MEG Plant Flyer

- 1. corrosion.curtin.edu.auMake tomorrow better. Curtin University, sponsored by Chevron, as part of the WA:ERA Alliance, has built the first bench-top scale closed loop MEG regeneration/reclamation plant in Australia. What does it do? Curtinâs bench-top facility can: âĒ simulate the condensate carryover into the MEG pre-treatment vessel âĒ verify the compatibility of production chemical additives âĒ simulate corrosion strategy, such as the switch over between film forming corrosion inhibition to pH stabilisation and vice versa âĒ simulate realistic production fluids, such as condensate mixtures and simulated formation of water/brines (but not hydrocarbon gases) âĒ study corrosion throughout the MEG plant âĒ optimise the salt removal processes âĒ utilise a side stream from the feed mixing vessel into a corrosion cell to evaluate the performance of corrosion inhibitors in MEG systems under realistic pipeline conditions âĒ study in-situ cleaning processes. Benefits of a bench-top system BETTER UNDERSTANDING OF THE MEG REGENERATION/ RECLAMATION PROCESSES The MEG closed loop system is a complex system containing various chemical and physical processes. A better understanding of these processes and how they affect MEG regeneration/reclamation can be useful to plant operations throughout the world. MORE COMPREHENSIVE LABORATORY TESTING The bench-top scale closed loop MEG regeneration/ reclamation plant can bridge the gap between individual laboratory-scale tests and comprehensive testing protocols. This enables laboratory-scale testing to be correlated to field conditions, which builds greater confidence for introducing new chemicals and/or operating strategies. SCIENCE AND ENGINEERING THE MEG BENCH-TOP REGENERATION/ RECLAMATION PLANT

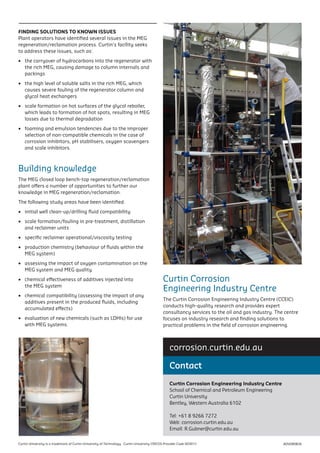

- 2. FINDING SOLUTIONS TO KNOWN ISSUES Plant operators have identified several issues in the MEG regeneration/reclamation process. Curtinâs facility seeks to address these issues, such as: âĒ the carryover of hydrocarbons into the regenerator with the rich MEG, causing damage to column internals and packings âĒ the high level of soluble salts in the rich MEG, which causes severe fouling of the regenerator column and glycol heat exchangers âĒ scale formation on hot surfaces of the glycol reboiler, which leads to formation of hot spots, resulting in MEG losses due to thermal degradation âĒ foaming and emulsion tendencies due to the improper selection of non-compatible chemicals in the case of corrosion inhibitors, pH stabilisers, oxygen scavengers and scale inhibitors. Building knowledge The MEG closed loop bench-top regeneration/reclamation plant offers a number of opportunities to further our knowledge in MEG regeneration/reclamation. The following study areas have been identified: âĒ initial well clean-up/drilling fluid compatibility âĒ scale formation/fouling in pre-treatment, distillation and reclaimer units âĒ specific reclaimer operational/viscosity testing âĒ production chemistry (behaviour of fluids within the MEG system) âĒ assessing the impact of oxygen contamination on the MEG system and MEG quality âĒ chemical effectiveness of additives injected into the MEG system âĒ chemical compatibility (assessing the impact of any additives present in the produced fluids, including accumulated effects) âĒ evaluation of new chemicals (such as LDHIs) for use with MEG systems. Curtin Corrosion Engineering Industry Centre The Curtin Corrosion Engineering Industry Centre (CCEIC) conducts high-quality research and provides expert consultancy services to the oil and gas industry. The centre focuses on industry research and finding solutions to practical problems in the field of corrosion engineering. ADV080826Curtin University is a trademark of Curtin University of Technology. Curtin University CRICOS Provider Code 00301J Curtin Corrosion Engineering Industry Centre School of Chemical and Petroleum Engineering Curtin University Bentley, Western Australia 6102 Tel: +61 8 9266 7272 Web: corrosion.curtin.edu.au Email: R.Gubner@curtin.edu.au Contact corrosion.curtin.edu.au