Lean manufacturing

- 1. LEAN LEAN MANUFACTURING MANUFACTURING Canada Post Puts Its Stamp on a Lean Transformation Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 1 b.s.abdur rahman university.

- 2. Lean Manufacturing CALGARY MAIL PROCESSING PLANT âĒBuilt in 1975 âĒ350,000 sq.ft âĒ430 employees on three shifts daily and weekends âĒProcesses 425 million pieces of mail annually âĒOne of two mechanized processing plants in Alberta âI used to think that we werenât a manufacturing company; we didnât produce anything,â âbut you can lean out mail operations. What weâre looking for is flow; in one door and out another.â said Don McLellan, director, mail operations, at the Calgary facility. Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 2 b.s.abdur rahman university.

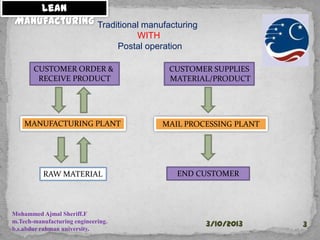

- 3. Lean Manufacturing Traditional manufacturing WITH Postal operation CUSTOMER ORDER & CUSTOMER SUPPLIES RECEIVE PRODUCT MATERIAL/PRODUCT MANUFACTURING PLANT MAIL PROCESSING PLANT RAW MATERIAL END CUSTOMER Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 3 b.s.abdur rahman university.

- 4. Lean Manufacturing Major problems âĒ More Takt time âĒ More Cycle time âĒ More Conveyor system âĒ More maintainance âĒ Back injuries to employees âĒ Jammed parcels Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 4 b.s.abdur rahman university.

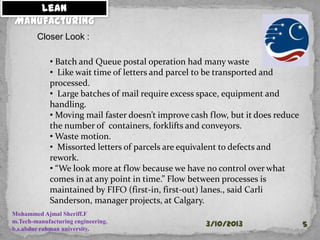

- 5. Lean Manufacturing Closer Look : âĒ Batch and Queue postal operation had many waste âĒ Like wait time of letters and parcel to be transported and processed. âĒ Large batches of mail require excess space, equipment and handling. âĒ Moving mail faster doesnât improve cash flow, but it does reduce the number of containers, forklifts and conveyors. âĒ Waste motion. âĒ Missorted letters of parcels are equivalent to defects and rework. âĒ âWe look more at flow because we have no control over what comes in at any point in time.â Flow between processes is maintained by FIFO (first-in, first-out) lanes., said Carli Sanderson, manager projects, at Calgary. Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 5 b.s.abdur rahman university.

- 6. Lean Manufacturing Four stream: âĒ Letters âĒ Parcels âĒ Express mail âĒ Publications and advertising mail âEach value stream has had success with applying lean,â said McLellan. Hereâs a look at how it was done in pubs and ad mail. Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 6 b.s.abdur rahman university.

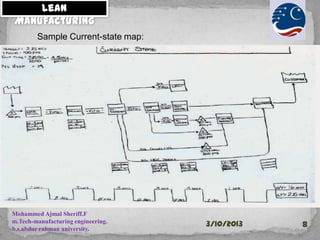

- 7. Lean Manufacturing Sweating the details: âĒ Value stream Action required to bring a product from concept to Launch and from order to delivery. âĒ Value stream mapping ïPrevious-state map ïCurrent-state map ïFuture-state map âĒ Operator balance chart (OBC) âĒ Standard Work Document Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 7 b.s.abdur rahman university.

- 8. Lean Manufacturing Sample Current-state map: Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 8 b.s.abdur rahman university.

- 9. Lean Manufacturing Sample Current-state map: Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 9 b.s.abdur rahman university.

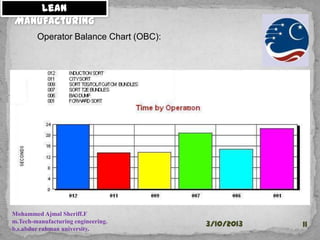

- 10. Lean Manufacturing TAKT TIME: ` Team members observed and timed operators lifting bags, reading destination tags, opening bags, dumping out the bundles of mail, reading addresses, tossing bundles of mail into containers, etc. T=24Sec Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 10 b.s.abdur rahman university.

- 11. Lean Manufacturing Operator Balance Chart (OBC): Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 11 b.s.abdur rahman university.

- 12. Lean Manufacturing Conveyor system: Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 12 b.s.abdur rahman university.

- 13. Lean Manufacturing STANDARD WORK DOCUMENT: Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 13 b.s.abdur rahman university.

- 14. Lean Manufacturing Lift assist arm : Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 14 b.s.abdur rahman university.

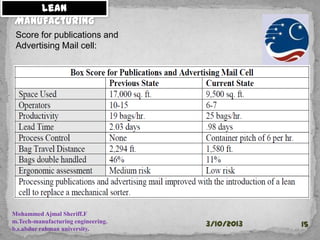

- 15. Lean Manufacturing Score for publications and Advertising Mail cell: Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 15 b.s.abdur rahman university.

- 16. Lean Manufacturing RESOLVED PROBLEMS: âĒ 3.2 million square feet of space freed-up for consolidation, reducing reliance on leases âĒ 10 years of consecutive profitability âĒ Returned dividends to the Canadian government each year, including $59 million in 2005 âĒ Reduced reliance on material handling equipment, overhead conveyors, forklifts, etc. âĒ Dramatically reduced on-floor inventories, reducing lead time, and improving quality âĒ Freed-up capacity and an increase in available machine time âĒ Improved labor relations âno labor disruptions since starting lean (The company said no one would lost their employment because of lean.) Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 16 b.s.abdur rahman university.

- 17. TRIP Steel Thank You Mohammed Ajmal Sheriff.F m.Tech-manufacturing engineering. 3/10/2013 17 b.s.abdur rahman university.