Lifting-tools-tackles rigging practice .ppt

- 2. 2 SAFETY IN OPERATION OF LIFTING TOOLS ? PURPOSE ? 40% Accidents are due to Material handling ? It accounts 40% production cost ? It does not add value to the product but it cost to the product ? A large cost of product cost is due to Material handing ? Major activities in Cement Industries is Material Handling ? Listing tools and tackles comes under Material handling activity ? It has potential for high risk and accidents

- 3. 3 TIPS FOR CORRECT LIFTING PRACTICE ? Find out the correct weight of the load to be lifted ? Slightly lift the load check for CG , imbalance etc ? While lifting ensure that the load is not obstructing to any ? of the parts of structure ? Loose nuts & bolts must be kept in a box and not on the ? structures.The box to be properly anchored. ? Avoid sudden break or sudden release of the load . Impact load may result in breaking of the rope/chain ? persons with B.P or epilepsy shall not be allowed to work at heights ? Barricade the area of loads lifting/ sparks falling ? Full body safety Harness is a must at heights more than 1.8M

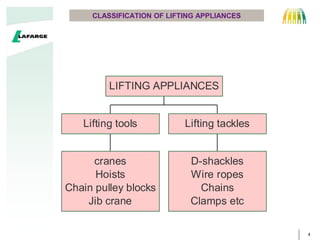

- 4. 4 CLASSIFICATION OF LIFTING APPLIANCES cranes Hoists Chain pulley blocks Jib crane Lifting tools D-shackles Wire ropes Chains Clamps etc Lifting tackles LIFTING APPLIANCES

- 5. 5 LIFTING TOOLS AND TACKLES Lifting tool is device which is used to lift load such ? Chain block ? Jacks ? Cranes etc ? Winch ? Mono rail Lofting tackle is device which is used to facilitates for lifting load such as ? Rope ? D- shackles ? Hooks ? Eye bolts etc

- 6. 6 CHAIN BLOCK PROPER USE OF CHAIN BLOCK ? Never drag the chain block on the floor. It must be caried ? Chin block when not in use must be hanged on hooks and kept under cover and not left on floor ? It must be inspected before and after use ? Chain block to be lubricated periodically ? Once in year or often dismantle the chain completely and examine the parts thoroughly and replace worn out parts. ? Maintain proper service record of chain block ? Load capacity never be exceed. It is advisable to lift 10% less load then specified. Jerks load while lifting to be avoided

- 7. 7 JACKS It is a portable tools used for lifting heavy load s through short distance. There are several types of jacks ? Screw Jacks ? Screw jacks with ratchet handle ? Hydraulic Jack with inbuilt pump ? Hydraulic jack with separate pump etc

- 8. 8 JACKS PROPER USE OF JACK ? Chose a jack of at least 25% higher capacity htna the load to be lifted ? Use wooden block below and above jacks to reduce chance of slipping ? Use same capacity and same stroke length jacks when lifting load with two or more jacks simultaneously ? Inspect, clean lubricate jacks before and after use of jacks ? Never drag the jacks on floor ? When not in store jacks properly in racks after applying a thin layer of grease to prevent rust ? Use jacks according to instruction of manufacturer. All jacks have a marks on the ram indicating the limits of ram travel which never be exceeded

- 9. 9 JACKS PROPER USE OF JACK ? Always use clean oil of given specification according to manufacturer ? Use standard length levers provided with hydraulic jacks not any available bars ? There are some jacks which are manufactured only for use in vertical position only which should not be used in horizontal position.

- 10. 10 CRANES- TYPES OF CRANE PROPER USE OF CRANES ? Type of cranes 1. Wall mounted cranes 2. Gantry cranes 3. One leg Gantry cranes 4. Jib cranes 5. Mobile cranes a. Truck mounted cranes b. Crawler crane c. Tyre mounted crane d. Loco Crane

- 11. 11 CRANES ®C OPERATION SAFETY The following factor to be consider while lifting load ? About the load ? Where the load will be shifted ? Method to be adopted 1. Manual handling 2. Mechanical handling ? About the operator ? About he Supervisor

- 12. 12 CRANES ? About the load 1. Weight of the item 2. Dimension 3. Special instruction if any 4. Hazardous/ Danger involved ? Where the load will be shifted 1. With in the Plant 2. With in the store area 3. Distance 4. Pathway is clear and free from any shorts of hazards

- 13. 13 CRANES ®C OPERATION SAFETY ? Method to be adopted 1. Manual handling a. Where the workers are trained b. Proper PPEs are available ? Mechanical handling 1. What is the handling equipment 2. Is it suitable for the load 3. Is the crane capacity is sufficient for the load 4. Is the all the tools are tested and examined by competent persons 5. Is the equipment is good working condition 6. Is the equipment is provided with safety devices

