indutrial training report

Download as pptx, pdf12 likes5,909 views

report of industrial training done at CTU chandigarh transport undertaking.(includes some description about the a

1 of 23

Downloaded 377 times

Recommended

Window ac

Window acGauri Singh

╠²

Window AC systems provide affordable air conditioning by fitting into windows. They have a single unit that contains both the compressor and condenser. Key parts include the refrigeration system, air circulation system, and control panel. Window ACs cool air by blowing room air over an evaporator coil, then circulating the chilled air back into the room while venting hot air outside through the condenser. They are easy to install but only condition a single room and block window access.Microgrid Presentation

Microgrid PresentationShahab Khan

╠²

Its a great presentation on Microgrid covering various aspects of Microgrid.

Guys who worked on this presentation:

1: Shahab Khan

2: Reshadat AliPRESENTATION ON MANUFACTURING OF TRANSFORMER By Dhruv Jimit

PRESENTATION ON MANUFACTURING OF TRANSFORMER By Dhruv JimitJimit Dhruv

╠²

THIS PRESENTATION WILL GIVE A GREAT KNOWLEDGE OF MANUFACTURING OF PRACTICAL AS WELL AS THEORETICAL TRANSFORMERS. UPSRTC Industry traning ppt (1) shubham.pptx 27 sep

UPSRTC Industry traning ppt (1) shubham.pptx 27 sepshubham saini

╠²

The document provides details about a regional workshop of UPSRTC (Uttar Pradesh State Road Transport Corporation) located in Saharanpur. The workshop performs maintenance and repair work on roadway passenger vehicles, including parts replacement, lubrication, inspection, and testing. The workshop has several sections dedicated to different vehicle components, such as the engine, differential gear, and clutch sections. The engine section performs maintenance on engine parts like the cylinder head, oil pump, piston, crankshaft, and valves. The differential gear section works on the differential, and the clutch section services clutches.smart grid in india

smart grid in indiaPratheeka p nair

╠²

OVERVIEW

WHAT IS SMART GRID?

NEED OF SMART GRID IN INDIAN CONTEXT.

SMART GRID ATTRIBUTES.

INDIAN GOVERNMENT INTIATIVE TOWARDS SMART GRID

SMART GRID PROJECTS IN INDIA.

INDIAN GOVT. APPROVED PROJECTS.

PRESENT STATUS OF PROJECTS

BARRIERS TO SMART GRID IMPLEMETATION

LAYOUT OF SMARTGRID

CONCLUSION

REFRERENCES

Sheet metal-operations

Sheet metal-operationsPrasanna M N

╠²

Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting. Sheet metal workers use tools like dies and presses to perform these operations and shape the metal.Transformer construction,types and working

Transformer construction,types and workingmaharshi dayanand university rohtak

╠²

this is good for electrical engineering students to present seminar in your college or university....ppt on Smart Grid

ppt on Smart Gridagr_vandana30

╠²

The document discusses the implementation of the Restructured Accelerated Power Development and Reforms Program (R-APDRP) in Rajasthan, India. Key points:

- R-APDRP aims to establish reliable baseline data and adopt IT in energy accounting to reduce losses before distribution strengthening projects.

- It has two parts - Part A focuses on IT applications for energy auditing and consumer services. Part B covers network renovation.

- The Discoms of Rajasthan have taken steps like forming implementation committees and appointing an IT consultant to timely execute the scheme and avail grants.

- Benefits of R-APDRP include increased consumer satisfaction, transparency, reduced outMorse test r

Morse test rrawaabdullah

╠²

This document describes a Morse test conducted on an internal combustion engine to determine the engine's indicated power (IP), brake power (BP), and friction power (FP). The test involves running the engine at a constant speed and cutting the ignition to individual cylinders while adjusting the load to maintain speed. The difference in BP readings gives the IP of the cut cylinder. Summing the IP values yields the engine's total IP. Subtracting BP from IP provides FP, and the ratios of these values can be used to calculate mechanical efficiency. The objectives, conditions, introduction, theory, procedure, calculations, discussion and references related to the Morse test are detailed in the document.MULTI-POINT FUEL INJECTION SYSTEM

MULTI-POINT FUEL INJECTION SYSTEMMihir Patel

╠²

Multipoint fuel injection (MPFI) systems provide better control of the air-fuel ratio compared to carburetors. MPFI systems use multiple fuel injectors, with one injector per cylinder, to inject fuel into the engine's intake ports or manifold. This allows supplying the optimum air-fuel ratio to each cylinder for all operating conditions. MPFI systems are electronically controlled using sensors to monitor various engine parameters and optimize fuel delivery and emissions performance. While more complex than carburetors, MPFI systems improve fuel efficiency, power, and reduce emissions.automobile workshop ppt Traning report by c rang rajan and sudhir kumar

automobile workshop ppt Traning report by c rang rajan and sudhir kumarchakrawarti rang rajan

╠²

The document provides an overview of the key components and systems of an automobile. It begins with an introduction to Karlo Automobiles, an Indian vehicle repair workshop. It then defines an automobile and describes its main parts like the engine, transmission system including the clutch, gearbox, propeller shaft, differential, wheels, axle and chassis. The document further explains the body, suspension system, cooling system, steering system, braking system and lighting system of a car. Diagrams and pictures are included to illustrate the different components. The presentation aims to provide trainees an understanding of the various parts that make up a motor vehicle.Dlw locomotive workshop

Dlw locomotive workshopShivam Prajapati

╠²

This document is an industrial training report submitted by Himanshu S. Singh to Ramendra Kr. Visen on his training at the Diesel Locomotive Workshop in Varanasi. The report provides background on Indian Railways and the history and operations of the Diesel Locomotive Workshop, including its establishment, annual production capacity, manufacturing processes, and departments.Mahindra & Mahindra training report.

Mahindra & Mahindra training report.Prithvi Raj

╠²

The document provides an overview of Mahindra First Choice Services, which is part of Mahindra & Mahindra's aftermarket sector. It discusses the foundation and business units of Mahindra, as well as details about Mahindra First Choice Services workshops. The workshop operates in cycles, providing services such as engine repair, brake repair, steering/suspension work, air conditioning, wheel balancing, denting/painting, and car grooming. It describes the process a vehicle goes through from entry to exit and highlights the various engine and vehicle services performed.Explanation about different car body styles

Explanation about different car body stylesCar Leasing Made Simple

╠²

This document discusses and defines different car body styles including 4x4, city car, coupe, estate, hatchback, MPV, saloon, and sports car. It provides details on each style such as 4x4 having all-wheel drive for rough terrain, city cars being compact for urban use, coupes having two doors and two or four seats, estates having additional cargo space, and hatchbacks having rear doors that open upward. MPVs are designed for multiple purposes like passenger and cargo transport, saloons have separate bonnets and boots, and sports cars prioritize handling and speed over comfort.Mercedes benz service centre training report

Mercedes benz service centre training reportPanchal Anand

╠²

Industrial training (Internship) Report.

