1 of 27

Downloaded 28 times

Ad

Recommended

Plastic moulding methods

Plastic moulding methodsDEBOLINAMUKHERJEE7

Мэ

This document discusses various plastic molding methods including compression molding, transfer molding, injection molding, extrusion molding, and blow molding. Compression and transfer molding are used for thermosetting materials, while injection molding and extrusion molding are generally used for thermoplastics. The document provides details on the processes and typical temperatures, pressures, and cycle times for each method. Calendering and laminating are also briefly described.Quy trГ¬nh gГЎn tбәЈi vГ tб»• hб»Јp tбәЈi trб»Қng trong Robot Structural

Quy trГ¬nh gГЎn tбәЈi vГ tб»• hб»Јp tбәЈi trб»Қng trong Robot StructuralHuytraining

Мэ

TГ i liб»Үu trГ¬nh bГ y quy trГ¬nh gГЎn tбәЈi vГ tб»• hб»Јp tбәЈi trб»Қng trong RSAP, bao gб»“m cГЎc loбәЎi tбәЈi trб»Қng tД©nh vГ Д‘б»ҷng cho cГЎc cбәҘu kiб»Үn nhЖ° sГ n, tЖ°б»қng vГ cбә§u thang. NГі cЕ©ng mГҙ tбәЈ cГЎch khai bГЎo cГЎc tб»• hб»Јp tбәЈi trб»Қng theo cГЎc trбәЎng thГЎi giб»ӣi hбәЎn khГЎc nhau. Cuб»‘i cГ№ng, tГ i liб»Үu hЖ°б»ӣng dбә«n cГЎch gГЎn tбәЈi trб»Қng vГ o mГҙ hГ¬nh mб»ҷt cГЎch chi tiбәҝt.2.de cuong thi cong coc ep

2.de cuong thi cong coc epGTVT

Мэ

Dб»ұ ГЎn xГўy dб»ұng cбә§u mб»ӣi qua sГҙng HГ n bao gб»“m viб»Үc thi cГҙng sГ n cбәЈnh quan bб»қ Д‘Гҙng vб»ӣi quy trГ¬nh lбәӯp kбәҝ hoбәЎch nhГўn lб»ұc vГ thiбәҝt bб»Ӣ cб»Ҙ thб»ғ. CГЎc biб»Үn phГЎp thi cГҙng cб»Қc Г©p vГ cГЎc vбәӯt liб»Үu sб»ӯ dб»Ҙng cбә§n tuГўn thủ theo tiГӘu chuбә©n hiб»Үn hГ nh Д‘б»ғ Д‘бәЈm bбәЈo an toГ n vГ chбәҘt lЖ°б»Јng cГҙng trГ¬nh. Dб»ұ ГЎn sбәҪ huy Д‘б»ҷng thГӘm thбә§u phб»Ҙ nбәҝu cбә§n thiбәҝt Д‘б»ғ Д‘бәЈm bбәЈo tiбәҝn Д‘б»ҷ theo kбәҝ hoбәЎch Д‘ГЈ Д‘Ж°б»Јc phГӘ duyб»Үt.Metal casting processes_1.pptx

Metal casting processes_1.pptxssusera85eeb1

Мэ

* Given casting dimensions: Length = 6 inches, Width = 4 inches, Height = 3 inches

* Material of casting: Grey cast iron

* Shrinkage allowance for grey cast iron up to 2 feet is 0.125 inch/foot

* Length of casting = 6 inches = 0.5 feet

* Shrinkage allowance = 0.5 * 0.125 = 0.0625 inch = 0.0625 inch

* Width of casting = 4 inches = 0.333 feet

* Shrinkage allowance = 0.333 * 0.125 = 0.0416 inch = 0.04 inch

* Height of casting = 3 inches = 0.25 feet

* Shrinkage allowance = 0.DiseГұo a travГ©s de la simulaciГіn para la producciГіn de piezas de plГЎsticoIntelligy

Мэ

El documento aborda el diseГұo y la simulaciГіn en la producciГіn de piezas de plГЎstico mediante moldeo por inyecciГіn, destacando la importancia de optimizar el diseГұo de moldes y piezas para evitar defectos de manufactura. Se presenta SolidWorks Plastics como una herramienta que permite realizar simulaciones detalladas del proceso de inyecciГіn, optimizando tanto el diseГұo de moldes como la ubicaciГіn de puntos de inyecciГіn. TambiГ©n se menciona la necesidad de eliminar retrabajos en moldes para mejorar costos y tiempos de producciГіn.Roll pass design in continuous bar mills

Roll pass design in continuous bar millsrahul kishore

Мэ

The document discusses various topics related to rolling mills and rolling processes. It defines a rolling mill as consisting of at least two cylindrical rolls used to shape or form metal. It describes different types of mill passes based on shape (definite, intermediate) and roll adjustment (open, closed). It provides formulas to calculate parameters for each pass like roll groove dimensions, roll gap, filled width, area reduction, and bite angle. It discusses concepts like number of passes required, spread calculation, and provides thumb rules and flow charts for roll pass design.Tama Proje Konteyner

Tama Proje KonteynerYusufzgen

Мэ

Tam YeraltДұ ГҮГ¶p Konteyneri, YarДұ Yer AltДұ ГҮГ¶p Konteyneri, Yer ГңstГј ГҮГ¶p Konteyneri, JaklДұ Sistem ГҮГ¶p Konteyneri, Plastik ГҮГ¶p Konteyneri, Metal ГҮГ¶p Konteyneri, Geri DГ¶nГјЕҹГјm Kutusu, Geri DГ¶nГјЕҹГјm KumbarasДұ, DДұЕҹ Mekan ГҮГ¶p KovalarДұ ve SДұfДұr AtДұk Projesi

https://www.tamaproje.com/Analysis of Various Cement grinding Systems with Respect to Power Consumption...

