Latest C.V.

Download as DOCX, PDF0 likes509 views

Jayadev Prasad Nath Sharma has over 13 years of experience in steel production. He holds a Diploma in Mechanical Engineering and B.Sc degree. Currently, he works as a Senior Engineer at OCL Iron & Steel Ltd, where he supervises the induction furnace, ladle refining furnace, and continuous casting machine to improve production and quality. Previously, he worked at Scan Steel Limited as a Shift In-Charge, where he focused on improving furnace lining life and reducing production costs.

1 of 3

Download to read offline

Recommended

resume

resume chinnem chinna subbarayudu

╠²

Chinnem Chinna Subbarayudu has over 2.5 years of experience in quality control for a switchgear components manufacturing company. He holds a B.Tech in Mechanical Engineering and is seeking a challenging position utilizing his education and experience. His responsibilities in his current role include developing quality programs, inspection plans, and resolving non-conformities. He also performs internal audits, trend analysis, and coordinates with suppliers. In his academic career, he earned over 70% in his B.Tech and over 80% in his intermediate and SSC exams.Martin-CV- M.Tech

Martin-CV- M.TechMartin James

╠²

Martin James is seeking a position that allows him to utilize his skills and abilities. He has a M.Tech in Production and Industrial Engineering and B.E. in Mechanical Engineering. He is proficient in English, Malayalam, Hindi, and Tamil both written and spoken. His work experience includes positions at Bond Interiors LLC as a MEP Engineer, HLL Lifecare Limited as a mechanical maintenance engineer, and Karpara Project Engineering Pvt. Ltd. as a construction engineer working on thermal power plant projects. He has strong communication, leadership, and project management skills. In his personal time, he enjoys traveling, swimming, reading, watching movies, and listening to music.REGIN - RESUME

REGIN - RESUMERegin K N

╠²

This document is a resume for Regin Kuzhikattil Narayanan seeking a career opportunity in the oil and shipping industry. It summarizes his work experience as a pipe fitter over 15 years for companies in India and Singapore, including current employment at Sunil Raj Engineering Works in Kochin, India. It lists his technical skills in pipe fabrication, welding, and maintenance. His education includes an ITI certificate and SSLC degree from schools in Kerala, India.RAM CV UPDATED

RAM CV UPDATEDV.Rama krishna

╠²

V. Ramakrishna is seeking a challenging position in engineering that allows for innovation, creativity, and learning. He has 4 years of experience in production and quality control at Agnideep Water Technologies Pvt Ltd, where his responsibilities included production planning and supervision, quality inspection, and ensuring schedules and quality standards were met. Ramakrishna holds a Bachelor's degree in Mechanical Engineering and has technical skills in AutoCAD, MS Office, and pursuing courses in SolidWorks and Unigraphics. His areas of interest include production, manufacturing, quality, and automobiles.AMIT KUMAR (3)

AMIT KUMAR (3)Amit Singh

╠²

Amit Kumar is seeking a position that allows advancement in technical knowledge and career progression. He has over 4 years of experience managing various projects including successfully completing the construction of a 500 TPD DRI plant and 340 TPH boiler power plant. He has skills in project management, contractor relations, design software, and maintenance. Amit holds a Bachelor's degree in Mechanical Engineering and has completed internships focusing on quality assurance and control.steel str cv

steel str cvr.jeyasankar ramasamy S

╠²

This document contains the resume of R Jeyasankar. It summarizes his objective, technical skills, educational qualifications, personal skills, project experience, responsibilities, linguistic abilities, foreign experience in various countries, and India experience. His career objective is to utilize his skills and talents for organizational development. He has a bachelor's degree in mechanical engineering and diploma in mechanical engineering. His technical skills include AutoCAD, MS Office, and CNC programming. He has over 15 years of experience in structural fabrication, welding supervision, and mechanical engineering roles in countries like Saudi Arabia, Congo, Afghanistan, Dubai and within India.Arvind CV

Arvind CVArvind Tiwari

╠²

This document contains the resume of Arvind Kumar Tiwari. It summarizes his educational qualifications including an M.Tech in Manufacturing Technology from Lovely Professional University and a B.E. in Mechanical Engineering. It lists his technical skills in CAD software and research papers published. It also outlines his internship experience at Steel Authority of India Ltd and a thermal power plant, as well as a live project modifying car parts designs.Yogesh_Amrale_new_resume.doc-Apr-2015

