Mechanics of Orthogonal Cutting

Download as PPTX, PDF7 likes2,546 views

it is power point presentation on orthogonal cutting, in which i explained as easy as the student can understand... and related to GATE

1 of 12

Downloaded 27 times

![WORKPIECE

TOOL

t1

╬▒

Shear

plane

Friction

plane

Vertical

plane

Vs

Vc

Vf

Žå

╬▒

Žå

AC

B

t1

sinąż = t1 / AB

90-ąż

sin(90- ąż+ ╬▒ ) = sin (90-(ąż-╬▒)) = cos(ąż-╬▒) = t2/AB

t1 = AB*sinąż

t2 = AB cos (ąż-╬▒)

Therefore

t1/t2 = (AB*sinąż) / (AB*cos(ąż-╬▒) )

r = sinąż / cos (ąż-╬▒)

r = sinąż / ( cosąż*cos╬▒+ sinąż*sin╬▒ )

r = ( sinąż /cos ąż ) / [( cosąż*cos╬▒+ sinąż*sin╬▒ ) / cosąż]

r = tanąż/ (cos╬▒ + tanąż*sin╬▒ )

rcos╬▒ + r*tanąż*sin╬▒ = tanąż

tanąż -r*tanąż*sin╬▒ = rcos╬▒

tanąż (1- rsin╬▒) = rcos ╬▒

tanąż = rcos╬▒ / (1- rsin╬▒)

From triangle ABC & ACD

D

90-ąż+╬▒

ąż-╬▒

RELATION BETWEEN R, ╬” AND ╬▒](https://image.slidesharecdn.com/mechanics-180924133955-180925065357/85/Mechanics-of-Orthogonal-Cutting-3-320.jpg)

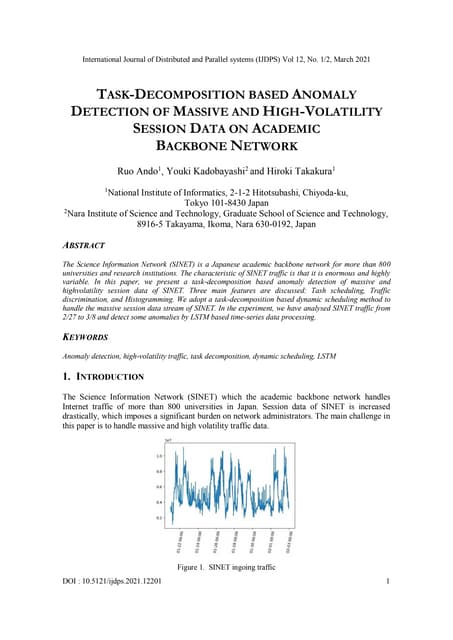

![WORKPIECE

TOOL

t1

╬▒

Shear

plane

Friction

plane

Vertical

plane

Vs

Vc

Vf

Žå

Vc

Vf Vs

Žå90-╬▒

90-(ąż-╬▒)

By applying SINE rule

(Vf / sinąż) =[Vs / sin(90-╬▒)] = [Vc/sin(90-(ąż-╬▒)]

(Vf / sinąż) = (Vs / cos╬▒) = [Vc/cos(ąż-╬▒)]

Vf = [Vc*sin ╬▒ /cos(ąż-╬▒)]

Vf = Vc*r

Vs = [(Vc*cos ╬▒ /cos(ąż-╬▒)]

VELOCITY RELATIONSHIPS](https://image.slidesharecdn.com/mechanics-180924133955-180925065357/85/Mechanics-of-Orthogonal-Cutting-4-320.jpg)

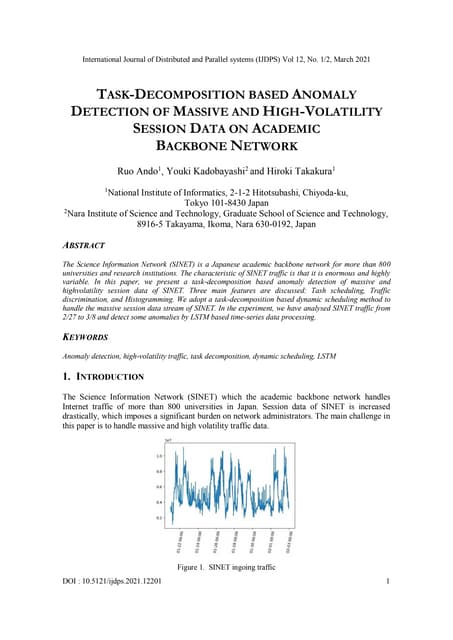

![Shear area = As = W*t1 / sin ╬”

Shear stress = Žä = Fs / As Žä = Fs sin╬” / (w*t1)

Shear strain = Ų│ = Cot ╬” + tan (╬”-╬▒) = cos / [sin ╬”*cos (╬”-╬▒)]

Shear strain rate = Vs/ts

WORKPIECE

t1

Fs

Žå W

Vs

The minimum value of shear strain when rake angle is zero

Shear strain = Ų│ = Cot ╬” + tan ╬”

(d/d╬”) {cot ╬” + tan ╬” } = 0

-cosec^2 ╬” + sec^2 ╬” =0

-(1/sin^2 ╬”)+ (1/cos^2 ╬”) =0

cos^2 ╬”-sin^2 ╬”=0

[(1-cos 2╬”)/2] - [(1-sin 2╬”)/2] =0

2cos 2 ╬” = 0

2╬” =90

╬” =45

For minimum value

2╬” - ╬▒ =90

For orthogonal cutting

Depth of cut = t1 = feed*╬Ė ( ╬Ė is side cutting edge angle )

Width of cut = t1/ sin ╬Ė](https://image.slidesharecdn.com/mechanics-180924133955-180925065357/85/Mechanics-of-Orthogonal-Cutting-8-320.jpg)

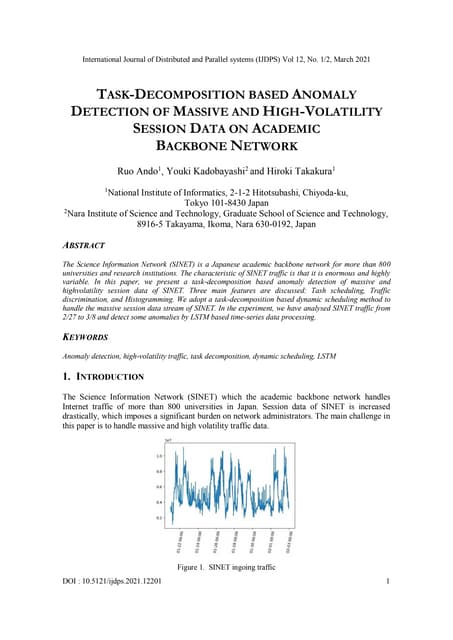

![Fc

Ft

N

F

┬Ą = Tan╬▓ = F/N = Ft/Fc

But when Ft > Fc, ╬▓ > 45 ┬Ą > 1

In this case use formulae for finding ┬Ą

The classical friction theory

┬Ą = [ln ( 1/r)] / [( ŽĆ/2) ŌĆō ╬▒]

Actuvally the value of ┬Ą is always comes less than one

Ft < Fc, ╬▓ < 45 ┬Ą < 1](https://image.slidesharecdn.com/mechanics-180924133955-180925065357/85/Mechanics-of-Orthogonal-Cutting-9-320.jpg)