Mercedes_benz Service centre.

Abstract: As a Mechanical Engineering Student I am very interested in automobile Engineering. I always keen to learn different mechanisms used in vehicles, I used to watch animated videos on YouTube about automobile mechanisms like Differential, Automatic transmission gearbox etc, but I never watched it in real. So, it was a great opportunity for me to do two weeks internship at Mercedes-benz Service centre, Ambli, Ahmedabad. The internship was concentrated on the car services. At the beginning of the internship I had several queries in my mind regarding the different technologies used in Mercedes-benz and what skills are needed in organization. During my internship several queries are cleared by doing some activities. The objective of this internship is to understand working of different mechanisms, to get knowledge of regular services and the major-minor problem that can be observed in day to day life. Apart from technical knowledge, I also learnt rules and safety instruction, Inventory management, Quality Control. I realize the responsibility of technicians working on the car. So, this internship was a great experience. I found out how much I am strong in automobile field. I gained new knowledge and skills and met many new people. Working together with people having different background and education was great experience. I also accompanied by other 2-3 students who were also on industrial training, so it was nice knowledge sharing. I achieved many of my learning goals. I got insight into the work of an organization. At last this internship has given me new insights and motivation to pursue a career in mechanical engineering.Steering System ( Anil Sharma )

Steering System ( Anil Sharma )ANIL SHARMA

╠²

This document discusses the steering system of a vehicle. It defines steering as converting the rotary movement of the steering wheel into angular turn of the front wheels. The steering system must multiply turning effort, be somewhat irreversible to shocks, and allow turning at the driver's will. There are two common steering mechanisms: Davis and Ackermann gears. Camber and caster angles are also discussed to explain how wheels are oriented for stability and wear. The document provides details on various components and specifications of a basic automotive steering system.UPSRTC LUCKNOW

UPSRTC LUCKNOWFaraz Khan

╠²

The document summarizes an industrial training presentation on the regional workshop of UPSRTC in Lucknow, India. The workshop services and maintains roadway passenger vehicles. It has sections for engine, differential gear, gear box, and clutch maintenance and repair. The engine section services parts like the cylinder head, oil pump, pistons, crankshaft, and camshaft. The differential gear distributes torque across the rear axles. The clutch connects and disconnects two rotating shafts to either lock or decouple their speeds.Power Steering

Power SteeringAnupam Kaler

╠²

The document provides an overview of power steering systems. It discusses the history of power steering from its invention in the early 1900s to its use in automobiles and agricultural vehicles. The key components of power steering systems are described including the reservoir, steering gearbox, rotary valve, and pump. The main types of power steering systems - hydraulic, electro-hydraulic, and electric - are outlined along with diagrams of how each system works. Advantages like reduced driver fatigue and continuous steering are balanced with potential disadvantages such as leakage and vibration.Multipurpose mechanical machine

Multipurpose mechanical machineganeshkhutwad18

╠²

This project is done by the mechanical diploma engineering student of tssm's bscoer poly., pune

design and development of multipurpose mechanical machine

last year project-2017-18

it is the best project for the engineering student for the last year by modification as per the needSummer Training Report for Diploma (mechanical) Students

Summer Training Report for Diploma (mechanical) StudentsKashifRaza113

╠²

This Training is completed at UPSRTC (Lucknow) by a student of polytechnic(mechanical) from Integral University Lucknow. UPSRTC is a Government Organisation for Public Transport in Uttar Pradesh. Layout

LayoutAjay Yadav

╠²

The document provides an overview of the key components and systems of an automobile, including:

- The basic structure or chassis, which includes the frame, suspension system, axles, wheels, and tires.

- The power unit, typically an internal combustion engine.

- The transmission system, which includes the clutch, gearbox, propeller shaft, and differential.

- Auxiliary components like the controls and superstructure that are mounted on the chassis.

It also discusses different suspension types, powertrain configurations like front-engine rear-wheel drive, and ways that automobiles can be classified.Automobile chassis frame

Automobile chassis framejjHF47

╠²

The document discusses automobile chassis frames. It defines a frame as the undercarriage or structure that supports the engine, cab, and body of a vehicle. There are three main types of frames: conventional frames with side members and cross members, integral frames where all components attach directly to the body, and semi-integral frames that have a partial front frame. The document outlines the functions of frames, provides examples of frame designs, and describes the materials, design considerations, and manufacturing processes involved in building frames, including cutting, bending, welding, and inspection stages. It concludes with details from a field visit to an automotive manufacturing plant. Diesel Locomotive Works (DLW)

Diesel Locomotive Works (DLW)Neha Gethe

╠²

The Diesel Locomotive Works (DLW) in Varanasi, India, is a production unit owned by Indian Railways, that manufactures diesel-electric locomotives and its spare parts. It is the largest diesel-electric locomotive manufacturer in India.

Locally it is called as D L W.

Multi point fuel injection

Multi point fuel injectionRAVI KUMAR

╠²

The document discusses multi-point fuel injection (MPFI) systems. It describes the components of an MPFI system, including the air intake system, pressure regulator system, control system, fuel pump control system, and functional divisions. An MPFI system injects fuel into individual cylinders based on commands from the engine control module. This provides faster throttle response and higher output under varying driving conditions compared to carburetor systems. The MPFI system can be divided into three main components: the electronic control unit, fuel system, and air induction system.BLW SUMMER TRAINING REPORT

BLW SUMMER TRAINING REPORTSIR CHHOTU RAM I E & Technology C C S U Meerut campus

╠²

This document is a summer internship report submitted by Iqubal Husain, a 2nd year mechanical engineering student, about his 4-week internship at Banaras Locomotive Works in Varanasi, India. The report includes an introduction to BLW, which was formerly known as Diesel Locomotive Works and now produces electric locomotives. It also describes some of the main shops at BLW, including the Maintenance Service Shop and Sheet Metal Shop, and provides details on key locomotives produced, such as the WAP-7 and WAG-9.DLW training report

DLW training reportIshant Gautam.

