Logistics Mgt Webcast

- 1. Looking To Transform Your Supply Chain And Save Money? Joel Stachowski, Infor Brian Randleman, Generac

- 2. Agenda Welcome and Introductions Who is Generac History, Product Line, Manufacturing, Customers Supply chain processes â A history at Generac Implementation process Metrics for success Key Lessons Learned Summary Next Steps Q & A Program Support Sales

- 3. Who Is Generac? Design and manufacture power generation systems Portable Home Standby Commercial/Industrial Telecom, Private Label and R/V also Based in Waukesha, WI Founded in 1959 by Dr. Robert Kern Sold to CCMP Capital in 2006, public in 2010

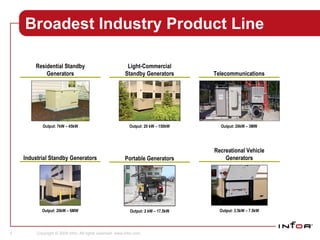

- 4. Broadest Industry Product Line Output: 7kW â 45kW Output: 20 kW â 150kW Output: 20kW â 6MW Output: 2 kW â 17.5kW Output: 3.5kW â 7.5kW Output: 20kW â 3MW Residential Standby Generators Light-Commercial Standby Generators Industrial Standby Generators Portable Generators Recreational Vehicle Generators Telecommunications

- 5. Manufacturing Capability 1,000,000 sq. ft. manufacturing space Eagle, WI Waukesha, WI Maquoketa, IA Whitewater, WI

- 6. Customers

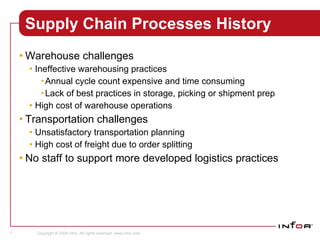

- 7. Supply Chain Processes History Warehouse challenges Ineffective warehousing practices Annual cycle count expensive and time consuming Lack of best practices in storage, picking or shipment prep High cost of warehouse operations Transportation challenges Unsatisfactory transportation planning High cost of freight due to order splitting No staff to support more developed logistics practices Sales

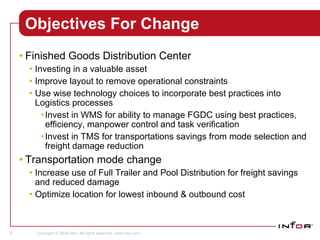

- 8. Objectives For Change Finished Goods Distribution Center Investing in a valuable asset Improve layout to remove operational constraints Use wise technology choices to incorporate best practices into Logistics processes Invest in WMS for ability to manage FGDC using best practices, efficiency, manpower control and task verification Invest in TMS for transportations savings from mode selection and freight damage reduction Transportation mode change Increase use of Full Trailer and Pool Distribution for freight savings and reduced damage Optimize location for lowest inbound & outbound cost Sales

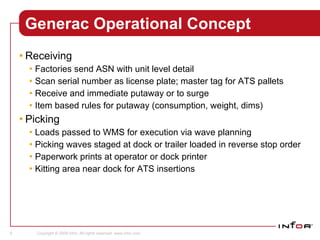

- 9. Generac Operational Concept Receiving Factories send ASN with unit level detail Scan serial number as license plate; master tag for ATS pallets Receive and immediate putaway or to surge Item based rules for putaway (consumption, weight, dims) Picking Loads passed to WMS for execution via wave planning Picking waves staged at dock or trailer loaded in reverse stop order Paperwork prints at operator or dock printer Kitting area near dock for ATS insertions

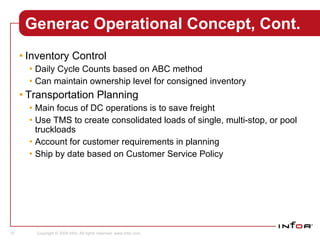

- 10. Generac Operational Concept, Cont. Inventory Control Daily Cycle Counts based on ABC method Can maintain ownership level for consigned inventory Transportation Planning Main focus of DC operations is to save freight Use TMS to create consolidated loads of single, multi-stop, or pool truckloads Account for customer requirements in planning Ship by date based on Customer Service Policy

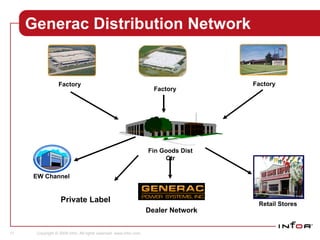

- 11. Generac Distribution Network Factory Factory Factory Fin Goods Dist Ctr Private Label Dealer Network EW Channel Retail Stores

