Kumar&Satodia_AUE867_P02

Download as PPTX, PDF0 likes104 views

The document studies the effect of end load and tool speed on torque, temperature, and quality in friction drilling processes. Experiments were conducted with aluminum alloy workpieces and tungsten carbide tools at various speed and load conditions. The results show that higher end loads and lower speeds increase torque on the tool but decrease maximum temperature in the workpiece. The joint quality is also better with higher end loads. A finite element model is able to predict maximum temperature but does not fully capture the drilling process. Future applications of friction drilling in automotive manufacturing are discussed.

1 of 20

Download to read offline

Recommended

Machine tool

Machine toolTahir Tariq

╠²

This document summarizes research into using high efficiency deep grinding (HEDG) for automotive crankshafts. Laboratory experiments examined material removal rates up to 2000 mm3/s on steel samples, measuring surface temperature and integrity. Production tests on steel and cast iron crankshafts achieved similar removal rates without thermal damage. Thermal modeling showed heat flux into the workpiece peaks then reduces with increasing removal rate. Microstructure analysis found no damage below 200mm3/s for steel or below 340 mm3/s for cast iron. HEDG can achieve high removal rates without thermal damage and improve component performance.FrictionDrilling LinkedIn

FrictionDrilling LinkedInalaaeldakrory

╠²

The document summarizes a thesis submitted for a Master's degree in Production Engineering. It investigates the friction drilling process through finite element modeling, experimental testing, and analysis of results. The study aims to introduce friction drilling to Egyptian industries by developing low-cost tooling, optimizing process parameters, and evaluating their effects on hole quality, material microstructure, and hardness. Key aspects examined include tool design, experimental setup and methodology, finite element modeling, microstructural analysis, and the influence of rotational speed, feed rate and workpiece material on forces, torque and hole quality. The results provide insight into friction drilling of aluminum, steel and stainless steel and validation of the finite element model.poster1 (1)

poster1 (1)Sneha More

╠²

The document describes the development of an algorithm to determine the interfacial heat transfer coefficient (IFHTC) during casting. A group of students developed an algorithm and programming to calculate the IFHTC based on the heat flux and temperature difference at the casting-mould interface. Their simulations showed that the optimum pouring temperature was between 700-750┬░C and pouring speed was 2-3 cm/s to minimize air gap defects in aluminum castings. The algorithm and programming were developed to analyze heat transfer during sand casting of aluminum plates and help improve casting quality.Experimental Investigation for Mechanical Properties of Aluminium Alloy Al 60...

Experimental Investigation for Mechanical Properties of Aluminium Alloy Al 60...IRJET Journal

╠²

This document presents an experimental investigation of the mechanical properties of friction stir welded aluminum alloy Al 6061 joints considering different friction stir welding parameters. Specifically, it examines the effects of tool shape (taper or threaded), welding speed, and feed rate on the tensile strength, impact toughness, and microhardness of the welded joints. Experiments were conducted according to a Taguchi L8 orthogonal array design of experiments. Results indicated that welding speed had the greatest influence on tensile strength, feed rate most influenced impact toughness and microhardness, and the optimal parameters were a taper tool, 600 RPM welding speed, and 40 mm/min feed rate. These parameters produced joints with maximum mechanical property strengths.Investigation of Effect of Process Parameters on Maximum Temperature during F...

Investigation of Effect of Process Parameters on Maximum Temperature during F...IJSRD

╠²

In case of friction stir welding, the maximum temperature along the weld line within appropriate range at tool workpiece interface is responsible for quality of welded joint. Through this paper, an attempt is made to establish a relationship between the input process parameters and the maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075. The design of pre-experimental simulation has been performed in accordance with full factorial technique. The simulation of friction stir welding has been performed by varying input parameters, tool rotational speed and welding speed. The analysis of variance (ANOVA) is used to investigate the effect of input parameters on maximum temperature during friction stir welding. A correlation was established between input parameters and maximum temperature by multiple regression lines. This study indicates that the tool rotational speed is the main input parameter that has high statistical influence on maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075.

A11 presentation

A11 presentationSrinivas Dr. Suri

╠²

This project investigates crack propagation in an aluminum 2014 alloy ingot subjected to wire cutting EDM operations. The aim is to examine the effects of wire EDM conditions on residual stresses and resulting crack growth. An aluminum 2014 alloy ingot will be cut using wire EDM to produce tensile test specimens. Microscopic examination, tensile testing, and finite element modeling will be used to analyze residual stresses and resulting cracks in the material. Results will be discussed to determine the causes of cracking and potential remedies.Ijsea04021006

Ijsea04021006Editor IJCATR

╠²

The main purpose of this research is to study the optimal process parameters for thermal friction drilling process on AISI 304 stainless steel. The experiments were conducted based on Taguchi experimental design method, and the multiple performance characteristics correlated with the resultant axial force, radial force, hole diameter dimensional error, roundness error, and bushing length, were investigated by fuzzy logic technique. The significant process parameters that most intensively affected the multiple performance characteristics and the optimal combination levels of process parameters were determined through the analysis of variance and the response graph. A test rig was manufactured at Shoman Company ŌĆÆ Egypt to perform the experimental work, and the tools were offered by Flowdrill Company ŌĆÆ Germany. Experimental results confirm that this approach is simple, effective and efficient for simultaneous optimization of multiple quality characteristics in thermal friction drilling process, as the bushing length produced is more than five times the workpiece thickness.Optimization of friction stir welding parameters for joining aluminum alloy 6...

Optimization of friction stir welding parameters for joining aluminum alloy 6...eSAT Journals

╠²

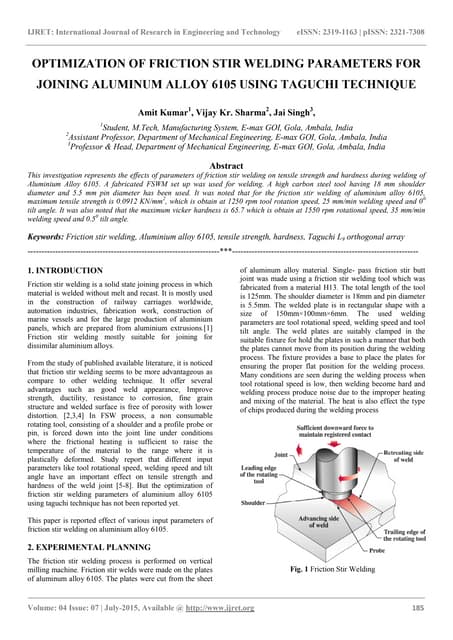

Abstract This investigation represents the effects of parameters of friction stir welding on tensile strength and hardness during welding of Aluminium Alloy 6105. A fabricated FSWM set up was used for welding. A high carbon steel tool having 18 mm shoulder diameter and 5.5 mm pin diameter has been used. It was noted that for the friction stir welding of aluminium alloy 6105, maximum tensile strength is 0.0912 KN/mm2, which is obtain at 1250 rpm tool rotation speed, 25 mm/min welding speed and 00 tilt angle. It was also noted that the maximum vicker hardness is 65.7 which is obtain at 1550 rpm rotational speed, 35 mm/min welding speed and 0.50 tilt angle. Keywords: Friction stir welding, Aluminium alloy 6105, tensile strength, hardness, Taguchi L9 orthogonal arrayAn Investigation on Effect of Welding Speed on Strength of Welded Joint using...