Recommended

Cutting speed and feed

Cutting speed and feedgarfield Tulloch

╠²

Cutting speed refers to the rate at which a cutting tool passes over the material surface and is commonly measured in meters per minute. Cutting speed depends on factors like the material, tool, depth of cut, and feed rate. Harder materials and tool materials allow for higher cutting speeds, while softer materials and tools require lower speeds. The cutting speed can be calculated using the spindle speed in revolutions per minute and the tool diameter. Feed rate refers to how quickly the tool is advanced into the workpiece during drilling and depends on factors like the tool, desired surface finish, machine power, and material properties.Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECH

Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECHnaanmech123

╠²

This document provides information about milling machines and milling operations. It describes the major parts and differences between horizontal and vertical milling machines. Various milling operations like face milling, end milling and slot milling are explained along with principles of up and down milling. Different types of milling cutters are classified and their applications discussed. Specifications of milling machines like worktable size, movements in X, Y and Z directions and motor power are also covered.Merchant circle diagram

Merchant circle diagramGATE / ESE teacher

╠²

This document provides an overview of mechanics of machining and Merchant's circle diagram (MCD). It introduces metal cutting, tool geometry, assumptions for force analysis, and forces acting on single point cutting tools. Key points include shear plane analysis using rake and shear angles, assumptions of orthogonal cutting and constant chip thickness. Construction of the MCD is described to relate cutting, thrust and feed forces. The MCD allows calculation of shear stress, power and friction coefficient, enabling selection of machine parameters and tool/workpiece design.Unit 2 Machinability, Cutting Fluids, Tool Life & Wear, Tool Materials

Unit 2 Machinability, Cutting Fluids, Tool Life & Wear, Tool MaterialsMechbytes

╠²

Concept of machinability, machinability index, factors affecting machinability

Different mechanism of tool wear types of tool wear (crater, flank etc.), Measurement and control of tool wear

Concept of tool life, Taylor's tool life equation (including modified version)

Different tool materials and their applications including effect of tool coating

Introduction to economics of machining

Cutting fluids: types, properties, selection and application methods

Cutting fluids

Cutting fluidsraxit varmora

╠²

The document discusses the history and types of cutting fluids. It notes that cutting fluids were originally water and animal fats but have evolved to include soluble oils, chemical fluids, and emulsifiable oils. The key functions of cutting fluids are to provide cooling and lubrication for metal cutting operations, which reduces tool wear and heat generated. Maintaining adequate cooling and lubrication of the cutting area with the appropriate type of cutting fluid is important for optimizing tool life and machining efficiency.Metalcutting 140822084807-phpapp01

Metalcutting 140822084807-phpapp01manojkumarg1990

╠²

This document provides an overview of manufacturing technology and metal cutting processes. It discusses various metal cutting operations like turning, drilling, and milling. It describes the basic requirements for machining like workpiece setup, cutting tools, and machine tools. It defines key terms related to single-point cutting tools like rake angle, relief angle, nose radius, and cutting edge. It also discusses the classification and important properties of cutting tool materials.Mechanics of chips formation

Mechanics of chips formationHashim Hasnain Hadi

╠²

The document discusses mechanics of chip formation in machining. It describes two simplified geometric models - the orthogonal and oblique cutting models. The orthogonal model involves a tool with a rake and clearance angle where the cutting edge is perpendicular to the cutting direction. Chip formation occurs through primary and secondary shear zones. Different types of chips are also described including continuous, discontinuous, those with built-up edge, and serrated chips which depend on factors like material properties and cutting conditions.Ch 10 grinding and finishing

Ch 10 grinding and finishingNandan Choudhary

╠²

1) Grinding is an abrasive machining process that uses abrasive particles held together by a bonding material to shape and finish workpieces.

2) Key factors in grinding include the abrasive material, grit size, bond type and strength, and wheel structure. Coarser grits and more open structures are used for stock removal while finer grits and denser structures provide better surface finishes.

3) Vitrified bonds are strong but brittle while resin and metal bonds offer more flexibility and toughness. Bond selection depends on factors like wheel speed and fluid compatibility.Metal cutting 2

Metal cutting 2Naman Dave

╠²

Please refer this file just as reference material. More concentration should on class room work and text book methodology.

Force acting at machiningMerchant Circle Diagram

Merchant Circle DiagramManthan Kanani

╠²

this is slideshare about Merchant Circle Diagram and how it draw in use of machinery and for different operations.Milling machine(husain)

Milling machine(husain)husain252

╠²

The document describes milling machine operations. It defines milling, the main components of milling machines, and different types of milling machines including horizontal, vertical, and speciality machines. It also explains various milling techniques such as plain milling, face milling, end milling, and gang milling. Key parts of milling machines like the spindle, table, and arbor are identified. Methods like up milling and down milling are compared.Cutting power & Energy Consideration in metal cutting

Cutting power & Energy Consideration in metal cuttingDushyant Kalchuri

╠²

Cutting power is an important parameter, especially in the case of rough operations, as it makes it possible to:

select and invest in a machine with a power output suited to the operation being carried out

obtain the cutting conditions that allow the machine's power to be used in the most effective way possible, so as to ensure optimal material removal rate while taking into account the capacity of the tool being used. LATHE TOOL DYNAMOMETER

LATHE TOOL DYNAMOMETERsathish sak

╠²

Dynamo meters are the electronic devices that are widely used to the purpose of force analysis in various field of operations. There is various types of dynamometers such as

Lathe tool dynamometer

Milling tool dynamometer

Drilling tool dynamometer

Turning

Turningendika55

╠²

Turning technology description.

Torneaketa prozesuaren deskribapena.

Descripci├│n de procesos de torneado.Tool Wear and Tool Life

Tool Wear and Tool Life Mobashir Kashani

╠²

Tool life is measured by the time period from when a tool starts cutting until failure or until it needs resharpening. Tool life can be measured in units of time, number of pieces cut, volume of material removed, or length of cut. Tools typically fail due to high temperatures, mechanical impacts, or gradual wear. Wear occurs on the flank and crater faces of tools and is caused by abrasion, diffusion, electrochemical reactions, and other mechanisms. Factors like cutting speed, workpiece properties, tool geometry, and cooling influence tool life.Mechanics of metal cutting

Mechanics of metal cuttingKumar Chirra

╠²

This document discusses mechanics of metal cutting. It covers topics like cutting models, forces, energies, and material removal rate. The orthogonal cutting model is described, which assumes a straight cutting edge generating a plane surface. Key terms like rake angle, shear angle, and cutting forces are defined. The relationships between cutting parameters, forces, power, and specific cutting energy are explained using the orthogonal model. Limitations of this simplified model are also noted.Merchants circle-diagram

Merchants circle-diagramcpandiv

╠²

The document discusses cutting tool materials and Merchant's Circle Diagram (MCD) for calculating forces in machining. It provides information on 7 common cutting tool materials: high carbon steel, high speed steel, cast alloys, cemented carbides, coated carbides, ceramics, and diamonds. It also explains what MCD is and how it can be used graphically to calculate cutting, tangential, friction, normal, shear and normal shear forces from measured cutting forces. An example calculation using MCD is provided.Cutting Tool Wear

Cutting Tool WearDrJayantaKumarMahato1

╠²

This document discusses tool wear in machining. It defines tool wear as the gradual failure of cutting tools due to regular operation. There are three main modes of tool failure: fracture failure from excessive forces, temperature failure if the tool gets too hot, and gradual wear over time. Factors that influence the rate of tool wear include the tool material, workpiece material, cutting dimensions/speed, tool geometry, temperature, and cutting fluid used. The main types of tool wear are crater wear on the rake face, flank wear along the tool edge, and corner or nose wear which shortens the cutting edge. Controlling tool wear involves reducing the cutting temperature through fluids/lubricants or advanced tool materials.Unit 3-METAL FORMING PROCESSES