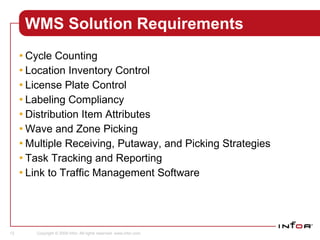

- 12. WMS Solution Requirements Cycle Counting Location Inventory Control License Plate Control Labeling Compliancy Distribution Item Attributes Wave and Zone Picking Multiple Receiving, Putaway, and Picking Strategies Task Tracking and Reporting Link to Traffic Management Software Sales

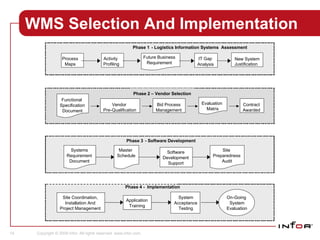

- 14. WMS Selection And Implementation Sales Systems Requirement Document Master Schedule Site Preparedness Audit Phase 3 - Software Development Software Development Support Systems Requirement Document Master Schedule Site Preparedness Audit Phase 3 - Software Development Software Development Support Vendor Pre - Qualification Functional Specification Document Phase 2 - Vendor Selection Bid Process Management Contract Awarded Evaluation Matrix Vendor Pre - Qualification Functional Specification Document Phase 2 â Vendor Selection Bid Process Management Contract Awarded Evaluation Matrix Site Coordination, Installation And Project Management System Acceptance Testing Application Training On - Going System Evaluation Site Coordination, Installation And Project Management System Acceptance Testing Application Training On - Going System Evaluation Phase 4 - Implementation IT Gap Analysis Activity Profiling Process Maps Phase 1 - LIS Assessment New System Justification Future Business Requirement IT Gap Analysis Activity Profiling Process Maps Phase 1 - Logistics Information Systems Assessment New System Justification Future Business Requirement

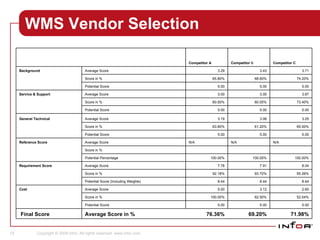

- 15. WMS Vendor Selection Competitor A Competitor B Competitor C Background Average Score 3.29 3.43 3.71 Ėý Score in % 65.80% 68.60% 74.20% Ėý Potential Score 5.00 5.00 5.00 Service & Support Average Score 3.00 3.00 3.67 Ėý Score in % 60.00% 60.00% 73.40% Ėý Potential Score 5.00 5.00 5.00 General Technical Average Score 3.19 3.06 3.25 Ėý Score in % 63.80% 61.20% 65.00% Ėý Potential Score 5.00 5.00 5.00 Reference Score Average Score N/A N/A N/A Ėý Score in % Ėý Ėý Ėý Ėý Potential Percentage 100.00% 100.00% 100.00% Requirement Score Average Score 7.78 7.91 8.04 Ėý Score in % 92.18% 93.72% 95.26% Ėý Potential Score (Including Weights) 8.44 8.44 8.44 Cost Average Score 5.00 3.12 2.60 Ėý Score in % 100.00% 62.50% 52.04% Ėý Potential Score 5.00 5.00 5.00 Ėý Final Score Average Score in % 76.36% 69.20% 71.98%

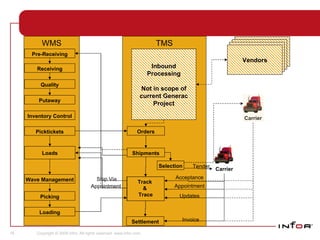

- 16. WMS TMS Pre-Receiving Receiving Quality Putaway Inventory Control Picktickets Wave Management Picking Loading Orders Carrier Acceptance Selection Appointment Updates Invoice Tender Settlement Shipments Ship Via Appointment Loads Track & Trace Inbound Processing Not in scope of current Generac Project Vendors Vendors Vendors Vendors Carrier