An Investigation on Effect of Welding Speed on Strength of Welded Joint using...IRJET Journal

╠²

This document investigates the effect of welding speed on the strength of welds using the TIG welding process. Specifically, it examines welding aluminum alloy AA6063 and AA5083 at various speeds ranging from 0.3 to 1.2 cm/sec. Tensile tests were performed on specimens welded at different speeds. The results showed that maximum tensile strength of 234 MPa was achieved at a welding speed of 0.6 cm/sec, while strength decreased at the highest speed of 1.2 cm/sec. In general, welding strength was lower than the base metal. The study aimed to determine the optimal welding speed to achieve high weld strength.Optimization of friction stir welding process parameter using taguchi method ...

Optimization of friction stir welding process parameter using taguchi method ...eSAT Journals

╠²

Abstract Friction stir welding (FSW) is relatively new solid state joining process. This joining technique is energy efficient, environment friendly and versatile. Welding is a multiinput-output process in which quality of welded joint is depends upon a input parameter. Therefore optimization of input process parameter is required to achieve good quality of welding. There are so many methods of optimization in which Taguchi method and Response surface methodology are selected for optimization of process parameter. In this review the effect of process parameter on welded joint studied and optimizes the parameter by using Taguchi method and Response surface methodology. The study of Friction stir welding of Aluminium alloy and High density polyethylene sheets shows the improvement in welded joint quality by optimization of process parameter. The main process parameters which affect the strength of welded joint is tool rotational speed, welding speed, axial force and tool pin profile. Keywords: Friction stir welding (FSW), Optimization, Taguchi Method Response surface Methodology Prediction modelsAn Experimental Investigation on Mechanical Properties of Friction Stir Weldi...

An Experimental Investigation on Mechanical Properties of Friction Stir Weldi...IRJET Journal

╠²

The document presents an experimental investigation on the mechanical properties of friction stir welding of aluminum alloy 6061-T6 and brass IS319 using EN19 tools with circular and taper profiles. Friction stir welding is a solid-state joining process that generates heat through friction between the rotating tool and workpieces.

The experiment was conducted on a milling machine using EN19 tools with circular and taper profiles to weld aluminum and brass plates. The welded joints were tested for tensile strength, yield strength, and hardness. The taper profile tool achieved a tensile strength of 108.5 N/mm2, yield strength of 76.05 N/mm2, and Vickers hardness of 51.73 HV. The circularH045054148

H045054148IJERA Editor

╠²

International Journal of Engineering Research and Applications (IJERA) is an open access online peer reviewed international journal that publishes research and review articles in the fields of Computer Science, Neural Networks, Electrical Engineering, Software Engineering, Information Technology, Mechanical Engineering, Chemical Engineering, Plastic Engineering, Food Technology, Textile Engineering, Nano Technology & science, Power Electronics, Electronics & Communication Engineering, Computational mathematics, Image processing, Civil Engineering, Structural Engineering, Environmental Engineering, VLSI Testing & Low Power VLSI Design etc.Heat flow prediction in friction stir welded aluminium alloy 1100

Heat flow prediction in friction stir welded aluminium alloy 1100IAEME Publication

╠²

The document summarizes research on predicting heat flow in friction stir welded aluminum alloy 1100. Experiments were conducted using a full factorial design to study the effects of tool rotational speed, weld speed, and tool pin diameter on temperature at the weld nugget and heat affected zone. Mathematical models were developed using regression analysis and checked for adequacy. An artificial neural network model was also developed and results compared to experimental values and the regression model. Microstructural analysis was performed to study effects of process variables on microstructure.Multi Cavities Casting Analysis

Multi Cavities Casting AnalysisFauzanil Azmy Iska

╠²

This document summarizes a casting simulation comparing two models. Model 2 has better filling performance while Model 1 has a better air pressure and entrapment performance. Both models show risks of shrinkage and porosity, especially at the top of rounded parts. The runner design of Model 2 creates a smoother molten flow pattern compared to Model 1.Improving Thermal Conductivity of Resin for Additive Manufacturing of Tooling...

Improving Thermal Conductivity of Resin for Additive Manufacturing of Tooling...Andrew Hollcraft

╠²

Polymer rapid prototyping of tooling inserts for injection molding is highly attractive as opposed to the long lead times of traditional tooling manufacturing. The primary challenges to polymers in this application are the high thermal conductivity, high temperature compressive modulus, and compressive strength required. A high heat deflection temperature nylon was compounded with 5 and 10 phr powdered zinc oxide using a designed experiment, with responses of thermal conductivity (determined by modulated differential scanning calorimetry) compressive yield strength, and hardness. It was found that the statistically significant thermal conductivity was increased by 40% at the 5 phr loading level, and matched well with theoretical models. In investigation of the residuals plot, it was found that the thermal conductivity spread also increased alongside loading, likely due to difficulty in metering of the fine powdered additive. Machining and Thermal aspects (MGU S8 ME)

Machining and Thermal aspects (MGU S8 ME)Denny John

╠²

The document summarizes heat generation during metal cutting and its effects. It discusses that 90-100% of mechanical energy during machining converts to thermal energy, raising temperatures. Heat affects tool life, surface finish, and dimensional accuracy. Heat is generated primarily at the shear and tool-chip interfaces due to plastic deformation and friction. Cutting temperature depends on work material properties, tool geometry, and cutting conditions like speed and fluid use. Higher speeds increase temperatures. Measurement methods include thermocouples and infrared detection. Effects of heat include tool wear and failure.Multi-Objective Optimization ( Surface Roughness & Material Removal Rate) of ...

Multi-Objective Optimization ( Surface Roughness & Material Removal Rate) of ...IJERA Editor

╠²

The present study applied Taguchi method through a case study in straight turning of AISI 202 stainless steel bar on CNC Machine ( Mfd by ACE DESIGNERS) using Titanium Carbide tool for the optimization of Material removal rate, Surface Roughness and tool wear process parameter.The study aimed at evaluating the best process environment which could simultaneously satisfy requirements of both quality as well as productivity with special emphasis on maximizing material removal rate and minimizing surface roughness and tool flank wear at various combination of cutting speed, feed, depth of cut. The predicted optimal setting ensured maximum MRR and minimum surface roughness and tool wear. Since optimum material removal rate is desired, so higher the better criteria of Taguchi signal to noise ratio is used for MRR ŌĆō SNs = -10 log(Sy2/n) For surface roughness and tool wear ŌĆō SNL = -10 log(S(1/y2)/n) The results have been verified with the help of S/N Ratios calculation and various graphs have been plotted to show the below mentioned observations.

a) MRR first increases with increase in cutting speed and then decreases.

b) With the increase in feed, MRR increases.

c) With the increase in depth of cut, MRR first increases and then decreases.

d) With the increase in cutting speed, Surface Roughness first decreases and then increases.

e) With the increase in feed, Surface Roughness increases.

f) With the increase in depth of cut, Surface Roughness first increases and then decreases.Problems of Heat, Mass and Momentum Transfer in Manufacturing Processes: A Br...