Analysis of Various Cement grinding Systems with Respect to Power Consumption...Karan Walia

Мэ

The dissertation by Karan Walia analyzes various grinding systems in cement production with respect to power consumption while maintaining quality parameters. The research, carried out at Colleagues Consultants Pvt. Ltd., focuses on evaluating different grinding technologies, including ball mills, vertical roller mills, and roller presses, and aims to determine their efficiency in energy usage. Key findings emphasize the significant energy demands in the cement industry, accounting for a large portion of industrial energy consumption.aula estampagem - processo de conformação mecanica.pptxJessicaHiplitodeVasc

Мэ

O documento aborda o processo de conformação mecГўnica de materiais metГЎlicos, destacando a estampagem como um mГ©todo de transformação que nГЈo remove material. A estampagem, utilizada em diversas indГәstrias, envolve processos como corte, dobra e conformação de chapas metГЎlicas, podendo ser realizada por mГ©todos como prensagem e estampagem progressiva. SГЈo discutidos os materiais utilizados, a lubrificação necessГЎria e os defeitos comuns encontrados nas peГ§as produzidas.severe plastic deformation (An approach to refine micro-structure ,improve st...

severe plastic deformation (An approach to refine micro-structure ,improve st...Om Prakash Kumawat

Мэ

This document summarizes severe plastic deformation (SPD) techniques for refining microstructure and improving strength and ductility of materials. SPD processes grains to the ultra-fine scale (<10 Ојm) through large plastic strain without changing overall dimensions. Techniques discussed include equal channel angular pressing, high pressure torsion, repetitive corrugation and straightening, accumulative roll bonding, and friction stir processing. SPD results in ultra-fine grain materials with higher strength, toughness, and potential applications in industries requiring lightweight components like aerospace, automotive, and medical implants. Further research is still needed to fully understand properties like thermal stability and strain hardening of SPD-processed materials.Safe trong tinh toan san btct

Safe trong tinh toan san btctДҗб»— Quang Дҗб»Ӣnh

Мэ

TГ i liб»Үu hЖ°б»ӣng dбә«n cГЎc bЖ°б»ӣc tГӯnh toГЎn sГ n bГӘ tГҙng cб»‘t thГ©p bбәұng phбә§n mб»Ғm ETABS vГ SAFE, tб»« viб»Үc nhбәӯp sб»‘ liб»Үu Д‘бә§u vГ o Д‘бәҝn viб»Үc phГўn tГӯch kбәҝt quбәЈ. CГЎc phбә§n quan trб»Қng bao gб»“m tГӯnh toГЎn mГҙ hГ¬nh, khai thГЎc lб»ұc vГ mГҙ men, vГ xuбәҘt kбәҝt quбәЈ dЖ°б»ӣi dбәЎng tб»Үp vДғn bбәЈn hoбә·c Excel. NgoГ i ra, tГ i liб»Үu cГІn hЖ°б»ӣng dбә«n cГЎch thiбәҝt lбәӯp cГЎc thГҙng sб»‘ kб»№ thuбәӯt cho cГЎc loбәЎi cбәҘu kiб»Үn nhЖ° sГ n, mГіng, vГ cГЎc phбә§n tб»ӯ chб»Ӣu lб»ұc khГЎc.So sГЎnh kбәҝt quбәЈ giб»Ҝa Etabs vГ Robot Structural

So sГЎnh kбәҝt quбәЈ giб»Ҝa Etabs vГ Robot StructuralHuytraining

Мэ

TГ i liб»Үu so sГЎnh hai mГҙ hГ¬nh vб»Ғ nб»ҷi lб»ұc, bao gб»“m tбәЈi trб»Қng bбәЈn thГўn, tбәЈi trб»Қng Д‘б»Ғu, tбәЈi trб»Қng ngang vГ Д‘б»ҷng Д‘бәҘt. Kбәҝt quбәЈ cho thбәҘy sб»ұ chГӘnh lб»Үch nб»ҷi lб»ұc giб»Ҝa hai mГҙ hГ¬nh chб»ү dЖ°б»ӣi 3%, cho thбәҘy tГӯnh khбәЈ thi của kбәҝt quбәЈ. NgЖ°б»қi thб»ұc hiб»Үn lГ Trбә§n Huy ThбәҜng, cГі thГҙng tin liГӘn lбәЎc rГө rГ ng.Casting unit 1 notes

Casting unit 1 notesrmkcet

Мэ

This document provides an overview of casting processes and patterns used in manufacturing. It discusses various types of foundries based on production levels. Patterns are models used to form mold cavities and can be made from various materials like wood, metal, and plastic. Allowances must be provided in patterns to account for shrinkage, draft, machining needs, and potential distortions during solidification. Different types of patterns are used depending on the part geometry, including single-piece, split, gated, sweep, and skeleton patterns.Deep Drowing

Deep Drowing Govt islamia college kasur

Мэ

Deep drawing is a metal forming process where a sheet metal blank is placed over a die opening and forced into the die cavity by a punch. It is commonly used to make cylindrical or box-shaped parts like pots, pans, and automotive fuel tanks. Metals used include alloys, aluminum, brass, cold rolled steel, and copper. Lubrication is applied to reduce forces and increase formability.Rapid heating and cooling in injection moulding

