Is your storeroom ready for a vmi solution

1 like310 views

A VMI managed storeroom solution can save time and reduce costs by improving availability of needed parts for storerooms that have a lot of free-issue items. An on-site assessment is conducted to determine if a VMI program is suitable, which is best for storerooms with parts that have frequent turnover. High turnover parts are identified and categorized for inclusion in the VMI program, while slow moving parts are identified as stock items to be ordered as needed. Regular reviews of the storeroom inventory are recommended every 6-9 months to adjust for changing conditions.

1 of 12

Download to read offline

Recommended

EPC Company Introdcution

EPC Company IntrodcutionColin Huang

Ěý

E.P.C Services is one of the professionally Facility Management Company using facility Automation Systems’ Integrators with a Major Vision to step in & Change the local Perception of Energy Management Solutions and has a distinctive approach of working in partnership with clients, understanding their needs and creating tailor-made solutions to address them.

Commercial Service Sales Presentation

Commercial Service Sales Presentationrobwhite1

Ěý

The document describes AirEconomics, a commercial HVAC service company. It outlines their Mechanical Safe-Guard program which aims to maximize comfort and efficiency while minimizing costs through regular maintenance. The program identifies customer objectives, meets needs through various maintenance tasks, analyzes costs savings, and provides benefits such as optimized costs and protected equipment.2015 Turn Cycle Solutions Millyard Resentation

2015 Turn Cycle Solutions Millyard Resentationmsnelling

Ěý

Turn Cycle Solutions is an energy auditing and retrofitting firm located in Nashua, NH that uses building inspections and analysis to develop energy reduction plans, implements upgrades like insulation, HVAC, and lighting replacements, and monitors results to ensure cost savings; they work with various utility rebate programs and have experience improving the efficiency of residential, commercial, and multi-unit properties.Improved Wind Station Profits Through Excellent O&M

Improved Wind Station Profits Through Excellent O&MNAES Corporation

Ěý

This document discusses how applying principles of traditional power plant operation and maintenance to wind farms can improve profits through increased availability and efficiency. Key points include having a small, well-trained staff develop annual maintenance plans using computerized systems to closely monitor equipment and identify issues. This allows owners to negotiate warranty resolutions and make well-informed decisions about transitioning from manufacturer support contracts to independent maintenance.Pec at ccse 2010

Pec at ccse 2010Center for Sustainable Energy

Ěý

The document discusses the importance of comprehensive energy efficiency projects over smaller, individual measures. It argues that integrated projects targeting areas like HVAC, controls, daylighting and fenestration can achieve 15% energy savings and 15% operational cost savings, with returns over 4%. In comparison, changing light bulbs alone may only achieve 10% energy savings with lower returns. The document advocates for performance monitoring to identify issues early and protect investments.Air co saver slide share intro

Air co saver slide share introcaltayrow

Ěý

Go green and save money at the same time! The Air-co Saver has proven cost saving potential of up to 35%. Stops abuse of your air-conditioning units and helps you lower carbon footprint. RC_Services Brochure

RC_Services BrochureRom-Control Pty Ltd

Ěý

Rom-Control offers electronic and process control equipment management services to help companies reduce equipment downtime and maintenance costs. This includes auditing a company's installed equipment and spare parts, identifying critical assets, and developing an asset maintenance program and spare parts strategy. Rom-Control can also provide repair/exchange programs, equipment refurbishment, and spare parts management to increase reliability and reduce capital expenditures.Lucas Indian service

Lucas Indian serviceChiyan Ashok K

Ěý

Lucas Indian Service Ltd. (LIS) is a specialist in sales and service of auto electrical equipment established in 1930. It manufactures automotive products like ignition coils and solenoid switches in Chennai. LIS distributes auto parts through partnerships and offers servicing, training, and sales/distribution of automotive spare parts for various manufacturers. The company has a widespread network of over 1500 dealers and 40 company-owned service workshops to provide sales, distribution, and after-sales service of auto electrical equipment and diesel fuel injection systems across India.Fugitive Emissions: How to Prevent Potential Leak Points