Problems of Heat, Mass and Momentum Transfer in Manufacturing Processes: A Br...drboon

╠²

In machining processes the chip flows over the tool rake and carries heat away as it moves. This is a case of mass transportation with heat transfer. Similarly, during hot forging, upsetting or coining processes heat is transferred from the hot billet to the relatively cooler dies, punches or hammers with momentum transfer under high impact load. Also, in high energy rate fabrication (HERF) processes, such as electromagnetic forming, explosive forming, impact extrusion, etc. heat is generated almost instantaneously, in milliseconds, and its dissipation is a serious industrial problem due to the very short process cycle time. In the present paper some of the problems related to heat, mass and momentum transfer in the above mentioned manufacturing processes are reviewed and compared with experimental results.Ppt on cutting temperatures of cutting tools to upload

Ppt on cutting temperatures of cutting tools to uploadVickram Srm

╠²

This case study aims to investigate factors that influence temperature distribution in ceramic tools during machining. Finite element analysis is used to calculate temperature distributions and compare them to experimental thermocouple measurements on the tool rake face. Experiments vary cutting parameters, tool geometries, tool conditions, and workpiece materials to study their effects on cutting edge temperatures. Results found an optimum rake angle of -20 degrees produced minimum edge temperatures, as more negative angles initially improved cooling but eventually intensified shear heating.STRESS DISTRIBUTION IN GRINDING BY FINITE ELEMENT ANALYSIS

STRESS DISTRIBUTION IN GRINDING BY FINITE ELEMENT ANALYSISBijoy Das

╠²

This document discusses a finite element analysis of stress distribution during grinding. The analysis models the temperature distribution and resulting stresses in a titanium workpiece under different grinding conditions (dry, wet, wet with pneumatic barrier) and infeeds (10, 20, 30 microns). The model calculates heat flux, temperature, and stresses based on material properties, grinding power, and heat transfer considerations. Results show that temperature profiles and residual stresses vary significantly depending on grinding environment and infeed parameters. Wet grinding and lower infeed generate less tensile stress than dry grinding or higher infeed rates.Friction stir-processing

Friction stir-processingsabry said

╠²

This document discusses friction stir processing (FSP), a technique for modifying the microstructure of metals near the surface. FSP uses a rotating tool to generate heat and plasticize the metal. As the tool traverses the material, it leaves behind a fine-grained microstructure. The document outlines the working principle of FSP and its applications, including fabricating surface composites, refining cast alloys, and producing superplasticity. FSP effectively improves mechanical properties like strength and ductility compared to the as-cast condition.IRJET- Investigation on Various Aspects of using Activated Tio2 Flux in G...

IRJET- Investigation on Various Aspects of using Activated Tio2 Flux in G...IRJET Journal

╠²

1) The document investigates the use of activated TiO2 flux in gas tungsten arc welding (GTAW) of stainless steel AISI 304L to improve weld penetration and hardness.

2) Experiments were conducted using Taguchi's design of experiments to evaluate the effects of welding current, speed, and flux amount on penetration and hardness.

3) Results showed that using TiO2 flux increased penetration compared to GTAW without flux. Hardness was also slightly lower when using flux, indicating less brittleness.MANUFACTURING SCIENCE S5ME -NITC-2016-SUBTOPICS

MANUFACTURING SCIENCE S5ME -NITC-2016-SUBTOPICS Jagadeesha Thimmaiah

╠²

The document discusses porosity in castings. It defines two types of porosity - macro and micro - based on pore size. Micro porosity forms due to gas pores when gas pressure exceeds external pressure during solidification. The document also discusses properties of aluminum alloys LM25 and LM6, types of feeding during solidification, and models for predicting microporosity evolution and grain structure evolution. It provides equations to calculate porosity based on hydrogen content and presents results showing increased porosity with higher hydrogen and slower cooling rates.Investigations on the surface roughness produced in turning of al6061 (as cas...

Investigations on the surface roughness produced in turning of al6061 (as cas...eSAT Journals

╠²

Abstract: Surface roughness produced on the machined component is one of the key attribute of machining process. In this work the effect of various turning process parameters on surface roughness produced on Al6061 (as cast condition) is investigated. Also the effect of using coolant on surface roughness while turning is also determined. It is observed increase in cutting speed by 39.29% resulted in decrease of surface roughness by 31.44%. Increase in feed rate and depth of cut leads to increase in surface roughness. Quantitative analysis of surface roughness obtained in machining with coolant and without coolant is also presented. Keywords: Al6061, Surface Roughness, Turning Process, Spindle Speed, Depth of Cut, ANOVAIRJET- Experimental Investigation on Autogenous Tungsten Inert Gas

IRJET- Experimental Investigation on Autogenous Tungsten Inert GasIRJET Journal

╠²

This document summarizes an experimental investigation of autogenous tungsten inert gas (TIG) welding. TIG welding was performed on 5 mm thick mild steel plates without filler material using different welding currents and speeds. Activated flux was also used to improve weld depth in some experiments. Maintaining a gap between plates during welding was found to allow full penetration welds with strength similar to the base material. Weld bead geometry, tensile strength, and hardness were evaluated for welds made with different parameters. Increasing welding current and maintaining a gap between plates both increased weld depth and width. Maintaining an appropriate gap allowed defect-free welding with proper material flow.Die design optimization and die stress analysis of control arm by simulation

Die design optimization and die stress analysis of control arm by simulation Kundan Kumar

╠²

The main objectives are as follows:

1.To develop a model for the automotive component ŌĆ£Control ArmŌĆØ

2.To analyse the simulation trials

3.To optimize the Stress

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...IJERA Editor

╠²

This document discusses optimizing the process parameters for friction stir welding (FSW) of similar aluminum alloy H30. Experiments were conducted using a Taguchi L9 orthogonal array with rotational speed, travel speed, and axial force as parameters. Tensile tests found strengths ranged from 32-80 MPa. Analysis of variance and signal-to-noise ratios identified axial force as the most significant parameter, with a strength-optimized level of 6000N. Rotational speed of 1600 RPM and travel speed of 20 mm/min also improved strength. The study aims to determine optimum parameters for high strength FSW joints of aluminum alloy H30.Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...IJERA Editor

╠²

This document discusses optimizing the process parameters for friction stir welding (FSW) of similar aluminum alloy H30 joints. Experiments were conducted using a Taguchi L9 orthogonal array with rotational speed, travel speed, and axial force as parameters. Tensile tests showed that maximum strength was achieved at 1600 RPM, 20 mm/min travel speed, and 6000N axial force. Analysis of variance identified axial force as the most significant parameter. The study aims to determine optimum parameters for high joint strength using Taguchi methodology.Surface hybrid nanocomposites via friction stir processing

Surface hybrid nanocomposites via friction stir processingmohammed noor

╠²

Friction stir Processing (FSP) is a new innovative technology developed based on the principle of Friction Stir Welding (FSW) technique.

In FSP, the ceramic particulates are reinforced into the base metal by adding it into the groove and Friction Stir Processing (FSP) is performed.

In this study, the aluminum alloy 6061 is chosen as the base metal, alumina and graphite Nano powder as reinforcement.

The process parameters such traverse speed of 64 mm/min and the tool rotational speed of 1060 rpm and tilt angle of 2deg were selected, The Friction Powder Processing was carried out on vertical milling machine.

New parameters such as powder type and number of passes were involved and we also study the effect of heat treatment.

The influence of FSP was checked using some tests such as the microstructure analysis that was carried out using optical microscope (OM) and the mechanical characteristics were analyzed using tensile test and hardness test.

The micrograph results revealed that powder particulates were evenly distributed in the stir zone and reduction in grain size also observed; the reason for the grain size reduction was stirring action of the FPP toolŌĆÖs pin.

The tensile strength results showed a significant improvement in strength by a percent of

50% compared to base metal but when T6 heat treatment is applied, the tensile strength decreased.

Extrusion process and parameters involved in the experimental and numerical i...