╠²

This 3 sentence summary provides an overview of the document:

The document is a summer field training report submitted by Ishant Gautam to the Department of Mechanical Engineering at Translam Institute of Technology & Management in Meerut, India. The report details Ishant Gautam's training experience at Diesel Locomotive Works in Varanasi, India, including backgrounds on DLW, its facilities, production processes, and products with a focus on locomotive design and manufacturing.DLW Summer training report

DLW Summer training reportEshver chandra

╠²

The document provides an overview of Diesel Locomotive Works (DLW) in Varanasi, India, which produces diesel-electric locomotives. DLW was established in 1961 through collaboration with American Locomotive Company and has since produced locomotives using both ALCO and Electro-Motive Division technologies. The document details the various types of locomotives produced at DLW, including their specifications and components.Training Report Maruti Suzuki (Imran Alam)

Training Report Maruti Suzuki (Imran Alam)IMRAN ALAM

╠²

The document provides an acknowledgement and preface for a project report on an automotive training completed at "Harisons Motor Panipat". It thanks the instructors and staff for their guidance and cooperation during the training period. The contents section outlines topics that will be covered in the report, including the history of Maruti Suzuki, vehicle specifications, engine systems, and other automotive parts and their functions.INDUSTRIA TRAINING PRESENTATION ON REGIONAL WORKSHOP OF UPSRTC.pptx

INDUSTRIA TRAINING PRESENTATION ON REGIONAL WORKSHOP OF UPSRTC.pptxSachinYadav490276

╠²

The UPSRTC workshop in Agra maintains and repairs roadway buses for Uttar Pradesh. The workshop has several sections for engine maintenance and repair, including the engine section, differential gear section, gear box section, and clutch section. The presentation described key engine parts like the cylinder block, piston, flywheel, crankshaft, and camshaft. It also provided specifications for the Tata TC 1312 engine model used in the buses, including the number of cylinders and bore size. The differential gear section houses gears that allow the average angular velocity of connected parts, while the clutch section contains mechanisms for transmitting rotation between rotating shafts.Loco workshop

Loco workshopDeepak Solanki

╠²

Presentation on the 'Loco Workshop' ,i.e. fabrication , assembly of parts and various departments such as dismantling, fabrication , assembly,etc..:):)More Related Content

What's hot (20)

Morse test r

Morse test rrawaabdullah

╠²

This document describes a Morse test conducted on an internal combustion engine to determine the engine's indicated power (IP), brake power (BP), and friction power (FP). The test involves running the engine at a constant speed and cutting the ignition to individual cylinders while adjusting the load to maintain speed. The difference in BP readings gives the IP of the cut cylinder. Summing the IP values yields the engine's total IP. Subtracting BP from IP provides FP, and the ratios of these values can be used to calculate mechanical efficiency. The objectives, conditions, introduction, theory, procedure, calculations, discussion and references related to the Morse test are detailed in the document.MULTI-POINT FUEL INJECTION SYSTEM

MULTI-POINT FUEL INJECTION SYSTEMMihir Patel

╠²

Multipoint fuel injection (MPFI) systems provide better control of the air-fuel ratio compared to carburetors. MPFI systems use multiple fuel injectors, with one injector per cylinder, to inject fuel into the engine's intake ports or manifold. This allows supplying the optimum air-fuel ratio to each cylinder for all operating conditions. MPFI systems are electronically controlled using sensors to monitor various engine parameters and optimize fuel delivery and emissions performance. While more complex than carburetors, MPFI systems improve fuel efficiency, power, and reduce emissions.automobile workshop ppt Traning report by c rang rajan and sudhir kumar

automobile workshop ppt Traning report by c rang rajan and sudhir kumarchakrawarti rang rajan

╠²

The document provides an overview of the key components and systems of an automobile. It begins with an introduction to Karlo Automobiles, an Indian vehicle repair workshop. It then defines an automobile and describes its main parts like the engine, transmission system including the clutch, gearbox, propeller shaft, differential, wheels, axle and chassis. The document further explains the body, suspension system, cooling system, steering system, braking system and lighting system of a car. Diagrams and pictures are included to illustrate the different components. The presentation aims to provide trainees an understanding of the various parts that make up a motor vehicle.Dlw locomotive workshop

Dlw locomotive workshopShivam Prajapati

╠²

This document is an industrial training report submitted by Himanshu S. Singh to Ramendra Kr. Visen on his training at the Diesel Locomotive Workshop in Varanasi. The report provides background on Indian Railways and the history and operations of the Diesel Locomotive Workshop, including its establishment, annual production capacity, manufacturing processes, and departments.Mahindra & Mahindra training report.

Mahindra & Mahindra training report.Prithvi Raj

╠²

The document provides an overview of Mahindra First Choice Services, which is part of Mahindra & Mahindra's aftermarket sector. It discusses the foundation and business units of Mahindra, as well as details about Mahindra First Choice Services workshops. The workshop operates in cycles, providing services such as engine repair, brake repair, steering/suspension work, air conditioning, wheel balancing, denting/painting, and car grooming. It describes the process a vehicle goes through from entry to exit and highlights the various engine and vehicle services performed.Explanation about different car body styles

Explanation about different car body stylesCar Leasing Made Simple

╠²

This document discusses and defines different car body styles including 4x4, city car, coupe, estate, hatchback, MPV, saloon, and sports car. It provides details on each style such as 4x4 having all-wheel drive for rough terrain, city cars being compact for urban use, coupes having two doors and two or four seats, estates having additional cargo space, and hatchbacks having rear doors that open upward. MPVs are designed for multiple purposes like passenger and cargo transport, saloons have separate bonnets and boots, and sports cars prioritize handling and speed over comfort.Mercedes benz service centre training report

Mercedes benz service centre training reportPanchal Anand

╠²

Industrial training (Internship) Report.

Mercedes_benz Service centre.

