Lean fundamentals

Download as pptx, pdf0 likes173 views

The document discusses Lean principles and concepts. It defines Lean as focusing on reducing waste to increase customer value. The roots of Lean come from the Toyota Production System after World War 2. The document outlines the five Lean principles: identify value, map the value stream, create flow, establish pull, and strive for perfection. It defines the seven types of waste in Lean: overproduction, waiting, transportation, overprocessing, inventory, motion, and defects. Benefits of Lean include increased profits, customer collaboration, and employee morale. Challenges can include disruptions during implementation and the need to rethink process flows with changes.

1 of 13

Downloaded 11 times

Ad

Recommended

Tw2

Tw2NIDA Business School

╠²

Toyota became the world's best manufacturer through innovations stemming from the Toyoda family. Sakichi Toyoda invented automatic looms and his son Kiichiro founded Toyota Motor Corporation. After WWII, Toyota rebuilt by adopting strict cost-cutting and building trucks. Taiichi Ohno helped develop the Toyota Production System using just-in-time production and one-piece flow to produce high quality, low cost vehicles with flexibility. This system eliminated waste and improved processes using Deming's principles and continuous kaizen improvement.Lean Thinking in Government Services

Lean Thinking in Government Servicesbenthatcher

╠²

This document provides an overview of applying Lean principles to local government services. It discusses what Lean is, how Southlake, Texas has implemented Lean processes to reduce development approval times by over 300% and budget development times by 33%. It encourages focusing on eliminating waste from processes by establishing flow, implementing pull systems, and continuously improving to provide the best value and service to customers. Local governments are encouraged to apply Lean thinking to any processes where time or customer satisfaction is important.Lean Manufacturing (Concepts, Tools and Quality Management)

Lean Manufacturing (Concepts, Tools and Quality Management)Mohammad Azam Khan

╠²

Lean manufacturing is an operational excellence strategy focused on eliminating waste and enhancing value for customers through continuous improvement. It emphasizes a culture of respect for people, high quality, and stable processes, driven by management commitment and practical tools. Key principles include understanding customer needs, mapping value streams, and ensuring quality through just-in-time production and empowerment of associates.Lean manufacturing concepts and tools and quality management1

Lean manufacturing concepts and tools and quality management1hgalinova

╠²

Lean is an operational strategy that focuses on eliminating waste to improve quality, reduce costs and lead times, and increase customer satisfaction. It involves identifying value from the customer's perspective and mapping the workflow to create an uninterrupted flow. Key lean principles include identifying value streams, minimizing waste, and continuously improving through tools like 5S, visual controls, and plan-do-check-act cycles. Lean thinking emphasizes respect for people, continuous improvement, and understanding customer needs.lean-091119135641-phpapp01.pptx

lean-091119135641-phpapp01.pptxRenaldiPrimaSaputra1

╠²

Lean is a systematic approach to eliminating waste. Its goals are to improve quality, reduce time and costs, and eliminate waste through techniques like standardized work, visual controls, just-in-time production, and continuous improvement. The key principles are to specify value from the customer's perspective, identify the value stream, create smooth product flow, use pull systems, and seek perfection through ongoing waste elimination.lean-091119135641-phpapp01.pptx

lean-091119135641-phpapp01.pptxRenaldiPrimaSaputra1

╠²

Lean is a systematic approach to eliminating waste. Its goals are to improve quality, reduce time and costs, and eliminate waste through techniques like just-in-time production, continuous improvement, and visual workplace organization. Common types of waste include overproduction, waiting, transportation, extra processing, inventory, motion, and defects. Companies implement lean by designing simple manufacturing systems, recognizing there is always room for improvement, and continuously refining their processes.TOYOTA PS

TOYOTA PSJitesh Gaurav

╠²

The document discusses the Toyota Production System (TPS) and its management principles. It provides an overview of TPS, explaining its focus on eliminating waste, creating continuous flow, using a pull system to avoid overproduction, leveling out workload, and using jidoka to stop the line when there are quality issues. The document also presents several models that illustrate the key aspects of TPS, including its emphasis on long-term philosophy, processes, people, and problem solving.T0 yota ps

T0 yota psJitesh Gaurav

╠²

The document discusses the Toyota Production System (TPS) and its management principles. It provides an overview of TPS and its focus on eliminating waste, creating continuous flow, using a pull system, leveling out workload, stopping production to fix problems, using visual controls and standardized tasks. It also covers the 14 principles of the Toyota Way, including basing decisions on long-term philosophy, challenging people to continuously improve, and growing leaders who teach the company's philosophy. The overall document serves to explain the philosophy and processes that have made Toyota one of the most successful automakers.Lean ppt

Lean pptshoban44

╠²

The document provides an overview of lean principles and tools. It defines lean as eliminating waste to add value for customers. Key points include: the 5 principles of lean - specify value, identify the value stream, create flow, pull from customers, seek perfection; the 7 forms of waste - overproduction, waiting, transportation, inappropriate processing, inventory, motion, defects; and lean tools like 5S, poka yoke, just-in-time. It also outlines steps to achieve lean systems like designing a simple manufacturing system, recognizing room for improvement, and continuous improvement.Lesson 1 - Introduction of LEAN