Extrusion process and parameters involved in the experimental and numerical i...IJERD Editor

╠²

This document reviews extrusion processes and parameters for investigating aluminum alloys Al6061, Al6063, and Al7075. It discusses experimental and numerical methods used to study the effects of parameters like die angle, billet temperature, speed, and geometry. Taguchi methods were used to optimize parameters for Al6061 extrusion. Numerical analysis found the maximum stresses occur at square tube corners. The document concludes that smaller extrusion ratios and stresses result from thicker products and fixed billet dimensions. Parameters like die angle, temperature, speed, and geometry influence load, strength, and deformation during aluminum extrusion.More Related Content

What's hot (17)

An Investigation on Effect of Welding Speed on Strength of Welded Joint using...

An Investigation on Effect of Welding Speed on Strength of Welded Joint using...IRJET Journal

╠²

This document investigates the effect of welding speed on the strength of welds using the TIG welding process. Specifically, it examines welding aluminum alloy AA6063 and AA5083 at various speeds ranging from 0.3 to 1.2 cm/sec. Tensile tests were performed on specimens welded at different speeds. The results showed that maximum tensile strength of 234 MPa was achieved at a welding speed of 0.6 cm/sec, while strength decreased at the highest speed of 1.2 cm/sec. In general, welding strength was lower than the base metal. The study aimed to determine the optimal welding speed to achieve high weld strength.Optimization of friction stir welding process parameter using taguchi method ...

Optimization of friction stir welding process parameter using taguchi method ...eSAT Journals

╠²

Abstract Friction stir welding (FSW) is relatively new solid state joining process. This joining technique is energy efficient, environment friendly and versatile. Welding is a multiinput-output process in which quality of welded joint is depends upon a input parameter. Therefore optimization of input process parameter is required to achieve good quality of welding. There are so many methods of optimization in which Taguchi method and Response surface methodology are selected for optimization of process parameter. In this review the effect of process parameter on welded joint studied and optimizes the parameter by using Taguchi method and Response surface methodology. The study of Friction stir welding of Aluminium alloy and High density polyethylene sheets shows the improvement in welded joint quality by optimization of process parameter. The main process parameters which affect the strength of welded joint is tool rotational speed, welding speed, axial force and tool pin profile. Keywords: Friction stir welding (FSW), Optimization, Taguchi Method Response surface Methodology Prediction modelsAn Experimental Investigation on Mechanical Properties of Friction Stir Weldi...

An Experimental Investigation on Mechanical Properties of Friction Stir Weldi...IRJET Journal

╠²

The document presents an experimental investigation on the mechanical properties of friction stir welding of aluminum alloy 6061-T6 and brass IS319 using EN19 tools with circular and taper profiles. Friction stir welding is a solid-state joining process that generates heat through friction between the rotating tool and workpieces.

The experiment was conducted on a milling machine using EN19 tools with circular and taper profiles to weld aluminum and brass plates. The welded joints were tested for tensile strength, yield strength, and hardness. The taper profile tool achieved a tensile strength of 108.5 N/mm2, yield strength of 76.05 N/mm2, and Vickers hardness of 51.73 HV. The circularH045054148

H045054148IJERA Editor

╠²

International Journal of Engineering Research and Applications (IJERA) is an open access online peer reviewed international journal that publishes research and review articles in the fields of Computer Science, Neural Networks, Electrical Engineering, Software Engineering, Information Technology, Mechanical Engineering, Chemical Engineering, Plastic Engineering, Food Technology, Textile Engineering, Nano Technology & science, Power Electronics, Electronics & Communication Engineering, Computational mathematics, Image processing, Civil Engineering, Structural Engineering, Environmental Engineering, VLSI Testing & Low Power VLSI Design etc.Heat flow prediction in friction stir welded aluminium alloy 1100

Heat flow prediction in friction stir welded aluminium alloy 1100IAEME Publication

╠²

The document summarizes research on predicting heat flow in friction stir welded aluminum alloy 1100. Experiments were conducted using a full factorial design to study the effects of tool rotational speed, weld speed, and tool pin diameter on temperature at the weld nugget and heat affected zone. Mathematical models were developed using regression analysis and checked for adequacy. An artificial neural network model was also developed and results compared to experimental values and the regression model. Microstructural analysis was performed to study effects of process variables on microstructure.Multi Cavities Casting Analysis

Multi Cavities Casting AnalysisFauzanil Azmy Iska

╠²

This document summarizes a casting simulation comparing two models. Model 2 has better filling performance while Model 1 has a better air pressure and entrapment performance. Both models show risks of shrinkage and porosity, especially at the top of rounded parts. The runner design of Model 2 creates a smoother molten flow pattern compared to Model 1.Improving Thermal Conductivity of Resin for Additive Manufacturing of Tooling...

Improving Thermal Conductivity of Resin for Additive Manufacturing of Tooling...Andrew Hollcraft

╠²

Polymer rapid prototyping of tooling inserts for injection molding is highly attractive as opposed to the long lead times of traditional tooling manufacturing. The primary challenges to polymers in this application are the high thermal conductivity, high temperature compressive modulus, and compressive strength required. A high heat deflection temperature nylon was compounded with 5 and 10 phr powdered zinc oxide using a designed experiment, with responses of thermal conductivity (determined by modulated differential scanning calorimetry) compressive yield strength, and hardness. It was found that the statistically significant thermal conductivity was increased by 40% at the 5 phr loading level, and matched well with theoretical models. In investigation of the residuals plot, it was found that the thermal conductivity spread also increased alongside loading, likely due to difficulty in metering of the fine powdered additive. Machining and Thermal aspects (MGU S8 ME)

Machining and Thermal aspects (MGU S8 ME)Denny John

╠²

The document summarizes heat generation during metal cutting and its effects. It discusses that 90-100% of mechanical energy during machining converts to thermal energy, raising temperatures. Heat affects tool life, surface finish, and dimensional accuracy. Heat is generated primarily at the shear and tool-chip interfaces due to plastic deformation and friction. Cutting temperature depends on work material properties, tool geometry, and cutting conditions like speed and fluid use. Higher speeds increase temperatures. Measurement methods include thermocouples and infrared detection. Effects of heat include tool wear and failure.Multi-Objective Optimization ( Surface Roughness & Material Removal Rate) of ...

Multi-Objective Optimization ( Surface Roughness & Material Removal Rate) of ...IJERA Editor

╠²

The present study applied Taguchi method through a case study in straight turning of AISI 202 stainless steel bar on CNC Machine ( Mfd by ACE DESIGNERS) using Titanium Carbide tool for the optimization of Material removal rate, Surface Roughness and tool wear process parameter.The study aimed at evaluating the best process environment which could simultaneously satisfy requirements of both quality as well as productivity with special emphasis on maximizing material removal rate and minimizing surface roughness and tool flank wear at various combination of cutting speed, feed, depth of cut. The predicted optimal setting ensured maximum MRR and minimum surface roughness and tool wear. Since optimum material removal rate is desired, so higher the better criteria of Taguchi signal to noise ratio is used for MRR ŌĆō SNs = -10 log(Sy2/n) For surface roughness and tool wear ŌĆō SNL = -10 log(S(1/y2)/n) The results have been verified with the help of S/N Ratios calculation and various graphs have been plotted to show the below mentioned observations.

a) MRR first increases with increase in cutting speed and then decreases.

b) With the increase in feed, MRR increases.

c) With the increase in depth of cut, MRR first increases and then decreases.

d) With the increase in cutting speed, Surface Roughness first decreases and then increases.

e) With the increase in feed, Surface Roughness increases.

f) With the increase in depth of cut, Surface Roughness first increases and then decreases.Problems of Heat, Mass and Momentum Transfer in Manufacturing Processes: A Br...

