Keyless Locking Device Training_Level 1

- 1. Keyless Locking Devices Application Training

- 2. Climax Metal Products Company... Who are We? ŌĆó Established in 1946, Climax Metal Products Company is an ISO 9001:2008 certified manufacturing company ŌĆó In June 2011 Climax joined forces with MAV S.p.A. in Italy, a worldwide leader in the design and manufacturing of KLDs and related products for over 30 years ŌĆó Division of RBC Bearings Company Oxford, Connecticut ŌĆó Located in Mentor, Ohio ŌĆó Thousands of SKUs in inventory ŌĆó Custom applications to meet your special needs ŌĆó Customer Service Representatives and Outside Sales Representatives trained to answer your questions

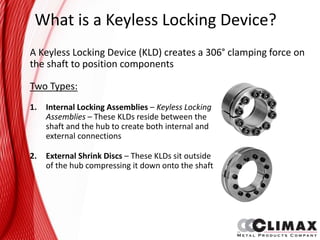

- 3. What is a Keyless Locking Device? A Keyless Locking Device (KLD) creates a 306┬░ clamping force on the shaft to position components Two Types: 1. Internal Locking Assemblies ŌĆō Keyless Locking Assemblies ŌĆō These KLDs reside between the shaft and the hub to create both internal and external connections 2. External Shrink Discs ŌĆō These KLDs sit outside of the hub compressing it down onto the shaft

- 4. KLDs Provide Advantages over Traditional Shaft/Hub Connections ŌĆó Keys/Keyways/Setscrews ŌĆó Splines ŌĆó Shrink or Press Fits ŌĆó QD/Taperlock Bushings ŌĆó Hex Nut Keyless Bushings

- 5. Keys, Keyways, and Set screws ŌĆó While inexpensive, keyways are subject to wallowing out over time when subject to reversing and start/stop motion ŌĆó The erosion of keyways can cause backlash and fretting ŌĆó In some cases, this fretting can lead to cold welding of the hub to the shaft, or even fracturing of the shaft itself The KLD Advantage: Because KLDs do not require a keyway, these problems are not present when they replace keyways and setscrews

- 6. Splines ŌĆó Both shaft and drive elements must be machined, which is costly and time consuming ŌĆó Splines also have backlash and associated problems ŌĆó Splines cannot be repaired in the field The KLD Advantage: It is simple and quick to replace a KLD because no machining is required

- 7. Shrink or Press Fits ŌĆó These fits require close tolerances and expensive finished ŌĆó The applications for shrink fits (heat/dry ice) are expensive, cumbersome, and potentially hazardous ŌĆó Dismounting/reinstallation in the field is difficult and time consuming. The KLD Advantage: KLDs are quick, safe, and easy to install and disassemble with no need for treatment

- 8. QD or Taperlock Bushings ŌĆó Keyways are still required; wallowing occurs which can eventually lead to fretting and backlash ŌĆó These designs require either a tapered bore in the component or a mating weld-on hub ŌĆó They are not meant to transmit reverse bending loads The KLD Advantage: Without keyways or a need for a modified bore in the component, KLDs are flexible for any design

- 9. Hex Nut Keyless Bushings ŌĆó It is difficult to apply measured torque to a tightening nut ŌĆó Hex nut keyless bushings are not self-locking; dynamic loading can loosen the connection The KLD Advantage: KLDs are self-locking and have a number of separate locking screws so measuring torque during installation is simple

- 10. Working Principle of a Keyless Locking Assembly ŌĆó Tapered rings work like wedges to convert clamp loads into radial contact pressure ŌĆō As the screws are tightened, the wedges come together to tighten down on the shaft as well as expand into the hub of the component ŌĆó When the specified screw tightening the torque is reached, the predetermined load capacity is achieved

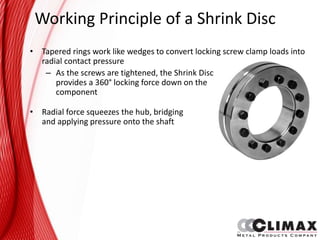

- 11. Working Principle of a Shrink Disc ŌĆó Tapered rings work like wedges to convert locking screw clamp loads into radial contact pressure ŌĆō As the screws are tightened, the Shrink Disc provides a 360┬░ locking force down on the component ŌĆó Radial force squeezes the hub, bridging and applying pressure onto the shaft

- 12. Assembly and Disassembly ŌĆó Mating components should be machined with a straight-bore ŌĆō Locking assemblies can be installed over a keyed shaft ŌĆó Locking assemblies drop in with generous clearance fits and are typically installed with machine oil on all mating components ŌĆó Shrink Discs demand tighter machining tolerances to limit diametrical clearance and are typically installed with clean and dry shaft/hub interface ŌĆó By loosing the screws, all KLDs are easily disassembled ŌĆó All KLDs are shipped with written instructions

- 13. Sales Tips & TechniquesŌĆ” Why your customers want Climax Keyless Locking Devices ŌĆó Product Breadth and Availability ŌĆō Located east of Cleveland, Ohio we have thousands of KLD SKUs ŌĆō Shipped from inventory same day ŌĆō Drop shipments at no additional charge ŌĆō Most extensive coverage in both imperial and metric sizes ŌĆō No minimum required ŌĆó Price ŌĆō Fair market price ŌĆō Products consistently provide excellent profit margins ŌĆó Customer Service ŌĆō Over 70 years of proven selling experience ŌĆō Knowledgeable staff can provide recommendations on product styles and selections

- 14. SummaryŌĆ” What you should know ŌĆó Understand the difference between an internal locking assembly and an external shrink disc ŌĆó Understand the advantages of KLDs over traditional shaft/hub connections ŌĆó Understand the basic working principle of locking assemblies and shrink discs ŌĆó Understand reasons to select Climax Keyless Locking Devices

- 15. Climax Keyless Locking Devices Training Complete! Thank you for your attention. If you have questions or need additional information, please contact our Customer Service Department at 800-542-6552 Monday-Friday 8:00am till 5:30pm EST.

Editor's Notes

- #3: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #4: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #5: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #6: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #14: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #15: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.

- #16: Give a brief overview of the presentation. Describe the major focus of the presentation and why it is important. Introduce each of the major topics. To provide a road map for the audience, you can repeat this Overview slide throughout the presentation, highlighting the particular topic you will discuss next.