Rapid heating and cooling in injection mouldingJerinJoseph56

Мэ

This document discusses rapid heating and cooling mold (RHCM) technology for injection molding. RHCM aims to improve plastic part surface quality without increasing cycle times. It works by heating the mold cavity surface before injection to a high temperature using various heating methods. The mold is then rapidly cooled after filling to solidify the plastic melt and eject the part. RHCM offers benefits like better surface quality and reduced defects, but has disadvantages such as high energy consumption and maintenance costs.Screw and Barrel Inspection

Screw and Barrel InspectionR&B Plastics Machinery

Мэ

The document outlines a comprehensive procedure for inspecting screws and barrels, which are crucial components in extrusion, injection molding, and blow molding. It emphasizes the importance of measuring wear at least annually and details the necessary tools, techniques, and standards for accurate measurements. Additionally, the document provides specific metrics and guidelines for assessing various aspects of screw and barrel performance to maintain optimal production efficiency.Core type and applications (1.2)

Core type and applications (1.2)Pravinkumar

Мэ

The document discusses the key characteristics and preparation methods for core sands used in metal casting. Core sands must have strength, permeability, thermal stability, and collapsibility. They are prepared using silica sand and can be bonded with sodium silicate, oil, or resin. Cores can be produced through green sand, dry sand, or hardened processes like CO2 or hot box. Common core types include horizontal, vertical, cover, balanced, drop, and kiss cores which are positioned differently in the mold. Core boxes are used to form cores and come in various styles.Methoding Of Casting

Methoding Of Castingkaran bind

Мэ

The document consists of repeated mentions of being scanned by CamScanner. It does not provide substantial content or information beyond these repetitions. Overall, it lacks meaningful details or context.Die casting

Die castingZharlene Soliguen

Мэ

Die casting is a metal casting process where molten metal is forced under high pressure into a mold cavity created by hardened steel dies. Most die castings are made from non-ferrous metals like zinc, aluminum, magnesium, and copper. There are two main types of die casting machines: hot-chamber machines that keep molten metal in the machine, and cold-chamber machines that melt metal separately before injection. Common die casting defects include misruns, cold shuts, gas porosity, and shrinkage caused by issues like cold dies, low metal temperature, or lack of venting during solidification.U2 p2 moulds & moulding materials

U2 p2 moulds & moulding materialsgautam buddha university

Мэ

The document discusses various types of molding materials and properties of molding sand used in casting processes. It describes the common molding materials as sand, metals, plaster, ceramic, graphite, and rubber. The key properties of molding sand that influence its suitability are also outlined, such as refractoriness, permeability, collapsibility, plasticity, and strength. The document further discusses the typical composition of molding sand and the role of additives in enhancing properties. Different types of sands including silica, zircon, olivine, and chromite sands are also compared.Manual passo a passo instalação moldura 2 DIN Fiat Ducato/Peugeot Boxer/Citro...IndГәstria e ComГ©rcio de AutopeГ§as Autoplast

Мэ

Este manual em 5 passos ensina a instalação de uma moldura 2 DIN no painel de veГӯculos Fiat Ducato, Peugeot Boxer e CitroГ«n Jumper entre 2006 e 2015. O primeiro passo Г© inserir o aparelho multimГӯdia e parafusos sem apertar, e inserir a cobertura 2 DIN. O segundo passo Г© apertar os parafusos com o aparelho posicionado. O terceiro passo Г© conectar cabos e encaixar a base no painel. O quarto passo requer remover a cobertura 2Point Collocation Method used in the solving of Differential Equations, parti...

Point Collocation Method used in the solving of Differential Equations, parti...Suddhasheel GHOSH, PhD

Мэ

The document discusses the point collocation method for solving differential equations, presenting formulas and techniques for dealing with boundary value problems. It includes detailed steps for deriving polynomial approximations of solutions through matrix formulations and provides a practical example using specific boundary conditions. The focus is on achieving a solution at specified collocation points with the final output showing the polynomial representation of the solution.Claudius peters-eta-cooler-brochure-en

Claudius peters-eta-cooler-brochure-enNguynThanh234

Мэ

This document summarizes the evolution of clinker cooling technology from Claudius Peters. It describes how Claudius Peters developed the first cooler with a capacity of 500 tons per day in the 1950s and now builds systems with capacities over 13,000 tons per day. It highlights the ETA Cooler system as the pinnacle of clinker cooling technology, which has highly efficient transport, optimized cooling, and dramatically reduced maintenance costs compared to previous cooler designs.Nonlinear static simulation of automotive bumper of a passenger car in low sp...

Nonlinear static simulation of automotive bumper of a passenger car in low sp...eSAT Journals

Мэ

This document summarizes a study on the nonlinear static finite element analysis (FEA) simulation of an automotive front bumper. It describes the bumper components and their purpose in absorbing impact forces during collisions. Experimental testing of the bumper was conducted according to standard procedures. The bumper CAD model was meshed and simulated under static loads applied at different points. The simulation results showed displacements up to 31.5 mm under 250 N of load. Comparison to physical test data found errors ranging from 3.4% to 28.36% due to factors like contact modeling, meshing issues, and differences in the material model. Improving the modeling of these factors led to better correlation between simulation and test results.05) Gating System.ppsx

05) Gating System.ppsxSayaliParabhanikar50

Мэ

This document discusses the elements and design of gating systems used in casting processes. It describes the key components of a gating system including the pouring basin, sprue, runner, and gates. It explains the requirements for an effective gating system and factors that control its functioning. The document provides equations to calculate the optimum pouring time and choke area based on properties of the casting material and part design. It also covers guidelines for designing the sprue, runner, and different types of gates.Tyre cross section measurement

