Introduction to wet processing of fabric

- 1. Introduction to Wet Processing OF COTTON FABRIC By: Deepati Singh

- 3. FABRIC ŌĆó Fabric is made either by interlacement of at least 2 sets of yarns(eg. Woven Fabric) or inter-looping of at least single set of yarn(eg. Knitted fabric) or Directly by binding fibres together by suitable methods(eg. Non-Woven Fabric) ŌĆó The raw fabric that is made by the processes mentioned above is known as Greige Fabric or Grey Fabric

- 4. GREY FABRIC ŌĆó Grey Fabric: The term does not indicate the color of the fabric but the finish. ŌĆó This fabric might have stains, discoloration and other undesirable characteristics ŌĆó It is treated with various chemicals under pre determined conditions to improve its functionality as well as aesthetics ŌĆó The types of processes carried out depends mainly on the type of fabric (raw material used- Natural/Synthetic)

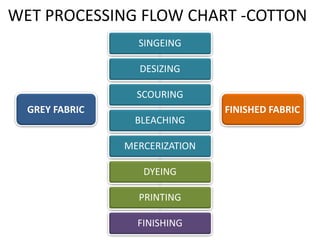

- 5. WET PROCESSING ŌĆó The processes that are carried out to convert grey fabric to finished fabric is known as Wet Processing because these are generally carried out in aqueous medium ŌĆó These are mainly characterized as pre- treatment processes, coloring process and finishing processes ŌĆó Pre-treatments carried out for cotton fabric are different than the fabrics made of synthetic fibres

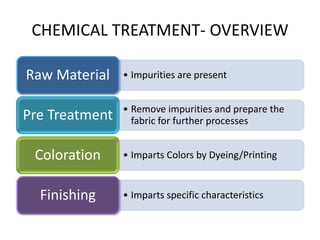

- 6. CHEMICAL TREATMENT- OVERVIEW ŌĆó Impurities are present Raw Material ŌĆó Remove impurities and prepare the fabric for further processes Pre Treatment ŌĆó Imparts Colors by Dyeing/Printing Coloration ŌĆó Imparts specific characteristics Finishing

- 7. SINGEING DESIZING SCOURING BLEACHING MERCERIZATION DYEING PRINTING FINISHING GREY FABRIC FINISHED FABRIC WET PROCESSING FLOW CHART -COTTON

- 8. SINGEING ŌĆó Singeing is the first step of pretreatment ŌĆó Singe means ŌĆśto burn something superficially or lightlyŌĆÖ ŌĆó It is the process of removal of protruding fibres, yarn ends or fuzz from the surface of the fabric ŌĆó This process can also be applied to yarns ŌĆó End result of singeing is an even surface, free from fuzz

- 9. DESIZING ŌĆó Size(mainly starch and wax) is applied on the warp yarns to make it strong enough to withstand the tensions of loom ŌĆó Desizing is the process of removal of added (eg. starch) as well as other natural impurities from the fabric ŌĆó It improves the absorbency and lustre of the fabric and prepares the fabric for further processes

- 10. SCOURING ŌĆó Scouring is a purifying treatment and make the fabric hydrophilic ŌĆó It is also known as kiering or kier boiling ŌĆó It is the process by which natural (oil, wax, gum, fat etc) as well as added (during fabrication process) impurities are removed completely as possible. ŌĆó It makes the textile materials highly absorptive without undergoing chemical or physical damage significantly.

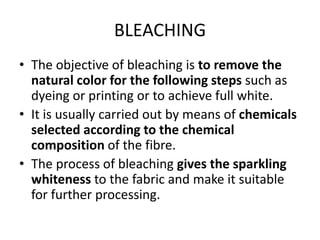

- 11. BLEACHING ŌĆó The objective of bleaching is to remove the natural color for the following steps such as dyeing or printing or to achieve full white. ŌĆó It is usually carried out by means of chemicals selected according to the chemical composition of the fibre. ŌĆó The process of bleaching gives the sparkling whiteness to the fabric and make it suitable for further processing.

- 12. MERCERIZATION ŌĆó Mercerization is one of the most important process carried out for cotton and other cellulosic fibres ŌĆó The fabric is treated with concentrated solution of sodium hydroxide which results in swelling and make the cross-sectional area round, hence improving the lustre and absorbency ŌĆó It results in improvement of lustre, strength and hand of the fabric

- 13. DYEING ŌĆó Dyeing is the process of imparting color to textile material ŌĆó It can be carried out at any stage (Fibre/Yarn/ Fabric/End product) ŌĆó Dyes are selected on the basis of the raw material of textile products ŌĆó Different fibres have different affinity towards specific dyes ŌĆó Dye fastness is an important parameter for selecting a specific dye

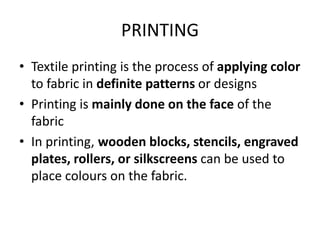

- 14. PRINTING ŌĆó Textile printing is the process of applying color to fabric in definite patterns or designs ŌĆó Printing is mainly done on the face of the fabric ŌĆó In printing, wooden blocks, stencils, engraved plates, rollers, or silkscreens can be used to place colours on the fabric.

- 15. FINISHING ŌĆó Finishing is any process performed after dyeing the yarn or fabric to improve the look, performance, or hand (feel) of the finish textile or clothing ŌĆó It can be done by using chemicals or by mechanical means ŌĆó It adds specific aesthetic and technical qualities to each fabric

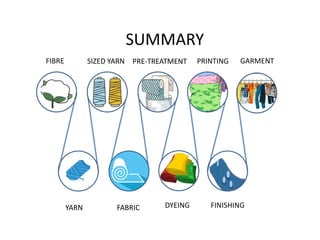

- 16. YARN FABRIC DYEING FINISHING FIBRE SIZED YARN PRE-TREATMENT PRINTING GARMENT SUMMARY