Unit 3-METAL FORMING PROCESSESKIT-Kalaignar Karunanidhi Institute of Technology

╠²

The document discusses various metal forming processes. It describes hot working and cold working of metals, where hot working involves shaping metals above their recrystallization temperature and cold working is below this temperature. Specific metal forming processes covered include forging processes like open die forging, closed die forging, and roll forging. Other forming methods discussed are drawing, extrusion, and bending. The advantages and limitations of hot and cold working are also compared.METAL CUTTING

METAL CUTTINGKunj Thummar

╠²

This presentation contains various aspects of metal cutting like mechanics of chip formation, single point cutting tool, chip breakers, types of chips,etcTool wear, tool life & machinability

Tool wear, tool life & machinabilityDENNY OTTARACKAL

╠²

This document discusses tool wear, tool life, and machinability. It defines tool life as the useful cutting time before tool failure or need for resharpening. Tool wear is caused by various mechanisms like abrasion, diffusion, and plastic deformation, and is measured by flank and crater wear. Machinability is determined by factors like surface finish, tool life, cutting forces, and chip control. The machinability of different materials depends on their properties and varies significantly. Cutting fluids are used to decrease power needs, increase heat dissipation, and improve other machinability factors.Tool wear and tool Life

Tool wear and tool LifeDr. Bolleddu Venkateshwarlu

╠²

The document provides information about tool wear and tool life in machining processes. It discusses how tool wear occurs due to forces, temperature, and sliding action during cutting. The three main types of tool wear are flank wear, crater wear, and chipping. Flank wear is caused by abrasion from hard particles in the workpiece while crater wear results from high temperatures and diffusion at the tool-chip interface. Maintaining optimal cutting conditions and tool geometry can increase tool life. The document also covers tool materials, machinability factors, cutting fluids, machining forces, and lathe operations such as turning, facing, and threading.Metal cutting and Machining tools

Metal cutting and Machining toolsSHIVAM AGRAWAL

╠²

This slide is all about Metal cutting and Machining tools insights. It covers Mechanics of metal cutting, orthogonal and oblique machining, Tools geometry, Types of Chips, and Tools Signature.Merchant's circle

Merchant's circleSumit Shrivastava

╠²

Graphical method of Cutting Force analysis in Orthogonal Cutting of Metal cutting proposed by scientists "Ernst and Merchant"Theory of metal cutting MG University(S8 Production Notes)

Theory of metal cutting MG University(S8 Production Notes)Denny John

╠²

Theory of metal cutting MG University(S8 Production Notes)

Scenario of manufacturing process ŌĆō Deformation of metals,

SchmidŌĆÖs law (review only) ŌĆō Performance and process parameters ŌĆō single point cutting

tool nomenclature - attributes of each tool nomenclature - attributes of feed and tool

signature on surface roughness obtainable, role of surface roughness on crack initiation -

Oblique and orthogonal cutting ŌĆō Mechanism of metal removal - Primary and secondary

deformation shear zones - Mechanism of chip formation, card model, types of chip,

curling of chips, flow lines in a chip, BUE, chip breakers, chip thickness ratio ŌĆō

Mechanism of orthogonal cutting: Thin zone and thick zone, MerchantŌĆÖs analysis ŌĆō shear

angle relationship, Lee and Shaffer`s relationship, simple problems ŌĆō Friction process in

metal cutting: nature of sliding friction, columb`s law, adhesion theory, ploughing, sublayer

flow ŌĆō Empirical determination of force component.Chip formation and types

Chip formation and typesKANNANS94

╠²

1) Chip formation involves the shear deformation of work material to form a chip as new material is exposed during cutting.

2) There are four basic types of chips in machining: continuous, discontinuous, serrated, and those with built-up edge (BUE).

3) The type of chip formed depends on factors like the work material, tool geometry, cutting speeds and feeds, and machining environment. Understanding chip formation helps optimize the machining process.Metal cutting 1

Metal cutting 1Naman Dave

╠²

This chapter aims to provide basic backgrounds of different types of machining processes and highlights on an understanding of important parameters which affects machining of metals with their chip removals.

’éŚ

Metal cutting or Machining is the process of producing workpiece by removing unwanted material from a block of metal. in the form of chips. This process is most important since almost all the products get their final shape and size by metal removal. either directly or indirectly.

’éŚ

The major drawback of the process is loss of material in the form of chips. In this chapter. we shall have a fundamental understanding of the basic metal process.4. gear manufacturing

4. gear manufacturingMody Institute of Tecnology and Science (MITS)

╠²

Gears are used to transmit power and motion between shafts. There are several types of gears including spur gears, helical gears, herringbone gears, worm gears, bevel gears, rack and pinion gears, and internal gears. Gears can be produced through forming methods like milling or shaping that use cutters with the same tooth form as the gear. They can also be produced through generating methods like hobbing that use cutters with involute teeth to cut gears of the same module. Forming is less accurate while generating provides higher accuracy and productivity.Formula Book.pdf

Formula Book.pdfDrAungKoLatt

╠²

The document provides equations and concepts related to stresses in mechanical elements. It includes equations for normal and shear stresses in simple members under tension and bending. It also provides locations of the neutral axis and distances to the outer surfaces for common cross sections. Additional sections cover stresses in curved beams, torsion in shafts, stresses in gears and pulleys, and equations for power screws and threaded fasteners.03 Cap 2 - fourier-analysis-2015.pdf

03 Cap 2 - fourier-analysis-2015.pdfROCIOMAMANIALATA1

╠²

This document discusses Fourier analysis and periodic functions. It defines periodic functions and introduces Fourier series representation of periodic functions as the sum of sinusoidal components. The key points are:

1) A periodic function can be represented by an infinite series of sinusoids of harmonically related frequencies, known as Fourier series representation.

2) The coefficients of the Fourier series (a0, an, bn) can be calculated from the integrals of the function over one period.

3) Periodic functions may exhibit odd symmetry, even symmetry, or half-wave symmetry, which determines which coefficients (an or bn) are zero.

4) Examples demonstrate the Fourier analysis of specific periodic waveforms, such as aMore Related Content

What's hot (20)

Metal cutting 2

Metal cutting 2Naman Dave

╠²

Please refer this file just as reference material. More concentration should on class room work and text book methodology.

Force acting at machiningMerchant Circle Diagram

Merchant Circle DiagramManthan Kanani

╠²

this is slideshare about Merchant Circle Diagram and how it draw in use of machinery and for different operations.Milling machine(husain)

Milling machine(husain)husain252

╠²

The document describes milling machine operations. It defines milling, the main components of milling machines, and different types of milling machines including horizontal, vertical, and speciality machines. It also explains various milling techniques such as plain milling, face milling, end milling, and gang milling. Key parts of milling machines like the spindle, table, and arbor are identified. Methods like up milling and down milling are compared.Cutting power & Energy Consideration in metal cutting

Cutting power & Energy Consideration in metal cuttingDushyant Kalchuri

╠²

Cutting power is an important parameter, especially in the case of rough operations, as it makes it possible to:

select and invest in a machine with a power output suited to the operation being carried out

obtain the cutting conditions that allow the machine's power to be used in the most effective way possible, so as to ensure optimal material removal rate while taking into account the capacity of the tool being used. LATHE TOOL DYNAMOMETER

LATHE TOOL DYNAMOMETERsathish sak

╠²

Dynamo meters are the electronic devices that are widely used to the purpose of force analysis in various field of operations. There is various types of dynamometers such as

Lathe tool dynamometer

Milling tool dynamometer

Drilling tool dynamometer

Turning

Turningendika55

╠²

Turning technology description.