Tyre cross section measurement Dr. Hartwig Suhr

Мэ

The document outlines the specifications and features of the Gamma-X systems for tire structure analysis, detailing measurement capabilities such as distance, angle, and area, along with high-resolution imaging options. It includes descriptions of specialized software for evaluation, dimensioning, and statistical analysis, along with the hardware features of the systems. Additional options for measurements and porosity analysis are also mentioned, emphasizing their application in various tire inspection processes.SocialMediaHandbook_3

SocialMediaHandbook_3Jonathan Pollock

Мэ

The document provides guidance for social media use and engagement for a church called Real Life. It discusses how social media is changing interactions and how words last forever online, so content must be well-thought out. It emphasizes inviting people to attend church events and services through engaging posts. The document outlines strategies for different platforms like Facebook, Twitter, Instagram and YouTube. It provides best practices for personal accounts, such as being engaged with followers, watching what you share, and lifting up the church vision. Throughout, it stresses maintaining a consistent brand and voice to remain recognizable online.More Related Content

What's hot (20)

Tama Proje Konteyner

Tama Proje KonteynerYusufzgen

Мэ

Tam YeraltДұ ГҮГ¶p Konteyneri, YarДұ Yer AltДұ ГҮГ¶p Konteyneri, Yer ГңstГј ГҮГ¶p Konteyneri, JaklДұ Sistem ГҮГ¶p Konteyneri, Plastik ГҮГ¶p Konteyneri, Metal ГҮГ¶p Konteyneri, Geri DГ¶nГјЕҹГјm Kutusu, Geri DГ¶nГјЕҹГјm KumbarasДұ, DДұЕҹ Mekan ГҮГ¶p KovalarДұ ve SДұfДұr AtДұk Projesi

https://www.tamaproje.com/Analysis of Various Cement grinding Systems with Respect to Power Consumption...

Analysis of Various Cement grinding Systems with Respect to Power Consumption...Karan Walia

Мэ

The dissertation by Karan Walia analyzes various grinding systems in cement production with respect to power consumption while maintaining quality parameters. The research, carried out at Colleagues Consultants Pvt. Ltd., focuses on evaluating different grinding technologies, including ball mills, vertical roller mills, and roller presses, and aims to determine their efficiency in energy usage. Key findings emphasize the significant energy demands in the cement industry, accounting for a large portion of industrial energy consumption.aula estampagem - processo de conformação mecanica.pptxJessicaHiplitodeVasc

Мэ

O documento aborda o processo de conformação mecГўnica de materiais metГЎlicos, destacando a estampagem como um mГ©todo de transformação que nГЈo remove material. A estampagem, utilizada em diversas indГәstrias, envolve processos como corte, dobra e conformação de chapas metГЎlicas, podendo ser realizada por mГ©todos como prensagem e estampagem progressiva. SГЈo discutidos os materiais utilizados, a lubrificação necessГЎria e os defeitos comuns encontrados nas peГ§as produzidas.severe plastic deformation (An approach to refine micro-structure ,improve st...

severe plastic deformation (An approach to refine micro-structure ,improve st...Om Prakash Kumawat

Мэ

This document summarizes severe plastic deformation (SPD) techniques for refining microstructure and improving strength and ductility of materials. SPD processes grains to the ultra-fine scale (<10 Ојm) through large plastic strain without changing overall dimensions. Techniques discussed include equal channel angular pressing, high pressure torsion, repetitive corrugation and straightening, accumulative roll bonding, and friction stir processing. SPD results in ultra-fine grain materials with higher strength, toughness, and potential applications in industries requiring lightweight components like aerospace, automotive, and medical implants. Further research is still needed to fully understand properties like thermal stability and strain hardening of SPD-processed materials.Safe trong tinh toan san btct

Safe trong tinh toan san btctДҗб»— Quang Дҗб»Ӣnh

Мэ

TГ i liб»Үu hЖ°б»ӣng dбә«n cГЎc bЖ°б»ӣc tГӯnh toГЎn sГ n bГӘ tГҙng cб»‘t thГ©p bбәұng phбә§n mб»Ғm ETABS vГ SAFE, tб»« viб»Үc nhбәӯp sб»‘ liб»Үu Д‘бә§u vГ o Д‘бәҝn viб»Үc phГўn tГӯch kбәҝt quбәЈ. CГЎc phбә§n quan trб»Қng bao gб»“m tГӯnh toГЎn mГҙ hГ¬nh, khai thГЎc lб»ұc vГ mГҙ men, vГ xuбәҘt kбәҝt quбәЈ dЖ°б»ӣi dбәЎng tб»Үp vДғn bбәЈn hoбә·c Excel. NgoГ i ra, tГ i liб»Үu cГІn hЖ°б»ӣng dбә«n cГЎch thiбәҝt lбәӯp cГЎc thГҙng sб»‘ kб»№ thuбәӯt cho cГЎc loбәЎi cбәҘu kiб»Үn nhЖ° sГ n, mГіng, vГ cГЎc phбә§n tб»ӯ chб»Ӣu lб»ұc khГЎc.So sГЎnh kбәҝt quбәЈ giб»Ҝa Etabs vГ Robot Structural

So sГЎnh kбәҝt quбәЈ giб»Ҝa Etabs vГ Robot StructuralHuytraining

Мэ

TГ i liб»Үu so sГЎnh hai mГҙ hГ¬nh vб»Ғ nб»ҷi lб»ұc, bao gб»“m tбәЈi trб»Қng bбәЈn thГўn, tбәЈi trб»Қng Д‘б»Ғu, tбәЈi trб»Қng ngang vГ Д‘б»ҷng Д‘бәҘt. Kбәҝt quбәЈ cho thбәҘy sб»ұ chГӘnh lб»Үch nб»ҷi lб»ұc giб»Ҝa hai mГҙ hГ¬nh chб»ү dЖ°б»ӣi 3%, cho thбәҘy tГӯnh khбәЈ thi của kбәҝt quбәЈ. NgЖ°б»қi thб»ұc hiб»Үn lГ Trбә§n Huy ThбәҜng, cГі thГҙng tin liГӘn lбәЎc rГө rГ ng.Casting unit 1 notes