Fugitive Emissions: How to Prevent Potential Leak Points WIKA Instrument, LP

Ěý

Fugitive emissions present a great challenge because they are tough to detect. Learn how you can stop gauges from becoming a potential leak pointrc_Capability_Statement

rc_Capability_StatementRom-Control Pty Ltd

Ěý

Rom-Control is an electronics repair and refurbishment company located in Clayton, Victoria. It aims to be the first choice for repair of industrial electronic equipment through continuous improvement, teamwork, and innovation. The company offers a range of services including circuit board repair, refurbishment, electronic equipment auditing, and testing. It employs highly skilled engineers with extensive experience repairing and working with industrial electronic systems.Sespl Profile for Energy Auditing

Sespl Profile for Energy AuditingMaxpromotion

Ěý

Solitis Electrical Solutions Pvt. Ltd. is multi-disciplined management and engineering consultancy in Pune, Maharashtra that provides complete electrical engineering design and project management services. We are also actively involved in trading of electrical equipment and components along with consultancy.Meter Asset Management at Coop's, IOU's and Muni's

Meter Asset Management at Coop's, IOU's and Muni'sTESCO - The Eastern Specialty Company

Ěý

This presentation will discuss how Asset Tracking for Metering has changed dramatically over the past dozen years and what the term “asset tracking” will mean for meter services in the future.

In the past we had Corporate asset management systems that originated on the financial side of the business and we had meter record systems that handled all metering test results. Between the two we would have all of our bases covered.

Meter Asset Management at Coop's, IOU's, & Muni's

Meter Asset Management at Coop's, IOU's, & Muni'sTESCO - The Eastern Specialty Company

Ěý

This document discusses best practices for asset management of meters and related equipment for utilities implementing AMI systems. It outlines how traditional asset tracking systems were inadequate for advanced metering needs. Utilities are now using enterprise asset management systems as the backbone, with bolt-on solutions to handle AMI-specific requirements over time. Interoperability between systems is key, as is ensuring seamless transfer of data between the utility and vendors. With the right hybrid approach, utilities can have flexible, future-proof asset management.KD4010 Magnetism And Electronics.docx

KD4010 Magnetism And Electronics.docxstirlingvwriters

Ěý

This document discusses quality control procedures for LCR meter manufacturers. It explains that LCR meters are precision instruments used to measure inductance, capacitance and resistance. Quality control is important throughout the manufacturing process, including component selection, data collection, and process optimization. Standards like ISO 9001 help guide quality control procedures. Key steps include inspecting components, testing circuit boards, approving first article samples, and ensuring traceability. Maintaining a clean production environment and using certified technicians are also important for quality control when manufacturing LCR meters.Delvin bolling resume

Delvin bolling resumeDelvinBolling

Ěý

This document provides a summary of Delvin Bolling's skills, qualifications, and work history. It lists his contact information and objective of seeking career growth opportunities. His skills include experience with various software programs and inventory management systems. His work history details roles as a CMMS Administrator and Quality Inspector/Technician where he was responsible for procurement, inventory management, quality inspection, and process improvement.Final Presentation

Final PresentationTyler Ross Lambert

Ěý

Tyler Ross Lambert presented on his co-op experience at Rheem. He conducted several projects including:

1) Developing programs to streamline reporting and generate warranty analysis reports.

2) Assisting with failure analysis by performing tank teardowns to identify common failure modes.

3) Designing an expansion to increase testing capacity and updating troubleshooting manuals.

4) Developing an early warning system using sales and call data to flag potential product issues.

5) Improving Reliance by creating consolidated escalation notices and adding cost tracking features.Maintenance and Test Equipment Cyber Security

Maintenance and Test Equipment Cyber Security Michael Toecker

Ěý

Presentation at 4SICS (4SICS.SE) in 2015 regarding the cyber security of maintenance and test equipment.Amc presentation

Amc presentationNew Microcode

Ěý

Reliable Annual Maintenance Contract (AMC) is provided to various Electrical systems like Substations, Switchyards and HV & LV Switchgears. We offer Maintenance / Development plans, Energy Saving plans, Site visits, Need assessment, Competitive proposal and quotations to our clients.How Voice, Scanning and Automation Improve Distribution/Fulfillment Operations

How Voice, Scanning and Automation Improve Distribution/Fulfillment OperationsJohn Schriefer

Ěý

Marcone Supply and Oriental Trading Company both implemented voice-directed mobile work execution systems to improve their warehouse operations and meet increasing customer demands. Marcone used voice to optimize receiving, putaway, picking, and inventory processes, doubling productivity and improving accuracy. Oriental Trading supplemented its automated warehouse with voice to optimize case-breaking, batch picking, and provide real-time worker assignments. Both companies streamlined manual processes, increased productivity over 20%, and achieved faster order processing and higher accuracy.Sure Controls