Abstract: As a Mechanical Engineering Student I am very interested in automobile Engineering. I always keen to learn different mechanisms used in vehicles, I used to watch animated videos on YouTube about automobile mechanisms like Differential, Automatic transmission gearbox etc, but I never watched it in real. So, it was a great opportunity for me to do two weeks internship at Mercedes-benz Service centre, Ambli, Ahmedabad. The internship was concentrated on the car services. At the beginning of the internship I had several queries in my mind regarding the different technologies used in Mercedes-benz and what skills are needed in organization. During my internship several queries are cleared by doing some activities. The objective of this internship is to understand working of different mechanisms, to get knowledge of regular services and the major-minor problem that can be observed in day to day life. Apart from technical knowledge, I also learnt rules and safety instruction, Inventory management, Quality Control. I realize the responsibility of technicians working on the car. So, this internship was a great experience. I found out how much I am strong in automobile field. I gained new knowledge and skills and met many new people. Working together with people having different background and education was great experience. I also accompanied by other 2-3 students who were also on industrial training, so it was nice knowledge sharing. I achieved many of my learning goals. I got insight into the work of an organization. At last this internship has given me new insights and motivation to pursue a career in mechanical engineering.Steering System ( Anil Sharma )

Steering System ( Anil Sharma )ANIL SHARMA

╠²

This document discusses the steering system of a vehicle. It defines steering as converting the rotary movement of the steering wheel into angular turn of the front wheels. The steering system must multiply turning effort, be somewhat irreversible to shocks, and allow turning at the driver's will. There are two common steering mechanisms: Davis and Ackermann gears. Camber and caster angles are also discussed to explain how wheels are oriented for stability and wear. The document provides details on various components and specifications of a basic automotive steering system.UPSRTC LUCKNOW

UPSRTC LUCKNOWFaraz Khan

╠²

The document summarizes an industrial training presentation on the regional workshop of UPSRTC in Lucknow, India. The workshop services and maintains roadway passenger vehicles. It has sections for engine, differential gear, gear box, and clutch maintenance and repair. The engine section services parts like the cylinder head, oil pump, pistons, crankshaft, and camshaft. The differential gear distributes torque across the rear axles. The clutch connects and disconnects two rotating shafts to either lock or decouple their speeds.Power Steering

Power SteeringAnupam Kaler

╠²

The document provides an overview of power steering systems. It discusses the history of power steering from its invention in the early 1900s to its use in automobiles and agricultural vehicles. The key components of power steering systems are described including the reservoir, steering gearbox, rotary valve, and pump. The main types of power steering systems - hydraulic, electro-hydraulic, and electric - are outlined along with diagrams of how each system works. Advantages like reduced driver fatigue and continuous steering are balanced with potential disadvantages such as leakage and vibration.Multipurpose mechanical machine

Multipurpose mechanical machineganeshkhutwad18

╠²

This project is done by the mechanical diploma engineering student of tssm's bscoer poly., pune

design and development of multipurpose mechanical machine

last year project-2017-18

it is the best project for the engineering student for the last year by modification as per the needSummer Training Report for Diploma (mechanical) Students

Summer Training Report for Diploma (mechanical) StudentsKashifRaza113

╠²

This Training is completed at UPSRTC (Lucknow) by a student of polytechnic(mechanical) from Integral University Lucknow. UPSRTC is a Government Organisation for Public Transport in Uttar Pradesh. Layout

LayoutAjay Yadav

╠²

The document provides an overview of the key components and systems of an automobile, including:

- The basic structure or chassis, which includes the frame, suspension system, axles, wheels, and tires.

- The power unit, typically an internal combustion engine.

- The transmission system, which includes the clutch, gearbox, propeller shaft, and differential.

- Auxiliary components like the controls and superstructure that are mounted on the chassis.

It also discusses different suspension types, powertrain configurations like front-engine rear-wheel drive, and ways that automobiles can be classified.Automobile chassis frame

Automobile chassis framejjHF47

╠²

The document discusses automobile chassis frames. It defines a frame as the undercarriage or structure that supports the engine, cab, and body of a vehicle. There are three main types of frames: conventional frames with side members and cross members, integral frames where all components attach directly to the body, and semi-integral frames that have a partial front frame. The document outlines the functions of frames, provides examples of frame designs, and describes the materials, design considerations, and manufacturing processes involved in building frames, including cutting, bending, welding, and inspection stages. It concludes with details from a field visit to an automotive manufacturing plant. Diesel Locomotive Works (DLW)

Diesel Locomotive Works (DLW)Neha Gethe

╠²

The Diesel Locomotive Works (DLW) in Varanasi, India, is a production unit owned by Indian Railways, that manufactures diesel-electric locomotives and its spare parts. It is the largest diesel-electric locomotive manufacturer in India.

Locally it is called as D L W.

Multi point fuel injection

Multi point fuel injectionRAVI KUMAR

╠²

The document discusses multi-point fuel injection (MPFI) systems. It describes the components of an MPFI system, including the air intake system, pressure regulator system, control system, fuel pump control system, and functional divisions. An MPFI system injects fuel into individual cylinders based on commands from the engine control module. This provides faster throttle response and higher output under varying driving conditions compared to carburetor systems. The MPFI system can be divided into three main components: the electronic control unit, fuel system, and air induction system.BLW SUMMER TRAINING REPORT

BLW SUMMER TRAINING REPORTSIR CHHOTU RAM I E & Technology C C S U Meerut campus

╠²

This document is a summer internship report submitted by Iqubal Husain, a 2nd year mechanical engineering student, about his 4-week internship at Banaras Locomotive Works in Varanasi, India. The report includes an introduction to BLW, which was formerly known as Diesel Locomotive Works and now produces electric locomotives. It also describes some of the main shops at BLW, including the Maintenance Service Shop and Sheet Metal Shop, and provides details on key locomotives produced, such as the WAP-7 and WAG-9.DLW training report

DLW training reportIshant Gautam.

╠²

This 3 sentence summary provides an overview of the document:

The document is a summer field training report submitted by Ishant Gautam to the Department of Mechanical Engineering at Translam Institute of Technology & Management in Meerut, India. The report details Ishant Gautam's training experience at Diesel Locomotive Works in Varanasi, India, including backgrounds on DLW, its facilities, production processes, and products with a focus on locomotive design and manufacturing.DLW Summer training report

DLW Summer training reportEshver chandra

╠²

The document provides an overview of Diesel Locomotive Works (DLW) in Varanasi, India, which produces diesel-electric locomotives. DLW was established in 1961 through collaboration with American Locomotive Company and has since produced locomotives using both ALCO and Electro-Motive Division technologies. The document details the various types of locomotives produced at DLW, including their specifications and components.Training Report Maruti Suzuki (Imran Alam)

Training Report Maruti Suzuki (Imran Alam)IMRAN ALAM

╠²

The document provides an acknowledgement and preface for a project report on an automotive training completed at "Harisons Motor Panipat". It thanks the instructors and staff for their guidance and cooperation during the training period. The contents section outlines topics that will be covered in the report, including the history of Maruti Suzuki, vehicle specifications, engine systems, and other automotive parts and their functions.Similar to indutrial training report (20)

