Kaizen

- 1. Kaiz en

- 2. ’üČ Japanese word ’üČ Kai meaning ŌĆ£ changeŌĆØ Zen meaning ŌĆ£goodŌĆØ ’üČ It is a continuous improvement with involvement of everybody in organization so as to generate cus Overview Of Kaizen

- 3. ’üČ Based on belief that there will be no progress if you keep on doing things exactly same way all the time ’üČ Basically say that no day should go without some kind of improvement made somewhere ’üČ Stresses upon process oriented Belief And Views Of Kaizen

- 4. Better quality of product and services Faster work cycles Greater Flexibility Low cost And Low Wastage How To Implement Kaizen

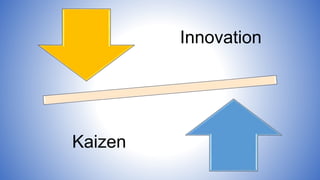

- 6. Innovation Kaizen Creativity Adaptability Individualism Teamwork Technology oriented People Oriented Seeks New Technology Development in Existing ’üČ Basically many of us are confused that innovation and Kaizen can be regarded as same thing ’üČ But No!!!!! ’üČ Kaizen is Small Improvement ’üČ Innovation is Very big and drastic improvement Kaizen V/s Innovations

- 8. Concentrate on strategic and logistic issues Provide momentum to keep up progress Must spent 50% time on it Management Oriented Permanent approach Quality circles and Small group Activities Group In form of suggestions Morale Booster Individual Overview!!!

- 9. Steps In Kaizen Programme

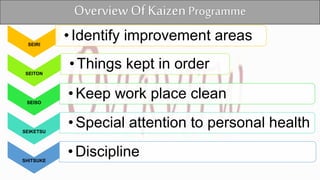

- 10. SEIRI ŌĆó Identify improvement areas SEITON ŌĆó Things kept in order SEISO ŌĆó Keep work place clean SEIKETSU ŌĆó Special attention to personal health SHITSUKE ŌĆó Discipline Overview Of KaizenProgramme

- 11. Case Study

- 12. ’üČThe philosophy of kaizen is one of ToyotaŌĆÖs core values. ’üČIt means ŌĆścontinuous improvementŌĆÖ ’üČThe Toyota Production System invites team members to think about the process and make timely decisions in order to keep it running smoothly,’üČRather than merely operating like machines ’üČThis involvement creates responsibility for the success of the process, increasing both Toyota Case Study