- 14. 14 CRANES ®C OPERATION SAFETY ? About the operator 1. Is the operator trained for operation 2. Does poses license if required 3. Is the operator is aware about method of handling 4. Is the operator is aware about the hazards associated with the handling and course of action to be taken by him in case of emergency or accident ? About he Supervisor 1. Is he trained 2. Is he familiar with statutory requirement 3. Is he capable of handling emergency

- 15. 15 CRANES- OPERATION SAFETY Operate the equipment if 1. Equipment has been operated bare once 2. The load has been correctly fastened/ Balance way 3. Suitable PPEs has been provided 4. Environment is safe

- 16. 16 OTHER IMPORTANT FACTOR FOR CRANE OPERATION ? Before start of lifting following conditions to be fulfilled 1. Slings must not be kinked 2. Load must be must be in plumb line 3. There must not be sudden jerks 4. The load should be lifted few inches first and observed the balance to know the degree of tilt 5. No body is allowed to be under the suspended load 6. Obstruction/Entangle of load should be avoid because it will over stretch the hoisting rope 7. Rubbing of hoisting hope with any stationary/moving object should be avoided

- 17. 17 OTHER IMPORTANT FACTOR FOR CRANE OPERATION ? Transversing of load 1. The load must be move after hoisting and clearing the obstruction 2. Two movement should not be done same time 3. Uniform speed to be maintained 4. The sweeping zone should be kept free from obstruction 5. During movement of load it must be kept visible as far as practicable to operator. If it is not posible thenhelp to be taken from Signaler. 6. The movement operation will be suspended if load fall freely under neutral condition

- 18. 18 OTHER IMPORTANT FACTOR FOR CRANE OPERATION ? Lowering and positioning of load 1. The to be lowered slowly and carefully 2. Nobody is allowed under the load while lowering 3. Nobody is allow3d inside the cabin while loading the trucks 4. Positioning and resting of load on plum line and it will be standstill upto removal of load

- 19. 19 INSPECTION LIFTING TOOLS ? It is divided into two type 1. Frequent inspection Daily , Monthly and weekly and monthly 2. Periodic Inspection Quarterly, Half yearly and yearly ? Frequent Inspection ? All functional operating systems like winch assembly, control blocks, safety devices, electrical equipments hydraulic system etc must be inspected daily ? Running ropes shall be inspected on monthly basis and record to be kept

- 20. 20 INSPECTION LIFTING TOOLS Periodic Inspection ? It includes 1. Oil levels and lubrication of all the parts 2. Inspection of rope and rope termination fittings 3. Spillage oil grease, grease and other materials 4. The function of brakes 5. Functioning of limit switches 6. Functioning of electrical switches 7. The cover and safety guards 8. Functioning alarm 9. Functioning of load indicating system

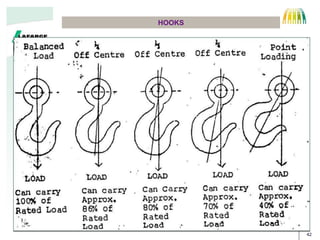

- 21. 21 INSPECTION LIFTING TOOLS- PERIODIC INSPECTION Periodic Inspection 1. Deformation cracks, corrosion of jibs, blocks etc 2. Deformation like throat opening and bending of hooks ( Throat opening 15% with latch and 8% with out latch). Max bending allowed is 5% either side 3. Loose bolts, rivets and bearings 4. Worn out hooks, pins, bearings, shaft, gears, rollers locking and clamping device 5. Excessive wearing on break system and lining 6. Improper functioning electrical devices including limit switches

- 22. 22 PREACUTION TO BE TAKEN DURING MAINTENANCE 1. The crane must be moved to a location with at least interface with other carne/equipments or operator 2. All the controller must be off position 3. LOTOTO to be applied 4. Warning sign crane under maintenance 5. Rail stopper to be provided 6. Crane must not take into operation if the guards are not put properly

- 23. 23 LIFTING TACKLES Lofting tackle is device which is used to facilitates for lifting load such as ? Rope ? D- shackles ? Hooks ? Eye bolts etc

- 24. 24 ROPE Lofting tackle is device which is used to facilitates for lifting load such as ? Rope 1. Fibre rope 2. Wire rope 3. Synthetic rope 4. Chain

- 25. 25 FIBRE ROPE Handling care and Use of Fibre rope ? Fibre rope never be stores on floor or in box. It should be hang on well ventilated room. A wet rope should be throughly dried and cleaned before storage. It must not be kept near high temp area. Carbon mono-oxide and Carbon di-oxide causes rapid deterioration of the rope ? When a rope is used as as sling, it should not pass over sharp edge of casing/beam. ( If rope rope makes an angle of 60 Deg with horizontal then they have only 86% of its strength, 71% at 45 Deg and 50% at 30 Deg ? Rope should not be dragged on ground ? Fibre rope should be inspected thoroughly before and after use the out side as well as inside ( by untwisting the strand). Accumulation like powder like saw dust inside rope indicate excessive internal wear. Excessive oil on the outside of the rope is the indication of overload