Lesson 1 - Introduction of LEANTunAnhTrnh9

╠²

Lean management focuses on eliminating waste to optimize processes and reduce costs. It originated from Henry Ford's assembly line and was further developed by Toyota. The key principles of lean are identifying value, streamlining workflows, establishing pull systems, and continuously seeking perfection. Implementing lean offers benefits like increased capacity and cash flow, but can be challenging for processes with disruptions, customization or low volume/high mix. The goals of lean are to produce more value for customers using fewer resources.Lean manufacturing system (lms) 19-march-sgd

Lean manufacturing system (lms) 19-march-sgdSanjeev Deshmukh

╠²

The document outlines lean manufacturing, originating from Taiichi Ohno's Toyota production system, emphasizing waste elimination and resource optimization in production processes. It details principles and steps for implementing a lean manufacturing system aimed at delivering maximum value to customers with minimal waste. Key benefits include reduced costs, improved quality, and enhanced customer satisfaction.Medical Services Client Vsm 10 10 11

Medical Services Client Vsm 10 10 11Jamie Voster

╠²

The document summarizes an upcoming value stream mapping event for a home healthcare services company. The 2-day agenda includes lean education, creating a current state map to understand existing processes, identifying improvement opportunities, designing an improved future state map, and developing an action plan. The goal is to streamline processes, eliminate waste, and improve customer satisfaction through applying lean principles like value stream mapping.Medical Services Client Vsm 10 10 11

Medical Services Client Vsm 10 10 11laukoamy

╠²

The document provides an agenda for a two-day Lean consulting event focused on value stream mapping for a home healthcare services client. Day one will involve Lean education, understanding the current state process, building the current state map, and prioritizing improvement areas. Day two will review identified wastes, brainstorm the future state, design the future state process, and develop an action plan for implementation. The event aims to streamline the process, eliminate wastes, and create an action plan to implement improvements within 30-60 days.Lean Fundamentals And Line Design 06 04 01

Lean Fundamentals And Line Design 06 04 01Dan Junkins

╠²

This document provides an overview and summary of a Lean Fundamentals seminar presented by the Lean Supplier Association in Austin, Texas. The 3-page summary covers the following key points:

1. It introduces lean thinking principles like eliminating waste, specifying value from the customer perspective, and making products flow without interruption.

2. It describes tools used in lean like value stream mapping, the 5S methodology of sorting, setting in order, shining, standardizing, and sustaining workplace organization.

3. It emphasizes the importance of measurements and metrics in lean to establish baselines, monitor improvements, and ensure goals are being met. A hierarchy of measurements across different organizational levels is recommended.Cindy Novak Quality Expo 092209 Presentation

Cindy Novak Quality Expo 092209 PresentationCindy Novak

╠²

The document discusses Lean Six Sigma and ISO 9001:2008 quality standards and how they can be used together. It defines the eight types of waste (WORMPIIT) according to Lean principles and how eliminating these wastes through Lean Six Sigma can benefit sustainability efforts and customer satisfaction. Lean Six Sigma and ISO 9001:2008 complement each other by providing methods to achieve quality objectives through prevention of defects, statistical process control, and continuous improvement.Lean principles taster

Lean principles tasterStephenLipscombe

╠²

This document provides an overview of Lean principles and their origins. It discusses:

- 19th century origins in Time and Motion Study by Taylor and Gilbreth to improve efficiency

- Development of the Toyota Production System in 1948 to smooth production flow and reduce waste

- Six Sigma strategy from 1981 focusing on reducing defects and variability in processes

- Emergence of Lean in the 1990s focusing specifically on eliminating waste to improve efficiency

It then examines the seven types of waste and how to identify and remove non-value added steps and establish continuous flow to maximize value for the customer.Lean basics

Lean basicsAryan Viswakarma

╠²

Lean manufacturing aims to maximize customer value and minimize waste. It involves identifying the value stream and eliminating non-value adding activities. The core principles of lean are specifying value from the customer's perspective, establishing a continuous flow of materials, and having production pulled by customer demand rather than being pushed based on forecasts. Implementing lean seeks to reduce costs, shorten lead times, improve quality, and increase flexibility through techniques like just-in-time production and continuous improvement.Principles Of Lean And Value Stream Mapping Overview

Principles Of Lean And Value Stream Mapping Overviewjheaton418

╠²

The document provides an overview of lean principles and value stream mapping. It discusses that value stream mapping is a visual tool to understand the flow of material and information required to deliver a product or service. It also outlines the current and future state metrics that would be used to quantify improvements from value stream mapping. Examples of improvement targets are reducing process time, inventory, costs and increasing capacity. The key is to identify tasks, assign responsibilities, and regularly review progress to implement the future state goals.Lean Production