Casting unit 1 notesrmkcet

Мэ

This document provides an overview of casting processes and patterns used in manufacturing. It discusses various types of foundries based on production levels. Patterns are models used to form mold cavities and can be made from various materials like wood, metal, and plastic. Allowances must be provided in patterns to account for shrinkage, draft, machining needs, and potential distortions during solidification. Different types of patterns are used depending on the part geometry, including single-piece, split, gated, sweep, and skeleton patterns.Deep Drowing

Deep Drowing Govt islamia college kasur

Мэ

Deep drawing is a metal forming process where a sheet metal blank is placed over a die opening and forced into the die cavity by a punch. It is commonly used to make cylindrical or box-shaped parts like pots, pans, and automotive fuel tanks. Metals used include alloys, aluminum, brass, cold rolled steel, and copper. Lubrication is applied to reduce forces and increase formability.Rapid heating and cooling in injection moulding

Rapid heating and cooling in injection mouldingJerinJoseph56

Мэ

This document discusses rapid heating and cooling mold (RHCM) technology for injection molding. RHCM aims to improve plastic part surface quality without increasing cycle times. It works by heating the mold cavity surface before injection to a high temperature using various heating methods. The mold is then rapidly cooled after filling to solidify the plastic melt and eject the part. RHCM offers benefits like better surface quality and reduced defects, but has disadvantages such as high energy consumption and maintenance costs.Screw and Barrel Inspection

Screw and Barrel InspectionR&B Plastics Machinery

Мэ

The document outlines a comprehensive procedure for inspecting screws and barrels, which are crucial components in extrusion, injection molding, and blow molding. It emphasizes the importance of measuring wear at least annually and details the necessary tools, techniques, and standards for accurate measurements. Additionally, the document provides specific metrics and guidelines for assessing various aspects of screw and barrel performance to maintain optimal production efficiency.Core type and applications (1.2)

Core type and applications (1.2)Pravinkumar

Мэ

The document discusses the key characteristics and preparation methods for core sands used in metal casting. Core sands must have strength, permeability, thermal stability, and collapsibility. They are prepared using silica sand and can be bonded with sodium silicate, oil, or resin. Cores can be produced through green sand, dry sand, or hardened processes like CO2 or hot box. Common core types include horizontal, vertical, cover, balanced, drop, and kiss cores which are positioned differently in the mold. Core boxes are used to form cores and come in various styles.Methoding Of Casting

Methoding Of Castingkaran bind

Мэ

The document consists of repeated mentions of being scanned by CamScanner. It does not provide substantial content or information beyond these repetitions. Overall, it lacks meaningful details or context.Die casting

Die castingZharlene Soliguen

Мэ

Die casting is a metal casting process where molten metal is forced under high pressure into a mold cavity created by hardened steel dies. Most die castings are made from non-ferrous metals like zinc, aluminum, magnesium, and copper. There are two main types of die casting machines: hot-chamber machines that keep molten metal in the machine, and cold-chamber machines that melt metal separately before injection. Common die casting defects include misruns, cold shuts, gas porosity, and shrinkage caused by issues like cold dies, low metal temperature, or lack of venting during solidification.U2 p2 moulds & moulding materials

U2 p2 moulds & moulding materialsgautam buddha university

Мэ

The document discusses various types of molding materials and properties of molding sand used in casting processes. It describes the common molding materials as sand, metals, plaster, ceramic, graphite, and rubber. The key properties of molding sand that influence its suitability are also outlined, such as refractoriness, permeability, collapsibility, plasticity, and strength. The document further discusses the typical composition of molding sand and the role of additives in enhancing properties. Different types of sands including silica, zircon, olivine, and chromite sands are also compared.Manual passo a passo instalação moldura 2 DIN Fiat Ducato/Peugeot Boxer/Citro...IndГәstria e ComГ©rcio de AutopeГ§as Autoplast

Мэ

Este manual em 5 passos ensina a instalação de uma moldura 2 DIN no painel de veГӯculos Fiat Ducato, Peugeot Boxer e CitroГ«n Jumper entre 2006 e 2015. O primeiro passo Г© inserir o aparelho multimГӯdia e parafusos sem apertar, e inserir a cobertura 2 DIN. O segundo passo Г© apertar os parafusos com o aparelho posicionado. O terceiro passo Г© conectar cabos e encaixar a base no painel. O quarto passo requer remover a cobertura 2Point Collocation Method used in the solving of Differential Equations, parti...

Point Collocation Method used in the solving of Differential Equations, parti...Suddhasheel GHOSH, PhD

Мэ

The document discusses the point collocation method for solving differential equations, presenting formulas and techniques for dealing with boundary value problems. It includes detailed steps for deriving polynomial approximations of solutions through matrix formulations and provides a practical example using specific boundary conditions. The focus is on achieving a solution at specified collocation points with the final output showing the polynomial representation of the solution.Claudius peters-eta-cooler-brochure-en

Claudius peters-eta-cooler-brochure-enNguynThanh234

Мэ

This document summarizes the evolution of clinker cooling technology from Claudius Peters. It describes how Claudius Peters developed the first cooler with a capacity of 500 tons per day in the 1950s and now builds systems with capacities over 13,000 tons per day. It highlights the ETA Cooler system as the pinnacle of clinker cooling technology, which has highly efficient transport, optimized cooling, and dramatically reduced maintenance costs compared to previous cooler designs.Nonlinear static simulation of automotive bumper of a passenger car in low sp...

