Manufacturing

- 2. Context: “Prototype” vs. “Product” Toy RC car Product 5,000 $5-10 Little Automobile Product 10,000 $10,000+ Very little ME72 Device Prototype Quantity 1 $200 in parts + your effort Mfg. cost Variability Can be a lot

- 3. Prototype -> Product • Prototypes are one-offs • Products are to be manufactured • What if someone wanted you to make 1,000 of your device for $50 each? – What would you change? • How do you make it to meet scale, cost, and repeatability? – “Better, faster, cheaper” – Manufacturing Processes • What processes should you use? – Design for manufacturability • How do you design so it is easily made/assembled?

- 4. METAL CASTING AND POWDER PROCESSES CASTING CASTING OF INGOTS CONTINUOUS CASTING SAND CASTING SHELL MOLDING SLURRY MOLDING INVESTMENT CASTING (LOW-WAX PROCESS) EVAPORATIVE CASTING DIE CASTING (GRAVITY-FEED, PRESSURIZED…) CENTRIFUGAL CASTING SQUEEZE CASTING RHEOCASTING CRYSTAL GROWING •CRYSTAL-PULLING •ZONE MELTING Electro forming Plasma Spraying POWDER METALLURGY PRESSING ISOSTATIC PRESSING SINTERING JOINING PROCESSES MECHANICAL JOINING •BOLTS, SCREWS, RIVETS SOLID-STATE WELDING •DIFFUSION, FORGING, FRICTION, DEFORMATION LIQUID STATE WELDING •RESISTANCE WELDING •ARC WELDING •THERMAL WELDING HIGH-ENERGY BEAM WELDING •ELECTRONIC BEAM, LASER LIQUID-SOLID STATE BONDING •BRAZING •SOLDERING ADHESIVE BONDING •PLASTICS AND COMPOSITES JOINING (MECHANICAL, HEATING, SOLVENTS, ULTRASONICS) MACHINING PROCESSES SINGLE POINT MACHINING •TURNING •BORING •FACING •FORMING •SHAPING,PLANNING MULTIPOINT MACHINING •DRILLING •MILLING •SAWING, FILING •BROACHING, THREAD CUTTING, GRINDING •SURFACE GRINDING •CYLINDRICAL GRINDING •CENTERLESS GRINDING •INTERNAL GRINDING •FORM GRINDING ABRASIVE WIRE CUTTING HONING LAPPING ULTRASONIC MACHINING BUFFING, POLISHING BURNISHING TUMBLING GRIT BLASTING CHEMICAL MACHINING •ENGRAVING •CHEMICAL MILLING •CHEMICAL BLANKING ELECTROCHEMICAL MACHINING ELECTRICAL DISCHARGE MACHINING LASTER MACHINING ELECTRON BEAM MACHINING PLASMA-ARC CUTTING FLAME CUTTING, WATER JET CUTTING DEFORMATION PROCESSES OPEN-DIE FORGING IMPRESSION-DIE FORGING CLOSED-DIE FORGING •PRECISION OR FLASHLESS FORGING •COINING •HEADING, PIERCING, HUBBING, COGGING, FULLERING, EDGING, ROLL FORGING, SKEW ROLLING ROLLING •FLAT, RING, THREAD, GEAR, PIERCING EXTRUSION •DIRECT, INDIRECT HYDROSTATIC, IMPACT, BACKWARD DRAWING •ROD & WIRE, FLAT STRIP, TUBES SWAGING SHEARING BENDING •PRESS-BRAKE FORMING, ROLL FORMING TUBE FORMING BEADING, FLANGING, HEMMING, SEAMING STRECH FORMING BULGING DEEP DRAWING PRESS FORMING RUBBER FORMING SPINNING EXPLOSIVE FORMING ELECTROHYDRAULIC FORMING MAGNETIC-PULSE FORMING SUPERPLASTIC FORMING Source: Gutowski Manufacturing process (page 1)

- 5. MICROELECTRONICS PROCESSING CRYSTAL GROWTH •CZOCHRALSKI CRYSTAL GROWTH •FLOAT-ZONE CRYSTAL GROWTH WAFER PROCESSING •SLICING, ETCHING, POLISHINNG SURFACE PROCESSES •CHEMICAL VAPOR DEPOSITION (CVD) •EPITAXIAL FILM GROWTH •POLY CRYSTALLINE FILM GROWTH •S102 FILMS •OTHER (DIELECTRICS, METALS) OXIDATION •ION IMPLANTATION •PHYSICAL VAPOR DEPOSITION •SPUTTERING •EVAPORATION LITHOGRAPHY •PHOTORESIST •ELECTRON BEAM, X-RAY, ION BEAM LITHOGRAPHY WET ETCHING •CHEMICAL DRY ETCHING •PLASMA •SPUTTER •REACTIVE ION PACKAGING •DICING •DIE ATTACHMENT •WIRE BONDING •ENCAPSULATION POLYMER PROCESSES EXTRUSION FIBER SPINNING CALANDERING FILM BLOWING COATING (MELTS, SOLUTION, PLASMA, ELECTROSTATIC, PLASTISOL, UV CURABLE…) BLOW MOLDING INJECTION MOLDING REACTION INJECTION MOLDING (RIM) COMPRESSION MOLDING TRANSFER MOLDING CASTING THERMOFORMING ROTATIONAL MOLDING SOLID STATE FORMING MACHINING ETCHING SOLVENT PROCESSING FOAMING BONDING IMPREGNATING PAINTING COMPOSITES PROCESSES (POLYMER COMPOSITES) PULTRUSION FILAMENT WINDING PULL FORMING BRAIDING AUTOCLAVE MOLDING COMPRESSION MOLDING (SMC) RESIN TRANSFER MOLDING AUTOCOMP MOLDING HAND LAY-UP SPRAY-UP AUTOMATIC TAPE LAY-UP STAMPING DIAPHGRAM FORMING INJECTION MOLDING (FILLED THERMOPLASTICS, BMC…) REINFORCED REACTION INJECTION MOLDING (RRIM) (METAL MATRIX COMPOSITES) HOT PRESSURE BONDING HOT ISOSTATIC PRESSING LIQUID METAL INFILTRATION ELECTRODEPOSITION PLASMA SPRAY DEPOSITION CERAMICS PROCESSES POWER PROCESSES •CONSOLIDATION •SINTERING MELT PROCESSES •CRYSTALLINE MATERIALS (SILICON) •GLASSES •DRAWING, CASTING, BLOWING, TEMPERING (OPTICAL & STRUCTURAL FILTERS) •COATING SOL-GEL CERAMICS PROCESSING Source: Gutowski Manufacturing process (page 2)