Sure ControlsTerry Brei

Ěý

This document summarizes the services and solutions provided by Sure Controls Inc., an automation company founded in 1984. They provide industrial automation products and services including control systems, control panels, SCADA systems, field services, training, and more. Their mission is to delight customers with design expertise, innovative products, and responsive service. They have recently completed automation projects in various industries across the US, Canada, Europe, Mexico and Wales.Worldwide Power Products offers Preventative Maintenance Plans for your Gener...

Worldwide Power Products offers Preventative Maintenance Plans for your Gener...Worldwide Power Products

Ěý

The document discusses the importance of preventative maintenance plans for generators. It notes that generators require regular maintenance to extend their lifespan and ensure optimal performance. A preventative maintenance plan from Worldwide Power Products includes annual inspections and repairs as well as scheduled replacements of parts like batteries every three years. Enrolling in such a plan can help avoid costly repairs and power outages.Asset Tracking Systems for Meter Services

Asset Tracking Systems for Meter ServicesTESCO - The Eastern Specialty Company

Ěý

This presentation discusses how asset tracking systems for meter services have changed with the adoption of AMI. Traditionally, utilities used asset management systems focused on basic tracking of name, rank and serial number, but meter services required tracking additional data like test results. As AMI brought multiple serialized components under each meter cover, traditional systems could not handle the increased tracking needs. Most utilities have implemented or are implementing enterprise asset management systems like SAP, along with bolt-on solutions to provide the extended functionality required for meter services. The future of asset tracking relies on interoperability between utility systems and manufacturer systems to seamlessly share meter data.Case 4. 2 Summit electric lights up with a new erp system

Case 4. 2 Summit electric lights up with a new erp systemniz73

Ěý

- Summit Electric Supply Co. is a wholesale distributor of electrical equipment and supplies. It obtains goods from manufacturers and sells to contractors. As the middleman, it must handle high transaction volumes and swift inventory turnover.

- Summit's old information systems from the 1980s could no longer keep up with its growth. The systems had limited capabilities and caused delays.

- Summit implemented a new ERP system using SAP to improve operational efficiency. The system allowed for more frequent inventory updates and better inventory management at job sites. It also enhanced business intelligence and chargeback processing.Acopian VA5H1700M

Acopian VA5H1700Msavomir

Ěý

This document provides information about an Acopian VA5H1700M power supply that is in stock. It describes how to purchase the item through Launch 3 Telecom by phone, email, or online request form. Launch 3 Telecom offers same-day shipping for orders received by 3PM, along with order tracking and customer support. The company also provides services like equipment repair, maintenance contracts, de-installation, and recycling.Acopian VA5MT600M

Acopian VA5MT600Msavomir

Ěý

This document provides information about purchasing an Acopian VA5MT600M power supply from Launch 3 Telecom. It describes the product, payment and shipping options, warranty, and additional services offered by Launch 3 such as repairs, maintenance contracts, de-installation, and recycling. Customers can purchase the power supply by phone, email, or online form and receive same-day shipping with tracking.Energy Management and the Evolution of Intelligent Motor Control and Drives @...

Energy Management and the Evolution of Intelligent Motor Control and Drives @...ARC Advisory Group

Ěý

Intelligent motor control and drives have evolved from providing safe and flexible motor control to acting as smart energy managers. They perform critical protective, diagnostic, and troubleshooting functions to improve productivity and minimize downtime, especially in applications where even short periods of downtime can be costly. The document discusses a survey of electrical power system end users that found most operate systems 11-30 years old. While many exceed equipment suppliers' stated obsolescence dates, practices for justifying upgrades focus on lost production, failure costs, and failure frequency. Condition assessments before upgrades help prevent future downtime.Egotia- The Process

Egotia- The ProcessEddie Bonuchi

Ěý

Egotia performs site survey consulting evaluations, proposals, and installations of proprietary systems that significantly reduce energy usage and costs. We finance all energy efficiency systems and guarantee the savings quotes with a third party insurance policy.

Egotia is a professional team of energy consultants, bankers, purchasers of electricity and natural gas, and engineers with extensive expertise in implementing well designed, financeable, and guaranteed energy saving solutions.