Yogesh_Amrale_new_resume.doc-Apr-2015yogesh amrale

╠²

The document is a resume for Yogesh Amrale seeking a position in safety, health, and environment. It summarizes his 18 years of experience in fields like construction safety, engineering projects, and waste water treatment. He has a bachelor's degree in engineering and postgraduate qualifications in industrial safety, fire engineering, and occupational health and safety. The resume provides details of his work experience at various organizations in roles like EHS Head, SHE Consultant, and Chief HSE Manager, demonstrating his experience in developing safety systems and managing safety compliance on large projects.m.k.singh R

m.k.singh RAdarsh K. Jain

╠²

This document is a curriculum vitae for Manjit Kr. Singh that includes his personal and contact information, education history, work experience, skills, and a declaration. It outlines his objective to contribute effectively to organizational growth in engineering. It details his Bachelor's degree in electronics and communication engineering, ITI certification in electrical work, work experience including 11 months with Hindustan Alcox Ltd on airport projects and 6 months of maintenance engineering. It also lists his technical skills and personal information.muthu_kumaran

muthu_kumaranmuthu kumaran

╠²

S. Muthu Kumaran is seeking a long-term employment opportunity. He has over 10 years of experience as a CNC operator and programmer in India and the UAE. He is currently working at WEIR OIL & GAS in Dubai as a CNC turning machine programmer/operator. His responsibilities include effective planning and scheduling to meet production targets, quality control and assurance, and machine operation and programming. He is proficient in FANUC and SIEMENS control systems and has experience operating machines like VTLs, DOOSAN PUMAs, and Trevision 5-axis machines.vikram resume.

vikram resume.vikram s

╠²

Vikram S., a mechanical engineer with 1 year of experience in purchase department, is seeking a career opportunity in purchase or quality area. He has a BE in Mechanical Engineering from R.V.S College of Engineering & Technology with a CGPA of 7.31. His technical skills include CAD packages like AutoCAD and Pro-E, as well as MS Office applications. At his previous job at Unipres India Private Limited, his responsibilities included material procurement, vendor management, quality control activities and project work involving fabrication and manufacturing.maintenance engineer

maintenance engineerASHOK SINGH

╠²

Ashok Kumar Singh is a mechanical engineer seeking a position that allows him to enhance his technical skills and contribute value. He has over 5 years of experience in maintenance engineering and project execution roles. He is proficient in maintenance procedures, equipment inspections, and managing vendors. Ashok holds a Bachelor's degree in Mechanical Engineering and has experience working for companies in the composite materials and electrostatic precipitator industries.shahzad anjum c.v

shahzad anjum c.vRana Shahzad Anjum

╠²

Shahzad Anjum is applying for the position of Foreman (Electrical). He has over 10 years of experience working in various electrical roles on large infrastructure projects. His most recent role was as a Foreman (Electrical) with Habib Rafiq (PVT) Ltd where he led teams and oversaw electrical works on several projects including power plants and motorways. He is seeking to enhance his skills and help organizations grow through challenging work.AJMAL CV,

AJMAL CV,ajmal mirza

╠²

Mohd. Ajmal Beg is seeking a position where he can utilize his technical and analytical skills. He has over 3 years of experience as a Production Incharge in Saudi Arabia, where he oversees blow molding and injection molding machines making packaging bottles. He holds a Post Graduate Diploma in Plastic Processing & Testing from Central Institute of Plastic Engg. & Technology in India. His professional skills include processing techniques like injection molding and testing of materials properties.QC201601

QC201601kumaravel s

╠²

Kumaravel S is applying for a quality control role. He currently works as a Quality Engineer at AKME Technologies where he is responsible for initial product verification, managing defects, quality inspections, and more. Previously, he worked as a Quality Engineer at Freedom Ophthalmic Pvt Ltd where his responsibilities included raw material verification, inspections, analyzing customer feedback, and maintaining quality management systems. He has a B.E. in Mechanical Engineering from Anna University and experience with AutoCAD, MS Office, and ERP systems. His objective is to join a motivated team and implement innovative ideas to accomplish organizational goals.suresh_resume

suresh_resumeSuresh Menaria

╠²

Suresh Menaria is a chemical engineer seeking a position that allows him to utilize his technical, analytical, and management skills. He has over 10 years of experience in various roles related to work-over operations on land rigs, including currently working as a tool pusher. His qualifications include a Bachelor's degree in chemical engineering and various certifications in well intervention from completion to production.Michael Louel M 2

Michael Louel M 2michael louel dioneda

╠²

This document contains a resume and application for the position of Welding Foreman/Tig Welder from Michael Louel M. Dioneda. It includes his contact information, objective, educational background studying Architectural Drafting and Arc Welding, and extensive work experience as both a Welder and Welding Foreman on various industrial construction projects in the Philippines, Indonesia, Qatar, and Saudi Arabia since 2006. It also lists his safety training qualifications and welding certifications from Tesda Training Center in Oxy/Acetylene Welding, Industrial Pipefitting, and Electrical Arc Welding.OKORIE SUNDAY

OKORIE SUNDAYOkorie Sunday

╠²

This document is a resume for an individual seeking a challenging position in engineering or technology. It includes sections on career objective, personal profile, education history, qualifications, professional experience, responsibilities, hobbies and references. The applicant has an HND in Mechanical Engineering and has worked as a Maintenance Officer and Supervisor for engineering companies, with responsibilities including mechanical works coordination, project scheduling, and quality assurance.Rajesh Sree Ramachandran Nair Original Copy

Rajesh Sree Ramachandran Nair Original Copymindstutor

╠²

Mechanical Engineer having around 13 years of experience in Projects for construction /maintenance of Oil/Infrastructural projectskhaled CV.doc

khaled CV.dockhaled arafat

╠²

Khaled Arafat is seeking a position in metallurgy or materials engineering. He has a B.S. in Metallurgy and Materials Engineering from Cairo University and over 2 years of experience as a project engineer and production shift manager at Suez Steel Company. His responsibilities included optimizing steel production processes and equipment use. He also completed training programs in steelmaking, welding metallurgy, heat treatment, and aluminum smelting and casting.Resume