Lean Productionnewvision19

╠²

This document discusses lean manufacturing principles and techniques. It begins with a brief history of lean production and Toyota's production system. It then compares traditional vs lean manufacturing and lists the five principles of lean: define value, map the value stream, create flow, establish pull, and pursue perfection. The document outlines the seven types of waste in lean systems and provides examples. It also describes basic lean tools like 5S, just-in-time, kaizen, and kanban. Finally, it discusses how lean manufacturing aims to remove waste, gain satisfied customers, and improve profits.introduction dans les prarique de Lean.ppt

introduction dans les prarique de Lean.pptJabirArif

╠²

The document provides a comprehensive overview of lean manufacturing, explaining its philosophy focused on eliminating waste and enhancing productivity. It outlines the objectives of lean manufacturing, including improving quality, reducing costs, and increasing customer satisfaction through various metrics and strategies. Key elements discussed include waste identification, standardized work, value stream mapping, and the importance of a culture centered on continuous improvement.Lean mangement

Lean mangementAkash Patel

╠²

This document discusses lean principles and concepts. It defines lean as eliminating waste to add value for the customer. Key lean goals are to improve quality, eliminate waste, reduce lead time and reduce total costs. The document identifies seven types of waste - overproduction, waiting, transportation, inappropriate processing, unnecessary inventory, motion, and defects. It also outlines five lean principles - specify value, identify the value stream, create flow, let the customer pull and seek perfection. Finally, it lists three steps to achieve lean systems - design a simple system, recognize room for improvement, and continuously improve.Lean In Life

Lean In Lifeabhinav

╠²

The document outlines the principles of lean philosophy aimed at eliminating waste to enhance value for customers. It emphasizes the identification and reduction of non-value adding activities and presents five key lean principles: specifying value, mapping the value stream, establishing flow, implementing pull, and striving for perfection. Visual controls and personal management of time are discussed as methods to increase efficiency and productivity in both workplace and daily life.Lean Fundamentals Course Preview

Lean Fundamentals Course PreviewInvensis Learning

╠²

The document outlines the principles and evolution of Lean methodology aimed at reducing cycle times and eliminating waste to enhance customer value and operational efficiency. It highlights key concepts such as defining value from the customer's perspective, identifying value streams, establishing flow, and continuously improving processes. The material also addresses the seven types of waste and provides actionable guidelines for implementing Lean principles across various processes.Introduction to Lean Transformation

Introduction to Lean Transformation Amanda Gilmore

╠²

This document discusses using Lean principles to improve government processes and reduce waste. It defines Lean as eliminating non-value added activities through continuous improvement. There are eight types of waste, including transport, inventory, motion, waiting, overproduction, overprocessing, defects, and skills. Only activities that add value from the customer's perspective should remain. Case studies show how mapping current and future states of processes can help quantify waste and set goals to dramatically improve cycle time, throughput, and other metrics over several months through specific action items. Tips for using Lean to manage email more efficiently are also provided.Understanding and concept Lean cheat sheet.pdf

Understanding and concept Lean cheat sheet.pdfpriyaagrawalpefn20

╠²

The document provides a lean cheat sheet that defines key lean concepts and tools. It defines lean as focusing on delivering value to customers by removing waste through an empowered workforce. Key concepts explained include value, waste, flow, and visual management. Tools summarized are leveling and sequencing, standardizing processes, just-in-time, jidoka, andon, error proofing, total productive maintenance, takt time vs. cycle time, 5S, standardized work, kaizen, and PDCA. The goal of lean is to improve understanding of value and mapping the value stream to create continuous flow and pull systems that engage workers.Redesigning IT and Service Organisations for Flow

Redesigning IT and Service Organisations for FlowLean Enterprise Academy

╠²

The document discusses a re-design of SAP's organizational flow and IT infrastructure, focusing on enhancing customer service delivery through lean practices. It emphasizes the importance of understanding customer needs, reducing wasted time, and adapting management styles to create efficient processes. The presentation outlines a structured approach to improve operational effectiveness and organizational design through value streams and responsive service frameworks.The Toyota Way

The Toyota WayKamarulzaman Darus

╠²

The document summarizes the Toyota Way, which is built upon two pillars - "Continuous Improvement" and "Respect for People". Management's role is to motivate large numbers of people to work together toward common goals by defining the goals, sharing a path to achieve them, and removing obstacles. Toyota designed quality into every step of their production process with few labor hours through a system involving standardized work, stopping production to fix problems, visual controls, and respect for employees. The success of the Toyota Way comes from balancing an organizational culture that values continuous improvement by people with a technical system focused on efficient "flow".Basics Of Python Programming

Basics Of Python ProgrammingBhawna Tuteja

╠²

This document discusses the key features and advantages of the Python programming language. It outlines that Python is dynamically typed, uses readable English-like commands, and requires less lines of code than other languages. Additionally, Python has a simple syntax, strongly typed data grouping, an extensive library of reusable code, and can be used for a wide range of applications across desktops, databases, networking, games, web development, and more.The Power Of Full Engagement

