Marshall test

- 1. MARSHALL TEST RESULTâS ïŪ IT IS CONDUCTED IN TWO STAGEâS ïŪ SPECIMEN PREPARATION. ïŪ SPECIMEN TESTING.

- 2. SAMPLE GRADED AND DRIED HEATING UP SAMPLE MIX WITH BITUMEN MOULDING SAMPLE READY FOR TESTING

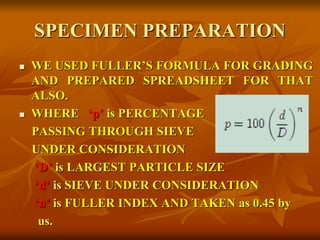

- 3. SPECIMEN PREPARATION ïŪ WE USED FULLERâS FORMULA FOR GRADING AND PREPARED SPREADSHEET FOR THAT ALSO. ïŪ WHERE âpâ is PERCENTAGE PASSING THROUGH SIEVE UNDER CONSIDERATION âDâ is LARGEST PARTICLE SIZE âdâ is SIEVE UNDER CONSIDERATION ânâ is FULLER INDEX AND TAKEN as 0.45 by us.

- 5. NOTATIONS W1, W2, W3 AND Wb ARE WEIGHT OF COARSE AGGREGATES, FINE AGGREGATES, FILLER AND BITUMEN RESPECTIVELY. V1, V2, V3, Vb AND Vv ARE VOLUME OF COARSE AGGREGATES, FINE AGGREGATES, FILLER, BITUMEN AND AIR VOIDS G1, G2, G3 AND Gb ARE SPECIFIC GRAVITIES OF COARSE AGGREGATES, FINE AGGREGATES, FILLER AND BITUMEN

- 6. FORMULAâS USED Gt THEORETICAL SPECIFIC GRAVITY Gm BULK SPECIFIC GRAVITY Vv AIR VOIDS IN SAMPLE Vb VOIDS FILLED WITH BITUMEN VMA VOIDS IN MINERAL AGGREGATES VFB VOIDS FILLED BY BITUMEN

- 8. TESTING DATA FOR OPTIMUM BITUMEN CONTENT Sample No. Bitumen Content (%) Marshall Stability Value (kg) Flow Value (in 0.25mm units) Bulk Specific Gravity Air Voids (%) VFB (%) 1) 4 1037.31 10 2.37 3.83 71.54 2) 4.5 1632.62 11 2.39 2.26 83.74 3) 5 2035.48 12 2.40 1.85 86.29 4) 5.5 2084.40 14 2.39 1.53 89.26 5) 6 1379.62 17 2.38 0.93 93.90

- 9. CHARTS ïŪ MARSHALL STABILITY VS BITUMEN CONTENT

- 10. CHARTS ïŪ FLOW VALUE VS BITUMEN CONTENT

- 11. CHARTS ïŪ AIR VOIDS VS BITUMEN CONTENT

- 12. CHARTS ïŪ BULK SPECIFIC GRAVITY VS BITUMEN CONTENT

- 13. CHARTS ïŪ VFB VS BITUMEN CONTENT

- 14. OPTIMUM BITUMEN CONTENT ïŪ BITUMEN CONTENT CORRESPONDING TO MAXIMUM MARSHALL STABILITY VALUE= 5.5% ïŪ BITUMEN CONTENT CORRESPONDING TO MAXIMUM BULK SPECIFIC GRAVITY= 5% ïŪ BITUMEN CONTENT CORRESPONDING TO MEDIAN (4%) OF AIR VOIDS %= 4% ïŪ AVERAGE VALUE= 4.8% ïŪ THEREFORE OPTIMUM BITUMEN CONTENT= 4.8%

- 15. âEngineering problems are under-defined, there are many solutions, good, bad and indifferent. The art is to arrive at a good solution. This is a creative activity, involving imagination, intuition and deliberate choice.â OVE ARUP Engineers âĶ are not superhuman. They make mistakes in their assumptions, in their calculations, in their conclusions. That they make mistakes is forgivable; that they catch them is imperative. Thus it is the essence of modern engineering not only to be able to check oneâs own work but also to have oneâs work checked and to be able to check the work of others.

- 16. THANK YOU