One stop expertise. Product agnostic rate of return driven solutions. Better Power. Less Cost. Higher Profits. Less Energy Usage. Lower Overhead. Higher Margins. Better Bottom Line. Cost Savings.

OPS 571 GENIUS You can do it--ops571genius.com

OPS 571 GENIUS You can do it--ops571genius.comagathachristie218

Ěý

This document provides sample questions that may appear on an OPS 571 final exam, covering topics like supply chain classification, economic order quantity, production planning strategies, forecasting, problem definition frameworks, project management using critical path method, inventory management models, lean production concepts, learning curves, process quality monitoring charts, queuing systems, operations design, productivity metrics, and theory of constraints. It contains over 50 multiple choice questions testing knowledge of these operations and supply chain management topics.The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ěý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

More Related Content

Similar to Is your storeroom ready for a vmi solution (20)

Fugitive Emissions: How to Prevent Potential Leak Points

Fugitive Emissions: How to Prevent Potential Leak Points WIKA Instrument, LP

Ěý

Fugitive emissions present a great challenge because they are tough to detect. Learn how you can stop gauges from becoming a potential leak pointrc_Capability_Statement

rc_Capability_StatementRom-Control Pty Ltd

Ěý

Rom-Control is an electronics repair and refurbishment company located in Clayton, Victoria. It aims to be the first choice for repair of industrial electronic equipment through continuous improvement, teamwork, and innovation. The company offers a range of services including circuit board repair, refurbishment, electronic equipment auditing, and testing. It employs highly skilled engineers with extensive experience repairing and working with industrial electronic systems.Sespl Profile for Energy Auditing

Sespl Profile for Energy AuditingMaxpromotion

Ěý

Solitis Electrical Solutions Pvt. Ltd. is multi-disciplined management and engineering consultancy in Pune, Maharashtra that provides complete electrical engineering design and project management services. We are also actively involved in trading of electrical equipment and components along with consultancy.Meter Asset Management at Coop's, IOU's and Muni's

Meter Asset Management at Coop's, IOU's and Muni'sTESCO - The Eastern Specialty Company

Ěý

This presentation will discuss how Asset Tracking for Metering has changed dramatically over the past dozen years and what the term “asset tracking” will mean for meter services in the future.

In the past we had Corporate asset management systems that originated on the financial side of the business and we had meter record systems that handled all metering test results. Between the two we would have all of our bases covered.

Meter Asset Management at Coop's, IOU's, & Muni's

Meter Asset Management at Coop's, IOU's, & Muni'sTESCO - The Eastern Specialty Company

Ěý

This document discusses best practices for asset management of meters and related equipment for utilities implementing AMI systems. It outlines how traditional asset tracking systems were inadequate for advanced metering needs. Utilities are now using enterprise asset management systems as the backbone, with bolt-on solutions to handle AMI-specific requirements over time. Interoperability between systems is key, as is ensuring seamless transfer of data between the utility and vendors. With the right hybrid approach, utilities can have flexible, future-proof asset management.KD4010 Magnetism And Electronics.docx

KD4010 Magnetism And Electronics.docxstirlingvwriters

Ěý

This document discusses quality control procedures for LCR meter manufacturers. It explains that LCR meters are precision instruments used to measure inductance, capacitance and resistance. Quality control is important throughout the manufacturing process, including component selection, data collection, and process optimization. Standards like ISO 9001 help guide quality control procedures. Key steps include inspecting components, testing circuit boards, approving first article samples, and ensuring traceability. Maintaining a clean production environment and using certified technicians are also important for quality control when manufacturing LCR meters.Delvin bolling resume

Delvin bolling resumeDelvinBolling

Ěý

This document provides a summary of Delvin Bolling's skills, qualifications, and work history. It lists his contact information and objective of seeking career growth opportunities. His skills include experience with various software programs and inventory management systems. His work history details roles as a CMMS Administrator and Quality Inspector/Technician where he was responsible for procurement, inventory management, quality inspection, and process improvement.Final Presentation

Final PresentationTyler Ross Lambert

Ěý

Tyler Ross Lambert presented on his co-op experience at Rheem. He conducted several projects including:

1) Developing programs to streamline reporting and generate warranty analysis reports.

2) Assisting with failure analysis by performing tank teardowns to identify common failure modes.