ResumeMRINMAY BERA

╠²

An experienced Mechanical Engineer with over 10 years of experience in production planning, procurement, engineering coordination, erection, and commissioning of multidisciplinary projects. Currently working as Project and Purchase Head at Jindal Tubular India Ltd, handling the spiral pipe and internal coating plant, as well as the purchase department. Possesses strong skills in fabrication, welding, machine manufacturing, and experience setting up HSAW pipe mills and conveyor systems.CV shamsheer

CV shamsheershamsheer ck

╠²

Shamsheer C.K. is seeking an engineering position and has over 7 years of experience in facilities management. He currently works as a site engineer for Emrill LLC in Dubai, where he is responsible for day-to-day engineering activities and ensuring maintenance is carried out according to schedules and contracts. Previously, he has held roles as a facilities engineer and maintenance engineer trainee in Dubai and India. He has a bachelor's degree in electrical and electronics engineering and proficiencies in PLC, SCADA, and Microsoft Office.Mukesh Sharma - CV update (2) (6) (1) (1) (1)

Mukesh Sharma - CV update (2) (6) (1) (1) (1)Mukesh Kumar Sharma

╠²

Mukesh Kumar Sharma has over 15 years of experience in security management, operations, and supervision roles. He has worked as a Security Supervisor for the US Embassy in Mumbai, Australian High Commission in New Delhi, and currently works as a Security Officer for Amtek Auto Limited in New Delhi. Sharma has a diploma in air conditioning and refrigeration and seeks to further his career in a responsible security position that allows growth.CURICULAM VAITE

CURICULAM VAITECHEMARLA Vengal Reddy

╠²

C. Vengal Reddy is a DGM of Refractories at Jindal Steel and Power Limited in Angul, Odisha. He has over 21 years of experience in the refractories field working for various steel and ceramic companies. He holds a diploma in Ceramic Technology and B-Tech in Ceramic Technology. His responsibilities have included annual budgeting, technical discussions with vendors, minimizing refractory consumption and cost control, and handling refractory management services.M.Ayaz updated Cv

M.Ayaz updated CvEngr. Ayaz

╠²

Muhammad Ayaz is seeking a career opportunity where he can apply his theoretical knowledge in metallurgy and materials engineering. He has a BE degree from Dawood University of Engineering & Technology and internship experience at Pakistan Steel Karachi and Karachi Shipyard & Engineering Works Ltd. His final year project focused on improving the mechanical properties of steels through cryogenic heat treatment.Resume

ResumeImran Reza

╠²

Md Imran Reza is a service field engineer currently working for Maktoom Trading & Contracting Co. LLC in Oman. He has over 5 years of experience in fields like quality control engineering, materials management, and field engineering. Imran holds a Bachelor's degree in Mechanical Engineering from Visvesvaraya Technological University in India. He is proficient in CAD/CAM software like SolidEdge and SAP modules including SRM and SCM. Imran is looking to relocate for new opportunities and can be reached by email or phone.resumeanbu

resumeanbuvadivelu anbu

╠²

V. Anbu is seeking a position that allows him to contribute to an organization's growth. He has over 10 years of experience in marine hydraulic systems and offshore oil and gas. Some of his qualifications include certification in winch service, offshore safety training, and an engineering degree. He is currently working as a service engineer in Singapore, with experience commissioning and maintaining various marine equipment.GHOLAMALI MOKHTARI

GHOLAMALI MOKHTARIgholamali mokhtari

╠²

Golamali Mokhtari is a Refinery Material Specialist with over 20 years of experience in the oil refining industry. He prepares material requests and specifications for maintenance projects at Abadan Refinery, Iran's largest oil refinery. Prior to his current role, Mokhtari worked as a Mechanical Technician at Abadan Refinery for over 10 years. He has expertise in machinery vibration analysis and decreasing refinery shutdown failures. Mokhtari holds a High Diploma in Mechanic, Air Conditioning & Refrigeration and a MA in Industrial Management.harish cv

harish cvHarish Rathore

╠²

Harish Kumar Rathore is seeking a senior level position in a reputed organization. He has over 7 years of experience in metal manufacturing industries, currently working as an Assistant Manager of Operations at Aditya Aluminium earning Rs. 10.1 lakhs annually. He has a B.Tech in Metallurgical Engineering from NIT Raipur and experience in roles like Metallurgist Engineer, Junior Manager, and furnace commissioning. His skills include aluminum cast house operation, continuous casting, quality testing, safety training, and SAP/ERP.Dhananjay_Kumar_Chaubey_2016

Dhananjay_Kumar_Chaubey_2016Chothe

╠²

Dhananjay Kumar Chaubey is an Assistant Manager at Jindal Steel & Power Ltd. in Angul, Orissa with over 7.5 years of experience in electrical, automation, and instrumentation engineering. He is seeking middle-level positions utilizing his expertise in areas such as project management, maintenance, commissioning, PLC programming, SCADA systems, drives, and instrumentation. He has a Bachelor's degree in Electrical and Electronics Engineering and has managed the successful commissioning of various plants and equipment during his career.More Related Content