The Power Of Full EngagementBhawna Tuteja

╠²

The document discusses the principles of full engagement as outlined by Tony Schwartz and Dr. Jim Loehr, focusing on the importance of managing four sources of energy: physical, emotional, mental, and spiritual. It emphasizes the need for balance between energy expenditure and renewal, and encourages practices similar to elite athletes to enhance capacity. The change process is also outlined, emphasizing purpose, facing truths, and taking action to close the gap between current and desired states.More Related Content

Similar to Lean fundamentals (20)

Lean ppt

Lean pptshoban44

╠²

The document provides an overview of lean principles and tools. It defines lean as eliminating waste to add value for customers. Key points include: the 5 principles of lean - specify value, identify the value stream, create flow, pull from customers, seek perfection; the 7 forms of waste - overproduction, waiting, transportation, inappropriate processing, inventory, motion, defects; and lean tools like 5S, poka yoke, just-in-time. It also outlines steps to achieve lean systems like designing a simple manufacturing system, recognizing room for improvement, and continuous improvement.Lesson 1 - Introduction of LEAN

Lesson 1 - Introduction of LEANTunAnhTrnh9

╠²

Lean management focuses on eliminating waste to optimize processes and reduce costs. It originated from Henry Ford's assembly line and was further developed by Toyota. The key principles of lean are identifying value, streamlining workflows, establishing pull systems, and continuously seeking perfection. Implementing lean offers benefits like increased capacity and cash flow, but can be challenging for processes with disruptions, customization or low volume/high mix. The goals of lean are to produce more value for customers using fewer resources.Lean manufacturing system (lms) 19-march-sgd

Lean manufacturing system (lms) 19-march-sgdSanjeev Deshmukh

╠²

The document outlines lean manufacturing, originating from Taiichi Ohno's Toyota production system, emphasizing waste elimination and resource optimization in production processes. It details principles and steps for implementing a lean manufacturing system aimed at delivering maximum value to customers with minimal waste. Key benefits include reduced costs, improved quality, and enhanced customer satisfaction.Medical Services Client Vsm 10 10 11

Medical Services Client Vsm 10 10 11Jamie Voster

╠²

The document summarizes an upcoming value stream mapping event for a home healthcare services company. The 2-day agenda includes lean education, creating a current state map to understand existing processes, identifying improvement opportunities, designing an improved future state map, and developing an action plan. The goal is to streamline processes, eliminate waste, and improve customer satisfaction through applying lean principles like value stream mapping.Medical Services Client Vsm 10 10 11

Medical Services Client Vsm 10 10 11laukoamy

╠²

The document provides an agenda for a two-day Lean consulting event focused on value stream mapping for a home healthcare services client. Day one will involve Lean education, understanding the current state process, building the current state map, and prioritizing improvement areas. Day two will review identified wastes, brainstorm the future state, design the future state process, and develop an action plan for implementation. The event aims to streamline the process, eliminate wastes, and create an action plan to implement improvements within 30-60 days.Lean Fundamentals And Line Design 06 04 01

Lean Fundamentals And Line Design 06 04 01Dan Junkins

╠²

This document provides an overview and summary of a Lean Fundamentals seminar presented by the Lean Supplier Association in Austin, Texas. The 3-page summary covers the following key points:

1. It introduces lean thinking principles like eliminating waste, specifying value from the customer perspective, and making products flow without interruption.

2. It describes tools used in lean like value stream mapping, the 5S methodology of sorting, setting in order, shining, standardizing, and sustaining workplace organization.

3. It emphasizes the importance of measurements and metrics in lean to establish baselines, monitor improvements, and ensure goals are being met. A hierarchy of measurements across different organizational levels is recommended.Cindy Novak Quality Expo 092209 Presentation

Cindy Novak Quality Expo 092209 PresentationCindy Novak

╠²

The document discusses Lean Six Sigma and ISO 9001:2008 quality standards and how they can be used together. It defines the eight types of waste (WORMPIIT) according to Lean principles and how eliminating these wastes through Lean Six Sigma can benefit sustainability efforts and customer satisfaction. Lean Six Sigma and ISO 9001:2008 complement each other by providing methods to achieve quality objectives through prevention of defects, statistical process control, and continuous improvement.Lean principles taster

Lean principles tasterStephenLipscombe

╠²

This document provides an overview of Lean principles and their origins. It discusses:

- 19th century origins in Time and Motion Study by Taylor and Gilbreth to improve efficiency

- Development of the Toyota Production System in 1948 to smooth production flow and reduce waste

- Six Sigma strategy from 1981 focusing on reducing defects and variability in processes

- Emergence of Lean in the 1990s focusing specifically on eliminating waste to improve efficiency

It then examines the seven types of waste and how to identify and remove non-value added steps and establish continuous flow to maximize value for the customer.Lean basics

Lean basicsAryan Viswakarma

╠²

Lean manufacturing aims to maximize customer value and minimize waste. It involves identifying the value stream and eliminating non-value adding activities. The core principles of lean are specifying value from the customer's perspective, establishing a continuous flow of materials, and having production pulled by customer demand rather than being pushed based on forecasts. Implementing lean seeks to reduce costs, shorten lead times, improve quality, and increase flexibility through techniques like just-in-time production and continuous improvement.Principles Of Lean And Value Stream Mapping Overview