Torneaketa prozesuaren deskribapena.

Descripci├│n de procesos de torneado.Tool Wear and Tool Life

Tool Wear and Tool Life Mobashir Kashani

╠²

Tool life is measured by the time period from when a tool starts cutting until failure or until it needs resharpening. Tool life can be measured in units of time, number of pieces cut, volume of material removed, or length of cut. Tools typically fail due to high temperatures, mechanical impacts, or gradual wear. Wear occurs on the flank and crater faces of tools and is caused by abrasion, diffusion, electrochemical reactions, and other mechanisms. Factors like cutting speed, workpiece properties, tool geometry, and cooling influence tool life.Mechanics of metal cutting

Mechanics of metal cuttingKumar Chirra

╠²

This document discusses mechanics of metal cutting. It covers topics like cutting models, forces, energies, and material removal rate. The orthogonal cutting model is described, which assumes a straight cutting edge generating a plane surface. Key terms like rake angle, shear angle, and cutting forces are defined. The relationships between cutting parameters, forces, power, and specific cutting energy are explained using the orthogonal model. Limitations of this simplified model are also noted.Merchants circle-diagram

Merchants circle-diagramcpandiv

╠²

The document discusses cutting tool materials and Merchant's Circle Diagram (MCD) for calculating forces in machining. It provides information on 7 common cutting tool materials: high carbon steel, high speed steel, cast alloys, cemented carbides, coated carbides, ceramics, and diamonds. It also explains what MCD is and how it can be used graphically to calculate cutting, tangential, friction, normal, shear and normal shear forces from measured cutting forces. An example calculation using MCD is provided.Cutting Tool Wear

Cutting Tool WearDrJayantaKumarMahato1

╠²

This document discusses tool wear in machining. It defines tool wear as the gradual failure of cutting tools due to regular operation. There are three main modes of tool failure: fracture failure from excessive forces, temperature failure if the tool gets too hot, and gradual wear over time. Factors that influence the rate of tool wear include the tool material, workpiece material, cutting dimensions/speed, tool geometry, temperature, and cutting fluid used. The main types of tool wear are crater wear on the rake face, flank wear along the tool edge, and corner or nose wear which shortens the cutting edge. Controlling tool wear involves reducing the cutting temperature through fluids/lubricants or advanced tool materials.Unit 3-METAL FORMING PROCESSES

Unit 3-METAL FORMING PROCESSESKIT-Kalaignar Karunanidhi Institute of Technology

╠²

The document discusses various metal forming processes. It describes hot working and cold working of metals, where hot working involves shaping metals above their recrystallization temperature and cold working is below this temperature. Specific metal forming processes covered include forging processes like open die forging, closed die forging, and roll forging. Other forming methods discussed are drawing, extrusion, and bending. The advantages and limitations of hot and cold working are also compared.METAL CUTTING

METAL CUTTINGKunj Thummar

╠²

This presentation contains various aspects of metal cutting like mechanics of chip formation, single point cutting tool, chip breakers, types of chips,etcTool wear, tool life & machinability

Tool wear, tool life & machinabilityDENNY OTTARACKAL

╠²

This document discusses tool wear, tool life, and machinability. It defines tool life as the useful cutting time before tool failure or need for resharpening. Tool wear is caused by various mechanisms like abrasion, diffusion, and plastic deformation, and is measured by flank and crater wear. Machinability is determined by factors like surface finish, tool life, cutting forces, and chip control. The machinability of different materials depends on their properties and varies significantly. Cutting fluids are used to decrease power needs, increase heat dissipation, and improve other machinability factors.Tool wear and tool Life

Tool wear and tool LifeDr. Bolleddu Venkateshwarlu

╠²

The document provides information about tool wear and tool life in machining processes. It discusses how tool wear occurs due to forces, temperature, and sliding action during cutting. The three main types of tool wear are flank wear, crater wear, and chipping. Flank wear is caused by abrasion from hard particles in the workpiece while crater wear results from high temperatures and diffusion at the tool-chip interface. Maintaining optimal cutting conditions and tool geometry can increase tool life. The document also covers tool materials, machinability factors, cutting fluids, machining forces, and lathe operations such as turning, facing, and threading.Metal cutting and Machining tools

Metal cutting and Machining toolsSHIVAM AGRAWAL

╠²

This slide is all about Metal cutting and Machining tools insights. It covers Mechanics of metal cutting, orthogonal and oblique machining, Tools geometry, Types of Chips, and Tools Signature.Merchant's circle

Merchant's circleSumit Shrivastava

╠²

Graphical method of Cutting Force analysis in Orthogonal Cutting of Metal cutting proposed by scientists "Ernst and Merchant"Theory of metal cutting MG University(S8 Production Notes)

Theory of metal cutting MG University(S8 Production Notes)Denny John

╠²

Theory of metal cutting MG University(S8 Production Notes)

Scenario of manufacturing process ŌĆō Deformation of metals,

SchmidŌĆÖs law (review only) ŌĆō Performance and process parameters ŌĆō single point cutting

tool nomenclature - attributes of each tool nomenclature - attributes of feed and tool

signature on surface roughness obtainable, role of surface roughness on crack initiation -

Oblique and orthogonal cutting ŌĆō Mechanism of metal removal - Primary and secondary

deformation shear zones - Mechanism of chip formation, card model, types of chip,

curling of chips, flow lines in a chip, BUE, chip breakers, chip thickness ratio ŌĆō

Mechanism of orthogonal cutting: Thin zone and thick zone, MerchantŌĆÖs analysis ŌĆō shear

angle relationship, Lee and Shaffer`s relationship, simple problems ŌĆō Friction process in

metal cutting: nature of sliding friction, columb`s law, adhesion theory, ploughing, sublayer

flow ŌĆō Empirical determination of force component.Chip formation and types

Chip formation and typesKANNANS94

╠²

1) Chip formation involves the shear deformation of work material to form a chip as new material is exposed during cutting.

2) There are four basic types of chips in machining: continuous, discontinuous, serrated, and those with built-up edge (BUE).

3) The type of chip formed depends on factors like the work material, tool geometry, cutting speeds and feeds, and machining environment. Understanding chip formation helps optimize the machining process.Metal cutting 1

Metal cutting 1Naman Dave

╠²

This chapter aims to provide basic backgrounds of different types of machining processes and highlights on an understanding of important parameters which affects machining of metals with their chip removals.

’éŚ

Metal cutting or Machining is the process of producing workpiece by removing unwanted material from a block of metal. in the form of chips. This process is most important since almost all the products get their final shape and size by metal removal. either directly or indirectly.

’éŚ

The major drawback of the process is loss of material in the form of chips. In this chapter. we shall have a fundamental understanding of the basic metal process.4. gear manufacturing

4. gear manufacturingMody Institute of Tecnology and Science (MITS)

╠²

Gears are used to transmit power and motion between shafts. There are several types of gears including spur gears, helical gears, herringbone gears, worm gears, bevel gears, rack and pinion gears, and internal gears. Gears can be produced through forming methods like milling or shaping that use cutters with the same tooth form as the gear. They can also be produced through generating methods like hobbing that use cutters with involute teeth to cut gears of the same module. Forming is less accurate while generating provides higher accuracy and productivity.Similar to Mechanics of Orthogonal Cutting (20)

Formula Book.pdf

Formula Book.pdfDrAungKoLatt

╠²

The document provides equations and concepts related to stresses in mechanical elements. It includes equations for normal and shear stresses in simple members under tension and bending. It also provides locations of the neutral axis and distances to the outer surfaces for common cross sections. Additional sections cover stresses in curved beams, torsion in shafts, stresses in gears and pulleys, and equations for power screws and threaded fasteners.03 Cap 2 - fourier-analysis-2015.pdf

03 Cap 2 - fourier-analysis-2015.pdfROCIOMAMANIALATA1

╠²

This document discusses Fourier analysis and periodic functions. It defines periodic functions and introduces Fourier series representation of periodic functions as the sum of sinusoidal components. The key points are:

1) A periodic function can be represented by an infinite series of sinusoids of harmonically related frequencies, known as Fourier series representation.