What's hot (20)

m.k.singh R

m.k.singh RAdarsh K. Jain

╠²

This document is a curriculum vitae for Manjit Kr. Singh that includes his personal and contact information, education history, work experience, skills, and a declaration. It outlines his objective to contribute effectively to organizational growth in engineering. It details his Bachelor's degree in electronics and communication engineering, ITI certification in electrical work, work experience including 11 months with Hindustan Alcox Ltd on airport projects and 6 months of maintenance engineering. It also lists his technical skills and personal information.muthu_kumaran

muthu_kumaranmuthu kumaran

╠²

S. Muthu Kumaran is seeking a long-term employment opportunity. He has over 10 years of experience as a CNC operator and programmer in India and the UAE. He is currently working at WEIR OIL & GAS in Dubai as a CNC turning machine programmer/operator. His responsibilities include effective planning and scheduling to meet production targets, quality control and assurance, and machine operation and programming. He is proficient in FANUC and SIEMENS control systems and has experience operating machines like VTLs, DOOSAN PUMAs, and Trevision 5-axis machines.vikram resume.

vikram resume.vikram s

╠²

Vikram S., a mechanical engineer with 1 year of experience in purchase department, is seeking a career opportunity in purchase or quality area. He has a BE in Mechanical Engineering from R.V.S College of Engineering & Technology with a CGPA of 7.31. His technical skills include CAD packages like AutoCAD and Pro-E, as well as MS Office applications. At his previous job at Unipres India Private Limited, his responsibilities included material procurement, vendor management, quality control activities and project work involving fabrication and manufacturing.maintenance engineer

maintenance engineerASHOK SINGH

╠²

Ashok Kumar Singh is a mechanical engineer seeking a position that allows him to enhance his technical skills and contribute value. He has over 5 years of experience in maintenance engineering and project execution roles. He is proficient in maintenance procedures, equipment inspections, and managing vendors. Ashok holds a Bachelor's degree in Mechanical Engineering and has experience working for companies in the composite materials and electrostatic precipitator industries.shahzad anjum c.v

shahzad anjum c.vRana Shahzad Anjum

╠²

Shahzad Anjum is applying for the position of Foreman (Electrical). He has over 10 years of experience working in various electrical roles on large infrastructure projects. His most recent role was as a Foreman (Electrical) with Habib Rafiq (PVT) Ltd where he led teams and oversaw electrical works on several projects including power plants and motorways. He is seeking to enhance his skills and help organizations grow through challenging work.AJMAL CV,

AJMAL CV,ajmal mirza

╠²

Mohd. Ajmal Beg is seeking a position where he can utilize his technical and analytical skills. He has over 3 years of experience as a Production Incharge in Saudi Arabia, where he oversees blow molding and injection molding machines making packaging bottles. He holds a Post Graduate Diploma in Plastic Processing & Testing from Central Institute of Plastic Engg. & Technology in India. His professional skills include processing techniques like injection molding and testing of materials properties.QC201601

QC201601kumaravel s

╠²

Kumaravel S is applying for a quality control role. He currently works as a Quality Engineer at AKME Technologies where he is responsible for initial product verification, managing defects, quality inspections, and more. Previously, he worked as a Quality Engineer at Freedom Ophthalmic Pvt Ltd where his responsibilities included raw material verification, inspections, analyzing customer feedback, and maintaining quality management systems. He has a B.E. in Mechanical Engineering from Anna University and experience with AutoCAD, MS Office, and ERP systems. His objective is to join a motivated team and implement innovative ideas to accomplish organizational goals.suresh_resume

suresh_resumeSuresh Menaria

╠²

Suresh Menaria is a chemical engineer seeking a position that allows him to utilize his technical, analytical, and management skills. He has over 10 years of experience in various roles related to work-over operations on land rigs, including currently working as a tool pusher. His qualifications include a Bachelor's degree in chemical engineering and various certifications in well intervention from completion to production.Michael Louel M 2

Michael Louel M 2michael louel dioneda

╠²

This document contains a resume and application for the position of Welding Foreman/Tig Welder from Michael Louel M. Dioneda. It includes his contact information, objective, educational background studying Architectural Drafting and Arc Welding, and extensive work experience as both a Welder and Welding Foreman on various industrial construction projects in the Philippines, Indonesia, Qatar, and Saudi Arabia since 2006. It also lists his safety training qualifications and welding certifications from Tesda Training Center in Oxy/Acetylene Welding, Industrial Pipefitting, and Electrical Arc Welding.OKORIE SUNDAY

OKORIE SUNDAYOkorie Sunday

╠²

This document is a resume for an individual seeking a challenging position in engineering or technology. It includes sections on career objective, personal profile, education history, qualifications, professional experience, responsibilities, hobbies and references. The applicant has an HND in Mechanical Engineering and has worked as a Maintenance Officer and Supervisor for engineering companies, with responsibilities including mechanical works coordination, project scheduling, and quality assurance.Rajesh Sree Ramachandran Nair Original Copy