Principles Of Lean And Value Stream Mapping Overviewjheaton418

╠²

The document provides an overview of lean principles and value stream mapping. It discusses that value stream mapping is a visual tool to understand the flow of material and information required to deliver a product or service. It also outlines the current and future state metrics that would be used to quantify improvements from value stream mapping. Examples of improvement targets are reducing process time, inventory, costs and increasing capacity. The key is to identify tasks, assign responsibilities, and regularly review progress to implement the future state goals.Lean Production

Lean Productionnewvision19

╠²

This document discusses lean manufacturing principles and techniques. It begins with a brief history of lean production and Toyota's production system. It then compares traditional vs lean manufacturing and lists the five principles of lean: define value, map the value stream, create flow, establish pull, and pursue perfection. The document outlines the seven types of waste in lean systems and provides examples. It also describes basic lean tools like 5S, just-in-time, kaizen, and kanban. Finally, it discusses how lean manufacturing aims to remove waste, gain satisfied customers, and improve profits.introduction dans les prarique de Lean.ppt

introduction dans les prarique de Lean.pptJabirArif

╠²

The document provides a comprehensive overview of lean manufacturing, explaining its philosophy focused on eliminating waste and enhancing productivity. It outlines the objectives of lean manufacturing, including improving quality, reducing costs, and increasing customer satisfaction through various metrics and strategies. Key elements discussed include waste identification, standardized work, value stream mapping, and the importance of a culture centered on continuous improvement.Lean mangement

Lean mangementAkash Patel

╠²

This document discusses lean principles and concepts. It defines lean as eliminating waste to add value for the customer. Key lean goals are to improve quality, eliminate waste, reduce lead time and reduce total costs. The document identifies seven types of waste - overproduction, waiting, transportation, inappropriate processing, unnecessary inventory, motion, and defects. It also outlines five lean principles - specify value, identify the value stream, create flow, let the customer pull and seek perfection. Finally, it lists three steps to achieve lean systems - design a simple system, recognize room for improvement, and continuously improve.Lean In Life

Lean In Lifeabhinav

╠²

The document outlines the principles of lean philosophy aimed at eliminating waste to enhance value for customers. It emphasizes the identification and reduction of non-value adding activities and presents five key lean principles: specifying value, mapping the value stream, establishing flow, implementing pull, and striving for perfection. Visual controls and personal management of time are discussed as methods to increase efficiency and productivity in both workplace and daily life.Lean Fundamentals Course Preview

Lean Fundamentals Course PreviewInvensis Learning

╠²

The document outlines the principles and evolution of Lean methodology aimed at reducing cycle times and eliminating waste to enhance customer value and operational efficiency. It highlights key concepts such as defining value from the customer's perspective, identifying value streams, establishing flow, and continuously improving processes. The material also addresses the seven types of waste and provides actionable guidelines for implementing Lean principles across various processes.Introduction to Lean Transformation

Introduction to Lean Transformation Amanda Gilmore

╠²

This document discusses using Lean principles to improve government processes and reduce waste. It defines Lean as eliminating non-value added activities through continuous improvement. There are eight types of waste, including transport, inventory, motion, waiting, overproduction, overprocessing, defects, and skills. Only activities that add value from the customer's perspective should remain. Case studies show how mapping current and future states of processes can help quantify waste and set goals to dramatically improve cycle time, throughput, and other metrics over several months through specific action items. Tips for using Lean to manage email more efficiently are also provided.Understanding and concept Lean cheat sheet.pdf

Understanding and concept Lean cheat sheet.pdfpriyaagrawalpefn20

╠²

The document provides a lean cheat sheet that defines key lean concepts and tools. It defines lean as focusing on delivering value to customers by removing waste through an empowered workforce. Key concepts explained include value, waste, flow, and visual management. Tools summarized are leveling and sequencing, standardizing processes, just-in-time, jidoka, andon, error proofing, total productive maintenance, takt time vs. cycle time, 5S, standardized work, kaizen, and PDCA. The goal of lean is to improve understanding of value and mapping the value stream to create continuous flow and pull systems that engage workers.Redesigning IT and Service Organisations for Flow

Redesigning IT and Service Organisations for FlowLean Enterprise Academy

╠²

The document discusses a re-design of SAP's organizational flow and IT infrastructure, focusing on enhancing customer service delivery through lean practices. It emphasizes the importance of understanding customer needs, reducing wasted time, and adapting management styles to create efficient processes. The presentation outlines a structured approach to improve operational effectiveness and organizational design through value streams and responsive service frameworks.The Toyota Way

The Toyota WayKamarulzaman Darus

╠²

The document summarizes the Toyota Way, which is built upon two pillars - "Continuous Improvement" and "Respect for People". Management's role is to motivate large numbers of people to work together toward common goals by defining the goals, sharing a path to achieve them, and removing obstacles. Toyota designed quality into every step of their production process with few labor hours through a system involving standardized work, stopping production to fix problems, visual controls, and respect for employees. The success of the Toyota Way comes from balancing an organizational culture that values continuous improvement by people with a technical system focused on efficient "flow".More from Bhawna Tuteja (6)

