Logistics In Agritex

- 1. Logistics and More… The Case Study of Agritex Energy S.A. Vassily Haitas - Managing Director Andreas Kiziris - Crop Manager

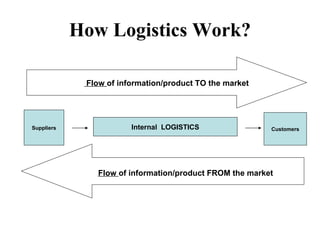

- 2. How Logistics Work? Flow of information/product FROM the market Flow of information/product TO the market Suppliers Internal LOGISTICS Customers

- 3. Enormous glass warehouse… Total area: 10 Ha Height: 5.5 m Length: 500 m Width: 200 m 620 working paths of total 60 km Total volume of 500.000 m 3 5,5m 200m 500m

- 4. Why so high, why vertically? 0,5 m from ground till growing gutter 3,0 m from gutter till growing wire 2,0 m till highest point

- 5. Time needed of the final product Time needed to produce seedlings ( Fixed and specified) Time needed from flowering till harvesting ( Variable but specified ) Time needed from harvesting till shipping (when Minimum =succeeded Logistics)

- 6. 1. Time Needed time for seedling production Depending on: Season of wanted cultivar Variety of tomato S pecifications For Agritex= 28 days

- 7. 2. Time needed from flowering till harvesting Flowering and setting Impact of the energy from “ Degree Days” Cluster ready to harvest 42-77 days Flowering and setting Harvesting truss 2,5 m

- 8. Time needed from flowering till harvesting (continued) Flowering and fruit setting Gradual color change 1 10 1 2 3 4 5

- 9. Convenience - perfect working height - Direct eye contact Perfect results increased productivity with higher quality 3. Time needed from harvesting till shipping

- 12. Tomato fruit production time Χ= α ( min, max) + β(min,max) + γ (min,max) α = nursery time (24-30 days) β = from flowering –fruit setting to cluster ripening (42-77 days ) γ = harvesting-packing- transportation - palletizing (0,5-3 hours ) Χ minimum = 66 days + 0,5 hours Χ maximum = 107 days + 3 hours

- 13. Climate + Irrigation Control = Max. income Irrigation Control + Fertilization Control = Maximum water & nutrients availability and efficiency via hydroponics method Climate Control + Nutrients Control = up to 4 times more production with high quality tomato fruits

- 14. Supporting procedures for tomato production Works on plants Clipping - plants supporting Thieving -side shoots elimination Pruning - flower elimination Deleafing - leaves removal

- 15. View of the software, daily registration

- 16. NOMAD: Supportive Tool for Labor Management ( Registration and administration ) Labor registration by TIME-PLACE-TYPE Quick Problem Solving Quick and clear view C ontinuous I mprovement

- 17. Big project = Team building Collaborations with strong partners Knowledge and information diffusion Effective Team work between production-sales Serial work flow ( finishing one step-go to second )

- 18. Active Networking = Perfect results

- 19. Thank you! In case of questions please e-mail: [email_address] Or visit us at www.agritex.gr Or visit our premises in Alexandria, Greece Photos courtesy of Babis Giritziotis

![Thank you! In case of questions please e-mail: [email_address] Or visit us at www.agritex.gr Or visit our premises in Alexandria, Greece Photos courtesy of Babis Giritziotis](https://image.slidesharecdn.com/logisticseng-13230134267661-phpapp02-111204094507-phpapp02/85/Logistics-In-Agritex-19-320.jpg)