Rajesh Sree Ramachandran Nair Original Copymindstutor

╠²

Mechanical Engineer having around 13 years of experience in Projects for construction /maintenance of Oil/Infrastructural projectskhaled CV.doc

khaled CV.dockhaled arafat

╠²

Khaled Arafat is seeking a position in metallurgy or materials engineering. He has a B.S. in Metallurgy and Materials Engineering from Cairo University and over 2 years of experience as a project engineer and production shift manager at Suez Steel Company. His responsibilities included optimizing steel production processes and equipment use. He also completed training programs in steelmaking, welding metallurgy, heat treatment, and aluminum smelting and casting.Resume

ResumeMRINMAY BERA

╠²

An experienced Mechanical Engineer with over 10 years of experience in production planning, procurement, engineering coordination, erection, and commissioning of multidisciplinary projects. Currently working as Project and Purchase Head at Jindal Tubular India Ltd, handling the spiral pipe and internal coating plant, as well as the purchase department. Possesses strong skills in fabrication, welding, machine manufacturing, and experience setting up HSAW pipe mills and conveyor systems.CV shamsheer

CV shamsheershamsheer ck

╠²

Shamsheer C.K. is seeking an engineering position and has over 7 years of experience in facilities management. He currently works as a site engineer for Emrill LLC in Dubai, where he is responsible for day-to-day engineering activities and ensuring maintenance is carried out according to schedules and contracts. Previously, he has held roles as a facilities engineer and maintenance engineer trainee in Dubai and India. He has a bachelor's degree in electrical and electronics engineering and proficiencies in PLC, SCADA, and Microsoft Office.Mukesh Sharma - CV update (2) (6) (1) (1) (1)

Mukesh Sharma - CV update (2) (6) (1) (1) (1)Mukesh Kumar Sharma

╠²

Mukesh Kumar Sharma has over 15 years of experience in security management, operations, and supervision roles. He has worked as a Security Supervisor for the US Embassy in Mumbai, Australian High Commission in New Delhi, and currently works as a Security Officer for Amtek Auto Limited in New Delhi. Sharma has a diploma in air conditioning and refrigeration and seeks to further his career in a responsible security position that allows growth.CURICULAM VAITE

CURICULAM VAITECHEMARLA Vengal Reddy

╠²

C. Vengal Reddy is a DGM of Refractories at Jindal Steel and Power Limited in Angul, Odisha. He has over 21 years of experience in the refractories field working for various steel and ceramic companies. He holds a diploma in Ceramic Technology and B-Tech in Ceramic Technology. His responsibilities have included annual budgeting, technical discussions with vendors, minimizing refractory consumption and cost control, and handling refractory management services.M.Ayaz updated Cv

M.Ayaz updated CvEngr. Ayaz

╠²

Muhammad Ayaz is seeking a career opportunity where he can apply his theoretical knowledge in metallurgy and materials engineering. He has a BE degree from Dawood University of Engineering & Technology and internship experience at Pakistan Steel Karachi and Karachi Shipyard & Engineering Works Ltd. His final year project focused on improving the mechanical properties of steels through cryogenic heat treatment.Resume

ResumeImran Reza

╠²

Md Imran Reza is a service field engineer currently working for Maktoom Trading & Contracting Co. LLC in Oman. He has over 5 years of experience in fields like quality control engineering, materials management, and field engineering. Imran holds a Bachelor's degree in Mechanical Engineering from Visvesvaraya Technological University in India. He is proficient in CAD/CAM software like SolidEdge and SAP modules including SRM and SCM. Imran is looking to relocate for new opportunities and can be reached by email or phone.resumeanbu

resumeanbuvadivelu anbu

╠²

V. Anbu is seeking a position that allows him to contribute to an organization's growth. He has over 10 years of experience in marine hydraulic systems and offshore oil and gas. Some of his qualifications include certification in winch service, offshore safety training, and an engineering degree. He is currently working as a service engineer in Singapore, with experience commissioning and maintaining various marine equipment.GHOLAMALI MOKHTARI

GHOLAMALI MOKHTARIgholamali mokhtari

╠²

Golamali Mokhtari is a Refinery Material Specialist with over 20 years of experience in the oil refining industry. He prepares material requests and specifications for maintenance projects at Abadan Refinery, Iran's largest oil refinery. Prior to his current role, Mokhtari worked as a Mechanical Technician at Abadan Refinery for over 10 years. He has expertise in machinery vibration analysis and decreasing refinery shutdown failures. Mokhtari holds a High Diploma in Mechanic, Air Conditioning & Refrigeration and a MA in Industrial Management.Similar to Latest C.V. (20)

harish cv

harish cvHarish Rathore

╠²

Harish Kumar Rathore is seeking a senior level position in a reputed organization. He has over 7 years of experience in metal manufacturing industries, currently working as an Assistant Manager of Operations at Aditya Aluminium earning Rs. 10.1 lakhs annually. He has a B.Tech in Metallurgical Engineering from NIT Raipur and experience in roles like Metallurgist Engineer, Junior Manager, and furnace commissioning. His skills include aluminum cast house operation, continuous casting, quality testing, safety training, and SAP/ERP.Dhananjay_Kumar_Chaubey_2016