Basics Of Python Programming

Basics Of Python ProgrammingBhawna Tuteja

╠²

This document discusses the key features and advantages of the Python programming language. It outlines that Python is dynamically typed, uses readable English-like commands, and requires less lines of code than other languages. Additionally, Python has a simple syntax, strongly typed data grouping, an extensive library of reusable code, and can be used for a wide range of applications across desktops, databases, networking, games, web development, and more.The Power Of Full Engagement

The Power Of Full EngagementBhawna Tuteja

╠²

The document discusses the principles of full engagement as outlined by Tony Schwartz and Dr. Jim Loehr, focusing on the importance of managing four sources of energy: physical, emotional, mental, and spiritual. It emphasizes the need for balance between energy expenditure and renewal, and encourages practices similar to elite athletes to enhance capacity. The change process is also outlined, emphasizing purpose, facing truths, and taking action to close the gap between current and desired states.Git-Basics

Git-BasicsBhawna Tuteja

╠²

GIT is a distributed version control system that allows tracking code revision history, sharing codebases with collaborators, and merging collaborator code. It offers advantages like performance through object-based storage, security through integrity checks, flexibility through branching and tagging, and open source acceptance. Potential disadvantages include a steep learning curve and slower performance for binary files. Common GIT commands include init, clone, status, add, commit, pull, push, branch, checkout, merge, and log.Six sigma

Six sigmaBhawna Tuteja

╠²

Six Sigma is a data-driven methodology for improving processes by reducing variability and defects. It was developed by Motorola in the 1980s and aims for near-perfect process outputs. The objectives of Six Sigma are to understand and reduce variation in processes. It uses various quality tools like cause-and-effect diagrams, control charts, and value stream mapping. A key benefit is increased business performance through stable and consistent processes. Establishing a no-blame culture is important for Six Sigma, with a focus on accountability, teamwork, and continuous improvement.Coding Best Practices For Memory Management

Coding Best Practices For Memory Management Bhawna Tuteja

╠²

The document discusses the problems associated with memory leaks in applications, explaining what a memory leak is and how it affects performance. It provides best practices for memory management in several programming languages, including C#, JavaScript, Python, and C++, emphasizing efficient memory usage and resource management. Additionally, it prompts developers to consider code optimization strategies before writing code.How google-tests-software

How google-tests-softwareBhawna Tuteja

╠²

1. The document discusses quality processes at Google, including that testing involves many developers and one tester.

2. It describes different types of tests - unit, integration, and system - and how they are used to validate code quality and product quality at different stages.

3. Key aspects of Google's quality process include classifying tests by size, enforcing time limits, ensuring tests are independent and have no side effects, and using test results to guide continuous integration.Ad

Recently uploaded (20)

FIDO Seminar: New Data: Passkey Adoption in the Workforce.pptx

FIDO Seminar: New Data: Passkey Adoption in the Workforce.pptxFIDO Alliance

╠²

FIDO Seminar: New Data: Passkey Adoption in the WorkforceTechniques for Automatic Device Identification and Network Assignment.pdf

Techniques for Automatic Device Identification and Network Assignment.pdfPriyanka Aash

╠²

Techniques for Automatic Device Identification and Network AssignmentFIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptx

FIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptxFIDO Alliance

╠²

FIDO Seminar: Evolving Landscape of Post-Quantum CryptographyLessons Learned from Developing Secure AI Workflows.pdf

Lessons Learned from Developing Secure AI Workflows.pdfPriyanka Aash

╠²

Lessons Learned from Developing Secure AI WorkflowsOpenACC and Open Hackathons Monthly Highlights June 2025

OpenACC and Open Hackathons Monthly Highlights June 2025OpenACC

╠²

The OpenACC organization focuses on enhancing parallel computing skills and advancing interoperability in scientific applications through hackathons and training. The upcoming 2025 Open Accelerated Computing Summit (OACS) aims to explore the convergence of AI and HPC in scientific computing and foster knowledge sharing. This year's OACS welcomes talk submissions from a variety of topics, from Using Standard Language Parallelism to Computer Vision Applications. The document also highlights several open hackathons, a call to apply for NVIDIA Academic Grant Program and resources for optimizing scientific applications using OpenACC directives.FIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptx

FIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptxFIDO Alliance

╠²

FIDO Seminar: Targeting Trust: The Future of Identity in the WorkforcePyCon SG 25 - Firecracker Made Easy with Python.pdf

PyCon SG 25 - Firecracker Made Easy with Python.pdfMuhammad Yuga Nugraha

╠²

Explore the ease of managing Firecracker microVM with the firecracker-python. In this session, I will introduce the basics of Firecracker microVM and demonstrate how this custom SDK facilitates microVM operations easily. We will delve into the design and development process behind the SDK, providing a behind-the-scenes look at its creation and features. While traditional Firecracker SDKs were primarily available in Go, this module brings a simplicity of Python to the table.Creating Inclusive Digital Learning with AI: A Smarter, Fairer Future

Creating Inclusive Digital Learning with AI: A Smarter, Fairer FutureImpelsys Inc.

