Kes

- 1. Shipping: Process to Pull MRLĪ»s & Requisitions November 2011 Kaizen Event

- 2. Preparation Work: Establish the Need (Business case). Performance Metrics. Demand Value Statement, Key ReqmĪ»ts, Collect Team Member Ideas Outline of the Week

- 3. Day 1 : Grasp the Current State Map the current state Spaghetti Diagrams Map the Information & Material Flow Study each process step. Process cycle times, WIP, total flow time, etc Statement of the Ideal Create Future State Day 2: Big Changes (make the change) Day 3: Run the new process Day 4: Standardize & Train ©C Stabilize new process Day 5: Report results. Outline of the Week

- 4. Business Case Growth is expected: From $120 M to $200 M approx 15-20% / year Market Pressures Drive: Complexity Speed Quality Pricing Create a process capable of making: perfect shipments, more often, with less effort. Shipments 2010 2011 2012 Parts Shipped / month 210,000 220,000 235,000

- 5. Value Statement What Value does the Shipping Team bring to HF and The customers? Product Knowledge JIT Delivery in Perfect Condition With product knowledegable personnel we will deliver to our customer the products when wanted, where wanted, and in perfect condition.

- 6. Stand Up Rack V S M

- 7. Requisition V S M

- 8. Key Requirements Billing and shipping Must be in the same month Transport Weight RqmtĪ»s (DOT) 4,000#/ Basket 3,500# Basket for CA (only) HF Basket / handling system (Physical /Mech) API Aware of 8Ī» support RqmĪ»t Maintain FIFO

- 9. Performance Metrics Quality: Order Accuracy Current : 35-65 errors / Wk Target: Less than 5 errors / Wk Delivery: Time to Pull (Single route) Current: Brownsfield Range from 3:20Ī» - 5:30Ī» Hobbs Range 4:45Ī» - 7:20Ī» Productivity: Parts / man hour Line Items / man hour

- 10. Statement of the Ideal On Demand: JIT Flow: Simple & Direct Defect Free 1 by 1 Easy & Low Cost methods

- 11. Was

- 12. Shipping Dock

- 13. Bundling Area

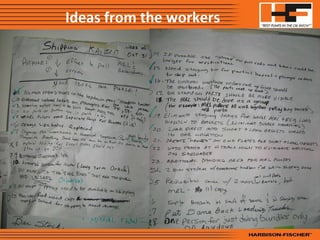

- 14. Ideas from the workers On Demand: JIT Flow: Simple & Direct Defect Free 1 by 1 Easy & Low Cost methods

- 16. Moving the racks

- 17. Current State

- 19. After Kaizen MRL Stations

- 20. After Kaizen Stand Up

- 21. After Kaizen Dock Area