Dhananjay_Kumar_Chaubey_2016Chothe

╠²

Dhananjay Kumar Chaubey is an Assistant Manager at Jindal Steel & Power Ltd. in Angul, Orissa with over 7.5 years of experience in electrical, automation, and instrumentation engineering. He is seeking middle-level positions utilizing his expertise in areas such as project management, maintenance, commissioning, PLC programming, SCADA systems, drives, and instrumentation. He has a Bachelor's degree in Electrical and Electronics Engineering and has managed the successful commissioning of various plants and equipment during his career.resume for jayanta das (3)

resume for jayanta das (3)Jayanta Das

╠²

Jayanta Das is a mechanical engineer currently working as a senior engineer at Bhushan Steel Limited in Angul, Odisha. He has over 15 years of experience in plant maintenance and utility roles. He holds a diploma in mechanical engineering and bachelor's degree in science. His responsibilities have included equipment erection, commissioning, operations, and maintenance roles. He is seeking new opportunities and aims to take on more leadership responsibilities over the long run.CV - 19 yrs exp at HOT ROLLING MILL operation with DME & MBA in Operation Man...

CV - 19 yrs exp at HOT ROLLING MILL operation with DME & MBA in Operation Man...Arun Chowdhury

╠²

This document is a curriculum vitae for Arun Chowdhury, who has 19 years of experience in steel industry operations and production, including at hot rolling mills, seamless pipe plants, and other steel processing facilities in India and Africa. He currently works as the Works Manager at Tembo Steel in Uganda, overseeing their rolling mills. He holds an MBA in Operations Management and a Diploma in Mechanical Engineering, and seeks a new position with a negotiable compensation package.d.p15

d.p15DURG PAL SINGH

╠²

Durg Pal Singh is seeking a position that allows him to utilize his 13 years of experience in production planning and control. He is currently an Assistant Manager at C&S Electric Ltd, a large manufacturer of bus ducts and control panels. Previously, he held senior engineering roles at Sundweep Engineers and other companies. His responsibilities have included supervising multiple shops, managing personnel, production planning, meeting targets, and training workers. He has a diploma in mechanical engineering and relevant training in areas such as metrology, ERP systems and non-destructive testing.CV_Anup

CV_AnupAnup Kumar Mondal

╠²

Anup Kumar Mondal is seeking a new job and provides his career objective, personal details, educational qualifications, technical qualifications, work experiences, languages known, and computer skills. He has over 25 years of experience in cost estimation, project management, and technical roles for the steel and power industries. His current role is as Assistant General Manager at Danieli India Ltd where he is responsible for project review, estimation, tendering, and vendor development.harish cv

harish cvHarish Rathore

╠²

Harish Kumar Rathore is seeking a senior level position in a reputed organization. He has over 7 years of experience in metal manufacturing industries including iron and steel, aluminum, and continuous casting and rolling mills. Currently he works as an Assistant Manager of Operations at Aditya Aluminum, Hindalco Industries Ltd. He holds a B.Tech in Metallurgical Engineering from NIT Raipur and has experience in areas such as production planning, quality testing, safety training, new product development, and cost optimization. He is proficient in SAP, Oracle, and ERP systems.harish cv

harish cvHarish Rathore

╠²

Harish Kumar Rathore is seeking a senior level position in a reputed organization. He has over 7 years of experience in metal manufacturing industries including iron and steel, aluminum, and continuous casting and rolling mills. Currently he works as an Assistant Manager of Operations at Aditya Aluminum, Hindalco Industries Ltd. He holds a B.Tech in Metallurgical Engineering from NIT Raipur and has experience in areas such as production planning, quality testing, safety training, new product development, and cost optimization. He is proficient in SAP, Oracle, and ERP systems.AMIT KUMAR (3)

AMIT KUMAR (3)Amit Singh

╠²

Amit Kumar is seeking a position that allows advancement in technical knowledge and career progression. He has 4 years of experience managing various projects including successfully completing the construction of a 500 TPD DRI plant and 340 TPH boiler power plant. He has skills in project management, contractor relations, design software, and SAP. Amit holds a Bachelor's degree in Mechanical Engineering and has completed internships focusing on quality assurance.abelsingh

abelsinghabel singh

╠²

Abel Singh has over 9 years of experience in electroplating, including 2.5 years working in the United Arab Emirates. He is currently a production in-charge for electroless nickel plating at Balambig Metal Finishers in Bangalore, India, where he is responsible for customer dealings, managing personnel, and production planning. Previously, he worked as a senior electroplater in Dubai where he developed electroplating processes and supervised projects and staff. He has expertise in various electroplating chemicals and analytical testing methods.resume gaurav new

resume gaurav newGaurav Srivastav

╠²

The document provides a summary of an individual's qualifications for a quality engineer position. It includes their objective to utilize their skills and knowledge, professional experience as a quality engineer inspecting welding and materials, academic qualifications including a B.Tech in mechanical engineering, technical skills in non-destructive testing and software, an internship in manufacturing, and hobbies including machine design and sports. Personal details such as name, address, and languages are also provided.arjun_dongre

arjun_dongreArjun Dongre

╠²

Arjun Dongre is seeking a position that allows him to contribute to organizational growth and realize his potential. He has over 5 years of experience as an electrical engineer, currently working for Bhusan Power & Steel Ltd in Odisha. Previously, he worked for Indian Steel Corporation Ltd in Gujarat. He has experience in electrical maintenance, commissioning, and projects. He has a Bachelor's degree in Electrical and Electronics Engineering.PM_SSN_Steel.