╠²

Have you ever struggled to read a tiny label on a medicine box or tried to navigate a confusing website? Now imagine if every learning experience felt that wayŌĆöevery single day.

For millions of people living with disabilities, poorly designed content isnŌĆÖt just frustrating. ItŌĆÖs a barrier to growth. Inclusive learning is about fixing that. And today, AI is helping us build digital learning thatŌĆÖs smarter, kinder, and accessible to everyone.

Accessible learning increases engagement, retention, performance, and inclusivity for everyone. Inclusive design is simply better design.FIDO Seminar: Authentication for a Billion Consumers - Amazon.pptx

FIDO Seminar: Authentication for a Billion Consumers - Amazon.pptxFIDO Alliance

╠²

FIDO Seminar: Authentication for a Billion Consumers - AmazonThe Future of AI Agent Development Trends to Watch.pptx

The Future of AI Agent Development Trends to Watch.pptxLisa ward

╠²

The Future of AI Agent Development: Trends to Watch explores emerging innovations shaping smarter, more autonomous AI solutions for businesses and technology.

AI VIDEO MAGAZINE - June 2025 - r/aivideo

AI VIDEO MAGAZINE - June 2025 - r/aivideo1pcity Studios, Inc

╠²

AI VIDEO MAGAZINE - r/aivideo community newsletter ŌĆō Exclusive Tutorials: How to make an AI VIDEO from scratch, PLUS: How to make AI MUSIC, Hottest ai videos of 2025, Exclusive Interviews, New Tools, Previews, and MORE - JUNE 2025 ISSUE -Cluster-Based Multi-Objective Metamorphic Test Case Pair Selection for Deep N...

Cluster-Based Multi-Objective Metamorphic Test Case Pair Selection for Deep N...janeliewang985

╠²

the slides of the MP selection approach CMPSFrom Manual to Auto Searching- FME in the Driver's Seat

From Manual to Auto Searching- FME in the Driver's SeatSafe Software

╠²

Finding a specific car online can be a time-consuming task, especially when checking multiple dealer websites. A few years ago, I faced this exact problem while searching for a particular vehicle in New Zealand. The local classified platform, Trade Me (similar to eBay), wasnŌĆÖt yielding any results, so I expanded my search to second-hand dealer sitesŌĆöonly to realise that periodically checking each one was going to be tedious. ThatŌĆÖs when I noticed something interesting: many of these websites used the same platform to manage their inventories. Recognising this, I reverse-engineered the platformŌĆÖs structure and built an FME workspace that automated the search process for me. By integrating API calls and setting up periodic checks, I received real-time email alerts when matching cars were listed. In this presentation, IŌĆÖll walk through how I used FME to save hours of manual searching by creating a custom car-finding automation system. While FME canŌĆÖt buy a car for youŌĆöyetŌĆöit can certainly help you find the one youŌĆÖre after!Securing Account Lifecycles in the Age of Deepfakes.pptx

Securing Account Lifecycles in the Age of Deepfakes.pptxFIDO Alliance

╠²

Securing Account Lifecycles in the Age of DeepfakesConnecting Data and Intelligence: The Role of FME in Machine Learning

Connecting Data and Intelligence: The Role of FME in Machine LearningSafe Software

╠²

In this presentation, we want to explore powerful data integration and preparation for Machine Learning. FME is known for its ability to manipulate and transform geospatial data, connecting diverse data sources into efficient and automated workflows. By integrating FME with Machine Learning techniques, it is possible to transform raw data into valuable insights faster and more accurately, enabling intelligent analysis and data-driven decision making.Improving Data Integrity: Synchronization between EAM and ArcGIS Utility Netw...

Improving Data Integrity: Synchronization between EAM and ArcGIS Utility Netw...Safe Software

╠²

Utilities and water companies play a key role in the creation of clean drinking water. The creation and maintenance of clean drinking water is becoming a critical problem due to pollution and pressure on the environment. A lot of data is necessary to create clean drinking water. For fieldworkers, two types of data are key: Asset data in an asset management system (EAM for example) and Geographic data in a GIS (ArcGIS Utility Network ). Keeping this type of data up to date and in sync is a challenge for many organizations, leading to duplicating data and creating a bulk of extra attributes and data to keep everything in sync. Using FME, it is possible to synchronize Enterprise Asset Management (EAM) data with the ArcGIS Utility Network in real time. Changes (creation, modification, deletion) in ArcGIS Pro are relayed to EAM via FME, and vice versa. This ensures continuous synchronization of both systems without daily bulk updates, minimizes risks, and seamlessly integrates with ArcGIS Utility Network services. This presentation focuses on the use of FME at a Dutch water company, to create a sync between the asset management and GIS.The Future of Technology: 2025-2125 by Saikat Basu.pdf

