L7-Welding defects & precision and non precision finishing operation.pptx

- 1. IPE 331: Production Process Welding Defects Dr. A. B. M. Mainul Bari Assistant Professor Dept of IPE, BUET.

- 2. A defective weldment fails under service conditions and causes damage to property and loss of human lives. Improper welding parameters and base metal and wrong welding procedures introduce defects or faults in the weld metal and around (i.e., in the heat-affected zone). The significance of individual defects depends on (i) The microstructure in which the defect occurs. (ii) The mechanical properties of the material with particular reference to notch toughness. (iii) The type of general loading (static, cyclical or shock). (iv) The environment (corrosive or non-corrosive). (v) Section thickness. (vi) Type and size of defect, and (vii) The stress pattern local to the defect. Welding defects

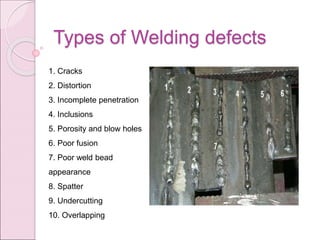

- 3. 1. Cracks 2. Distortion 3. Incomplete penetration 4. Inclusions 5. Porosity and blow holes 6. Poor fusion 7. Poor weld bead appearance 8. Spatter 9. Undercutting 10. Overlapping Types of Welding defects

- 4. Cracks may be on microscopic scale or macroscopic scale depending upon their size. Cracks may appear in the base metal, base metal-weld metal boundary, or in the weld metal. Cracks may be on the weld surface or under the weld bead. Cracks may appear in the crater or in the root. Cracks

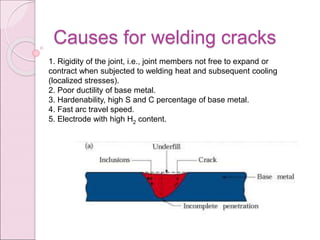

- 5. 1. Rigidity of the joint, i.e., joint members not free to expand or contract when subjected to welding heat and subsequent cooling (localized stresses). 2. Poor ductility of base metal. 3. Hardenability, high S and C percentage of base metal. 4. Fast arc travel speed. 5. Electrode with high H2 content. Causes for welding cracks

- 6. Distortion is the change in shape and difference between the positions of the two plates before welding and after welding. Distortion

- 7. 1. More number of passes with small diameter electrodes. 2. Slow arc travel speed. 3. Type of joint. A V joint needs more metal to be deposited to fill the groove as compared to a U joint, thus leading to comparatively more distortion. 4. High residual stresses in plates to be welded. 5. Welding sequence being improper. Use of jigs and fixtures, clamps, presetting, wedging and proper tacking may minimize distortion. Factors leading to Distortion

- 8. Penetration is the distance from base plate top surface to the, maximum extent of the weld nugget. Incomplete penetration

- 9. 1. Improper joints. 2. Too large root face. 3. Root gap too small. 4. Less arc current. 5. Faster arc travel speed. 6. Too large electrode diameter. 7. Longer arc length. 8. Wrongly held electrode. Causes for Incomplete penetration

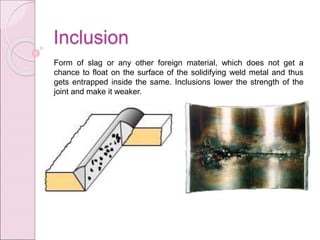

- 10. Form of slag or any other foreign material, which does not get a chance to float on the surface of the solidifying weld metal and thus gets entrapped inside the same. Inclusions lower the strength of the joint and make it weaker. Inclusion

- 11. 1. Too high or too low arc current. 2. Long arcs. 3. Too large electrode diameter. 4. Insufficient chipping and cleaning of previous passes in multipass welding. 5. Under cutting (it can entrap slag particles). 6. Wrongly placed tack welds. Factors leading to inclusion

- 12. Small metal particles which are thrown out of the arc during welding and get deposited on the base metal around the weld bead along its length. Spatter

- 13. 1. Excessive arc current. 2. Longer arcs. 3. Damp electrodes. 4. Electrodes being coated with improper flux ingredients. 5. Arc blow making the arc uncontrollable. 6. Bubbles of gas becoming entrapped in the molten globule of metal, expanding with great violence and projecting small drops of metal outside the arc steam. Causes for spatter

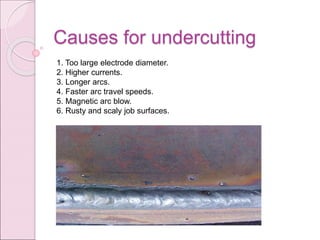

- 14. Formed in the parent metal along the sides of the weld bead. Groove reduces the thickness of the plate and thus the area along the bead, which in turn weakens the weld. Undercutting

- 15. 1. Too large electrode diameter. 2. Higher currents. 3. Longer arcs. 4. Faster arc travel speeds. 5. Magnetic arc blow. 6. Rusty and scaly job surfaces. Causes for undercutting

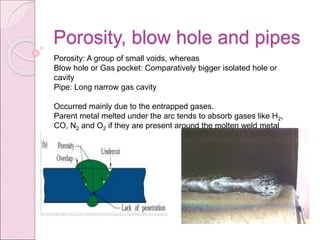

- 16. Porosity: A group of small voids, whereas Blow hole or Gas pocket: Comparatively bigger isolated hole or cavity Pipe: Long narrow gas cavity Occurred mainly due to the entrapped gases. Parent metal melted under the arc tends to absorb gases like H2, CO, N2 and O2 if they are present around the molten weld metal pool. Porosity, blow hole and pipes