PM_SSN_Steel.Satpal Singh Nagi

╠²

Satpal Singh Nagi is a mechanical engineer with 20 years of experience in project management for major steel plants. He has expertise in managing engineering, layouts, equipment selection, and projects for greenfield and brownfield sites. Nagi is skilled in assembly, erection, commissioning, and testing of plant equipment for steel, power, and chemical industries. He seeks managerial positions involving project planning, execution, erection, and commissioning.New resume

New resumeRitesh Panchal

╠²

Ritesh Panchal is seeking new opportunities with experience in aluminum alloy production and wind turbine maintenance. He has a diploma in mechanical engineering and over 2 years of work experience at Met Trade India and Vestas Wind Technology. His experience includes overseeing aluminum and lead production processes, implementing quality improvement techniques, and performing scheduled and unscheduled maintenance on wind turbines. He is looking to utilize his skills in manufacturing engineering, quality control, and maintenance.Sandy's resume updated

Sandy's resume updatedSandeep Mamgain

╠²

Sandeep Mamgain is seeking a challenging position that utilizes his engineering and technical skills. He has over 5 years of experience in galvanizing process production at Bhushan Steels Ltd and 11 months of supervisory experience at Jagdamba Liquefied Steels Ltd. He has a B.Tech in Industrial Production Engineering from Dehradun Institute of Technology and is proficient in production planning, scheduling, and costing. He is self-motivated, hard-working, and has strengths in adaptability, teamwork, analytical thinking, and leadership.yogendra singh rajawat

yogendra singh rajawatyogendra rajawat

╠²

Yogendra Singh Rajawat is applying for an electrical engineering position. He has a Bachelor's degree in electrical engineering with over 66% marks. He has 4 years of experience working as a shift engineer in electrical maintenance departments for two companies, Uttam Galva Steels Ltd and Indian Steel Corporation Ltd. In his resume, he provides details of his educational qualifications and professional experience in electrical maintenance, including working with PLC systems, cranes, furnaces, and other industrial equipment. He is seeking new opportunities to further contribute his skills and knowledge.Nirav v

Nirav vtalaviya nirav

╠²

This document is a curriculum vitae for Niravkumar Talaviya, who has 6 years of experience in heavy fabrication production. He has a B.E. in Mechanical Engineering and a diploma in Mechanical Engineering. His objective is to expand his growth horizon. He has worked as a Senior Production Engineer at Anupam Mitsubishi Heavy Industries Ltd since 2014 where he supervised fabrication and coordinated production. Previously he worked as a Production Engineer at Novatech Engineers from 2011-2013 and Offshore Infrastructure Ltd from 2009-2011 where he ensured production met quality standards. He has knowledge of materials, welding processes, AutoCAD and ASME codes.Angad CV.Doc

Angad CV.DocAngad Yadav

╠²

Angad Yadav is seeking a position in electrical product design and development where he can utilize his skills and experience. He has over 6 years of experience working in electrical maintenance and control logic roles for various industrial plants in Turkey, Iraq, and India. His experience includes working with PLCs and drives from manufacturers such as ABB, Siemens, Allen-Bradley, and more. He is proficient in maintenance, commissioning, troubleshooting, and process improvement. Angad holds a diploma in electrical engineering and an ITI qualification with experience in various systems including rolling mills, galvanizing lines, and furnaces.Ashfaq Resume new

Ashfaq Resume newAshfaq Ahmad

╠²

Ashfaq Ahmad is an instrumentation and control engineer with over 10 years of experience in basic and detailed engineering for steel plant projects. He has extensive experience in instrumentation design, calibration, installation, commissioning, and troubleshooting of field instruments. Currently, he works as a senior manager at SMS Group in India where he has worked on various projects for clients like Tata Steel, Bhushan Steel, and IISCO.sks

skssanjay kumar singh

╠²

This resume is for Sanjay Kumar Singh, an Indian citizen seeking a career incorporating creativity and innovation. He has a Bachelor of Engineering degree in Mechanical Engineering from Pune University. His experience includes over 15 years working in operations roles at various steel mills and companies in India, starting as a Graduate Engineer Trainee and rising to Manager of Production and Assembly. His current role oversees both production and the roll shop department at India Steel Works Limited, where he manages equipment maintenance, production reporting, and quality control.Latest C.V.