The Future of Technology: 2025-2125 by Saikat Basu.pdfSaikat Basu

╠²

A peek into the next 100 years of technology. From Generative AI to Global AI networks to Martian Colonisation to Interstellar exploration to Industrial Nanotechnology to Artificial Consciousness, this is a journey you don't want to miss. Which ones excite you the most? Which ones are you apprehensive about? Feel free to comment! Let the conversation begin!UserCon Belgium: Honey, VMware increased my bill

UserCon Belgium: Honey, VMware increased my billstijn40

╠²

VMwareŌĆÖs pricing changes have forced organizations to rethink their datacenter cost management strategies. While FinOps is commonly associated with cloud environments, the FinOps Foundation has recently expanded its framework to include ScopesŌĆöand Datacenter is now officially part of the equation. In this session, weŌĆÖll map the FinOps Framework to a VMware-based datacenter, focusing on cost visibility, optimization, and automation. YouŌĆÖll learn how to track costs more effectively, rightsize workloads, optimize licensing, and drive efficiencyŌĆöall without migrating to the cloud. WeŌĆÖll also explore how to align IT teams, finance, and leadership around cost-aware decision-making for on-prem environments. If your VMware bill keeps increasing and you need a new approach to cost management, this session is for you!Ad

Lean fundamentals

- 1. Topics ŌĆó WHAT IS LEAN ŌĆó HISTORY OF LEAN ŌĆó LEAN PRINCIPLES ŌĆó TYPES OF WASTES ŌĆó LEAN SUCCESS AND BENEFITS ŌĆó LEAN CHALLENGES

- 2. WHAT IS LEAN Lean is set of principles to perform certain activities that reduces waste to add/increase customer value. Motto behind Lean was ŌĆ£Offer higher quality, and more affordable products in less timeŌĆØ

- 3. LEAN HISTORY Roots of the lean are derived from Toyota Production System After world war, Japanese economy was rebuilding and based on FordŌĆÖs original thinking, series of simple innovation steps we implemented. These innovation steps were focused on improving end to end process rather than optimizing individual machines. The steady growth of Toyota, from a small company to the world's largest automaker, made world think how it has achieved this success. From this success, Lean principles came into picture.

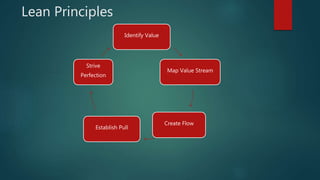

- 4. Lean Principles Identify Value Map Value Stream Create Flow Establish Pull Strive Perfection

- 5. Lean Principles Identify Value :Define value from customerŌĆÖs perspective and express in terms of specific product or service Identify Value Map Value Stream Create Flow Establish Pull Strive Perfectio n

- 6. Lean Principles Map Value Stream :Map all the step: value added and non-value added activities that bring product or service to the customer. Identify Value Map Value Stream Create Flow Establish Pull Strive Perfectio n

- 7. Lean Principles Create Flow : The continuous flow of products, services and information from end to end, through the process. Identify Value Map Value Stream Create Flow Establish Pull Strive Perfectio n

- 8. Lean Principles Establish Pull : Nothing is possible by upstream Process until downstream customer signals a need. Identify Value Map Value Stream Create Flow Establish Pull Strive Perfectio n

- 9. Lean Principles Strive Perfection : The complete elimination of waste ensuring all activities create value For customer through innovation and Continuous improvement projects. Identify Value Map Value Stream Create Flow Establish Pull Strive Perfectio n

- 10. Lean ŌĆōtypes of wastes Underutilized skills Wrong Automation Transportation Motion Waiting Defect Over Production Over Processing LEAN WASTES

- 11. Lean ŌĆōtypes of wastes Underutilize d skills Wrong Automatio n Transportatio n Motion Waiting Defect Over Production Over Processing LEAN WASTES Any movement of materials, suppliers or resources that doesnŌĆÖt add value to internal/external customer needs like extra carts, multiple storage locations etc. Any movement of people, resources or machine which doesnŌĆÖt contribute/add value to product/service like human/machine motion, lack of visual controls Long period of inactivity for people, machine or material waiting for each other leads to waste like late deliveries, people waiting for machine and resources. Producing faster/excess quantity than customer needs leads to waste like improper planning, producing earlier. Investment(money/time) that doesnŌĆÖt add any value to product/customer are considered as waste like Redundant approvals/Endless refinement. Any work done to rectify defects is considered as waste like testing/Re-testing and bug fixes. In todayŌĆÖs world, every organization is moving towards automation but if investment(time/effort/money) is more than that of manual then this is considered as waste. Any skill that is not used up to its full potential leads to waste like over/under qualification, low employee morale.

- 12. LEAN ŌĆō SUCCESS and BENEFITS Profit Increased Customer Collaboration Increased Employee Morale

- 13. LEAN Challenges ’éĘ Disruptions, Downtime and Design Failure People might not be ready to take new process, this could cause delay in delivery or even design failure because it was designed as per older process. ’éĘ Process changes causes rethinking of process flow Process require input/output and processing. If process changes it will alter any of these things.