Loto presentation

- 2. What is LOTO? Lock Out Tag Out Logout and Tagout procedures should be used to safeguard workers from the unexpected startup or release of stored energy service or maintenance activities likeâĶ. ïķRepairing ïķLubricating ïķCleaning ïķUnjamming machines and equipment

- 3. WHEN IS LOCK OUT TAG OUT REQUIRED? Servicing, maintaining, or unâjamming equipment where: âĒEmployees are required to place any part of their body in harmâs way. âĒEmployees are required to remove or bypass a safety device. âĒEmployees are exposed to hazardous energy. âĒ Hazardous energy exists âĒ When a startâup could occur

- 4. ENERGY SOURCES âĒMechanical âĒThermal âĒHydraulic âĒPneumatic âĒMagnetic âĒGravity âĒElectrical âĒGas âĒWater âĒOther stored energy (i.e. springs, capacitors)

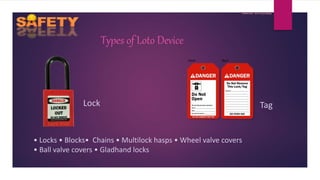

- 5. Types of Loto Device Lock Tag âĒ Locks âĒ BlocksâĒ Chains âĒ Multilock hasps âĒ Wheel valve covers âĒ Ball valve covers âĒ Gladhand locks

- 6. Departmental Lock colours Electrical Mechanical Operational

- 7. Tag Information This will typically include the Name of the person attaching the tag, the date on which it was attached, and in many cases, details about the work that is being done , contact of authorized worker.

- 8. REQUIREMENTS FOR LOTO DEVICES âĒDurable âĒStandardized âĒSubstantial âĒIdentifiable

- 9. Lockout Station All type of LOTO devices should be kept in LOCKOUT STATION

- 11. SIX STEPS OF LOTO SAFETY & LOCKOUT/TAGOUT PROCEDURES A lockout/tagout procedure should include the following six steps: 1. Preparation 2. Shutdown 3. Isolation 4. Lockout/tagout 5. Stored energy check 6. Isolation verification

- 12. PREPARATION âĒ Getting permission to work on equipment with a LOTO work permit âĒ Gathering all written LOTO procedures âĒ Identifying the location of energy isolation devices âĒ Getting all equipment needed and information on the type and amount of energy you are working with

- 13. SHUTDOWN âĒ With planning complete, the actual process of powering down and locking out machines begins. âĒ itâs time to shut down the machine or equipment that will be serviced or maintained. âĒ important part of this step is to inform any employee affected by the shutdown, even if they wonât play a role in the service or maintenance.

- 14. ISOLATION âĒ is to isolate the machine or equipment from any source of energy. âĒ This may mean any number of things, such as turning off power at a breaker or shutting a valve.

- 15. LOCKOUT AND TAGOUT âĒ During this step, the authorized employee will attach lockout and/or tagout devices to each energy-isolating device. âĒ isolating device in a way so it says in the âsafeâ position and cannot be moved to the unsafe position. âĒ Tagout refers to applying a tag on the device as well. This tag includes the name of the person who performed the lockout and additional information.

- 16. STORED ENERGY CHECK âĒ itâs important to look for any hazardous energy thatâs been âstoredâ within the machine, or any âresidualâ energy. âĒ During this phase, any potentially hazardous stored or residual energy must be releived, disconnected, restrained, or made non-hazardous in some other way.

- 17. ISOLATION VERIFICATION âĒ After shut down the machines, isolated them from their source of power, locked them out, and checked for hazardous stored energy. But nowâs the time to double-check that you did it all right and itâs now safe to work on the machine or equipment. âĒ At this point, an authorized employee verifies the machine has been properly isolated and de-energized

- 18. AUTHORIZED WORKERS 1. Authorized workers lock out and tag out machines or equipment to perform servicing and maintenance 2. Is properly and thoroughly trained to use lockout/tagout procedures 3. Operates equipment (sometimes)

- 19. AFFECTED WORKERS 2. Affected workers operate and use machines or equipment that is under LOTO. âĒ They do not perform LOTO or service and maintenance on machines or equipment. âĒ Occasionally adjust equipment that is subject to lockout tagout âĒ Work around

- 20. OTHER WORKERS 3.Other workers may be in the area where LOTO procedures are happening . They are informed about theâĶ.. âĒ Locks or tags put into place to prevent the startup of the machine or equipment âĒ Equipment that is being serviced or undergoing maintenance âĒ LOTO procedures

- 21. INSPECTION AND TRAINING 1. Inspection :- âĒ Inspect the energy control program every year âĒ Energy control program ïž Describes each machineâs energy sources ïž Describes companyâs procedures

- 22. INSPECTION AND TRAINING 2. Retraining :- âĒ Retraining is required when ïž If inspector is not satisfied with employeeâs knowledge of procedures ïž Whenever there is a change in job assignment ïž Whenever these is a change in machines equipment or processes ïž When there is a change in procedures

- 23. REMOVAL AND RE-ENERGIZING 1) Restore work area 2) Inform Affected Employees 3) Remove Devices 4) Re-energize

- 24. RESTORE WORK AREA 1) Restore the work area operating conditions 2) Ensure all tools have been removed 3) Double-check all equipment components 4) Machines must be operationally intact

- 25. INFORM AFFECTED EMPLOYEES âĒ Before and after removing lockout/tagout devices, inform all affected employees âĒ Before removing any devices and re-energizing equipment ïž Make sure all employees are out of the operating area

- 26. RE-ENERGIZE âĒ When re-energizing the equipment, follow standard procedures âĒ Double- check before restoring power to any machine

- 27. Obey LOTO âĒ Obey LOTO and protect your coworkers Because

- 28. Query if any Presented by:- Lalit Sharma Date:- 07/05/2020