Logistics management 3 Production Management MRP

- 1. Facult¨¦ de Droits & Economie ¨C #3 Production Management Shing Wyee Jolivel, Sino Qua Non Consulting Sino Qua Non Consulting 1

- 2. RECAP ON LESSON #2 Sino Qua Non Consulting 2

- 3. SCM ¨C DEFINITION BREAKDOWN BREAKDOWN OF DEFINITION : SUPPLY CHAIN MANAGEMENT UPSTREAM & DOWNSTREAM NETWORK OF COMPANIES LINKAGES ACTIVITIES & PROCESSES PRODUCE VALUE TO CUSTOMER AT LESS COST Sino Qua Non Consulting 3 INTERDEPENDENCY

- 4. Sino Qua Non Consulting 4 SUPPLY CHAIN MANAGEMENT DEFINITION IN IMAGES

- 5. Sino Qua Non Consulting 5 SUPPLY CHAIN MANAGEMENT ? How much stock? ? Optimum stk level ? Quantity ? Product life cycle? ? When to start sourcing? Where are my suppliers? Price,Delivery & payment conditions?Are suppliers able to stock in advance ? Dispatch to my end customers? SuppliersˇŻ transparency?Order processing compatibility? ? What processes? ? Stock management ? FIFO (First in- First out) ? ? LIFO? (Last-in First-out) ? ROBITISATION? SCANNER? BARCODE? RFID (Radio Freq Identification) ? Who are my customers? Who is selling my products? My distribution network Wholesalers? Retailers? Ecommerce? LOGISTICS MANAGEMENT Inbound, Warehousing, Outbound After sales service How do I treat return goods? Where do I stock defective goods? Do I integrate back into the system? Do I repair and resell it at a discount?

- 6. Sino Qua Non Consulting 6 PUSH VS PULL STRATEGIES

- 7. Sino Qua Non Consulting 7 PUSH VS PULL STRATEGIES Eg. Cars

- 8. Sino Qua Non Consulting 8 PUSH VS PULL STRATEGIES : COMPARISON -Producer centric -Longterm demand forecasts -Make-to-stock -High Inventory -Inability to meet changing demand -Less Marketing cost - Customer centric - Improve cash flow - Make-to-order - Lower inventory - Shorter lead-times - Lead to unhappy customers when badly implemented - Difficult to implement - High advertising costs Eg. MRP Eg. Kanban, JIT

- 9. TRENDS IN LOGISTICS MANAGEMENT ˇ. END OF RECAP Sino Qua Non Consulting 9

- 10. LOGISTICS ¨C AGENDA Sino Qua Non Consulting 10 1. INTRODUCTION TO LOGISTICS 2. SUPPLY CHAIN MANAGEMENT 3. PRODUCTION MANAGEMENT ¨C PUSH STRATEGY(MRP) 4. PRODUCTION MANAGEMENT ¨C PULL STRATEGY (KANBAN) 5. INVENTORY MANAGEMENT BEST PRACTICES 6. INTRODUCTION TO INTERNATIONAL LOGISTICS 7. INCOTERMS 8. LETTER OF CREDIT - DOCUMENTARY CREDIT 9. CUSTOMS

- 11. LESSON #3 PRODUCTION MANAGEMENT Sino Qua Non Consulting 11

- 12. PUSH SYSTEM : MRP (Materials Requirement Planning) Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well. An MRP system is intended to simultaneously meet three objectives: ? Ensure materials are available for production and products are available for delivery to customers. ? Maintain the lowest possible material and product levels in store ? Plan manufacturing activities, delivery schedules and purchasing activities. Sino Qua Non Consulting 12

- 13. PUSH SYSTEM : MRP (Materials Requirement Planning) Material requirements planning (MRP) answers the following questions : ? What is to be made and when? ? Materials and parts required to make the product ? What is in stock? ? What is on order? (expected receipts) ? How long does it take to get various components? Sino Qua Non Consulting 13

- 14. PUSH SYSTEM : MRP (Materials Requirement Planning) Sino Qua Non Consulting 14 DEMONSTRATION MRP FOR A PEN

- 15. PUSH SYSTEM : MRP (Materials Requirement Planning) Sino Qua Non Consulting 15 3 elements : ? Production tree (what goes into 1 pen) ? Master Production Schedule (Customer demand) ? MRP for each component

- 16. MRP FOR A PEN : 1 Production Tree Sino Qua Non Consulting 16 PEN BODY CAP INK BILL OF MATERIAL BOM 1 BOM 2 BOM 3CHILD PARENT

- 17. PUSH SYSTEM : MRP (Materials Requirement Planning) Sino Qua Non Consulting 17 Definition of terms : ? Gross Requirement is the independent demand qty for each item ? Schedule requirement are orders which have been placed but not yet completed or confirmed ? Availabilities : estimate amount of inventory available each week after gross requirement have been satisfied

- 18. PUSH SYSTEM : MRP (Materials Requirement Planning) Sino Qua Non Consulting 18 Definition of terms : ? Planned order receipt is the actual quantity determined to be received into the warehouse at the beginning of a time period. Contrary to scheduled requirements (which is the IDEAL inbound quantities), in real life situation, your supplier may not be able to deliver on time or only partial quantities. Therefore, the planned order receipt has to be adjusted all the time.

- 19. PUSH SYSTEM : MRP (Materials Requirement Planning) Sino Qua Non Consulting 19 Definition of terms : ? Planned order release amount of order planned for each time period (to your supplier)

- 20. MRP FOR A PEN : 2 Master Production Schedule Sino Qua Non Consulting 20 Week 1 2 3 4 5 6 7 8 Requirements 1000 1000 Master Production Schedule 1000 pens to be produced to meet customer order in WK5 Another 1000 pens to be produced to meet customer order in WK8

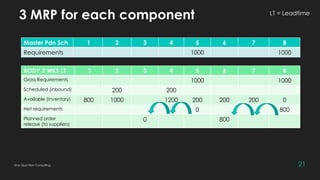

- 21. Sino Qua Non Consulting 21 3 MRP for each component Master Pdn Sch 1 2 3 4 5 6 7 8 Requirements 1000 1000 BODY 2 WKS LT 1 2 3 4 5 6 7 8 Gross Requirements 1000 1000 Scheduled (inbound) 200 200 Available (inventory) 800 1000 1200 200 200 200 0 Net requirements 0 800 Planned order release (to suppliers) 0 800 LT = Leadtime

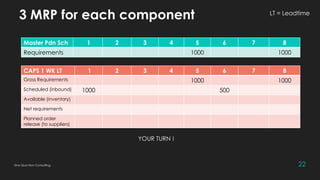

- 22. Sino Qua Non Consulting 22 3 MRP for each component Master Pdn Sch 1 2 3 4 5 6 7 8 Requirements 1000 1000 CAPS 1 WK LT 1 2 3 4 5 6 7 8 Gross Requirements 1000 1000 Scheduled (inbound) 1000 500 Available (inventory) Net requirements Planned order release (to suppliers) LT = Leadtime YOUR TURN !

- 23. Sino Qua Non Consulting 23 3 MRP for each component Master Pdn Sch 1 2 3 4 5 6 7 8 Requirements 1000 1000 INK 1 WK LT 1 2 3 4 5 6 7 8 Gross Requirements 1000 1000 Scheduled (inbound) 300 300 Available (inventory) 400 Net requirements Planned order release (to suppliers) LT = Leadtime YOUR TURN ! https://www.youtube.com/watch?v=KEvHwvrkwbU&t=20s

- 24. END #3 www.sinoquanon.com Sino Qua Non Consulting 24