Problems of Heat, Mass and Momentum Transfer in Manufacturing Processes: A Br...drboon

╠²

In machining processes the chip flows over the tool rake and carries heat away as it moves. This is a case of mass transportation with heat transfer. Similarly, during hot forging, upsetting or coining processes heat is transferred from the hot billet to the relatively cooler dies, punches or hammers with momentum transfer under high impact load. Also, in high energy rate fabrication (HERF) processes, such as electromagnetic forming, explosive forming, impact extrusion, etc. heat is generated almost instantaneously, in milliseconds, and its dissipation is a serious industrial problem due to the very short process cycle time. In the present paper some of the problems related to heat, mass and momentum transfer in the above mentioned manufacturing processes are reviewed and compared with experimental results.Ppt on cutting temperatures of cutting tools to upload

Ppt on cutting temperatures of cutting tools to uploadVickram Srm

╠²

This case study aims to investigate factors that influence temperature distribution in ceramic tools during machining. Finite element analysis is used to calculate temperature distributions and compare them to experimental thermocouple measurements on the tool rake face. Experiments vary cutting parameters, tool geometries, tool conditions, and workpiece materials to study their effects on cutting edge temperatures. Results found an optimum rake angle of -20 degrees produced minimum edge temperatures, as more negative angles initially improved cooling but eventually intensified shear heating.STRESS DISTRIBUTION IN GRINDING BY FINITE ELEMENT ANALYSIS

STRESS DISTRIBUTION IN GRINDING BY FINITE ELEMENT ANALYSISBijoy Das

╠²

This document discusses a finite element analysis of stress distribution during grinding. The analysis models the temperature distribution and resulting stresses in a titanium workpiece under different grinding conditions (dry, wet, wet with pneumatic barrier) and infeeds (10, 20, 30 microns). The model calculates heat flux, temperature, and stresses based on material properties, grinding power, and heat transfer considerations. Results show that temperature profiles and residual stresses vary significantly depending on grinding environment and infeed parameters. Wet grinding and lower infeed generate less tensile stress than dry grinding or higher infeed rates.Friction stir-processing

Friction stir-processingsabry said

╠²

This document discusses friction stir processing (FSP), a technique for modifying the microstructure of metals near the surface. FSP uses a rotating tool to generate heat and plasticize the metal. As the tool traverses the material, it leaves behind a fine-grained microstructure. The document outlines the working principle of FSP and its applications, including fabricating surface composites, refining cast alloys, and producing superplasticity. FSP effectively improves mechanical properties like strength and ductility compared to the as-cast condition.IRJET- Investigation on Various Aspects of using Activated Tio2 Flux in G...

IRJET- Investigation on Various Aspects of using Activated Tio2 Flux in G...IRJET Journal

╠²

1) The document investigates the use of activated TiO2 flux in gas tungsten arc welding (GTAW) of stainless steel AISI 304L to improve weld penetration and hardness.

2) Experiments were conducted using Taguchi's design of experiments to evaluate the effects of welding current, speed, and flux amount on penetration and hardness.

3) Results showed that using TiO2 flux increased penetration compared to GTAW without flux. Hardness was also slightly lower when using flux, indicating less brittleness.MANUFACTURING SCIENCE S5ME -NITC-2016-SUBTOPICS

MANUFACTURING SCIENCE S5ME -NITC-2016-SUBTOPICS Jagadeesha Thimmaiah

╠²

The document discusses porosity in castings. It defines two types of porosity - macro and micro - based on pore size. Micro porosity forms due to gas pores when gas pressure exceeds external pressure during solidification. The document also discusses properties of aluminum alloys LM25 and LM6, types of feeding during solidification, and models for predicting microporosity evolution and grain structure evolution. It provides equations to calculate porosity based on hydrogen content and presents results showing increased porosity with higher hydrogen and slower cooling rates.Investigations on the surface roughness produced in turning of al6061 (as cas...

Investigations on the surface roughness produced in turning of al6061 (as cas...eSAT Journals

╠²

Abstract: Surface roughness produced on the machined component is one of the key attribute of machining process. In this work the effect of various turning process parameters on surface roughness produced on Al6061 (as cast condition) is investigated. Also the effect of using coolant on surface roughness while turning is also determined. It is observed increase in cutting speed by 39.29% resulted in decrease of surface roughness by 31.44%. Increase in feed rate and depth of cut leads to increase in surface roughness. Quantitative analysis of surface roughness obtained in machining with coolant and without coolant is also presented. Keywords: Al6061, Surface Roughness, Turning Process, Spindle Speed, Depth of Cut, ANOVAIRJET- Experimental Investigation on Autogenous Tungsten Inert Gas

IRJET- Experimental Investigation on Autogenous Tungsten Inert GasIRJET Journal

╠²

This document summarizes an experimental investigation of autogenous tungsten inert gas (TIG) welding. TIG welding was performed on 5 mm thick mild steel plates without filler material using different welding currents and speeds. Activated flux was also used to improve weld depth in some experiments. Maintaining a gap between plates during welding was found to allow full penetration welds with strength similar to the base material. Weld bead geometry, tensile strength, and hardness were evaluated for welds made with different parameters. Increasing welding current and maintaining a gap between plates both increased weld depth and width. Maintaining an appropriate gap allowed defect-free welding with proper material flow.Similar to Kumar&Satodia_AUE867_P02 (20)

Die design optimization and die stress analysis of control arm by simulation

Die design optimization and die stress analysis of control arm by simulation Kundan Kumar

╠²

The main objectives are as follows:

1.To develop a model for the automotive component ŌĆ£Control ArmŌĆØ

2.To analyse the simulation trials

3.To optimize the Stress

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...IJERA Editor

╠²

This document discusses optimizing the process parameters for friction stir welding (FSW) of similar aluminum alloy H30. Experiments were conducted using a Taguchi L9 orthogonal array with rotational speed, travel speed, and axial force as parameters. Tensile tests found strengths ranged from 32-80 MPa. Analysis of variance and signal-to-noise ratios identified axial force as the most significant parameter, with a strength-optimized level of 6000N. Rotational speed of 1600 RPM and travel speed of 20 mm/min also improved strength. The study aims to determine optimum parameters for high strength FSW joints of aluminum alloy H30.Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...

Effect of Process Parameters of Friction Stir Welded Joint for Similar Alumin...IJERA Editor

╠²

This document discusses optimizing the process parameters for friction stir welding (FSW) of similar aluminum alloy H30 joints. Experiments were conducted using a Taguchi L9 orthogonal array with rotational speed, travel speed, and axial force as parameters. Tensile tests showed that maximum strength was achieved at 1600 RPM, 20 mm/min travel speed, and 6000N axial force. Analysis of variance identified axial force as the most significant parameter. The study aims to determine optimum parameters for high joint strength using Taguchi methodology.Surface hybrid nanocomposites via friction stir processing

Surface hybrid nanocomposites via friction stir processingmohammed noor

╠²

Friction stir Processing (FSP) is a new innovative technology developed based on the principle of Friction Stir Welding (FSW) technique.

In FSP, the ceramic particulates are reinforced into the base metal by adding it into the groove and Friction Stir Processing (FSP) is performed.