INDUSTRIA TRAINING PRESENTATION ON REGIONAL WORKSHOP OF UPSRTC.pptx

INDUSTRIA TRAINING PRESENTATION ON REGIONAL WORKSHOP OF UPSRTC.pptxSachinYadav490276

╠²

The UPSRTC workshop in Agra maintains and repairs roadway buses for Uttar Pradesh. The workshop has several sections for engine maintenance and repair, including the engine section, differential gear section, gear box section, and clutch section. The presentation described key engine parts like the cylinder block, piston, flywheel, crankshaft, and camshaft. It also provided specifications for the Tata TC 1312 engine model used in the buses, including the number of cylinders and bore size. The differential gear section houses gears that allow the average angular velocity of connected parts, while the clutch section contains mechanisms for transmitting rotation between rotating shafts.Loco workshop

Loco workshopDeepak Solanki

╠²

Presentation on the 'Loco Workshop' ,i.e. fabrication , assembly of parts and various departments such as dismantling, fabrication , assembly,etc..:):)INDUSTRIAL TRAINING AT KSRTC

INDUSTRIAL TRAINING AT KSRTCSarin John Skaria

╠²

The document summarizes an in-plant training report at the KSRTC Regional Workshop in Mavelikkara, Kerala from June 28th to July 7th. It describes the various maintenance sections at the workshop including the engine assembly, gearbox, propeller shaft, small units like air brakes and clutches, front axle, differential, fuel injection, electrical, steering, suspension, and body building sections. The training provided hands-on experience of repairing and maintaining different parts of KSRTC buses. It was a valuable opportunity for the trainees to apply their engineering knowledge and gain practical skills relevant to their future careers.cat presentation final.pptx

cat presentation final.pptxSAVANTPANWAR

╠²

contains basic knowledge of engine and different parts and system involved like fuel system, lube system, cooling system, combustion process, air system and circulation , working of external components of engine, reason and symptoms of wear of parts and components. This presentation is made to give the explanation of work done or things learnt during training in prestigious Gainwell Caterpillar.Training report FOR TTC HISAR

Training report FOR TTC HISARLFC Shams

╠²

This training report provides a summary of a 4-week training program conducted at the Northern Region Farm Machinery Training and Testing Institute in Hisar, Haryana, India from July 1-26, 2019. The training covered key topics in agricultural engineering including farm power, tractors, tractor systems (engine, transmission, hydraulics, brakes), tractor maintenance, and farm implements (tillage, harvesting, irrigation). The report provides details on dismantling and assembling a Kirloskar diesel engine and outlines the main components and functions of various tractor systems.Engine service and overshuling

Engine service and overshulingShahid Akram

╠²

Engine service and overhauling involves regularly maintaining a vehicle's engine through procedures like replacing parts. Overhauling specifically involves completely disassembling the engine, testing and replacing components as needed, and reassembling it to improve performance and longevity. The process requires various tools and involves carefully removing, inspecting, cleaning, measuring, and reinstalling all engine parts to factory specifications. Proper service and overhauling helps prevent sudden engine failures and keeps it functioning optimally for longer.Simpson Internship Report

Simpson Internship ReportAkshadha Krishnaswamy

╠²

The intern thanks various managers and departments at Simpson for providing guidance during their internship. Simpson manufactures diesel engines at two plants in Chennai. The intern spent three weeks touring departments like assembly, machine shop, and quality control to understand the engine manufacturing process. They then spent three weeks on a project for the materials department developing a statistical forecasting model to predict component procurement needs. The model used moving average forecasting on two years of fuel injection pump part data to estimate procurement quantities for the next year.03 engine bottom end

03 engine bottom endEmmanuel Kolo

╠²

The document discusses the key components that make up the bottom end of an engine, including the engine block, crankshaft, connecting rods, pistons, rings, and bearings. It describes the materials, functions, and terminology associated with each part. The crankshaft converts the reciprocating motion of the pistons into rotational motion to power the vehicle. Pistons harness the energy of combustion and transfer force to the crankshaft via connecting rods. Precise clearances and alignments are needed for proper engine operation and longevity.Dev kumar mahato assembly 2

Dev kumar mahato assembly 2Dev kumar

╠²

The document provides instructions for assembling an engine. It discusses cleaning and preparing engine components before assembly, installing core plugs and seals, assembling cylinder heads and installing valves, installing pistons and rings, attaching the heads to the block, installing rocker arms and adjusting valves, pre-oiling the engine, and testing the engine on a run-in stand. The document provides detailed steps and considerations for properly assembling the various engine components.Patri ppt2

Patri ppt2NISHANT552

╠²

The document provides information about Honda Cars India Limited's summer internship presentation. It discusses Honda's global operations and history. It then focuses on Honda's manufacturing unit in India, located in Tapukara, Rajasthan. The production flow and various production shops like Press, Aluminum, Engine, Paint, and Assembly are described. Key aspects of the Engine Assembly shop like the assembly line layout, tools and equipment used, and assembly processes followed are explained in detail.Koushik 20151026-093718

Koushik 20151026-093718koushik17

╠²

This document appears to be an industrial training report submitted by a student named Koushik Bibra after completing an internship at H.R.T.C. Dharamshala. The report includes an acknowledgements section, abstract, and sections covering the main parts of an automobile including the chassis, engine, transmission system, propeller shaft, differential, brakes, suspension system, and steering system. Diagrams and descriptions of these systems are provided.parts of ic engine

parts of ic engineTanveer Hussain

╠²

This document provides an overview of the key components of an internal combustion (IC) engine in an automobile. It lists and describes the main components, including the engine block, crankshaft, connecting rod, piston, piston rings, valves, camshaft, cylinder head, intake and exhaust manifolds, radiator, spark plugs, fuel system components, and more. The purpose is to familiarize mechanical engineering students with the basic parts of an engine and their basic functions.HMt training p pt

HMt training p ptHarpreet Singh

╠²

The document provides information about Harpreet Singh's training report at Hindustan Machine Tools (HMT) Pinjore division from June 2nd to July 11th, 2014. It discusses the company profile and various divisions of HMT including the Tractor Division, Engine Shop, Heavy Machine Shop, Engine Assembly, and Heat Treatment processes. The key activities at each division involve manufacturing and assembling various components for tractors through machining and other processes.Keeway superlight 125 service manual

Keeway superlight 125 service manualDaniel Rosario

╠²

This document provides a service and maintenance manual for a Superlight125/150 motorcycle. It begins with contact information for technical assistance. The contents section lists topics to be covered, including general information, products, service rules, and electrical work. Diagrams are provided to illustrate engine parts and cycles. Safety warnings are given for proper service. The tools list identifies special tools needed to disassemble and reassemble the engine. Finally, torque specifications are provided for critical fasteners in the engine and crankcase.UNIT-1-VEHICLE STRUCTURE AND ENGINES.ppt