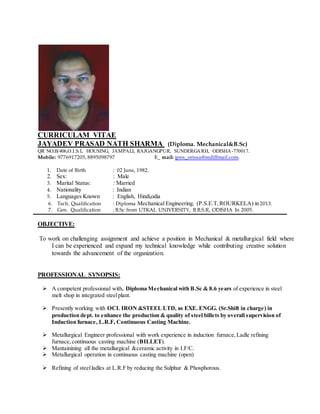

- 1. CURRICULAM VITAE JAYADEV PRASAD NATH SHARMA (Diploma. Mechanical&B.Sc) QR NO:B/406,O.I.S.L HOUSING, JAMPALI, RAJGANGPUR, SUNDERGARH, ODISHA-770017. Mobile: 9776917205, 8895098797 E_ mail: jpns_orissa@rediffmail.com. 1. Date of Birth : 02 June, 1982. 2. Sex: : Male 3. Marital Status: : Married 4. Nationality : Indian 5. Languages Known : English, Hindi,odia 6. Tech. Qualification : Diploma Mechanical Engineering. (P.S.E.T,ROURKELA) in 2013. 7. Gen. Qualification : B.Sc from UTKAL UNIVERSITY, B.B.S.R, ODISHA In 2005. OBJECTIVE: To work on challenging assignment and achieve a position in Mechanical & metallurgical field where I can be experienced and expand my technical knowledge while contributing creative solution towards the advancement of the organization. PROFESSIONAL SYNOPSIS: ’āś A competent professional with. Diploma Mechanical with B.Sc & 8.6 years of experience in steel melt shop in integrated steelplant. ’āś Presently working with OCL IRON &STEEL LTD, as EXE. ENGG. (Sr.Shift in charge) in production dept. to enhance the production & quality of steel billets by overall supervision of Induction furnace, L.R.F, Continuous Casting Machine. ’āś Metallurgical Engineer professional with work experience in induction furnace,Ladle refining furnace,continuous casting machine (BILLET). ’āś Mantainining all the metallurgical &ceramic activity in I.F/C. ’āś Metallurgical operation in continuous casting machine (open) ’āś Refining of steelladles at L.R.F by reducing the Sulphur & Phosphorous.

- 2. ’āś Alloying the steel to make different commercial grade steel. ’āś Knowledge of Documentation Total Productive Maintenance (TPM) and its various pillars with implementation. SOFTWARE & LANGUAGE: C, C++ and MS OFFICE, ŌĆśOŌĆÖ Level in Computer education,( DOEACC, NEW DELHI) In 2006. EXPERIENCE DETAILS: OCL IRON &STEEL LTD,RAJGANGPURL,ODISHA, INDIA Company: OCL IRON &STEEL LTD, RAJGANGPURL,ODISHA, INDIA Designation: Sr. ENGINEER- SMS. Duration: JUNE-2009- Till date. Role: Shift In charge- PRODUCTION Nature of Work: ŌĆó Skill Set: Overall production activities (induction Furnace, L.R.F, C.C.M.) ŌĆó To improve the productivity & quality of the steel billets.. ’éĘ Reducing the cost of production by making maximum recovery of the alloys in I F/C. ’éĘ Safely operate the induction furnace with 5% of charging material in induction furnace. ’éĘ Improving furnace lining life with proper operation in I.F/C. ’éĘ Knowledge of mechanical maintenance in I.F/C. ’éĘ Power control in induction furnace by proper coordination with captive power plant for smooth operation. ’éĘ Improving the lining life and productivity by maintaining the proper bath carbon during melting in the induction furnace. ’éĘ Safely operating the induction furnace with 100% D.R.I. Pallets in place of D.R.I lumps & fines. ’éĘ Maintaining proper Temp. & condition for smooth casting of steelbillets in open caster. ’éĘ Maintenance work of Withdrawal unit, oscillation unit, roller unit, water spray unit of continuous casting machine. ’éĘ Check & correct the physical defects of steelbillets. ’éĘ Improving Machine reliability by eliminating root cause defect & increase in plant yield ’éĘ Man power management to take out better output. ’éĘ To implement T.P.M& 5,S activities. ’éĘ Actively participated in the ISO 9001 Certification of the company. ’éĘ Operation of L.R.F for the reduction of Sulphur, Phos. ’éĘ Alloying in the steelladle at L.R.F. to make different grade of steel. ’éĘ Proper supervision and monitoring the RefractoryŌĆÖs used in L.R.F. ’éĘ Physical inspection of the melt inputs for induction furnace.

- 3. SCAN STEEL LIMITED, SUNDERGARH, ODISHA. Company SCAN STEEL LIMITED, SUNDERGARH, ODISHA Designation: Shift in charge- SMS. Duration: May- 2006- June-2009. Role: Shift In charge- Production Nature of Work: ŌĆó Skill Set:-Over all production activities. ŌĆó Improvement of lining life of both ladle & induction furnace to control the refractory cost. ŌĆó Reducing the cost of production by making maximum recovery of the alloys in I F/C. ŌĆó Improving Machine reliability by eliminating root cause defect & increase in plant yield. ŌĆó Critical spares parts availability planning for planned shutdown jobs & repair activities. ŌĆó Manpower management for respective days, week & months. Declaration: I hereby declare that all the information furnished above is true & best of my knowledge. Date: (signature) Place Jayadev Prasad Nath Sharma