- 6. Materials used in a car Source: K. H. Grote

- 7. Effect of manufacturing on geometry Source: Magrab

- 8. Performance measures • What makes a good manufacturing process? – Rate • Material flow through system – Time • Order to receipt • Setup time + part process time – Cost • Material + Labor + Tooling + Equipment – Quality • Deviation from target Source: Gutowski

- 9. Manufacturing processes 1. Subtractive – Material removal 2. Additive – Material addition, often in layers 3. Continuous – Continuous output (wire, rod) 4. Net shape – Output is the same as (or near) final shape Source: Gutowski

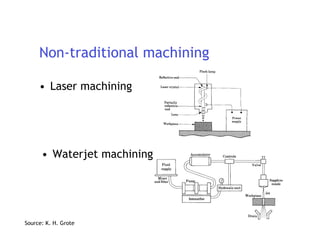

- 10. 1. Subtractive Processes • Machining – Turning – milling – boring – grinding • Non-traditional machining – Chemical milling – Waterjet machining • Micro-electronics processes – etching processes using either masks or beam

- 11. Milling Basic Types of Milling Cutters and Operations Source: K. H. Grote and Kalpakjian

- 12. Non-traditional machining • Laser machining • Waterjet machining Source: K. H. Grote

- 13. 2. Additive Processes • Joining – Welding, soldering, adhering • Rapid Prototyping/Layered manufacturing – Stereolithography, 3D printing • Composites

- 14. Welding • Shielded Metal-Arc Welding Process. 50% of all industrial welding employs this. Source: K. H. Grote

- 15. Stereolithography (SLA) • Photopolymers are exposed by laser and cured from a liquid to a solid. Source: http://cybercut.berkeley.edu/mas2/html/processes/stereolith/more.html

- 16. 3D printing • Thin layer of powder spread over surface • Like an ink-jet printer, binder material selectively joins particles to form the object Source: http://web.mit.edu/tdp/www/whatis3dp.html

- 18. Composites • Hand lay-up of layers of resin and fiber. • Lightweight & strong, but process is labor intensive. Source: http://www.saint-gobain-vetrotex.com.br/process_handlay.htm#01

- 19. 3. Continuous Processes • Extrusion of metals • Plastic Extrusion • Pultrusion of composites

- 20. Metal extrusion Direct extrusion Indirect Hydrostatic Source: K. H. Grote and Kalpakjian

- 21. Plastic extrusion Source: http://www.telfordsmith.com.au/products/

- 22. Pultrusion • For composites • Fiber reinforcing material is pulled through resin bath and into a die. Source: http://users.techline.com/lord/manu.html

- 23. 4. Net Shape forming • Solids – Metal Forming – stamping, forging – Powders • Liquids – Casting – Injection Molding, thermoforming, blow molding • Mixtures – Infiltration – Viscoelastics • Tolerances not as tight

- 24. Drawing and stretching • Sheet metal From: http://www.tms.org/pubs/journals/JOM/9911/Hosford-9911-figure1.html

- 25. Forging • Metal workpiece pressed under great pressure into high strength parts Closed die forging workpiece From: http://www.forging.org/facts/idproc.htm

- 26. Investment/lost wax Casting • A wax pattern is surrounded with investment material (sand), baked out, then metal is poured in the cavity. 1. Create wax pattern 2. Assemble patterns 3. Apply investment 4. Dewax 5. Fill shell 6. Knockout 7. Cutoff 8. Finished castings From: http://www.hitchiner.com/home.html

- 27. Compression Molding Rubber trivet Source: Byars 1998

- 28. 1. Compression molding machine 2. Slabs of HTV silicone rubber 3. Trim excess 4. Finished trivets

- 29. Injection Molding From: http://www.idsa-mp.org/proc/plastic/injection/injection_process.htm

- 30. Injection molding example Cutlery made of biodegradable starch Source: Byars 1998

- 31. 1. Starch 2. Pellets are formed 3. Injection molded forks on stem 4. Decomposing cutlery

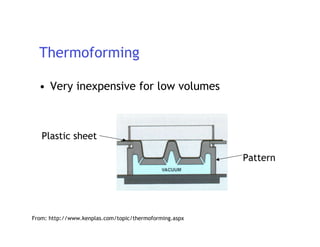

- 32. Thermoforming • Very inexpensive for low volumes Plastic sheet From: http://www.kenplas.com/topic/thermoforming.aspx Pattern