Nonlinear static simulation of automotive bumper of a passenger car in low sp...eSAT Journals

Мэ

This document summarizes a study on the nonlinear static finite element analysis (FEA) simulation of an automotive front bumper. It describes the bumper components and their purpose in absorbing impact forces during collisions. Experimental testing of the bumper was conducted according to standard procedures. The bumper CAD model was meshed and simulated under static loads applied at different points. The simulation results showed displacements up to 31.5 mm under 250 N of load. Comparison to physical test data found errors ranging from 3.4% to 28.36% due to factors like contact modeling, meshing issues, and differences in the material model. Improving the modeling of these factors led to better correlation between simulation and test results.05) Gating System.ppsx

05) Gating System.ppsxSayaliParabhanikar50

Мэ

This document discusses the elements and design of gating systems used in casting processes. It describes the key components of a gating system including the pouring basin, sprue, runner, and gates. It explains the requirements for an effective gating system and factors that control its functioning. The document provides equations to calculate the optimum pouring time and choke area based on properties of the casting material and part design. It also covers guidelines for designing the sprue, runner, and different types of gates.Tyre cross section measurement

Tyre cross section measurement Dr. Hartwig Suhr

Мэ

The document outlines the specifications and features of the Gamma-X systems for tire structure analysis, detailing measurement capabilities such as distance, angle, and area, along with high-resolution imaging options. It includes descriptions of specialized software for evaluation, dimensioning, and statistical analysis, along with the hardware features of the systems. Additional options for measurements and porosity analysis are also mentioned, emphasizing their application in various tire inspection processes.severe plastic deformation (An approach to refine micro-structure ,improve st...

severe plastic deformation (An approach to refine micro-structure ,improve st...Om Prakash Kumawat

Мэ

Manual passo a passo instalação moldura 2 DIN Fiat Ducato/Peugeot Boxer/Citro...IndГәstria e ComГ©rcio de AutopeГ§as Autoplast

Мэ

Point Collocation Method used in the solving of Differential Equations, parti...

Point Collocation Method used in the solving of Differential Equations, parti...Suddhasheel GHOSH, PhD

Мэ

Viewers also liked (13)

SocialMediaHandbook_3

SocialMediaHandbook_3Jonathan Pollock

Мэ

The document provides guidance for social media use and engagement for a church called Real Life. It discusses how social media is changing interactions and how words last forever online, so content must be well-thought out. It emphasizes inviting people to attend church events and services through engaging posts. The document outlines strategies for different platforms like Facebook, Twitter, Instagram and YouTube. It provides best practices for personal accounts, such as being engaged with followers, watching what you share, and lifting up the church vision. Throughout, it stresses maintaining a consistent brand and voice to remain recognizable online.Gemi Д°malatДұnda Radyografik Muayene

Gemi Д°malatДұnda Radyografik MuayeneYДұldДұz Teknik Гңniversitesi

Мэ

Gemi imalatДұnda kullanДұlan kaynaklДұ birleЕҹtirmelerin radyografik muayenesiMetal casting by yaser elkelawy

Metal casting by yaser elkelawyYasser Mohamed abbas elkelawy

Мэ

The document discusses various metal casting processes and techniques. It provides an overview of sand casting, describing the key steps of pouring molten metal into a sand mold, allowing it to solidify, breaking up the mold, and cleaning the casting. It also discusses mold materials, gating systems, risers, solidification processes for pure metals and alloys, and shrinkage and directional solidification techniques.Expandable Pattern Casting and Plaster Mold Casting

Expandable Pattern Casting and Plaster Mold CastingMarry Sol Lare

Мэ

Expandable pattern casting and plaster mold casting are two types of expendable mold casting processes. Expandable pattern casting uses an expandable polystyrene pattern that is coated, embedded in sand in a flask, and then vaporized when molten metal is poured, leaving an exact replica of the pattern. Plaster mold casting similarly uses a plaster mold instead of sand and is best for smaller, non-ferrous metal castings due to temperature limitations of plaster. Both methods can produce complex, close-tolerance castings with minimal finishing required.Flexible Manufacturing System

Flexible Manufacturing SystemDesai Vaishali

Мэ

The document discusses flexible manufacturing systems (FMS), highlighting their significance in addressing modern manufacturing challenges such as globalization, cost reduction, and quality improvement. It outlines the various types and layouts of FMS, including single machine cells, flexible manufacturing cells, and complex systems, and emphasizes the importance of flexibility in manufacturing processes. Additionally, it presents the advantages and disadvantages of FMS, as well as its applications in various manufacturing contexts.Flexible Manufacturing Systems V2 090310

Flexible Manufacturing Systems V2 090310Leicester College- Technology & Engineering Centre

Мэ

The document details the increasing use of Flexible Manufacturing Systems (FMS) in production, exploring their design parameters, types, and benefits. It describes key aspects such as system flexibility, operation requirements, and technological sophistication, along with comparisons between different types of manufacturing systems. The FMS is characterized by its ability to process a variety of part styles simultaneously, offering advantages like increased efficiency and reduced lead times.U3 p3 special casting methods

U3 p3 special casting methodsgautam buddha university

Мэ

This document discusses various molding and casting processes, including:

1. Carbon dioxide molding process, investment casting process, shell molding process, die casting process, full molding process, and vacuum-sealed casting process.

