L9 grinding2012

- 2. Grinding    Material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit. Grits are characterized by sharp cutting points, high hot hardness, chemical stability and wear resistance. The grits are held together by a suitable bonding material to give shape of an abrasive tool.

- 3. Grinding – Advantages & Applications  Advantages     Dimensional accuracy Good surface finish Good form accuracy Applications     Surface finishing Descaling, deburring Finishing of flat as well as cylindrical surface Grinding of tools and cutters and resharpening of the same.

- 4. Grinding Characteristics   Low material removal process capable of providing both high accuracy and high finish Advance Abrasive Machining – High Accuracy, Surface Finish, Material removal rate

- 5. Grinding Wheel & Workpiece interaction

- 6. Grinding Wheel & Workpiece interaction

- 7. Grinding Wheels Abrasive Particles Bond  Grinding wheel consists of hard abrasive grains called grits, which perform the cutting or material removal, held in the weak bonding matrix.  A grinding wheel commonly identified by the type of the abrasive material used.

- 8. Grinding Wheels Alumina   Silicon Carbide  The conventional wheels include Aluminium oxide and Silicon carbide wheels while Diamond and CBN (cubic boron nitride) wheels fall in the category of superabrasive wheel.

- 9. Specifications of Grinding Wheels  Geometrical specification    Wheel diameter, Width and depth of rim Bore diameter

- 10. Specifications of Grinding Wheels  Compositional specification       Type of grit material Grit size Bond strength of the wheel, commonly known as wheel hardness Structure of the wheel denoting the porosity i.e. the amount of inter grit spacing Type of bond material Other than these parameters, the wheel manufacturer may add their own identification code prefixing or suffixing (or both) the standard code.

- 11. Specifications of Grinding Wheels Prefix Grain Type Grain Size Aluminium Oxide (A) Silicon Carbide (C) 10-24: 30-60: 80-180: 220-600: Grade Wheel Structure B: Dense E: Normal R: Open S: Silicate V: Vitrified A-G: Soft H-P: Medium Q-Z: Hard Coarse Medium Fine Very Fine Bond Type 1-4: Dense H-P: Normal Q-Z: Open Suffix

- 12. Specifications of Grinding Wheels  A 60 K 5 V     The letter ‘A’ denotes that the type of abrasive is Aluminium oxide. In case of silicon carbide the letter ‘C’ is used. The number ‘60’ specifies the average grit size in inch mesh. For a very large size grit this number may be as small as 6 where as for a very fine grit the designated number may be as high as 600. The letter ‘K’ denotes the hardness of the wheel, which means the amount of force required to pull out a single bonded abrasive grit by bond fracture. The letter symbol can range between ‘A’ and ‘Z’, ‘A’ denoting the softest grade and ‘Z’ denoting the hardest one. The number ‘5’ denotes the structure or porosity of the wheel. This number can assume any value between 1 to 20, ‘1’ indicating high porosity and ‘20’ indicating low porosity.

- 13. Selection of Grinding Wheel  Selection of grinding wheel means selection of composition of the grinding wheel and this depends upon the following factors:    Physical and chemical characteristics of the work material Grinding conditions Type of grinding (stock removal grinding or form finish grinding)

- 14. Selection of Grinding Wheel  Type of Abrasives    Aluminium oxide  For high tensile strength materials e.g. steel, malleable and wrought iron Silicon Carbide  For low tensile strength, brittle materials and non-metallic materials  Cast iron, soft non-ferrous metals, marble, stone Diamond  For carbides and very hard materials

- 15. Selection of Grinding Wheel  Grit Size  Coarse grit  Soft or ductile materials when fast grinding is required  Fine grains  Hard and brittle materials  Good surface finish

- 16. Selection of Grinding Wheel  Grade       The worn out grit must pull out from the bond and make room for fresh sharp grit in order to avoid excessive rise of grinding force and temperature. Therefore, a soft grade should be chosen for grinding hard material. During grinding of low strength soft material grit does not wear out so quickly. Therefore, the grit can be held with strong bond so that premature grit dislodgement can be avoided. Rough grinding: Medium to Hard Grade Precision grinding needs soft wheels Higher the wheel speed, harder the grade required Harder grades used when coolant applied

- 17. Selection of Grinding Wheel  Structure        The structure should be open for grinding wheels engaged in high material removal to provide chip accommodation space. The space between the grits also serves as pocket for holding grinding fluid. On the other hand dense structured wheels are used for longer wheel life, for holding precision forms and profiles. Open structure for soft and ductile materials Surface grinding requires more open structure than cylindrical grinding Rough grinding requires open structure Fine finish needs close structure

- 18. Selection of Grinding Wheel  Bond Material     Vitrified Bond (V)  Wheel surface speed 2000 m/min  Can not be used where mechanical impact or thermal variations are like to occur. Resin bond (B)  For operations requiring very strong wheels  Surface speed up to 3000 m/min Shellac Bond (S)  Grinding fine edges on cutters  Making very large wheels Rubber (R)  High finish at 5000 m/min  Thin wheels for wet cut-off operation.

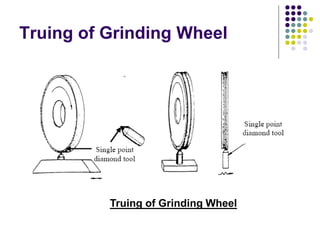

- 19. Truing of Grinding Wheel     Truing is the act of regenerating the required geometry on the grinding wheel, whether the geometry is a special form or flat profile. Truing produces the macro-geometry of the grinding wheel. Truing is also required on a new conventional wheel to ensure concentricity with specific mounting system. In practice the effective macro-geometry of a grinding wheel is of vital importance and accuracy of the finished workpiece is directly related to effective wheel geometry.

- 20. Truing of Grinding Wheel Truing of Grinding Wheel

- 21. Dressing of Grinding Wheel  Dressing is the conditioning of the wheel surface which ensures that grit cutting edges are exposed from the bond and thus able to penetrate into the workpiece material.  Also, in dressing attempts are made to splinter the abrasive grains to make them sharp and free cutting and also to remove any residue left by material being ground.

- 22. Dressing of Grinding Wheel  Dressing therefore produces micro-geometry. The structure of micro-geometry of grinding wheel determine its cutting ability with a wheel of given composition.  Dressing can substantially influence the condition of the grinding tool.