2) The coefficients of the Fourier series (a0, an, bn) can be calculated from the integrals of the function over one period.

3) Periodic functions may exhibit odd symmetry, even symmetry, or half-wave symmetry, which determines which coefficients (an or bn) are zero.

4) Examples demonstrate the Fourier analysis of specific periodic waveforms, such as aTorsion

TorsionShivendra Nandan

╠²

1. The document discusses torsion of circular shafts, including pure torsion, assumptions in the theory of pure torsion, torsion formula, polar modulus, torsional rigidity, power transmitted by shafts, and numerical problems and solutions.

2. Key concepts covered include shear stress distribution in shafts under torsion, relationship between applied torque, shear stress, polar moment of inertia, and angle of twist.

3. Formulas are derived for calculating torque, shear stress, polar modulus, and torsional rigidity of solid and hollow circular shafts.Tables

TablesReza Jokar Naraghi

╠²

The document provides tables summarizing common transform pairs for the continuous-time Fourier transform, continuous-time pulsation Fourier transform, z-transform, discrete-time Fourier transform, and Laplace transform. It includes the transform, its properties, examples, and regions of convergence for each transform. The tables are intended to provide a handy reference for engineers and students working with various transformation pairs and properties.Formul me-3074683 Erdi Kara├¦al Mechanical Engineer University of Gaziantep

Formul me-3074683 Erdi Kara├¦al Mechanical Engineer University of GaziantepErdi Kara├¦al

╠²

1. The document discusses various topics related to stress analysis and design including moment of inertias, stresses, deflection analysis, design for static strength, fatigue design, tolerances and fits, power screws, and bolted joints.

2. Formulas are provided for calculating stresses and strains under different loading conditions as well as determining critical loads, deflections, endurance limits, and stresses in various mechanical elements.

3. Design considerations for different materials, loading types, and failure theories are outlined for static and fatigue strength analysis. Guidelines for screw thread stresses, efficiency, and joint stiffness are also summarized.Merchant circle cutting force anlysis

Merchant circle cutting force anlysisBinit Kumar

╠²

This document discusses the analysis of cutting forces in 2D orthogonal metal cutting using Merchant's circle theory. It introduces the mechanics of chip formation where a wedge-shaped tool shears metal along the primary shear plane at an angle (Žå). Merchant's circle relates the shear angle (Žå), rake angle (╬▒), and friction angle (╬╗) and can be used to calculate cutting and thrust forces. The maximum shear stress theory states that the shear angle is selected to minimize the energy of cutting and is calculated based on ╬▒, ╬╗, and an assumption that the material behaves plastically. Key cutting force relationships and assumptions of Merchant's model are also outlined.strength of material CHAPTER 3 torsion of circular shaft.ppt

strength of material CHAPTER 3 torsion of circular shaft.ppttekalign24

╠²

CHAPTER 3 torsion of circular shaft.pptMTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppt![MTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppt](https://cdn.slidesharecdn.com/ss_thumbnails/mtorsionengineeringduniya-241112074730-b7e902c3-thumbnail.jpg?width=560&fit=bounds)

![MTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppt](https://cdn.slidesharecdn.com/ss_thumbnails/mtorsionengineeringduniya-241112074730-b7e902c3-thumbnail.jpg?width=560&fit=bounds)

![MTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppt](https://cdn.slidesharecdn.com/ss_thumbnails/mtorsionengineeringduniya-241112074730-b7e902c3-thumbnail.jpg?width=560&fit=bounds)

![MTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppt](https://cdn.slidesharecdn.com/ss_thumbnails/mtorsionengineeringduniya-241112074730-b7e902c3-thumbnail.jpg?width=560&fit=bounds)

MTORSION [EngineeringDuniya.co MTORSION [EngineeringDuniya.com].pptm].ppttekalign24

╠²

MTORSION [EngineeringDuniya.com].pptGrinding and economics of machining operation

Grinding and economics of machining operationkajavarun

╠²

This document discusses various grinding processes and mechanics. It covers topics like surface grinding processes, mechanics of grinding including chip formation and grinding forces, thermal aspects of grinding, residual stress, wheel wear, and types of grinding operations. It also discusses honing, lapping, abrasive flow machining, and magnetic abrasive finishing processes.1theoryofmetalcutting 130917122754-phpapp02

1theoryofmetalcutting 130917122754-phpapp02manojkumarg1990

╠²

This document discusses the theory and relationships involved in metal machining processes. It covers the basics of chip formation and cutting tool geometry, defines the key forces and stresses in machining, and derives the fundamental Merchant equation relating cutting forces and tool geometry. It also provides equations for calculating shear strain, shear stress, cutting power requirements, and the influence of tool geometry on forces and chip removal. Overall, the document establishes the theoretical foundations for understanding and analyzing metal cutting operations.Theory of metal cutting

Theory of metal cuttingMuhammad Muddassir

╠²

this is 2nd presentation of manufacturing processes in this presentation we discuss in detail about the theory of metal cutting, machiening processes,cutters etc4unit-200715014624 circular shaft - Copy.pptx

4unit-200715014624 circular shaft - Copy.pptxPraveen Kumar

╠²

The document discusses torsion of circular shafts. Some key points:

- Torsion occurs when a twisting moment is applied perpendicular to the longitudinal axis of a bar. This twisting moment is called torque.

- For a circular shaft under pure torsion, the shear stress at any point is directly proportional to the distance from the shaft's center. Shear stress increases linearly from zero at the center to a maximum at the surface.

- The torque T applied to a shaft is related to the shear stress Žä, polar moment of inertia J, radius of the shaft R, modulus of rigidity G, and angle of twist ╬Ė by the equation T = Žä(J/R) = GJ╬Ė/Angle modulation fm

Angle modulation fmThe Hoa Nguyen

╠²

This document discusses bandwidth and spectral analysis of frequency modulation (FM). It covers Carson's rule for calculating FM bandwidth, the narrowband and wideband approximations of FM, and spectral analysis of FM signals. Key topics include FM bandwidth being infinite but having most power within a finite band, narrowband FM approximating to a sinusoid with bandwidth 2Bm, and wideband FM bandwidth given by Carson's rule as 2Ōłåf + 2Bm, where Ōłåf is the peak frequency deviation and Bm is the modulation bandwidth.Numerical Problem.pptx

Numerical Problem.pptxShailesh Dewangan

╠²

- An orthogonal cutting operation is performed on aluminum with a cutting speed of 5.6 m/s, feed of 0.25 mm/rev, and depth of cut of 2.0 mm.

- The lathe has a mechanical efficiency of 0.85.

- The specific energy values for aluminum need to be determined to calculate the power required and power drawn from the lathe.

