ISMC 2012 Rubel Chakravarty

- 1. Role of Nanomaterials in RadiochemicalRole of Nanomaterials in Radiochemical Separations for Biomedical Applications:Separations for Biomedical Applications: Present status and future perspectivesPresent status and future perspectives Rubel ChakravartyRubel Chakravarty Radiopharmaceuticals DivisionRadiopharmaceuticals Division Bhabha Atomic Research Centre, Mumbai, IndiaBhabha Atomic Research Centre, Mumbai, India EE--Mail: rubelc@barc.gov.inMail: rubelc@barc.gov.in 1

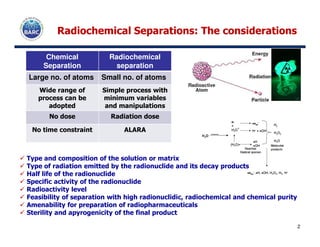

- 2. Radiochemical Separations: The considerationsRadiochemical Separations: The considerations Chemical Separation Radiochemical separation Large no. of atoms Small no. of atoms Wide range of process can be adopted Simple process with minimum variables and manipulations No dose Radiation dose No time constraint ALARA Type and composition of the solution or matrix Type of radiation emitted by the radionuclide and its decay products Half life of the radionuclide Specific activity of the radionuclide Radioactivity level Feasibility of separation with high radionuclidic, radiochemical and chemical purity Amenability for preparation of radiopharmaceuticals Sterility and apyrogenicity of the final product 2

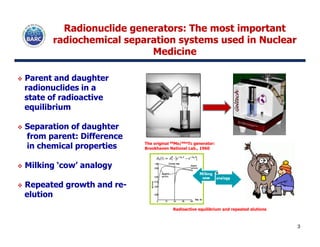

- 3. Radionuclide generators: The most importantRadionuclide generators: The most important radiochemical separation systems used in Nuclearradiochemical separation systems used in Nuclear MedicineMedicine Parent and daughter radionuclides in a state of radioactive equilibrium Separation of daughterSeparation of daughter from parent: Difference in chemical properties Milking ‘cow’ analogy Repeated growth and re- elution The original 99Mo/99mTc generator: Brookhaven National Lab., 1960 Radioactive equilibrium and repeated elutions 3

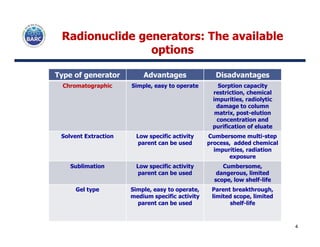

- 4. Radionuclide generators: The availableRadionuclide generators: The available optionsoptions Type of generator Advantages Disadvantages Chromatographic Simple, easy to operate Sorption capacity restriction, chemical impurities, radiolytic damage to column matrix, post-elution concentration and purification of eluatepurification of eluate Solvent Extraction Low specific activity parent can be used Cumbersome multi-step process, added chemical impurities, radiation exposure Sublimation Low specific activity parent can be used Cumbersome, dangerous, limited scope, low shelf-life Gel type Simple, easy to operate, medium specific activity parent can be used Parent breakthrough, limited scope, limited shelf-life 4

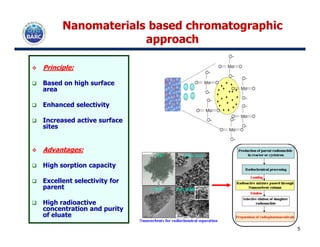

- 5. Nanomaterials based chromatographicNanomaterials based chromatographic approachapproach Principle: Based on high surface area Enhanced selectivity Increased active surface sites Increased active surface sites Advantages: High sorption capacity Excellent selectivity for parent High radioactive concentration and purity of eluate 5

