet steel. Such needs were met by the development of tandem mill rolling, a technology pioneered in the paper industry and subsequently adopted in the steel industry by the American Rolling Mill Company (Armco) and others. • During the latter half of the 20th century, the need to reduce the weight of automobiles to improve fuel economy spurred the development of various grades of high-strength sheet steels in addition to low-carbon and ultralow-carbon steels with improved formability. • These developments were aided by increased knowledge of the effect of alloying, rolling, and annealing practices on ductility, plastic anisotropy, and thus stamping performance as well as on post formed properties.

- 4. Metal Forming Processes • Metal forming process includes large number of manufacturing processes. • Plastic deformation is used to change the shape of the metal workpiece. • Deformation results from the use of a tool, usually called a die in metal forming, which applies stresses that exceed the yield strength of the metal. • The metal therefore deforms to take a shape determined by the geometry of the die.

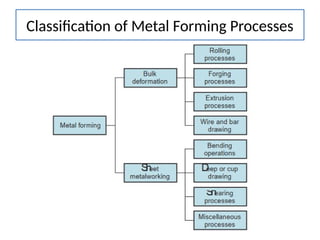

- 5. Classification of Metal Forming Processes

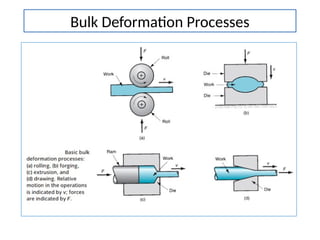

- 6. Bulk Deformation Processes • Bulk deformation processes are generally characterized by significant deformations and massive shape changes, and the surface area-to- volume of the work is relatively small. • The term bulk describes the work parts that have this low area to-volume ratio. • Starting work shapes for these processes include cylindrical billets and rectangular bars.

- 8. Sheet metal working • Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. • The surface area-to volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.

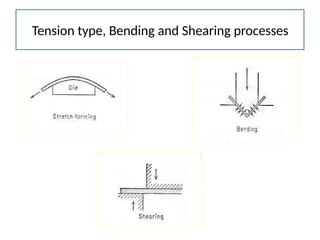

- 10. Classification of metal forming processes- Forces •Direct-compression-type processes •Indirect-compression processes •Tension type processes •Bending processes •Shearing processes

- 13. Tension type, Bending and Shearing processes

- 14. Classification of metal forming by subgroups