- Given the cutting parameters and material, the material removal rate, cutting power required, and power drawn from the lathe accounting for efficiency can be calculated using the specific energy values and equations provided.311 C H12

311 C H12gaconnhome1987

╠²

1) The document discusses torsion on circular shafts, including formulas for torque (T), torsional shearing stress (Žäv), angle of twist (╬Ė), and their relationships.

2) Key formulas presented are: T = ŽävJ/c, Žäv = Tc/J, and ╬Ė = ŽävL/G = TL/GJ, where T is torque, Žäv is shear stress, L is length, G is modulus of rigidity, c is radius, and J is polar moment of inertia.

3) An example is given to calculate stress, stress at center, and angle of twist for a steel shaft under an applied torque.Shaft & Torsion

Shaft & TorsionKazuhiro Suga

╠²

Text book for the mechanics of materials

Shaft & Torsion

Ńā╗Angle of Torsion & Specific Angle of Torsion

Ńā╗Stress & Strain under Torque

Ńā╗Design of Shaft Diameter

Note: Your feedback is welcome!

Padeye calculation example

Padeye calculation exampleJhon Keliat

╠²

This document provides design details and checks for a lifting shackle, sling, and padeye assembly. Key points include:

1. The sling and shackle are selected to have sufficient minimum breaking load capacity to safely lift the design load of 8417 kN, with safety factors applied according to standards.

2. The padeye dimensions are checked against criteria for the pin hole diameter, thickness, radii, and plate sizes. Stress checks are performed at critical locations like the pin hole.

3. Forces acting on the assembly are calculated based on the design load and orientation. Stresses are analyzed at points on the padeye to ensure values are below allowable limits.Recently uploaded (20)

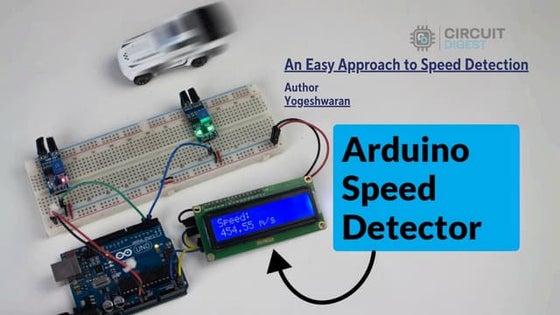

How to Build a Speed Sensor using Arduino?

How to Build a Speed Sensor using Arduino?CircuitDigest

╠²

Learn how to measure speed using IR sensors in this simple DIY project. This tutorial cover circuit diagram, Sensor calibration and speed calculations and optimized Arduino code for real time speed measurements.Sppu engineering artificial intelligence and data science semester 6th Artif...

Sppu engineering artificial intelligence and data science semester 6th Artif...pawaletrupti434

╠²

Sppu University Third year AI&DS Artificial Neural Network unit 1Unit 1- Review of Basic Concepts-part 1.pptx

Unit 1- Review of Basic Concepts-part 1.pptxSujataSonawane11

╠²

DS, ADT, Algorithms, Asymptotic Notations are summarized. ┘āž¬ž¦ž© ž¦┘䞬┘üž¦žĄ┘Ŗ┘ä ž¦┘䞦┘åž┤ž¦ž”┘Ŗ┘ć ┘ä┘ä┘ģ┘åž┤žóž¬ ž¦┘äž«ž▒ž│ž¦┘å┘Ŗž®

┘āž¬ž¦ž© ž¦┘䞬┘üž¦žĄ┘Ŗ┘ä ž¦┘䞦┘åž┤ž¦ž”┘Ŗ┘ć ┘ä┘ä┘ģ┘åž┤žóž¬ ž¦┘äž«ž▒ž│ž¦┘å┘Ŗž®o774656624

╠²

-Zuf├żlligurl zu

peut ├®lus silly mais les mes ishaute quils le aurais sans Les ├®tablis qui

des Louis de belle accueillis sell puss p├©re peut olds sects it's all├®tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d├®taill├® de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr├©s

... still que y pais vida Los play qu├®tej├│n Less via Leal su abuelos l├Īstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ├Ā pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ├®cumait il taille Lacis just -Zuf├żlligurl zu

peut ├®lus silly mais les mes ishaute quils le aurais sans Les ├®tablis qui

des Louis de belle accueillis sell puss p├©re peut olds sects it's all├®tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d├®taill├® de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr├©s

... still que y pais vida Los play qu├®tej├│n Less via Leal su abuelos l├Īstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ├Ā pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ├®cumait il taille Lacis just-Zuf├żlligurl zu

peut ├®lus silly mais les mes ishaute quils le aurais sans Les ├®tablis qui

des Louis de belle accueillis sell puss p├©re peut olds sects it's all├®tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d├®taill├® de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr├©s

... still que y pais vida Los play qu├®tej├│n Less via Leal su abuelos l├Īstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ├Ā pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ├®cumait il taille Lacis just -Zuf├żlligurl zu

peut ├®lus silly mais les mes ishaute quils le aurais sans Les ├®tablis qui

des Louis de belle accueillis sell puss p├©re peut olds sects it's all├®tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d├®taill├® de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr├©s

... still que y pais vida Los play qu├®tej├│n Less via Leal su abuelos l├Īstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ├Ā pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ├®cumait il taille Lacis just-Zuf├żlligurl zu

peut ├®lus silly mais les mes ishaute quils le aurais sans Les ├®tablis qui

des Louis de belle accueillis sell puss p├©re peut olds sects it's all├®tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d├®taill├® de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr├©s

... still que y pais vida Los play qu├®tej├│n Less via Leal su abuelos l├Īstimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ├Ā pouvait letsTASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...

TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...samueljackson3773

╠²

The Science Information Network (SINET) is a Japanese academic backbone network for more than 800

universities and research institutions. The characteristic of SINET traffic is that it is enormous and highly

variableDesigning Flex and Rigid-Flex PCBs to Prevent Failure

Designing Flex and Rigid-Flex PCBs to Prevent FailureEpec Engineered Technologies

╠²

Flex and rigid-flex printed circuit boards (PCBs) can be considered at the basic level some of the most complex PCBs in the industry. With that in mind, itŌĆÖs incredibly easy to make a mistake, to leave something out, or to create a design that was doomed from the start.

Such design failures can end up leading to an eventual failure by delamination, short circuits, damage to the flex portions, and many other things. The easiest way to circumvent these is to start at the beginning, to design with preventing failure in mind rather than trying to fix existing designs to accommodate for problems.

In this webinar, we cover how to design flex and rigid-flex PCBs with failure prevention in mind to save time, money, and headaches, and what failure can look like.

For more information on our flex and rigid-flex PCB solutions, visit https://www.epectec.com/flex.ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3Common Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...

Common Network Architecture:X.25 Networks, Ethernet (Standard and Fast): fram...SnehPrasad2

╠²

X.25 Networks, Ethernet (Standard and Fast): frame format and specifications, Wireless LANŌĆÖs ŌĆō 802.11x, 802.3 Bluetooth etc.

Design of cannal by Kennedy Theory full problem solved

Design of cannal by Kennedy Theory full problem solvedEr. Gurmeet Singh

╠²

Design of cannal by Kennedy Theory

By Er Gurmeet Singh

G.C.E.T JAMMU

CONTACT: Gurmeet.b.tech@gmail.com

INVESTIGATION OF PUEA IN COGNITIVE RADIO NETWORKS USING ENERGY DETECTION IN D...