2. It provides details on the steps and advantages/disadvantages of processes like shell molding, investment casting, plaster mold casting, and permanent mold casting.

3. References are made to keywords and websites for additional information on topics like sand casting and carbon dioxide molding.Topic 3 metal casting 160214

Topic 3 metal casting 160214Huai123

Мэ

This document provides an overview of metal casting fundamentals. It discusses the importance of metal casting in manufacturing due to its ability to produce complex internal and external shapes in large quantities. The document outlines the basic steps in the casting process, including heating the metal, pouring it into a mold, and allowing it to solidify. It also summarizes the solidification process for pure metals and alloys, including factors that influence solidification time and techniques to control shrinkage and promote directional solidification. Finally, it categorizes common metal casting processes as either expendable or permanent mold and discusses their relative advantages.Balancing of rotating masses

Balancing of rotating massesHareesha N Gowda, Dayananda Sagar College of Engg, Bangalore

Мэ

The document discusses the principles and methods of balancing rotating masses in machinery to reduce unbalanced forces caused by inertia. It covers static and dynamic balancing techniques, the necessity of balancing due to high machinery speeds, and the mechanics involved including centrifugal and disturbing forces. Various cases of balancing with single and multiple masses in the same or different planes are described, emphasizing the need for achieving equilibrium in dynamic systems.FLEXIBLE MANUFACTURING SYSTEM

FLEXIBLE MANUFACTURING SYSTEMAnand Khare

Мэ

This document provides an overview of flexible manufacturing systems (FMS). It defines FMS as an automated machine cell consisting of interconnected processing workstations and automated material handling. It discusses the history and purpose of FMS in optimizing manufacturing cycle times and reducing costs. The basic components of FMS are described as workstations, automated material handling systems, and computer control systems. The document outlines different types of FMS layouts and how flexibility is achieved. It provides examples of FMS applications and discusses the advantages of FMS in improving efficiency and reducing production time, while also noting the high expenses associated with implementation.Ad

Jant KapaДҹДұ Гңretimi

- 1. ГңRETД M YГ–NTEMLERД DERSД SUNUMU KONU: JANT KAPAДһI ГңRETД M AДЎAMALARI Г–DEVД HAZIRLAYANLAR: пҒ® пҒ® пҒ® KasДұm Ezel Ali Ersin GГјl Mehmet LГ¶k 1

- 2. JANT KAPAДһI ГңRETД MД 3 FARKLI MALZEMEDEN YAPILIR. PASLANMAZ ГҮELД K DKP SAC PLASTД K 2

- 4. Plastik malzemeden jant kapaДҹДұ Гјretiminde plastik enjeksiyon makineleri kullanДұlДұr. 4

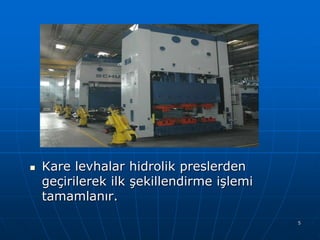

- 5. пҒ® Kare levhalar hidrolik preslerden geГ§irilerek ilk Еҹekillendirme iЕҹlemi tamamlanДұr. 5

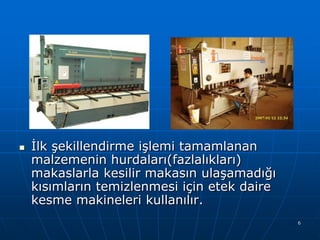

- 6. пҒ® Д lk Еҹekillendirme iЕҹlemi tamamlanan malzemenin hurdalarДұ(fazlalДұklarДұ) makaslarla kesilir makasДұn ulaЕҹamadДұДҹДұ kДұsДұmlarДұn temizlenmesi iГ§in etek daire kesme makineleri kullanДұlДұr. 6

- 7. Eksantrik preslerde; -kesme -bГјkme -derin cekme -yatДұrma -dikme iЕҹlemleri yapДұlarak istenilen Еҹekil elde edilir. 7

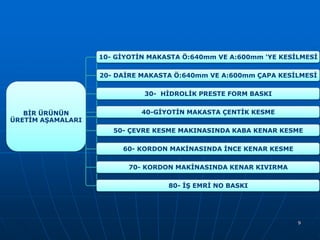

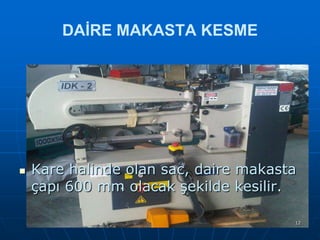

- 9. 10- GД°YOTД°N MAKASTA Г–:640mm VE A:600mm 'YE KESД°LMESД° 20- DAД°RE MAKASTA Г–:640mm VE A:600mm ГҮAPA KESД°LMESД° 30- HД°DROLД°K PRESTE FORM BASKI BД°R ГңRГңNГңN ГңRETД°M AЕһAMALARI 40-GД°YOTД°N MAKASTA ГҮENTД°K KESME 50- ГҮEVRE KESME MAKINASINDA KABA KENAR KESME 60- KORDON MAKД°NASINDA Д°NCE KENAR KESME 70- KORDON MAKД°NASINDA KENAR KIVIRMA 80- Д°Еһ EMRД° NO BASKI 9