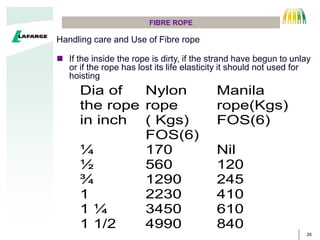

- 26. 26 FIBRE ROPE Handling care and Use of Fibre rope ? If the inside the rope is dirty, if the strand have begun to unlay or if the rope has lost its life elasticity it should not used for hoisting Dia of the rope in inch Nylon rope ( Kgs) FOS(6) Manila rope(Kgs) FOS(6) ? 170 Nil ? 560 120 ? 1290 245 1 2230 410 1 ? 3450 610 1 1/2 4990 840

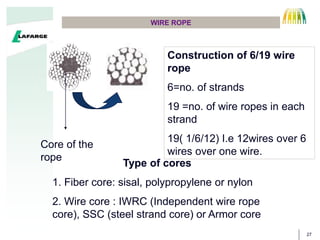

- 27. 27 WIRE ROPE Construction of 6/19 wire rope 6=no. of strands 19 =no. of wire ropes in each strand 19( 1/6/12) I.e 12wires over 6 wires over one wire. Core of the rope Type of cores 1. Fiber core: sisal, polypropylene or nylon 2. Wire core : IWRC (Independent wire rope core), SSC (steel strand core) or Armor core

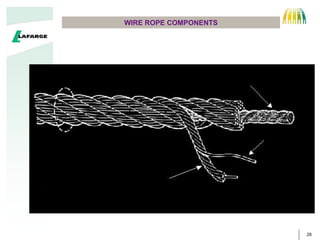

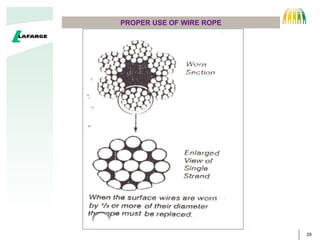

- 29. 29 PROPER USE OF WIRE ROPE CORE WIRE STRAND

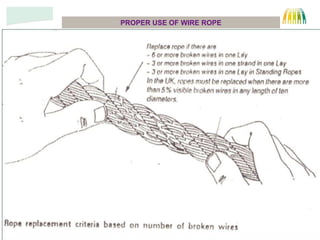

- 30. 30 PROPER USE OF WIRE ROPE CORE WIRE STRAND ? Reduction in diameter of the rope due to core failure , abrasion etc should not be more than ? 1.0 mm for the ropes up to---19mm dia ? 1.5mm for ropes of------------22-28mm dia ? 2.0mm for ropes of ------------32-38mm dia SUCH ROPE TO BE REPLACED

- 31. 31 PROPER USE OF WIRE ROPE CORE WIRE STRAND ? Reduction in diameter of the rope due to core failure , abrasion etc should not be more than ? 1.0 mm for the ropes up to---19mm dia ? 1.5mm for ropes of------------22-28mm dia ? 2.0mm for ropes of ------------32-38mm dia SUCH ROPE TO BE REPLACED

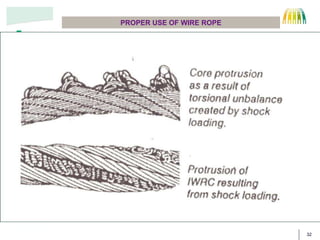

- 32. 32 PROPER USE OF WIRE ROPE CORE WIRE STRAND

- 33. 33 PROPER USE OF WIRE ROPE CORE WIRE STRAND

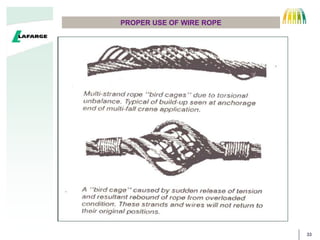

- 34. 34 PROPER USE OF WIRE ROPE CORE WIRE STRAND

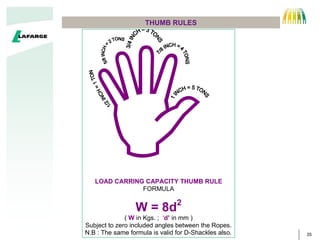

- 35. 35 THUMB RULES CORE WIRE STRAND ? LOAD CARRING CAPACITY THUMB RULE FORMULA W = 8d2 ( W in Kgs. ; °Æd°Ø in mm ) Subject to zero included angles between the Ropes. N.B : The same formula is valid for D-Shackles also.