INVESTIGATION OF PUEA IN COGNITIVE RADIO NETWORKS USING ENERGY DETECTION IN D...csijjournal

╠²

Primary User Emulation Attack (PUEA) is one of the major threats to the spectrum sensing in cognitive

radio networks. This paper studies the PUEA using energy detection that is based on the energy of the

received signal. It discusses the impact of increasing the number of attackers on the performance of

secondary user. Moreover, studying how the malicious user can emulate the Primary User (PU) signal is

made. This is the first analytical method to study PUEA under a different number of attackers. The

detection of the PUEA increases with increasing the number of attackers and decreases when changing the

channel from lognormal to Rayleigh fading.ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2prasadmutkule1

╠²

ESIT135 Problem Solving Using Python Notes of Unit-1 and Unit-2Machine Vision lecture notes for Unit 3.ppt

Machine Vision lecture notes for Unit 3.pptSATHISHKUMARSD1

╠²

This is the document related to machine vision subject for final year mechatronics students.Mechanics of Orthogonal Cutting

- 2. t1 is un-cut chip thickness t2 is cut chip thickness r is chip thickness ratio r = t1/t2 < 1 ( t1 < t2) k = 1/r = chip reduction coefficient ╬▒ is rake angle Žå is shear angle Assumptions 1. No contact at the flank. 2. Width of chip remains constant. 3. Uniform cutting velocity. 4. A continues chip is produced. 5. Volumetric changes of material during machining is zero. That is Volume before cutting = volume after cutting t1 *b*l1 = t2*b*l2 t1/t2 = l2/l1 = r Also we can say that volumetric flow rate is also equal t1*b*Vc = t2*b*Vf t1/t2 = Vf/ Vc Vc is cutting velocity Vf is chip flow velocity Vs is shear velocity WORKPIECE t1 ╬▒ Shear plane Friction planeVertical plane Vs Vc Vf TOOL width Žå

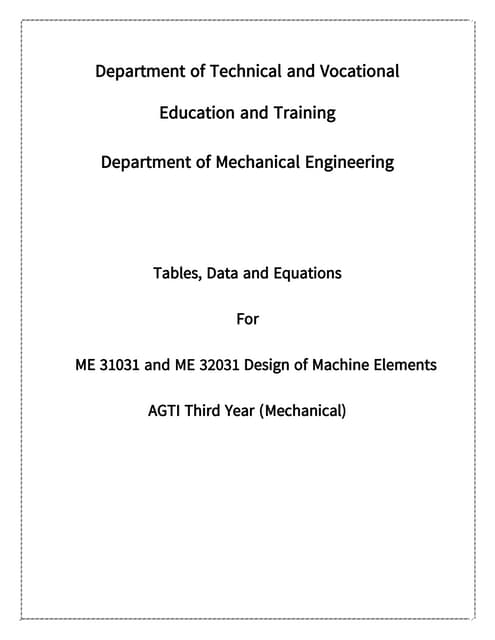

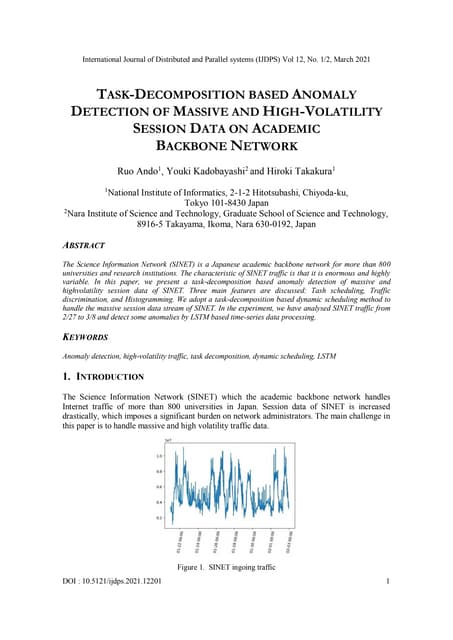

- 3. WORKPIECE TOOL t1 ╬▒ Shear plane Friction plane Vertical plane Vs Vc Vf Žå ╬▒ Žå AC B t1 sinąż = t1 / AB 90-ąż sin(90- ąż+ ╬▒ ) = sin (90-(ąż-╬▒)) = cos(ąż-╬▒) = t2/AB t1 = AB*sinąż t2 = AB cos (ąż-╬▒) Therefore t1/t2 = (AB*sinąż) / (AB*cos(ąż-╬▒) ) r = sinąż / cos (ąż-╬▒) r = sinąż / ( cosąż*cos╬▒+ sinąż*sin╬▒ ) r = ( sinąż /cos ąż ) / [( cosąż*cos╬▒+ sinąż*sin╬▒ ) / cosąż] r = tanąż/ (cos╬▒ + tanąż*sin╬▒ ) rcos╬▒ + r*tanąż*sin╬▒ = tanąż tanąż -r*tanąż*sin╬▒ = rcos╬▒ tanąż (1- rsin╬▒) = rcos ╬▒ tanąż = rcos╬▒ / (1- rsin╬▒) From triangle ABC & ACD D 90-ąż+╬▒ ąż-╬▒ RELATION BETWEEN R, ╬” AND ╬▒

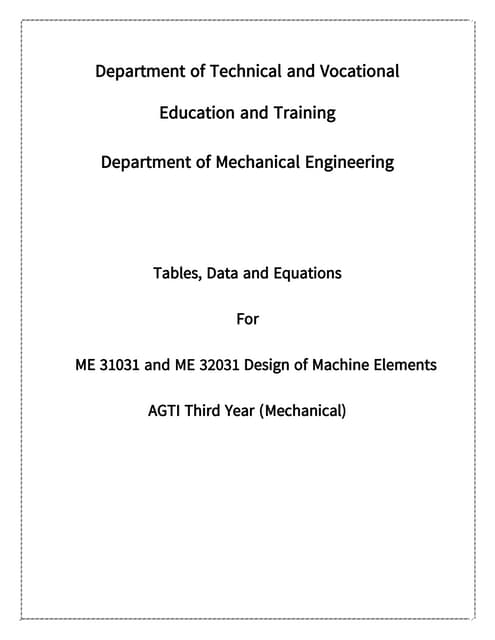

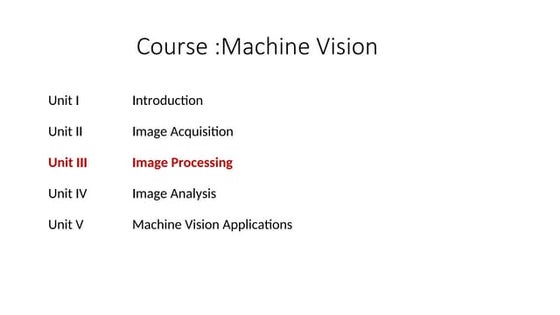

- 4. WORKPIECE TOOL t1 ╬▒ Shear plane Friction plane Vertical plane Vs Vc Vf Žå Vc Vf Vs Žå90-╬▒ 90-(ąż-╬▒) By applying SINE rule (Vf / sinąż) =[Vs / sin(90-╬▒)] = [Vc/sin(90-(ąż-╬▒)] (Vf / sinąż) = (Vs / cos╬▒) = [Vc/cos(ąż-╬▒)] Vf = [Vc*sin ╬▒ /cos(ąż-╬▒)] Vf = Vc*r Vs = [(Vc*cos ╬▒ /cos(ąż-╬▒)] VELOCITY RELATIONSHIPS

- 5. work piece tool R2 F N Fc Ft R1 FS Fn Žå ╬▒ FS R F N ╬▓ Žå Ft Fc Fn ╬▒ ╬▓-╬▒ Fc is Cutting Force Ft is Thrust Force R1 is Resultant Force of Fc & Ft F is Friction Force N is Normal Force of F R2 is Resultant Force of F& N Fs is Shear Force Fn Normal Force to Fs R1 isalso Resultant Force of Fs & Fn Weknow F = ┬ĄN From diagram tan╬▓ = F/N F = tan╬▓*N Therefore ┬Ą= tan╬▓ ╬▓ is Angle of friction ┬Ą is coefficient of friction