UNIT-1-VEHICLE STRUCTURE AND ENGINES.pptDineshKumar4165

╠²

Types of automobiles, vehicle construction and different layouts, chassis, frame and body, resistances to vehicle aerodynamics (various resistances and moments involved), IC engines-components functions and materials, variable valve timing (VVT).Engine Introduction.pptx

Engine Introduction.pptxSujit Regmi

╠²

This document provides an overview of diesel engine components and systems. It discusses the key parts of an engine including the cylinder head, block, valves, pistons, crankshaft, and injectors. It also describes the working principles of a compression ignition engine. The document reviews the major engine systems like air intake, lubrication, cooling, and fuel. It provides details on maintenance procedures such as engine dismantling and component measurements.Engine Introduction.pptx

Engine Introduction.pptxSujit Regmi

╠²

This document provides an overview of diesel engine components and systems. It discusses the working principle of a compression ignition engine. It describes major engine components like the cylinder head, block, valves, injectors, pistons, crankshaft and others. It outlines the procedures for engine dismantling and construction details. It also explains the air intake, lubrication, cooling and fuel systems of the engine.Recently uploaded (20)

Learning Spark- Lightning-Fast Big Data Analysis -- Holden Karau, Andy Konwin...

Learning Spark- Lightning-Fast Big Data Analysis -- Holden Karau, Andy Konwin...balbaliadam1980

╠²

big data1.9 Class,Object,Class Scope,Accessing Class members and Controlling access t...

1.9 Class,Object,Class Scope,Accessing Class members and Controlling access t...VikasNirgude2

╠²

Class,Object,Class Scope,Accessing Class members and Controlling access to membersInternational Journal of Advance Robotics & Expert Systems (JARES)

International Journal of Advance Robotics & Expert Systems (JARES)jaresjournal868

╠²

#robot #robotics #robots #art #technology #engineering #arduino #ai #toys #transformers #mecha

#d #scifi #anime #robotic #digitalart #electronics #tech #lego #gundam #drawing #artificialintelligence

#illustration #mainananak #automation #s #toyphotography #robotik #innovation #design

Call For Papers!!!

International Journal of Advance Robotics & Expert Systems (JARES)

Web page Link: http://airccse.com/jares/index.html

Submission Deadline :June17, 2025

submission Link: http://airccse.com/submission/home.html

Contact Us : jaresjournal@yahoo.com or eicjares@airccse.com or jares@aircconline.com

MODULE 4 BUILDING PLANNING AND DESIGN SY BTECH HVAC SYSTEM IN BUILDING

MODULE 4 BUILDING PLANNING AND DESIGN SY BTECH HVAC SYSTEM IN BUILDINGDr. BASWESHWAR JIRWANKAR

╠²

Module4: Ventilation

Definition, necessity of ventilation, functional requirements, various system & selection criteria.

Air conditioning: Purpose, classification, principles, various systems

Thermal Insulation: General concept, Principles, Materials, Methods, Computation of Heat loss & heat gain in BuildingsAdvanced Concrete Technology- Properties of Concrete

Advanced Concrete Technology- Properties of ConcreteBharti Shinde

╠²

Properties of Concrete, Wet and dry process of cement manufacturing, BogueŌĆÖs compoundVideo Games and Artificial-Realities.pptx

Video Games and Artificial-Realities.pptxHadiBadri1

╠²

¤Ģ╣’ĖÅ #GameDevs, #AIteams, #DesignStudios ŌĆö IŌĆÖd love for you to check it out.

This is where play meets precision. LetŌĆÖs break the fourth wall of slides, together. BEC602- Module 3-2-Notes.pdf.Vlsi design and testing notes

BEC602- Module 3-2-Notes.pdf.Vlsi design and testing notesVarshithaP6

╠²

Vlsi design and testing notes Introduction-to-Prestressed-Concrete.pdf

Introduction-to-Prestressed-Concrete.pdfBharti Shinde

╠²

Prestressed concrete, Pretension and PosttensioningBetter Builder Magazine, Issue 53 / Spring 2025

Better Builder Magazine, Issue 53 / Spring 2025Better Builder Magazine

╠²

Better Builder Magazine brings together premium product manufactures and leading builders to create better differentiated homes and buildings that use less energy, save water and reduce our impact on the environment. The magazine is published four times a year.ENERGY STORING DEVICES-Primary Battery.pdf

ENERGY STORING DEVICES-Primary Battery.pdfTAMILISAI R

╠²

ENERGY STORING DEVICES

Batteries -Introduction ŌĆō Cells ŌĆō Batteries ŌĆōTypes of Batteries- Primary batteries ŌĆō silver button cell[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)![[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)](https://cdn.slidesharecdn.com/ss_thumbnails/lokfittingen-250528072439-8696f1c6-thumbnail.jpg?width=560&fit=bounds)

![[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)](https://cdn.slidesharecdn.com/ss_thumbnails/lokfittingen-250528072439-8696f1c6-thumbnail.jpg?width=560&fit=bounds)

![[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)](https://cdn.slidesharecdn.com/ss_thumbnails/lokfittingen-250528072439-8696f1c6-thumbnail.jpg?width=560&fit=bounds)

![[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)](https://cdn.slidesharecdn.com/ss_thumbnails/lokfittingen-250528072439-8696f1c6-thumbnail.jpg?width=560&fit=bounds)

[HIFLUX] Lok Fitting&Valve Catalog 2025 (Eng)ĒĢśņØ┤Ēöīļ¤ŁņŖż / HIFLUX Co., Ltd.

╠²

Lok Fitting, VCR Fitting, Pipe FittingConcept Learning - Find S Algorithm,Candidate Elimination Algorithm

Concept Learning - Find S Algorithm,Candidate Elimination AlgorithmGlobal Academy of Technology

╠²

Concept Learning

Find S Algorithm

Candidate Elimination Algorithmelastic-plasticfracturemechanics-170722055208.pdf

elastic-plasticfracturemechanics-170722055208.pdflsolanoni

╠²

ingenieria mecanica electrica, ingenieria mecanicaDE-UNIT-V MEMORY DEVICES AND DIGITAL INTEGRATED CIRCUITS

DE-UNIT-V MEMORY DEVICES AND DIGITAL INTEGRATED CIRCUITSSridhar191373

╠²

Basic memory structure ŌĆō ROM -PROM ŌĆō EPROM ŌĆō EEPROM ŌĆōEAPROM, RAM ŌĆō Static and dynamic RAM - Programmable Logic Devices ŌĆō Programmable Logic Array (PLA) - Programmable Array Logic (PAL) ŌĆō Field Programmable Gate Arrays (FPGA) ŌĆō Implementation of combinational logic circuits using PLA, PAL. Digital integrated circuits: Logic levels, propagation delay, power dissipation, fan-out and fan-in, noise margin, logic families and their characteristics ŌĆō RTL, TTL, ECL and CMOS.