3) Designing an expansion to increase testing capacity and updating troubleshooting manuals.

4) Developing an early warning system using sales and call data to flag potential product issues.

5) Improving Reliance by creating consolidated escalation notices and adding cost tracking features.Maintenance and Test Equipment Cyber Security

Maintenance and Test Equipment Cyber Security Michael Toecker

Ěý

Presentation at 4SICS (4SICS.SE) in 2015 regarding the cyber security of maintenance and test equipment.Amc presentation

Amc presentationNew Microcode

Ěý

Reliable Annual Maintenance Contract (AMC) is provided to various Electrical systems like Substations, Switchyards and HV & LV Switchgears. We offer Maintenance / Development plans, Energy Saving plans, Site visits, Need assessment, Competitive proposal and quotations to our clients.How Voice, Scanning and Automation Improve Distribution/Fulfillment Operations

How Voice, Scanning and Automation Improve Distribution/Fulfillment OperationsJohn Schriefer

Ěý

Marcone Supply and Oriental Trading Company both implemented voice-directed mobile work execution systems to improve their warehouse operations and meet increasing customer demands. Marcone used voice to optimize receiving, putaway, picking, and inventory processes, doubling productivity and improving accuracy. Oriental Trading supplemented its automated warehouse with voice to optimize case-breaking, batch picking, and provide real-time worker assignments. Both companies streamlined manual processes, increased productivity over 20%, and achieved faster order processing and higher accuracy.Sure Controls

Sure ControlsTerry Brei

Ěý

This document summarizes the services and solutions provided by Sure Controls Inc., an automation company founded in 1984. They provide industrial automation products and services including control systems, control panels, SCADA systems, field services, training, and more. Their mission is to delight customers with design expertise, innovative products, and responsive service. They have recently completed automation projects in various industries across the US, Canada, Europe, Mexico and Wales.Worldwide Power Products offers Preventative Maintenance Plans for your Gener...

Worldwide Power Products offers Preventative Maintenance Plans for your Gener...Worldwide Power Products

Ěý

The document discusses the importance of preventative maintenance plans for generators. It notes that generators require regular maintenance to extend their lifespan and ensure optimal performance. A preventative maintenance plan from Worldwide Power Products includes annual inspections and repairs as well as scheduled replacements of parts like batteries every three years. Enrolling in such a plan can help avoid costly repairs and power outages.Asset Tracking Systems for Meter Services

Asset Tracking Systems for Meter ServicesTESCO - The Eastern Specialty Company

Ěý

This presentation discusses how asset tracking systems for meter services have changed with the adoption of AMI. Traditionally, utilities used asset management systems focused on basic tracking of name, rank and serial number, but meter services required tracking additional data like test results. As AMI brought multiple serialized components under each meter cover, traditional systems could not handle the increased tracking needs. Most utilities have implemented or are implementing enterprise asset management systems like SAP, along with bolt-on solutions to provide the extended functionality required for meter services. The future of asset tracking relies on interoperability between utility systems and manufacturer systems to seamlessly share meter data.Case 4. 2 Summit electric lights up with a new erp system

Case 4. 2 Summit electric lights up with a new erp systemniz73

Ěý

- Summit Electric Supply Co. is a wholesale distributor of electrical equipment and supplies. It obtains goods from manufacturers and sells to contractors. As the middleman, it must handle high transaction volumes and swift inventory turnover.

- Summit's old information systems from the 1980s could no longer keep up with its growth. The systems had limited capabilities and caused delays.

- Summit implemented a new ERP system using SAP to improve operational efficiency. The system allowed for more frequent inventory updates and better inventory management at job sites. It also enhanced business intelligence and chargeback processing.Acopian VA5H1700M

Acopian VA5H1700Msavomir

Ěý

This document provides information about an Acopian VA5H1700M power supply that is in stock. It describes how to purchase the item through Launch 3 Telecom by phone, email, or online request form. Launch 3 Telecom offers same-day shipping for orders received by 3PM, along with order tracking and customer support. The company also provides services like equipment repair, maintenance contracts, de-installation, and recycling.Acopian VA5MT600M

Acopian VA5MT600Msavomir

Ěý

This document provides information about purchasing an Acopian VA5MT600M power supply from Launch 3 Telecom. It describes the product, payment and shipping options, warranty, and additional services offered by Launch 3 such as repairs, maintenance contracts, de-installation, and recycling. Customers can purchase the power supply by phone, email, or online form and receive same-day shipping with tracking.Energy Management and the Evolution of Intelligent Motor Control and Drives @...