In this study, the aluminum alloy 6061 is chosen as the base metal, alumina and graphite Nano powder as reinforcement.

The process parameters such traverse speed of 64 mm/min and the tool rotational speed of 1060 rpm and tilt angle of 2deg were selected, The Friction Powder Processing was carried out on vertical milling machine.

New parameters such as powder type and number of passes were involved and we also study the effect of heat treatment.

The influence of FSP was checked using some tests such as the microstructure analysis that was carried out using optical microscope (OM) and the mechanical characteristics were analyzed using tensile test and hardness test.

The micrograph results revealed that powder particulates were evenly distributed in the stir zone and reduction in grain size also observed; the reason for the grain size reduction was stirring action of the FPP toolŌĆÖs pin.

The tensile strength results showed a significant improvement in strength by a percent of

50% compared to base metal but when T6 heat treatment is applied, the tensile strength decreased.

Extrusion process and parameters involved in the experimental and numerical i...

Extrusion process and parameters involved in the experimental and numerical i...IJERD Editor

╠²

This document reviews extrusion processes and parameters for investigating aluminum alloys Al6061, Al6063, and Al7075. It discusses experimental and numerical methods used to study the effects of parameters like die angle, billet temperature, speed, and geometry. Taguchi methods were used to optimize parameters for Al6061 extrusion. Numerical analysis found the maximum stresses occur at square tube corners. The document concludes that smaller extrusion ratios and stresses result from thicker products and fixed billet dimensions. Parameters like die angle, temperature, speed, and geometry influence load, strength, and deformation during aluminum extrusion.Investigation of Effect of Process Parameters on Maximum Temperature during F...

Investigation of Effect of Process Parameters on Maximum Temperature during F...IJSRD

╠²

This document summarizes a study that used finite element analysis to investigate the effect of process parameters on maximum temperature during friction stir welding of aluminium alloy AA-7075. Nine simulations were conducted using different combinations of tool rotational speed (300-450 RPM) and welding speed (2.5-5 mm/s). The results found that maximum temperature increased with increasing tool rotational speed but decreased with increasing welding speed. Statistical analysis showed that tool rotational speed had the strongest influence on maximum temperature. A regression model was developed that can predict maximum temperature based on rotational speed and welding speed. The model was validated and found to predict temperature accurately within about 2% error.Investigation of Effect of Process Parameters on Maximum Temperature during F...

Investigation of Effect of Process Parameters on Maximum Temperature during F...IJSRD

╠²

In case of friction stir welding, the maximum temperature along the weld line within appropriate range at tool workpiece interface is responsible for quality of welded joint. Through this paper, an attempt is made to establish a relationship between the input process parameters and the maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075. The design of pre-experimental simulation has been performed in accordance with full factorial technique. The simulation of friction stir welding has been performed by varying input parameters, tool rotational speed and welding speed. The analysis of variance (ANOVA) is used to investigate the effect of input parameters on maximum temperature during friction stir welding. A correlation was established between input parameters and maximum temperature by multiple regression lines. This study indicates that the tool rotational speed is the main input parameter that has high statistical influence on maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075.

FSW PROCESS DISSIMILAR (Al) AT 3G POSITION

FSW PROCESS DISSIMILAR (Al) AT 3G POSITIONMin Dzulkiflee

╠²

This document summarizes a research project on friction stir welding (FSW) of dissimilar aluminum alloys. The objectives were to design an FSW weld for joining different aluminum series in a 3G position, evaluate the best welding parameters such as rotational and transverse speed, and analyze tensile strength properties. FSW was performed using different transverse speeds and a fixed rotational speed. Tensile testing showed the highest strength was achieved with a transverse speed of 86mm/min, meeting the project's objectives.Performance Evaluation of a Low Cost Creep Testing Machine

Performance Evaluation of a Low Cost Creep Testing MachineAdib Bin Rashid

╠²

Mechanical systems and components like steam generators or boilers, nuclear reactors, turbine rotors

are operated at very high temperature under significant stress. For this reason, the components and structures need to be designed so that excessive creep distortion must not occur within the expected operating life of the system. Creep

is defined as a time-dependent deformation that happens when metals are subjected to constant load at high

temperature over a period of time. Knowledge of the creep behavior of metals is therefore important and for this

reason Creep testing machines are predominantly used to measure how a given material will perform under constant

load, at elevated temperature. This paper aims to study creep properties of various materials being used in high

temperature applications through locally made creep testing machine. The basic design of a creep testing machine is

the support structure, the loading device, the fixture device (grips and pull rods), and the furnace. The specimen

being tested is held in place by the grips and a furnace surrounds the test section and maintains a constant

temperature. Maximum applied load on the specimen can be 15 kg and tests could be carried out at maximum

temperature of 500┬░C. Creep curves of strain versus time of aluminum alloy were plotted at a different stress level

and temperature. The data are plotted in a simple manner, but analysis easily shows the effect of increased stress due

the reduction in specimen cross-section as strain increases. The creep testing machine developed in this work has proven to be satisfactory, cost effective and good alternative to imported creep testing machine.Study and Experimental Modelling of Welding Parameters on Hardness of Hot Air...

Study and Experimental Modelling of Welding Parameters on Hardness of Hot Air...IJSRD

╠²

The present work has been carried out to study the effect of some input parameters on the desired responses in the Poly Vinyl Chloride (PVC) plastic welding by hot air technique. The effect of hot air temperature, welding speed and air flow rate has been evaluated on the Hardness of the welded joints. These responses have been analysed using the analysis of variance (ANOVA) and experimental modeling. Plots of significant factors and experimental modeling have been used to determine the best fit relationship between the responses and the model parameters using MINITAB 17. This has been used to determine the most influencing parameter.

Effect of process parameters on residual stress in AA1050 friction stir welds

Effect of process parameters on residual stress in AA1050 friction stir weldsInternational Journal of Modern Research in Engineering and Technology

╠²

In the current work, aluminum AA1050 plates has been successfully joined using friction stir

welding (FSW) technique. The effect of processing parameters such as tool rotation speed and travel speed

on the mechanical properties are investigated. Residual stress has been carried out using the destructive

cutting length method; the results found that common stresses are compressive type, which are formed due to

friction stir welding process. The results revealed that welding travel speed has a remarkable influence on the

resultant residual stress.

FRICTION_STIR_WELDING.pptx

FRICTION_STIR_WELDING.pptxSATYAMMAURYAbetechst

╠²

Satyam Maurya presented on friction stir welding. The presentation covered the basics of friction stir welding including the process, microstructure, parameters, tooling, applications and advantages. Friction stir welding is a solid-state welding technique that uses a rotating tool to generate frictional heat and plasticize the materials being joined without melting them. It results in strong, high quality welds and is particularly useful for welding aluminum and magnesium alloys.A Report on Metal Drawing Operations

A Report on Metal Drawing OperationsMohit Rajput

╠²

This document provides an overview of metal drawing operations. It discusses the introduction to drawing, general operations like conditioning materials, process descriptions for shapes like rods/wires and tubes. It covers process requirements including tools, equipment, dies and load calculations. The key points are that metal drawing is a process that uses tensile forces to reduce cross-sectional area and elongate metal by pulling it through a die, important factors include the amount of reduction, speed, material properties and temperature. It can produce various shapes like rods, wires and tubes for different applications.ANALYSIS AND OPTIMIZATION OF EXTRUSION PROCESS USING HYPERWORKS

ANALYSIS AND OPTIMIZATION OF EXTRUSION PROCESS USING HYPERWORKSijsrd.com

╠²

Minimizing the amount of scrap generated in an aluminum extrusion process. An optimizing method is constructed based on Simulation Analysis approach. In present thesis the Simulation approach is presented to optimize the amount of Scrap generated during Aluminum extrusion process. The model applied to real data obtained from an existing extrusion factory. Results from using the suggested model provided substantial reductions in the amount of scrap generated. Using sound simulation analysis approaches contribute significantly in reducing waste and savings when compared to the existing nonscientific techniques.Effect of Tool Rotation Speed on the Hardness of Welded Joints of Aluminium A...