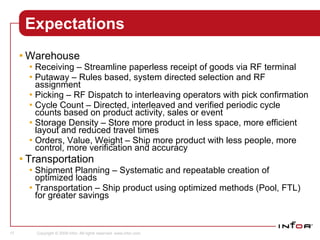

- 17. Expectations Warehouse Receiving â Streamline paperless receipt of goods via RF terminal Putaway â Rules based, system directed selection and RF assignment Picking â RF Dispatch to interleaving operators with pick confirmation Cycle Count â Directed, interleaved and verified periodic cycle counts based on product activity, sales or event Storage Density â Store more product in less space, more efficient layout and reduced travel times Orders, Value, Weight â Ship more product with less people, more control, more verification and accuracy Transportation Shipment Planning â Systematic and repeatable creation of optimized loads Transportation â Ship product using optimized methods (Pool, FTL) for greater savings Sales

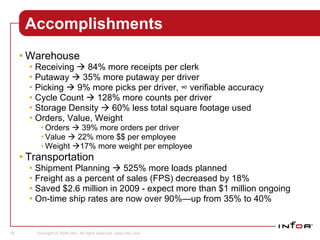

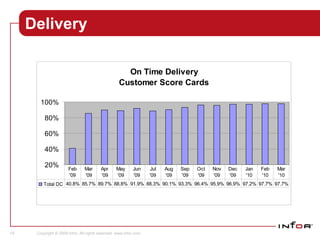

- 18. Accomplishments Warehouse Receiving ï 84% more receipts per clerk Putaway ï 35% more putaway per driver Picking ï 9% more picks per driver, â verifiable accuracy Cycle Count ï 128% more counts per driver Storage Density ï 60% less total square footage used Orders, Value, Weight Orders ï 39% more orders per driver Value ï 22% more $$ per employee Weight ï 17% more weight per employee Transportation Shipment Planning ï 525% more loads planned Freight as a percent of sales (FPS) decreased by 18% Saved $2.6 million in 2009 - expect more than $1 million ongoing On-time ship rates are now over 90%âup from 35% to 40%

- 19. Delivery

- 20. Key Factors For Success Have or create a Customer Service Policy CSP defines service targets and objectives for Logistics (in-stock, on-time, fill rate ï all for different customer segments) Project goals are to reduce Logistics Costs subject to the Customer Service Policy Design details to show preparation and depth of analysis Identify the stakeholders with real approval power Stay on time with regular stakeholder meetings Generac met bi-weekly with stakeholder to remove barriers Develop functional requirements Identify solutions that meet functional requirements to avoid customization Implement solution with best practices to improve your processes Sales

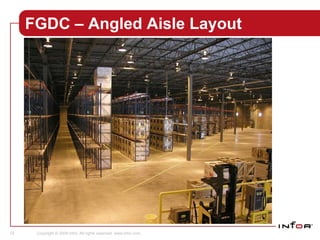

- 22. FGDC â Angled Aisle Layout

- 23. Next Steps For additional information on Supply Chain Management solutions visit: http://www.infor.com/solutions/scm/ If you have any questions, please contact: Christine BrownĖý|ĖýMarketing ProgramĖýManagerĖý| Infor | office:Ėý734.623.4030 | christine.brown@infor.com Program Support Sales

- 24. Thank You For Attending Today. Questions Sales

Editor's Notes

- #6: Manufacturing capacity was not our problem, it was fulfillment from three plants and a warehouse that was the problem

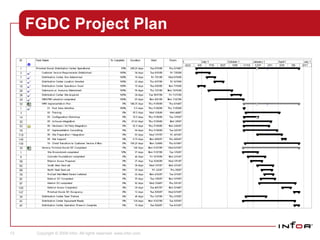

- #14: This project plan was last updated on 11/30 after the WMS/TMS selection had been completed. The project plan was aggressive but we managed to get everything done and meet our goal of occupancy and functionality on June 1 st . The final IT integration test only passed on 5/25, racking labels didnât arrive until 5/15, but couldnât be put up since racks didnât start installation until 5/22. On June 1 st , laborers were still caulking cracks in the floor and dropping decking into the 50% of the racks that were actually vertical. We joked that our goal was just to receive one pallet â receiving five pallets made it feel like winning the Boston Marathon.

- #22: No project would be complete without pictures. Construction began the week after Thanksgiving, which meant another winter of pouring foundations. Steel columns, tilt-up panels and a small internal office ï voila, your Finished Goods Distribution Center is ready. Because of our products there is no need for conveyors and the material handling interface headaches that brings. The coolest things in our FGDC are the vertical dock levelers and fast-charge lift trucks.

- #23: Plus this â the worldâs first angled aisle distribution center.