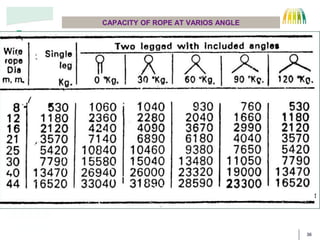

- 36. 36 CAPACITY OF ROPE AT VARIOS ANGLE CORE WIRE STRAND

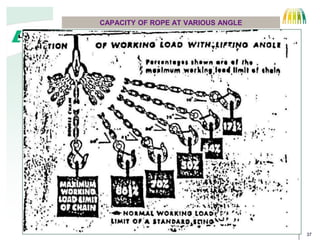

- 37. 37 CAPACITY OF ROPE AT VARIOUS ANGLE CORE WIRE STRAND

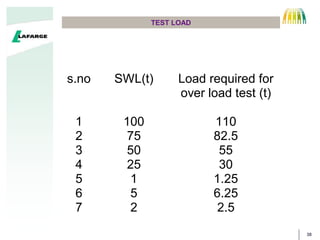

- 38. 38 TEST LOAD CORE WIRE STRAND s.no SWL(t) Load required for over load test (t) 1 100 110 2 75 82.5 3 50 55 4 25 30 5 1 1.25 6 5 6.25 7 2 2.5

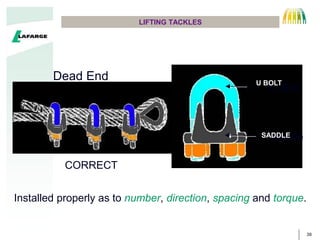

- 39. 39 LIFTING TACKLES CORE WIRE STRAND Dead End CORRECT Saddle U-Bolt Installed properly as to number, direction, spacing and torque. U BOLT SADDLE

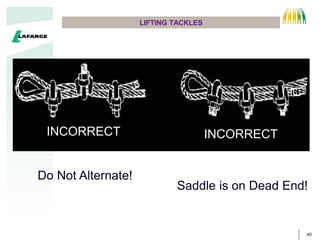

- 40. 40 LIFTING TACKLES CORE WIRE STRAND INCORRECT INCORRECT Do Not Alternate! Saddle is on Dead End!

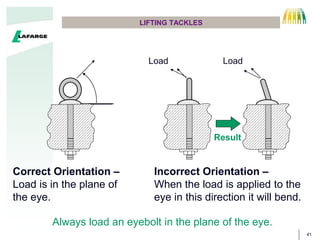

- 41. 41 LIFTING TACKLES CORE WIRE STRAND INCORRECT INCORRECT Result Load Load Correct Orientation ®C Load is in the plane of the eye. Incorrect Orientation ®C When the load is applied to the eye in this direction it will bend. Always load an eyebolt in the plane of the eye.

- 43. 43 Lifting Machines, Chains, Ropes and Lifting Tackles 1. Every chain, rope and lifting tackles for the purpose of raising or lowering persons goods or materials. a) All parts including the working gear, whether fixed or moveable of every lifting machine and every chain, rope or lifting tackle shall be- (i) of good construction, sound material and adequate strength and free from defects; (ii) Properly maintained and (iii) Thoroughly examined by a competent person at least once in every period of twelve months or at such intervals as the Chief Inspector may specify in writing, and a register shall be kept containing the prescribed particulars of every examination. b) No lifting machine and no chain, rope or lifting tackle shall except for the purpose of test, be loaded beyond the safe working load which shall be plainly marked thereon together with an identification mark and duly entered in the prescribed register; and where this is not practicable, a table showing the safe working loads of every kind and size of lifting machine or chain, rope or lifting tackle in use shall be displayed in prominent positions on the premises. LIFTING TOOLS AND TACKLES LEGAL PROVISION

- 44. 44 Lifting Machines, Chains, Ropes and Lifting Tackles c) While any person is employed or working on or near the wheel track of travelling crane in any place, where he would be liable to be struck by the crane, effective measures shall be taken to ensure that the crane does not approach within (six meters) of that place. 2. The State Government may make rules in respect of any lifting machine or any chain, rope or lifting tackle used in factories. a) Prescribing further requirement to be complied with in addition to those set our in this section. b) Providing for exemption from compliance with all or any of the requirements of this section, where in its opinion, such compliance is unnecessary or impracticable. For the purpose of this section a lifting machine or a chain rope or lifting tackle shall be deemed to have been thoroughly examined if a visual examination supplement, if necessary, by other means and by the dismantling of parts of the gear, has been carried out as carefully as the conditions permit in order to arrive at a reliable conclusion as to the safety of the parts examined. LIFTING TOOLS AND TACKLES LEGAL PROVISION