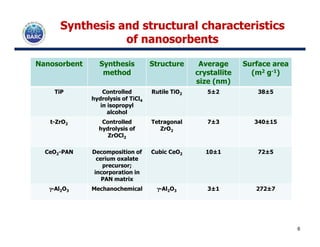

- 6. Synthesis and structural characteristicsSynthesis and structural characteristics ofof nanosorbentsnanosorbents Nanosorbent Synthesis method Structure Average crystallite size (nm) Surface area (m2 g-1) TiP Controlled hydrolysis of TiCl4 in isopropyl alcohol Rutile TiO2 5±2 38±5 t-ZrO2 Controlled Tetragonal 7±3 340±15 6 t-ZrO2 Controlled hydrolysis of ZrOCl2 Tetragonal ZrO2 7±3 340±15 CeO2-PAN Decomposition of cerium oxalate precursor; incorporation in PAN matrix Cubic CeO2 10±1 72±5 γγγγ-Al2O3 Mechanochemical γγγγ-Al2O3 3±1 272±7

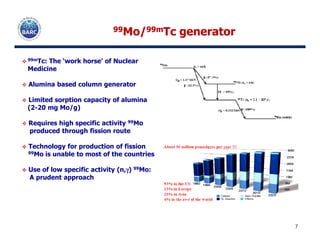

- 7. 9999Mo/Mo/99m99mTc generatorTc generator 99mTc: The ‘work horse’ of Nuclear Medicine Alumina based column generator Limited sorption capacity of alumina (2-20 mg Mo/g) Requires high specific activity 99MoRequires high specific activity 99Mo produced through fission route Technology for production of fission 99Mo is unable to most of the countries Use of low specific activity (n,γγγγ) 99Mo: A prudent approach 7

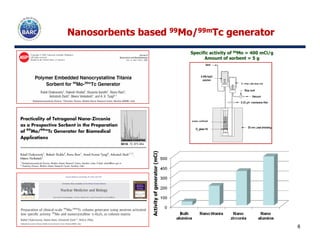

- 8. NanosorbentsNanosorbents basedbased 9999Mo/Mo/99m99mTc generatorTc generator Specific activity of 99Mo = 400 mCi/g Amount of sorbent = 5 g 8 Activityofgenerator(mCi)

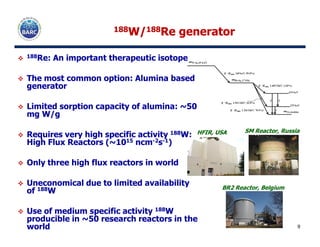

- 9. 188188W/W/188188Re generatorRe generator 188Re: An important therapeutic isotope The most common option: Alumina based generator Limited sorption capacity of alumina: ~50 mg W/g Requires very high specific activity 188W: High Flux Reactors (~1015 ncm-2s-1) Only three high flux reactors in world Uneconomical due to limited availability of 188W Use of medium specific activity 188W producible in ~50 research reactors in the world HFIR, USA SM Reactor, Russia BR2 Reactor, Belgium 9

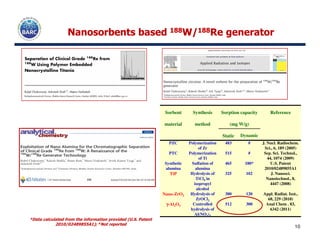

- 10. NanosorbentsNanosorbents basedbased 188188W/W/188188Re generatorRe generator Sorbent material Synthesis method Sorption capacity (mg W/g) Reference 10 material method (mg W/g) Static Dynamic PZC Polymerization of Zr 483 # J. Nucl. Radiochem. Sci., 6, 189 (2005) PTC Polymerization of Ti 515 # Sep. Sci. Technol., 44, 1074 (2009) Synthetic alumina Sulfation of alumina 465 180* U.S. Patent 2010/02489855A1 TiP Hydrolysis of TiCl4 in isopropyl alcohol 325 102 J. Nanosci. Nanotechnol., 8, 4447 (2008) Nano-ZrO2 Hydrolysis of ZrOCl2 300 120 Appl. Radiat. Isot., 68, 229 (2010) γγγγ-Al2O3 Controlled hydrolysis of Al(NO3)3 512 300 Anal Chem . 83, 6342 (2011) *Data calculated from the information provided (U.S. Patent 2010/02489855A1); #Not reported