- 17. 1. Improper (coating on the) electrode 2. Longer arcs 3. Faster arc travel speeds 4. Too low and too high arc currents 5. Incorrect welding technique 6. Electrode with damp and damaged coating 7. Scale, rust, oil, grease, moisture, etc. if present on the job surface 8. Improper base metal composition Factors leading to porous weld

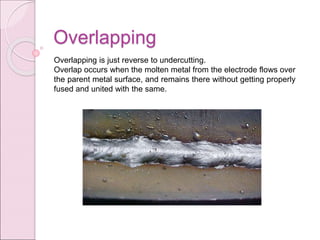

- 18. Overlapping is just reverse to undercutting. Overlap occurs when the molten metal from the electrode flows over the parent metal surface, and remains there without getting properly fused and united with the same. Overlapping

- 19. Causes for Overlapping 1. Lower arc current. 2. Slower arc travel speed. 3. Longer arcs. 4. Improper joint geometry (i.e., root gap). 5. Incorrect electrode diameter.

- 20. ’üČRemedies of Cracking ’üČRemedies of Inadequate Joint Penetration ’üČRemedies of Porosity ’üČRemedies of Inclusion ’üČRemedies of Incomplete Fusion Self ŌĆōstudy (pp 632)

- 21. Precision and non-precision Finishing Operations ’éŚ Achieve surface finish up to mirror like ’éŚ Very close dimensional precision ’éŚ Assigned as the last operation after conventional and abrasive machining process ŌŚ” Honing ŌŚ” Lapping ŌŚ” Super finishing ŌŚ” Polishing and buffing 26/21

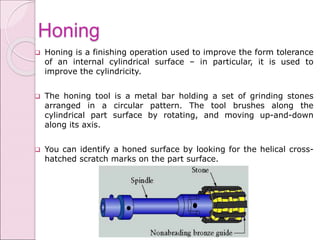

- 22. Honing ’ü▒ Honing is a finishing operation used to improve the form tolerance of an internal cylindrical surface ŌĆō in particular, it is used to improve the cylindricity. ’ü▒ The honing tool is a metal bar holding a set of grinding stones arranged in a circular pattern. The tool brushes along the cylindrical part surface by rotating, and moving up-and-down along its axis. ’ü▒ You can identify a honed surface by looking for the helical cross- hatched scratch marks on the part surface. 26/22

- 23. Honing 26/23

- 24. Superfinishing 26/24 Superfinishing is a finishing operation similar to honing, but it involves the use of a single abrasive stick. The reciprocating motion of the stick is performed at higher frequency and smaller amplitudes. Also, the grit size and pressures applied on the abrasive stick are smaller. A cutting fluid is used to cool the work surface and wash away chips. In superfinishing, the cutting action terminates by itself when a lubricant film is built up between the tool and work surface. Thus, superfinishing is capable only of improving the surface finish but not dimensional accuracy.The result of these operating conditions is mirror like finishes with surface roughness values around 0.01 ╬╝m. Superfinishing can be used to finish flat and external cylindrical surfaces.

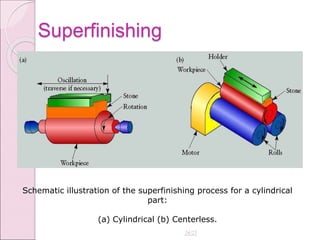

- 25. Superfinishing 26/25 Schematic illustration of the superfinishing process for a cylindrical part: (a) Cylindrical (b) Centerless.

- 26. Lapping 26/26 ’ü▒ Lapping is a finishing operation. The lapping tool is made of metal, leather, or cloth, impregnated with very fine abrasive particles. ’ü▒For preparing the surface of silicon wafers, lapping use a flat metal disc that rotates a small distance above the part. operations ’ü▒The gap is filled with a slurry containing fine abrasive grains. The rotation of the disc causes the slurry to flow relative to the part surface, resulting in very fine surface finish. ’ü▒This process gives dimensional tolerances of Ōēź 0.5╬╝m, and surface finish of up to 0.1 ╬╝m. ’ü▒The process is employed to get: ’ü▒Extreme accuracy of dimension ’ü▒Correction of minor imperfection of shape ’ü▒Refinement of the surface finish ’ü▒Close fit between mating surfaces.

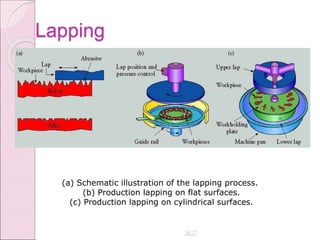

- 27. Lapping 26/27 (a) Schematic illustration of the lapping process. (b) Production lapping on flat surfaces. (c) Production lapping on cylindrical surfaces.

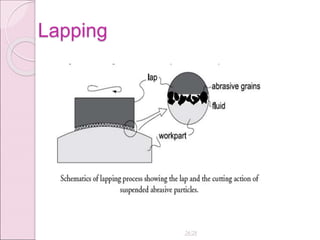

- 28. Lapping 26/28

- 29. Polishing and buffing 26/29 Polishing is a finishing operation to improve the surface finish by means of a polishing wheel made of fabrics or leather and rotating at high speed. The abrasive grains are glued to the outside periphery of the polishing wheel. Polishing operations are often accomplished manually. Buffing is a finishing operation similar to polishing, in which abrasive grains are not glued to the wheel but are contained in a buffing compound that is pressed into the outside surface of the buffing wheel while it rotates. As in polishing, the abrasive particles must be periodically replenished. Buffing is usually done manually, although machines have been designed to perform the process automatically. Polishing is used to remove scratches and burrs and to smooth rough surfaces while buffing is used to provide attractive surfaces with high glossy finish.