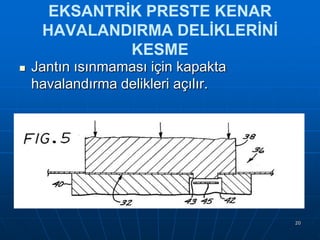

- 10. 90- POLД°SAJ 100-EKSANTRД°K PRESTE ARMA BAДһLANTI DELД°ДһД° AГҮMA 110- EKSANTRД°K PRESTE KENAR HAVALANDIRMA DELД°KLERД°NД° KESME BД°R ГңRГңNГңN ГңRETД°M AЕһAMALARI 120- EKSANTRД°K PRESTE KENAR HAVALANDIRMA DELД°KLERД°NД° KIVIRMA 130- MARKALAMA 140- EKSANTRД°K PRESTE BAДһLANTI PLASTД°ДһД° MONTAJ DELД°KLERД° DELME 150- YГңZEY TEMД°ZLEME (SICAK SU Д°LE) 160- ARMA VE BAДһLANTI PLASTД°KLERД° MONTAJI 10

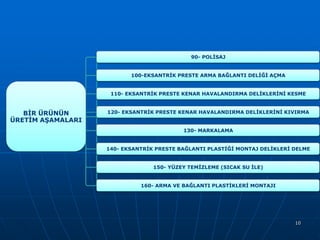

- 11. GД°YOTД°N MAKASTA KESME пҒ® Rulo halinde gelen paslanmaz sac, kare Дўeklinde kesilir. 11

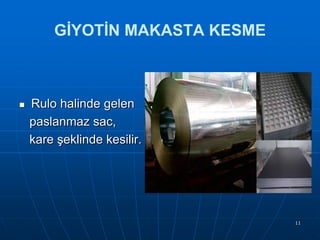

- 12. DAД°RE MAKASTA KESME пҒ® Kare halinde olan sac, daire makasta Г§apДұ 600 mm olacak Еҹekilde kesilir. 12

- 13. HД°DROLД°K PRESTE FORM BASKI пҒ® Daire sacДұn form kalДұbДұnda basДұlmasДұ 13

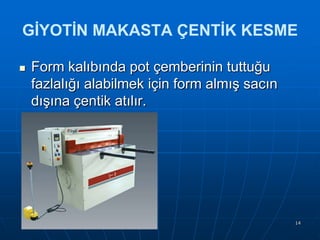

- 14. GД°YOTД°N MAKASTA ГҮENTД°K KESME пҒ® Form kalДұbДұnda pot Г§emberinin tuttuДҹu fazlalДұДҹДұ alabilmek iГ§in form almДұДў sacДұn dДұДўДұna Г§entik atДұlДұr. 14

- 15. ГҮEVRE KESME MAKINASINDA KABA KENAR KESME пҒ® Bu Г§entikten baДўlanarak kaba Г§evresi kesilir. 15

- 16. KORDON MAKД°NASINDA Д°NCE KENAR KESME пҒ® KДұvrДұlacak kДұsДұm iГ§eriye bДұrakДұlacak Дўekilde Г¶zenli olarak bir dДұДў kesim daha yapДұlДұr. 16

- 17. KORDON MAKД°NASINDA KENAR KIVIRMA пҒ® Kalan kenar, kДұvДұrma toplarДұ ile iГ§eriye doДҹru kДұvДұrДұlДұr. 17

- 18. POLД°SAJ пҒ® пҒ® Rulo halinde gelen sac form almadan Г¶nce ayna kadar parlaktДұ. YapДұlan iДўlemlerden sonra form alarak uzayan sac matlaДўtДұ. Bu matlДұДҹДұ ortadan kaldДұrmak iГ§in parlatma-polishing-polisaj prosesi uygulanДұr. 18

- 19. EKSANTRД°K PRESTE ARMA BAДһLANTI DELД°ДһД° AГҮMA пҒ® SacДұn ortasДұna takДұlan plastik yuvarlak parГ§anДұn tДұrnaklarДұnДұn geГ§eceДҹi delikleri aГ§ma. 19

- 20. EKSANTRД°K PRESTE KENAR HAVALANDIRMA DELД°KLERД°NД° KESME пҒ® JantДұn ДұsДұnmamasДұ iГ§in kapakta havalandДұrma delikleri aГ§ДұlДұr. 20

- 21. EKSANTRД°K PRESTE KENAR HAVALANDIRMA DELД°KLERД°NД° KIVIRMA пҒ® Kesilen deliklerin keskin yГјzeyleri iГ§eriye kДұvДұrДұlДұr. 21

- 22. EKSANTRД°K PRESTE BAДһLANTI PLASTД°ДһД° MONTAJ DELД°KLERД° DELME пҒ® KapaДҹДұn janta oturtturulmasДұ Г§eДўitli Дўekillerde olabilir. Bu Г¶rnekte baДҹlantДұ plastiДҹi kullanДұlmДұДўtДұr. KapaДҹДұn kenarДұna monte edilmiДў 5 adet plastikten her birinde allen vidalarДұ bulunur. Bu vidalar sДұkДұldДұДҹДұnda plastiДҹin alt bГ¶lГјmГј(Г§enesi) jantДұn aДҹzДұna kadar dayanДұr. Bu Дўekilde kapaДҹДұn janta montajДұ yapДұlmДұДў olur. 22

- 23. YГңZEY TEMД°ZLEME пҒ® пҒ® Polisaj fДұrГ§asДұnДұn artДұklarДұ kullanДұlan don yaДҹДұ ile birlikte polisaj sДұrasДұnda yГјzeye yapДұДўДұr. SДұcak su ile bunlarДұn temizlenmesi 23

- 24. пҒ® пҒ® пҒ® FД°NAL KONTROL GГ–RSEL ARMA VE BAДһLANTI PLASTД°KLERД° MONTAJI FД°NAL KONTROL Г–LГҮГңSEL 24

- 25. 25

- 27. TEЕһEKKГңRLER 27