ISO/IEC 15504

- 2. What is iso/iec 15504? ISO/IEC 15504 also known as SPICE (Software Process Improvement and Capability determination) is a "framework for the assessment of processes" developed by the Joint Technical Subcommittee between ISO ( International Organization for Standardization ) and IEC (International Electro technical Commission). ISO/IEC 15504 initially was derived from process lifecycle standard ISO 12207 and the ideas of many maturity models like Bootstrap, Trillium and the CMM

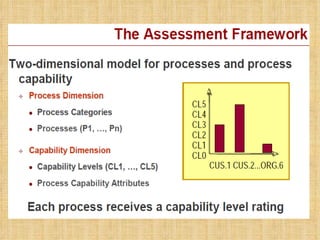

- 3. Reference model ISO/IEC 15504 contains a reference model. The reference model defines a process dimension and a capability dimension.

- 4. Processes The process dimension defines processes divided into the five process categories of: customer-supplier engineering supporting management organization

- 5. Ěý

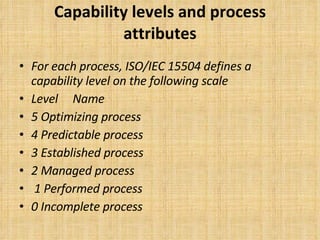

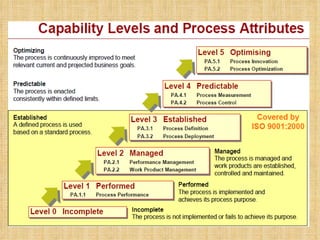

- 6. Capability levels and process attributes For each process, ISO/IEC 15504 defines a capability level on the following scale Level Name 5 Optimizing process 4 Predictable process 3 Established process 2 Managed process 1 Performed process 0 Incomplete process

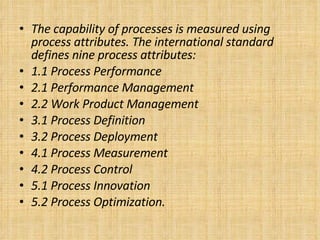

- 7. The capability of processes is measured using process attributes. The international standard defines nine process attributes: 1.1 Process Performance 2.1 Performance Management 2.2 Work Product Management 3.1 Process Definition 3.2 Process Deployment 4.1 Process Measurement 4.2 Process Control 5.1 Process Innovation 5.2 Process Optimization.

- 8. Ěý

- 9. Each process attribute is assessed on a four-point (N-P-L-F) rating scale: Not achieved (0 - 15%) Partially achieved (>15% - 50%) Largely achieved (>50%- 85%) Fully achieved (>85% - 100%).

- 10. Assessments ISO/IEC 15504 provides a guide for performing an assessment . This includes: The assessment process The model for the assessment Any tools used in the assessment

- 11. Assessment process The assessment process can be generalized as the following steps: initiate an assessment (assessment sponsor) select assessor and assessment team plan the assessment, including processes and organizational unit to be assessed (lead assessor and assessment team) pre-assessment briefing data collection data validation process rating reporting the assessment result

- 12. Assessment model The process assessment model (PAM) is the detailed model that is used for an actual assessment.

- 13. Tools used in the assessment There exist several assessment tools. The simplest comprise paper-based tools that are manually used. Assessors write down the assessment results and notes supporting the assessment judgment. There are a limited number of computer based tools that allow users to enter the assessment judgment and notes in formatted screens.

- 14. Assessor qualifications and competency For a successful assessment, the assessor must have a suitable level of the relevant skills and experience. These skills include: personal qualities such as communication skills. relevant education and training and experience. specific skills for particular categories, e.g. management skills for the management category.

- 15. ISO/IEC 15504 related training and experience in process capability assessments. In summary, the ISO/IEC 15504 specific training and experience for assessors comprise: completion of a 5 day lead assessor training course performing at least one assessment successfully under supervision of a competent lead assessor

- 16. Uses of ISO/IEC 15504 SO/IEC 15504 can be used in two contexts : Process improvement, and Capability determination (= evaluation of supplier's process capability)

- 17. Process improvement ISO/IEC 15504 can be used to perform process improvement within a technology organization. Process improvement is always difficult, and initiatives often fail, so it is important to understand the initial baseline level (process capability level), and to assess the situation after an improvement project.

- 18. Capability determination The organization can determine a target capability for suppliers, based on the organization's needs, and then assess suppliers against a set of target process profiles that specify this target capability