Effect of Tool Rotation Speed on the Hardness of Welded Joints of Aluminium A...ijsrd.com

╠²

Aluminum alloys are used in engineering design for their light weight, high strength-to weight ratio, corrosion resistance, and relatively low cost. Aluminum is available in various compositions, including ├ā┬ó├óŌĆÜ┬¼├ģŌĆ£pure├ā┬ó├óŌĆÜ┬¼├é┬Ø metal, alloys for casting, and alloys for the manufacture of wrought products wrought Alloys. Most aluminum alloys used for wrought products contain Less than 7 percent of alloying elements. By the regulation of the amount and type of elements added, the properties of the aluminum can be enhanced and its working characteristics improved. In this welding process we have study that two pieces of aluminum alloy (6063) were welded with the help of friction stir welding process and here in this welding process we have found that the microstructure of weld zone was characterized by dynamic recrastallization producing fine grain structure. The vickers hardness testing results obtained for welded specimens and we have observed that the hardness is increases and decreases on different parameters like tool rotation speed. But we have obtained that as the tool rotating speed is increases the hardness will aslo increases. Finally we obtained the max. hardness(Hv-40) on max. Tool rotation speed of (rpm-1800).W01226143147

W01226143147IOSR Journals

╠²

The document analyzes the mechanical properties of friction stir welded aluminum alloy AA6063 plates compared to metal inert gas arc welded AA6063 plates. Tensile strength and Rockwell hardness tests were performed on specimens cut from the welded plates. The results showed that the friction stir welded plates had superior tensile strength and hardness compared to the metal inert gas welded plates. Specifically, the ultimate tensile strength was higher and elongation was greater for friction stir welded specimens. Additionally, the Rockwell hardness values were higher for friction stir welded plates compared to metal inert gas welded plates. Therefore, the study demonstrated that friction stir welding can improve the quality and mechanical properties of welded aluminum alloy joints over conventionalProperties of MIM 4140 Alloy After Injection Molding and Sintering

Properties of MIM 4140 Alloy After Injection Molding and SinteringInternational Journal of Innovation Engineering and Science Research

╠²

Testing results of a multi-cavity mold for injection molding of MIM 4140 alloy are presented in the article. Recommendations for manufacturing of forming parts of the mold were given. Based on an implemented technological process of casting and subsequent laboratory researches an information was obtained about the condition of a casting (hardness on Super-Rockwell, shrinkage and quality of a surface layer of material before and after heat treatment). Calculated overall dimensions of the forming parts of the project mold will allow making forecast of shrinkage of MIM 4140 alloy after injection molding.external viva phase.pptx

external viva phase.pptxJayasimhaYadavRA

╠²

This document summarizes a student project on evaluating the performance of coated and uncoated tungsten carbide inserts in turning AISI304 stainless steel. The project aims to study the effect of cutting speed on tool wear and chip characteristics. Experiments were conducted using coated and uncoated inserts at various cutting speeds. Results showed that coated inserts exhibited less tool wear and higher hardness compared to uncoated inserts. Higher cutting speeds led to increased tool wear for both insert types. Chip and workpiece temperatures also increased with longer machining times. The project findings can help improve machining efficiency of hard materials like stainless steel.Modeling and Analysis for Cutting Temperature in Turning of Aluminium 6063 Us...

Modeling and Analysis for Cutting Temperature in Turning of Aluminium 6063 Us...IOSR Journals

╠²

Deviation in machining process due to the temperature influence, cutting force, tool wear leads to

highly inferior quality of finished product, especially in high speed machining operations where product quality

and physical dimensions seems to be meticulous. Moreover, temperature is a significant noise parameter which

directly affects the cutting tool and work piece. Hence the aim of this project work is to study the machining

effect on 6063 Aluminium alloy at varies combinations of process parameters such as speed, feed rate and depth

of cut; and also to determine the effect of those parameters over the quality of finished product. A L27

Orthogonal Array (OA) based Design of Experiments (DOE) approach and Response Surface Methodology

(RSM) was used to analyse the machining effect on work material in this study. Using the practical data

obtained, a mathematical model was developed to predict the temperature influence and surface quality of

finished product. The ultimate goal of the study is to optimize the machining parameters for temperature

minimization in machining zone and improvement in surface finish.Effect of Cooling Rate on Microstructure of Saw Welded Mild Steel Plate (Gra...

Effect of Cooling Rate on Microstructure of Saw Welded Mild Steel Plate (Gra...IJMER

╠²

Information Technology,Enviornmental Engineering,VLSI Design,Nano Technology,Mathematics,Test & Testability,Communication Engineering,Rural Technology,Textile Engineering ,Robotics,Embedded System,Plastic EngineeringSoftware engineeringEffect of process parameters on residual stress in AA1050 friction stir welds

Effect of process parameters on residual stress in AA1050 friction stir weldsInternational Journal of Modern Research in Engineering and Technology

╠²

Properties of MIM 4140 Alloy After Injection Molding and Sintering

Properties of MIM 4140 Alloy After Injection Molding and SinteringInternational Journal of Innovation Engineering and Science Research

╠²

Kumar&Satodia_AUE867_P02

- 1. EFFECT OF END LOAD AND TOOL SPEED ON TORQUE AND TEMPERATURE OF FRICTION DRILLING PROCESS: AN EXPERIMENTAL STUDY BY: VARUN KUMAR SHYAMAL SATODIA

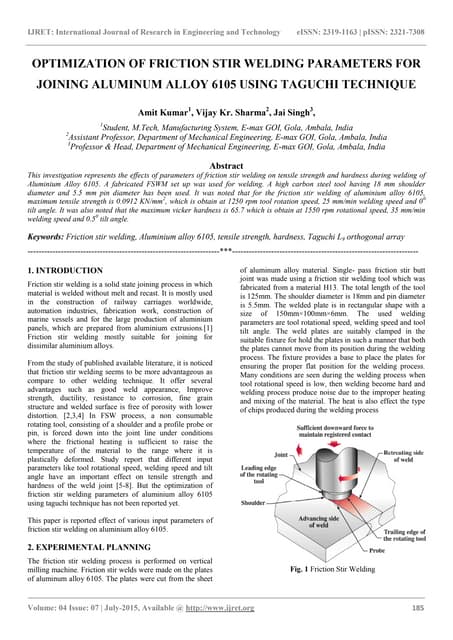

- 2. Introduction ’é¦Current sheet metal joining techniques include: ’é¦Arc welding ’é¦Resistance spot welding ’é¦These operations have drawbacks since: ’é¦Extra material is added, and quality issues are inevitable ’é¦Aluminum alloys, integral to automotive industry today can not be welded easily