Energy Management and the Evolution of Intelligent Motor Control and Drives @...ARC Advisory Group

Ěý

Intelligent motor control and drives have evolved from providing safe and flexible motor control to acting as smart energy managers. They perform critical protective, diagnostic, and troubleshooting functions to improve productivity and minimize downtime, especially in applications where even short periods of downtime can be costly. The document discusses a survey of electrical power system end users that found most operate systems 11-30 years old. While many exceed equipment suppliers' stated obsolescence dates, practices for justifying upgrades focus on lost production, failure costs, and failure frequency. Condition assessments before upgrades help prevent future downtime.Egotia- The Process

Egotia- The ProcessEddie Bonuchi

Ěý

Egotia performs site survey consulting evaluations, proposals, and installations of proprietary systems that significantly reduce energy usage and costs. We finance all energy efficiency systems and guarantee the savings quotes with a third party insurance policy.

Egotia is a professional team of energy consultants, bankers, purchasers of electricity and natural gas, and engineers with extensive expertise in implementing well designed, financeable, and guaranteed energy saving solutions.

One stop expertise. Product agnostic rate of return driven solutions. Better Power. Less Cost. Higher Profits. Less Energy Usage. Lower Overhead. Higher Margins. Better Bottom Line. Cost Savings.

OPS 571 GENIUS You can do it--ops571genius.com

OPS 571 GENIUS You can do it--ops571genius.comagathachristie218

Ěý

This document provides sample questions that may appear on an OPS 571 final exam, covering topics like supply chain classification, economic order quantity, production planning strategies, forecasting, problem definition frameworks, project management using critical path method, inventory management models, lean production concepts, learning curves, process quality monitoring charts, queuing systems, operations design, productivity metrics, and theory of constraints. It contains over 50 multiple choice questions testing knowledge of these operations and supply chain management topics.Worldwide Power Products offers Preventative Maintenance Plans for your Gener...

Worldwide Power Products offers Preventative Maintenance Plans for your Gener...Worldwide Power Products

Ěý

Energy Management and the Evolution of Intelligent Motor Control and Drives @...

Energy Management and the Evolution of Intelligent Motor Control and Drives @...ARC Advisory Group

Ěý

Recently uploaded (20)

The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75

Ěý

The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

Water Industry Process Automation & Control Monthly - March 2025.pdf

Water Industry Process Automation & Control Monthly - March 2025.pdfWater Industry Process Automation & Control

Ěý

Welcome to the March 2025 issue of WIPAC Monthly the magazine brought to you by the LinkedIn Group WIPAC Monthly.

In this month's edition, on top of the month's news from the water industry we cover subjects from the intelligent use of wastewater networks, the use of machine learning in water quality as well as how, we as an industry, need to develop the skills base in developing areas such as Machine Learning and Artificial Intelligence.

Enjoy the latest editionMulti objective genetic approach with Ranking

Multi objective genetic approach with Rankingnamisha18

Ěý

Multi objective genetic approach with Ranking Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ěý

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. Turbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

Ěý

High Efficiency Chiller System in HVACAir pollution is contamination of the indoor or outdoor environment by any ch...

Air pollution is contamination of the indoor or outdoor environment by any ch...dhanashree78

Ěý

Air pollution is contamination of the indoor or outdoor environment by any chemical, physical or biological agent that modifies the natural characteristics of the atmosphere.

Household combustion devices, motor vehicles, industrial facilities and forest fires are common sources of air pollution. Pollutants of major public health concern include particulate matter, carbon monoxide, ozone, nitrogen dioxide and sulfur dioxide. Outdoor and indoor air pollution cause respiratory and other diseases and are important sources of morbidity and mortality.

WHO data show that almost all of the global population (99%) breathe air that exceeds WHO guideline limits and contains high levels of pollutants, with low- and middle-income countries suffering from the highest exposures.

Air quality is closely linked to the earth’s climate and ecosystems globally. Many of the drivers of air pollution (i.e. combustion of fossil fuels) are also sources of greenhouse gas emissions. Policies to reduce air pollution, therefore, offer a win-win strategy for both climate and health, lowering the burden of disease attributable to air pollution, as well as contributing to the near- and long-term mitigation of climate change.