Department of Environment (DOE) Mix Design with Fly Ash.

Department of Environment (DOE) Mix Design with Fly Ash.MdManikurRahman

╠²

Concrete Mix Design with Fly Ash by DOE Method. The Department of Environmental (DOE) approach to fly ash-based concrete mix design is covered in this study.

The Department of Environment (DOE) method of mix design is a British method originally developed in the UK in the 1970s. It is widely used for concrete mix design, including mixes that incorporate supplementary cementitious materials (SCMs) such as fly ash.

When using fly ash in concrete, the DOE method can be adapted to account for its properties and effects on workability, strength, and durability. Here's a step-by-step overview of how the DOE method is applied with fly ash.Attenuation Models for Estimation of Vertical Peak Ground Acceleration Based ...

Attenuation Models for Estimation of Vertical Peak Ground Acceleration Based ...Journal of Soft Computing in Civil Engineering

╠²

Peak ground acceleration (PGA) is a critical parameter in ground-motion investigations, in particular in earthquake-prone areas such as Iran. In the current study, a new method based on particle swarm optimization (PSO) is developed to obtain an efficient attenuation relationship for the vertical PGA component within the northern Iranian plateau. The main purpose of this study is to propose suitable attenuation relationships for calculating the PGA for the Alborz, Tabriz and Kopet Dag faults in the vertical direction. To this aim, the available catalogs of the study area are investigated, and finally about 240 earthquake records (with a moment magnitude of 4.1 to 6.4) are chosen to develop the model. Afterward, the PSO algorithm is used to estimate model parameters, i.e., unknown coefficients of the model (attenuation relationship). Different statistical criteria showed the acceptable performance of the proposed relationships in the estimation of vertical PGA components in comparison to the previously developed relationships for the northern plateau of Iran. Developed attenuation relationships in the current study are independent of shear wave velocity. This issue is the advantage of proposed relationships for utilizing in the situations where there are not sufficient shear wave velocity data.Attenuation Models for Estimation of Vertical Peak Ground Acceleration Based ...

Attenuation Models for Estimation of Vertical Peak Ground Acceleration Based ...Journal of Soft Computing in Civil Engineering

╠²

indutrial training report

- 1. INDUSTRIAL TRAINING REPORT SUBITTED TO: SUBMITTED BY:kanwaldeep singh MR.RAJEEV K DANG SG12927 MR. GAURAV SAINI MECHANICAL 5TH SEM

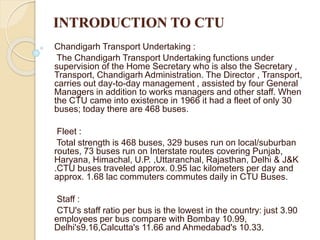

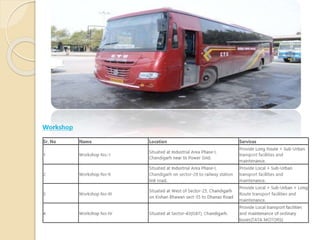

- 2. INTRODUCTION TO CTU Chandigarh Transport Undertaking : The Chandigarh Transport Undertaking functions under supervision of the Home Secretary who is also the Secretary , Transport, Chandigarh Administration. The Director , Transport, carries out day-to-day management , assisted by four General Managers in addition to works managers and other staff. When the CTU came into existence in 1966 it had a fleet of only 30 buses; today there are 468 buses. Fleet : Total strength is 468 buses, 329 buses run on local/suburban routes, 73 buses run on Interstate routes covering Punjab, Haryana, Himachal, U.P. ,Uttaranchal, Rajasthan, Delhi & J&K .CTU buses traveled approx. 0.95 lac kilometers per day and approx. 1.68 lac commuters commutes daily in CTU Buses. Staff : CTU's staff ratio per bus is the lowest in the country: just 3.90 employees per bus compare with Bombay 10.99, Delhi's9.16,Calcutta's 11.66 and Ahmedabad's 10.33.

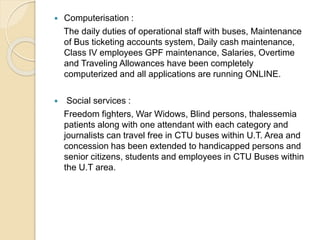

- 3. ’éŚ Computerisation : The daily duties of operational staff with buses, Maintenance of Bus ticketing accounts system, Daily cash maintenance, Class IV employees GPF maintenance, Salaries, Overtime and Traveling Allowances have been completely computerized and all applications are running ONLINE. ’éŚ Social services : Freedom fighters, War Widows, Blind persons, thalessemia patients along with one attendant with each category and journalists can travel free in CTU buses within U.T. Area and concession has been extended to handicapped persons and senior citizens, students and employees in CTU Buses within the U.T area.

- 7. MAIN SHOPS IN C.T.U WORKSHOP ’éŚ ENGINE SHOP ’éŚ GEAR SHOP ’éŚ WELDING SHOP ’éŚ PAINT SHOP ’éŚ TYRE SHOP ’éŚ ELECTRICAL SHOP ’éŚ A-SERVICE ’éŚ B-SERVICE

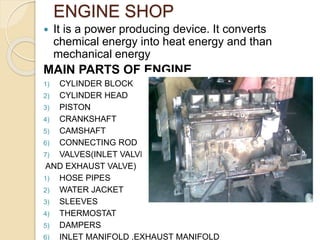

- 8. ENGINE SHOP ’éŚ It is a power producing device. It converts chemical energy into heat energy and than mechanical energy MAIN PARTS OF ENGINE 1) CYLINDER BLOCK 2) CYLINDER HEAD 3) PISTON 4) CRANKSHAFT 5) CAMSHAFT 6) CONNECTING ROD 7) VALVES(INLET VALVE AND EXHAUST VALVE) 1) HOSE PIPES 2) WATER JACKET 3) SLEEVES 4) THERMOSTAT 5) DAMPERS 6) INLET MANIFOLD ,EXHAUST MANIFOLD

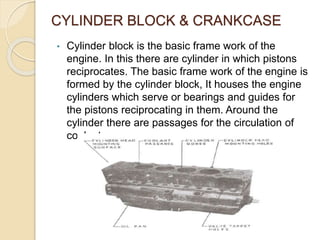

- 9. CYLINDER BLOCK & CRANKCASE ŌĆó Cylinder block is the basic frame work of the engine. In this there are cylinder in which pistons reciprocates. The basic frame work of the engine is formed by the cylinder block, It houses the engine cylinders which serve or bearings and guides for the pistons reciprocating in them. Around the cylinder there are passages for the circulation of coolant.