- 3. Introduction (Contd.) ’é¦Friction drilling is a new alternative for joining sheet bodies. ’é¦Also known as thermal or flow drilling, the heat generated due to friction between rotating tool and work piece is used to soften, penetrate and plastically deform the material to create a hole with a process generated sleeve, to be used for tapping later. ’é¦A conical shaped Silicon Carbide tool is used for the process due to high working temperature. ’é¦The height of the bush is almost twice the thickness of sheet metal

- 4. Friction Drilling process ’é¦ Step 1: Approaching conical tool ’é¦ Step 2: Penetration of tool tip into softened work piece ’é¦ Step 3: Material deformation due to heating ’é¦ Step 4: End of drilling process and formation of collar by shoulder ’é¦ Step 5: Tool retraction

- 5. Research background Authors/year Parameters studied Limitation of the study Streppel and Kal, 1983 Variations in end load, frictional moment and tool wear A theoretical model for calculation of thrust force, torque, frictional moment and wear rates missing. Kerkhofs et. al, 1994 Effect of tool coating of wear resistance, nature of tool failure Absence of Tool wear prediction time and tool failure prediction model Scott Miller et al. (2005-2007) Torque generation, thrust force model, heat generation rate, microstructural changes in work piece and tool, FEM modeling Nature of coefficient of friction undefined, tool feed not considered in torque models, model for temperature field absent, relationship between end load and process output missing. Qu and Blau, 2008 Model to calculate friction coefficient and shear stress Relation between end load and process output parameters.

- 6. Research motivation ’é¦ Absence of a correlation between the applied end load and tool speed on dependent variables of the process like torque, heat generation and temperature. ’é¦Lack of understanding about the nature of contact prevailing during drilling operations leaves doubts about the applicability of prior models developed.

- 7. Theoretical background ’é¦ Deformation of metal takes place due to development of shear zone at tool- workpiece interface ’é¦ Three different kinds of contact exist in thermal drilling process: sticking condition, sliding condition and partial sticking+sliding condition. ’é¦The relationship between contact pressure and shear stress is as follows in sticking condition is Where, p = contact pressure, ╬╝ = coefficient of friction shear p’ü┤ ’üŁ’ĆĮ

- 8. Theoretical background (cont.) ’é¦ Torque developed for a conical tool is given as: ’é¦ Rate of heat generation in conical tool is given as: ’é¦Temperature field in workpiece can be evaluated using 3 3 2 2 1 2 (h h ) tan 2 3cos 2 p T ’ü▒ ’ü░’üŁ ’ü▒ ’ĆŁ ’ĆĮ 3 3 3 2 1 (h h ) tan2 2( ) 3 sin 2 p q ’ü▒’ü░’üĘ’üŁ ’ü▒ ’ĆŁ ’ĆĮ& ( ) 2 0 0 2 (( ( v) ).r) 2 v y vtq H T T e Y kg g ’ü¼ ’ü¼ ’ü░ ’ĆŁ ’ĆŁ ’ĆŁ ’ĆĮ ’Ć½

- 9. FEM model ’é¦ To evaluate temperature generated in workpiece during thermal drilling, a FEM model was used. ’é¦The boundary conditions for the model include: ’é¦ Surface convection on top and bottom surfaces of plate ’é¦ Surface radiation from top of plate ’é¦ Dirichlet boundary conditions on side walls of the plate ’é¦Heat generated by the tool was applied in steps as the tool advances through the material to observe transient temperature field.

- 10. ’é¦ Deprag Flowform Screwdriving (FFS) ŌĆó AISI 1020 steel tool was used and Al 6063 alloy was used as work piece ŌĆó ThermoVision A40 Infrared Camera was used for temperature measurement ŌĆó Two different samples of 3.4 mm and two 1.3 mm (used together as 2.6 mm) were used ŌĆó The top surface of the work piece was painted black to increase the emissivity of surface for temperature detection from camera Experimental Setup Workpiece holder Tool holder Infrared camera

- 11. Experimental procedure ’é¦ 6 tests were conducted with for different conditions of speed and end load. Each condition was repeated with three samples to nullify process and material variations. ’é¦Test conditions have been shown in Annex A ’é¦No lubricant was used during the process ’é¦IR camera was used to generate the temperature variation while the servo motor mechanism in the drilling machine generated the torque variation during process.

- 12. Results from experiment ’é¦Cycle time is calculated between points A and B ’é¦Also, two peak torque locations were obtained for data points 1 and 2 corresponding to drilling and tapping operation respectively ’é¦The average cycle time (average of three samples tested for each condition) have been shown in table A B 1 2 Speed, (rpm) End load, (N) Thickness, (mm) Time (Sec) 6000 575 2.6 2.10 6000 650 2.6 1.088 5000 650 2.6 2.36 6000 700 3.4 1.728 6000 950 3.4 2.776 5000 950 3.4 3.87

- 13. Results (Contd.) ’é¦ Hypotheses H1a and H2a: Effect of end load and torque on cycle time. ’é¦The experimental conditions are shown in table below ’é¦The plot clearly shows that frictional torque experienced by the tool increases as end load is increased. Speed, rpm End load, N Thickness, mm 6000 575 2.6 6000 650 2.6

- 14. Results (Contd.) ’é¦ Hypothesis H1b: Effect of rotational speed on torque ’é¦Test conditions are shown in table below. ’é¦It was observed that increasing speed indeed reduces the frictional moment experienced by the tool Speed, (rpm) End load, (N) Thickness, (mm) 6000 950 3.4 5000 950 3.4

- 15. Results (Contd.) ’é¦ Hypothesis H3a: Effect of end load on temperature ’é¦ Test conditions are shown in the table below ’é¦ It can be seen that higher end loads reduce the maximum temperature attained in the material Speed, (rpm) End load, (N) Thickness, (mm) 6000 575 2.6 6000 650 2.6

- 16. FEM Results ’é¦Although the FEM model was not a complete representation of drilling process, its results could still predict the maximum temperatures ’é¦Test conditions were 650 N end load and 6000 rpm speed. ’é¦A maximum temperature of 197Ōäā can be seen in the workpiece. However, the maximum temperature observed in experiment was 206 deg.C for test condition with speed = 6000 RPM and end load = 650 N.

- 17. Joint Quality Process parameters for drilling affect the quality of the drill to a great extent The bushing of the left hole is comparatively smoother and of good quality as compared to the one on the right which shows the material of the bushing deformed in a very abnormal fashion

- 18. Future scopes Friction drilling process finds a huge scope in automotive industry for metal joining process in chassis and body Joint quality is much better as compared to resistance spot welding as the plate itself has a threaded bushing for fastening Its very clean process as its void of any lubrication which thereby do not contaminated the work piece

- 19. Annexure A- Experiment test conditions Test no. End load (N) Speed (RPM) Sheet thickness (mm) 1 575 6000 2.6 2 575 6000 2.6 3 575 6000 2.6 4 650 6000 2.6 5 650 6000 2.6 6 650 6000 2.6 7 950 6000 3.4 8 950 6000 3.4 9 950 6000 3.4 10 700 6000 3.4 11 700 6000 3.4 12 700 6000 3.4 13 650 5000 2.6 14 650 5000 2.6 15 650 5000 2.6 16 950 5000 3.4 17 950 5000 3.4 18 950 5000 3.4

- 20. Friction drill Tool ŌĆó The tool has 5 regions each playing a significant role in the process Center region: Tool penetration Conical region: Heat generating region Cylindrical region: Shapes the hole Shoulder region: Collar formation in the bush Shank region: Tool holding ŌĆó There can be threaded tool which relegates the need of separate tapping