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load Current Delay which delays the creation and storage of created Electromagnetic Field Energy around the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads, additional Input Power must be supplied to the Prime Mover and additional Mechanical Input Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator, an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1 MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the system.Frankfurt University of Applied Science urkunde

Frankfurt University of Applied Science urkundeLisa Emerson

Ěý

Duplicate Frankfurt University of Applied Science urkunde, make a Frankfurt UAS degree.IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Con...ssuserd9338b

Ěý

IPC-9716_2024 Requirements for Automated Optical Inspection (AOI) Process Control for Printed Board Assemblies.pdfUS Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load

Current Delay which delays the creation and storage of created Electromagnetic Field Energy around

the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field

Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the

generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of

an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In

Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be

generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing

zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity

Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any

magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared

to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy

performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to

the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and

the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads,

additional Input Power must be supplied to the Prime Mover and additional Mechanical Input

Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator,

an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive

Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1

MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the

Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric

Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the

Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field

Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the

system.

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptx

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxKesavanT10

Ěý

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxWater Industry Process Automation & Control Monthly - March 2025.pdf

Water Industry Process Automation & Control Monthly - March 2025.pdfWater Industry Process Automation & Control

Ěý

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

Ěý

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Ěý

Is your storeroom ready for a vmi solution

- 1. Do You Need a VMI Managed Storeroom? MRO Storeroom Solutions

- 2. What’s Your Current Storeroom Inventory? Electrical Equipment Company - eecoonline.com If your storeroom has a lot of free-issue items, a VMI solution will save time, reduces costs while improving availability of needed parts.

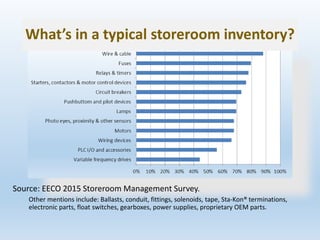

- 3. Source: EECO 2015 Storeroom Management Survey. Other mentions include: Ballasts, conduit, fittings, solenoids, tape, Sta-Kon® terminations, electronic parts, float switches, gearboxes, power supplies, proprietary OEM parts. What’s in a typical storeroom inventory?

- 4. Electrical Equipment Company - eecoonline.com Getting Ready for a Storeroom Assessment

- 5. Electrical Equipment Company - eecoonline.com Electrical Storeroom Self Evaluation Start with a 5-minute check up on your storeroom. If it’s been more than 3 years since the last review, our online storeroom evaluation will help.

- 6. Storeroom Optimization … Now you’re ready for an Electrical Storeroom Inventory Assessment Electrical Equipment Company - eecoonline.com After you complete the self-evaluation, get your historical records together. Last 2 years is ideal. Don’t worry about critical seldom used items. Conduct a review with stakeholders – maintenance, planning, purchasing to be sure their needs are heard. Tell plant management about your plan. Why optimize storerooms? To assure that the right parts are always available. The goal is reducing equipment downtime and improving efficiency.

- 7. First Our on-site assessment will determine if a VMI is right for you. A VMI is best for storerooms with parts that have frequent turns. Slow moving items will be classed as OANs or DNRs Electrical Equipment Company - eecoonline.com On-Site Storeroom Assessment

- 8. High Turnover Storeroom Parts Next We categorize high turnover items for inclusion in VMI. Parts are classified, assigned bin locations. Slow movers (OANs, DNRs) are identified.

- 9. Electrical Equipment Company - eecoonline.com Parts bins are labeled and barcoded for easy identification. “Right part, right time, right price”. Organized storerooms minimize the time to find parts. Inventory Barcoding, Labeling

- 10. 6 - 9 Months We review for stock outs, min/max levels, urgent order instances. Electrical Equipment Company - eecoonline.com Electrical Storeroom Review Conditions change over time. Regular reviews help anticipate these situations.

- 11. Electrical Equipment Company - eecoonline.com A Day in the Life of a Storeroom Manager Video

- 12. Visit eeconline.com for Electrical Storeroom VMI Solutions. Learn Electrical Storeroom Best Practices you should know. Ready to take the next step toward storeroom optimization? Email ISTeam@EECO-net.com Or call 800.993.3326 Electrical Equipment Company - eecoonline.com