Manufacturing Excellence Line- Efficiency Improvement Project

- 1. EFFICIENCY IMPROVEMENT THROUGH ME METHODOLOGY Style: FG36T380 Buyer: Walmart Line: 01 Unit: Unit-2

- 2. DEFINE

- 3. DEFINE Training & Development ŌĆó Training with Line chief, Supervisor& Line IE about ME Methodology . ŌĆó After that completed simulation exercise

- 4. MEASURE

- 5. MEASUREŌĆ”CONTINUE Category Current Target Efficiency 76% 91% Production 1000 pcs 1200 pcs People Ratio 77:5:18 79:5:16 SMV 24.3 23.3 Line Balancing 74% 86%

- 6. Category Attachment Base data Current OB Process flow chart People Ratio Capacity Graph Lay out Base data Current OB People Ratio Capacity Graph Process flow chart MEASUREŌĆ”CONTINUE Lay out

- 7. ANALYSIS

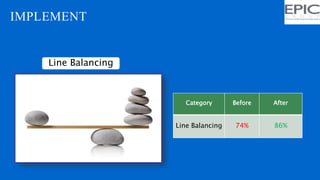

- 8. IMPROVE Benefits: ’āś Line 1 & 2 both line production increase ’āś 200 pcs production increase ’āś 17% efficiency improved Benefits: ’āś 12% balancing efficiency improved 1. Method analysis 2. Line balancing analysis

- 10. IMPLEMENT Line Balancing Category Before After Line Balancing 74% 86%

- 13. METHOD IMPROVEMENTŌĆ” Cuff Attach Category Before Method Improve After Method Improve Capacity 48 pcs 59 pcs Cycle time 62 sec 51 sec Result 110 pcs/day increase

- 14. METHOD IMPROVEMENTŌĆ” Box & cross stitch Category Before Method Improve After Method Improve Capacity 90 pcs 125 pcs Cycle time 33 sec 24 sec Result 350 pcs/day increase

- 15. METHOD IMPROVEMENTŌĆ” Att. sleeve tap 2 gamble Category Before Method Improve After Method Improve Capacity 111 pcs 130 pcs Cycle time 27 sec 23 sec Result 190 pcs/day increase