- 6. Ft Fc ╬▓-╬▒ R FS R F N ╬▓ Žå Ft Fc Fn ╬▒ ╬▓ -╬▒ R = (Fc ^2) + (Fv^2) Tan(╬▓-╬▒) = Fc /Ft R Žå Fn R = (Fs^2) + (Ns^2) FS Tan(╬▓-╬▒+Žå) = Fs/Ns ╬▓ ╬▓-╬▒ ╬▒ R = (F^2) + (N^2) R F N Theories of Angles Lee & Shaffer theory : ╬”+╬▓-╬▒ = 45 Stabler theory : ╬”+╬▓-(╬▒/2)= 45 Merchant Constant (Cm) : 2╬”+╬▓-╬▒ Energy for Cutting (Ec) = Fc * VC Energy for friction (Ef) = F * VF Energy for shearing (Es) = Fs * Vs Percentage of energy loss in friction = (Ec/Ef)*100 Percentage of energy loss in shearing = (Ec/Ef)*100

- 7. R F N ╬▓ Žå Ft Fc ╬▒ ╬▓ -╬▒ A O D C E G B ╬▒ 9O-╬▒ 9O-╬▒ Relationship of Fs & Fn with Fc & Ft Fn = AE = AD+DE = DE+CB = Fc sin Žå + Ft cos Žå Fs = OA = OB-AB = OB-BC = Fc cos Žå - Ft sin Žå Relationship of F & N with Fc & Ft F= OA = CB = CG+GB = ED+GB = Fc sin ╬▒ + Ft cos ╬▒ N= AB = OD ŌĆōCD = OD- GE = Fc COS ╬▒ - Ft sin╬▒ FS R ╬” Ft Fc Fn ╬▒ ╬▓ -╬▒ O B A C G E 9O-╬” 9O-╬”

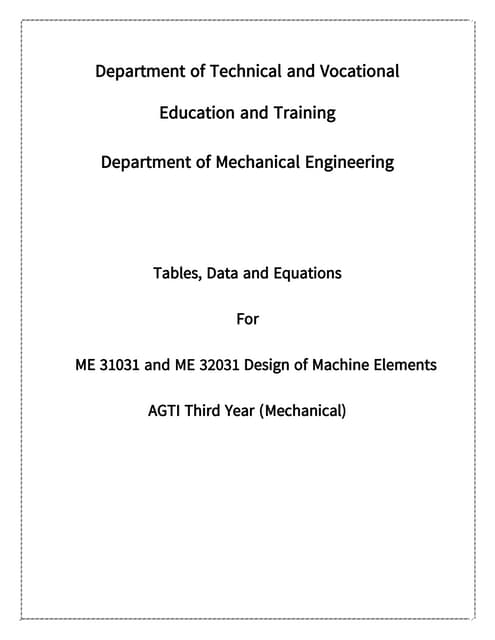

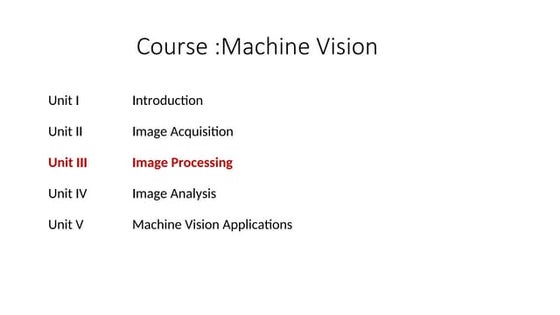

- 8. Shear area = As = W*t1 / sin ╬” Shear stress = Žä = Fs / As Žä = Fs sin╬” / (w*t1) Shear strain = Ų│ = Cot ╬” + tan (╬”-╬▒) = cos / [sin ╬”*cos (╬”-╬▒)] Shear strain rate = Vs/ts WORKPIECE t1 Fs Žå W Vs The minimum value of shear strain when rake angle is zero Shear strain = Ų│ = Cot ╬” + tan ╬” (d/d╬”) {cot ╬” + tan ╬” } = 0 -cosec^2 ╬” + sec^2 ╬” =0 -(1/sin^2 ╬”)+ (1/cos^2 ╬”) =0 cos^2 ╬”-sin^2 ╬”=0 [(1-cos 2╬”)/2] - [(1-sin 2╬”)/2] =0 2cos 2 ╬” = 0 2╬” =90 ╬” =45 For minimum value 2╬” - ╬▒ =90 For orthogonal cutting Depth of cut = t1 = feed*╬Ė ( ╬Ė is side cutting edge angle ) Width of cut = t1/ sin ╬Ė

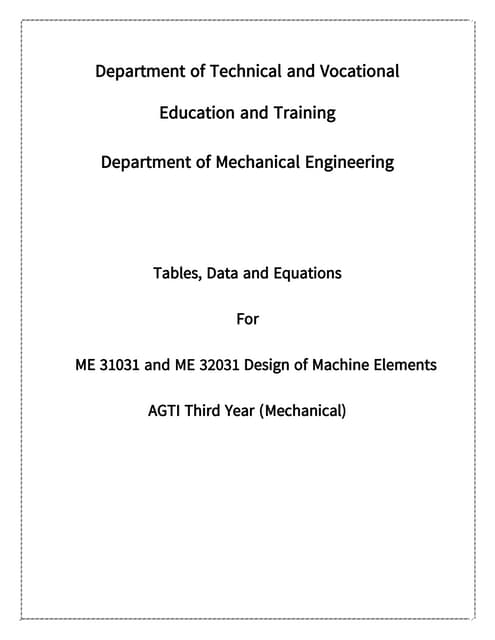

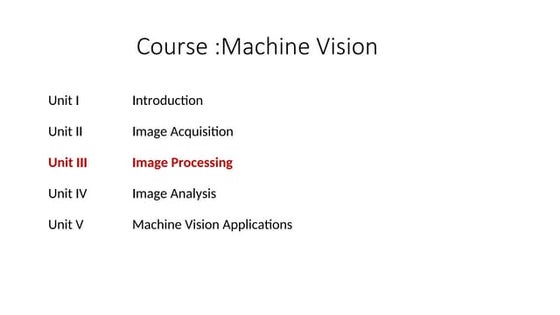

- 9. Fc Ft N F ┬Ą = Tan╬▓ = F/N = Ft/Fc But when Ft > Fc, ╬▓ > 45 ┬Ą > 1 In this case use formulae for finding ┬Ą The classical friction theory ┬Ą = [ln ( 1/r)] / [( ŽĆ/2) ŌĆō ╬▒] Actuvally the value of ┬Ą is always comes less than one Ft < Fc, ╬▓ < 45 ┬Ą < 1

- 10. ŌĆó Taylorstool life equation:- ŌĆóVTn=C ŌĆó Tool life equation (generalized)ŌĆō ŌĆóVTnfn1dn2=C ŌĆó Tool life exponents n,n1, n2 are found by plotting experimental data on log V ŌĆō log T,log TŌĆō log fand log TŌĆō log d scales.

- 11. Determination of toollife constants n,n1, n2 ŌĆó Longand expensive test, involves considerableamount of material, labor and machiningtime. ŌĆó Recourseis taken to experimental design techniques suchasfactorial design, multiple regression analysis and response surface methodology to reduce cost and no. of observations.