- 10. ’éŚ CYLINDER HEAD To form a combustion chamber above each cylinder the cylinder head is above the engine. ŌĆó OIL SUMP it is at the bottom of the engine. it is used to store the oil to collect the return oil

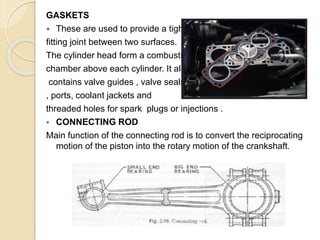

- 11. GASKETS ’éŚ These are used to provide a tight fitting joint between two surfaces. The cylinder head form a combustion chamber above each cylinder. It also contains valve guides , valve seals , ports, coolant jackets and threaded holes for spark plugs or injections . ’é¦ CONNECTING ROD Main function of the connecting rod is to convert the reciprocating motion of the piston into the rotary motion of the crankshaft.

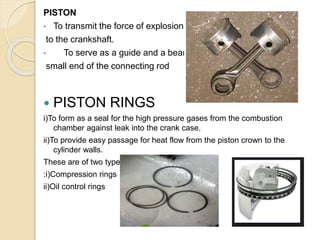

- 12. PISTON ŌĆó To transmit the force of explosion to the crankshaft. ŌĆó To serve as a guide and a bearing for small end of the connecting rod ’éŚ PISTON RINGS i)To form as a seal for the high pressure gases from the combustion chamber against leak into the crank case. ii)To provide easy passage for heat flow from the piston crown to the cylinder walls. These are of two types :i)Compression rings ii)Oil control rings

- 13. CRANK SHAFT ’éŚ It is the engine component from which the power is taken .It receives the power from the connecting rods to the clutch and to the wheels. VISCOUS FAN ’éŚ It is attached in the front of the engine. Its main function is cooling the engine. It is driven by a V-belt from the crankshaft pulley. It may have four to seven blades. MATERIAL It is generally made of sheet metal but these days mounted plastic material e.g. nylon or polypropylene are also being used for making fans.

- 14. ’éŚ PROCEDURE FOR DISMANTALLING THE ENGINE Following is the procedure for the dismantling of the engine: i) First of all caps are removed from the each valve with the help of spanner. ii) After this all the valve springs are removed with the help of valve spring remover and all the cotters are removed. These can also remove with the help of striking hammer on the top of the valves Springs. iv)The fuel injection pump is removed from the engine v)The oil cooler is removed by means of unscrewing the bolt sand nuts vi)Cylinder head is removed from the engine with this all the rocker arms are also removed. vii)After this the pistons are removed by opening the bearing from the crankshaft with the connecting rods & camshaft is removed . viii)At the end the crankshaft is removed from the cylinder block. x)After this all the parts of engine are washed with the help of diesel.

- 15. ’éŚ PROCEDURE FOR ASSEMBLY OF ENGINE Following is the procedure for the assembly of the engine. i)First of all the engine cylinder is kept on the table .ii)The cylinder boxes are checked with the help of dial gauge according to the given specifications. iii)After this the crankshaft bearings are checked with the help of dial gauge. iv)The crankshaft is fixed in the crankshaft bearing in the centre of the main bearing the thrust washer is fixed. v)After this the pistons are inserted in to the cylinders opf the engine and the connecting rod is connected to the piston with the help of piston pin and the crankshaft is connected to the Big end bearing of the connecting rod .vi)After this the water plate is connected to the engine

- 16. vii)After this the flywheel is connected to the crankshaft and clutch plate is also adjusted in to the engine. viii)After this the camshaft is connected to the engine and the air compressed piston is connected with the camshaft. ix)Camshaft is closed from both end and the gears are connectedwith the crankshaft and camshaft and the timing is adjusted .x)At the other side the two pulley are there by means of cylinder head is kept over the cylinder block by insertingthe nozzles and valves and rocker arms into the cylinder head .xii)The fuel injection pump is connected to the engine and theoil cooling plate is inserted into the engine. xiii)The injectors from the fuel injection pump is connected to the each nozzles by mean of fuel pipe.

- 17. ’éŚINSPECTION OF VARIOUS PARTS OF ENGINE 1.Inspection of the cylinder boring honing of the cylinder bore gone oval in shop inserting the cylinder liner or sleeve. 2. Inspection of the piston changing of piston if necessary. 3. Crank shaft grinding 4. Cam shaft grinding 5. Inspection of water gasket sand oil, galleried 6. Checking the valve mechanism. 7. Gasket and lubricating oil are changed after over hauling. 8. Inspection and replacing of the bearing. 9. Rings are settled with the held of piston ring compressor. 10. Piston ring expands is used for removing ring from piston.

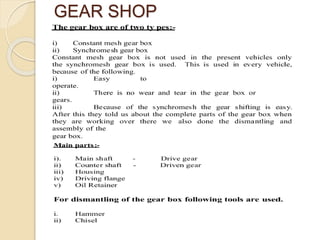

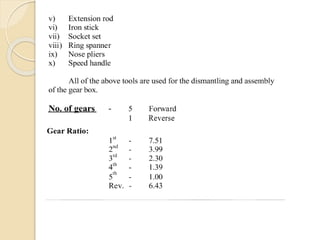

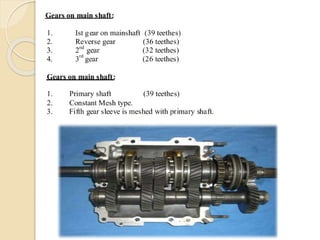

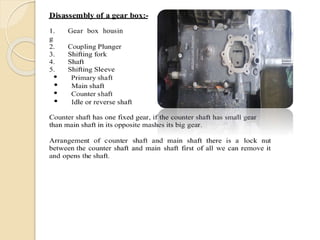

- 18. GEAR SHOP

- 23. CONCLUSION In my industrial training, I was introduced to industrial environment. I learned discipline and cooperation during my industrial training and I felt good when I came in contact with engineers and workers of workshop. Most importantly I had learned the process of doing work in big workshops with sound knowledge of Engine Shop and Gear Shop which will be useful for me when ever I will go to any industry or workshop as an employee.