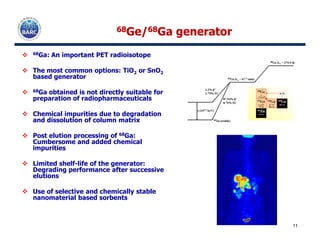

- 11. 6868Ge/Ge/6868Ga generatorGa generator 68Ga: An important PET radioisotope The most common options: TiO2 or SnO2 based generator 68Ga obtained is not directly suitable for preparation of radiopharmaceuticals Chemical impurities due to degradation and dissolution of column matrix 11 and dissolution of column matrix Post elution processing of 68Ga: Cumbersome and added chemical impurities Limited shelf-life of the generator: Degrading performance after successive elutions Use of selective and chemically stable nanomaterial based sorbents

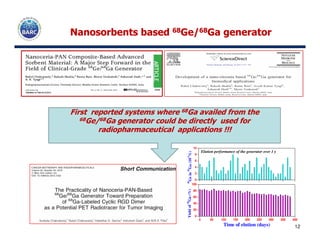

- 12. NanosorbentsNanosorbents basedbased 6868Ge/Ge/6868Ga generatorGa generator First reported systems where 68Ga availed from the 68Ge/68Ga generator could be directly used for 12 Ge/ Ga generator could be directly used for radiopharmaceutical applications !!! 0 50 100 150 200 250 300 350 400 0 20 40 60 80 100 Yieldof 68 Ga(%) Time of elution (days) 0 2 4 6 8 10 Elution performance of the generator over 1 y 68 Gein 68 Ga(10 -5 %)

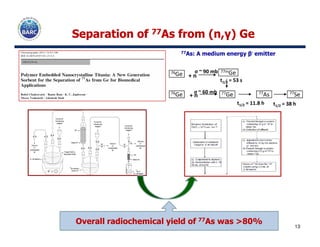

- 13. Separation ofSeparation of 7777As from (n,As from (n,γγ)) GeGe Funnel for introducing reagent Funnel for introducing 77As: A medium energy β- emitter 76Ge 77mGe 77As77Ge76Ge 77Se + n + n σ ~ 90 mb σ ~ 60 mb t1/2 = 53 s t1/2 = 38 ht1/2 = 11.8 h 13 Vaccum or compressed air reagent Funnel for introducing reagent Glass frit As in 0.1 M NaOH 77 As solution at pH=10 77 0.1 M NaOH Vaccum or compressed air Target (GeO ) dissolution flask 2 TiP TiP Glass frit Vaccum or compressed air introducing reagent Overall radiochemical yield of 77As was >80%

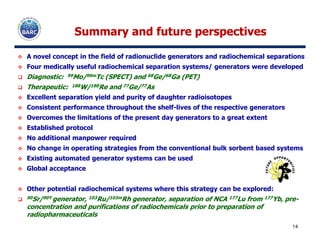

- 14. Summary and future perspectivesSummary and future perspectives A novel concept in the field of radionuclide generators and radiochemical separations Four medically useful radiochemical separation systems/ generators were developed Diagnostic: 99Mo/99mTc (SPECT) and 68Ge/68Ga (PET) Therapeutic: 188W/188Re and 77Ge/77As Excellent separation yield and purity of daughter radioisotopes Consistent performance throughout the shelf-lives of the respective generators Overcomes the limitations of the present day generators to a great extent 14 Established protocol No additional manpower required No change in operating strategies from the conventional bulk sorbent based systems Existing automated generator systems can be used Global acceptance Other potential radiochemical systems where this strategy can be explored: 90Sr/90Y generator, 103Ru/103mRh generator, separation of NCA 177Lu from 177Yb, pre- concentration and purifications of radiochemicals prior to preparation of radiopharmaceuticals

- 15. AcknowledgementsAcknowledgements Radiopharmaceuticals Division, BARC Chemistry Division, BARC Society of Materials Chemistry, India Prof. M.R.A. Pillai, Head, Radiopharmaceuticals Division, BARC Prof. Ashutosh Dash, Radiopharmaceuticals Division, BARC Prof. A.K. Tyagi, Chemistry Division, BARC Shri Rakesh Shukla, Chemistry Division, BARC All co-authors in the publications 15 Division, BARC

- 16. THANK YOU FOR YOUR ATTENTIONTHANK YOU FOR YOUR ATTENTION! rubelc@barc.gov.in 16