Membrane bio reactor- Waste water treatment

- 2. MBR ŌĆó MBR or Membrane bio reactor is the latest wastewater treatment technology which is the combination of microfiltration or ultrafiltration with bio reactors. ŌĆó The MBR technology provides the following advantages over ASP: 1. High-quality effluent 2. Less sludge production 3. Higher volumetric loading rates 4. Shorter hydraulic retention times (HRT). What is MBR???

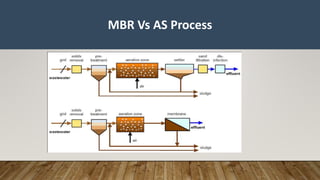

- 3. MBR PROCESSMBR Vs AS Process

- 4. ACTIVATED SLUDGE PROCESS (ASP) ŌĆó If we go for a conventional activated sludge process, the required aeration tank volume ; ŌĆó ØæģØæÆØæÄØæÉØæĪØæ£Øæ¤ ØæēØæ£ØæÖØæóØæÜØæÆ = 220 ØæÜ3 ØææØæÄØæ” ├Ś6000 ØæÜØæö/ØæÖ 0.1├Ś3500 ØæÜØæö/ØæÖ = 3771.43 ØæÜ3 ŌĆó So the reactor volume is practically impossible for the operation also the MLSS loading is less compared with the MBR operation. ŌĆó So ISL decided to go with MBR treatment technology rather than the conventional ASP process (We need several reactors to carryout the process if we need ASP).

- 7. MBR MEMBRANE . Hollow Fiber MBR MEMBRANE

- 8. OUR EXPERTISE IN MBRŌĆ”. ŌĆó ISL has successfully designed and commissioned MBR wastewater technology to pharmaceutical wastewater at Morison Limited. (Sub group of HEMAS Holdings). ŌĆó Daily wastewater discharge from Morison facility is 80 m3/day and influent quality was attached here.

- 9. MORISIONŌĆ”. ŌĆó After the Anoxic tank, wastewater directed to the MBR system with aeration tank where the 99% of reduction COD reduction occurs. ŌĆó In aeration the MLSS is kept as 8000 mg/l.

- 10. No Description Value Unit 1. Fat, Oil & Grease <10.0 mg/l 1. Total suspended solids (TSS) 200.00 mg/l 1. Turbidity 750 NTU 1. pH 4.5-6.0 1. Biological oxygen demand (BOD5) 100.00 mg/l 1. Chemical oxygen demand(COD) 1,500.00 mg/l 1. Electrical conductivity 1,000.00 ┬Ąs/cm 1. Total dissolved solids 650.00 mg/l 1. Sulphite 8.00 mg/l 1. Color range Yellow range 436 nm Red range 525 nm Blue range 620nm 20 14 12 m-1 m-1 m-1 Influent wastewater parameters

- 11. ŌĆó ISL Successfully complied with the SLS 614:2013 standards using MBR technology. No Description Value Unit 1. Fat, Oil & Grease N/D mg/l 1. Total suspended solids (TSS) <1 mg/l 1. Turbidity <2 NTU 1. pH 7.0-8.5 - 1. Biological oxygen demand (BOD5) Nil mg/l 1. Chemical oxygen demand(COD) <10 mg/l 1. Electrical conductivity <250 ┬Ąs/cm 1. Total dissolved solids <150 mg/l Treated water parameters

- 12. MBR DESIGN BASISŌĆ” ŌĆó Design Flux 20 LMH ŌĆó So the required membrane area only for the filtration of membrane = 11├Ś103 ØÉ┐/ŌäÄ 20 ØÉ┐ØæĆØÉ╗ = 550 ØæÜ2 ŌĆó Considering the backwash and CIP =2 m3 filtrate required per hour. ŌĆó Filtration pump minimum flow requirement - 13 m3/h

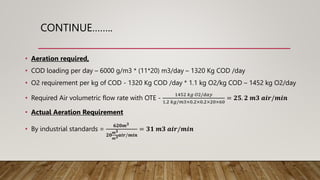

- 13. CONTINUEŌĆ”ŌĆ”.. ŌĆó Aeration required, ŌĆó COD loading per day ŌĆō 6000 g/m3 * (11*20) m3/day ŌĆō 1320 Kg COD /day ŌĆó O2 requirement per kg of COD - 1320 Kg COD /day * 1.1 kg O2/kg COD ŌĆō 1452 kg O2/day ŌĆó Required Air volumetric flow rate with OTE - 1452 ØæśØæö Øæé2/ØææØæÄØæ” 1.2 ØæśØæö/ØæÜ3├Ś0.2├Ś0.2├Ś20├Ś60 = ؤÉؤō. Ø¤É ØÆÄؤæ ØÆéØÆŖØÆō/ØÆÄØÆŖØÆÅ ŌĆó Actual Aeration Requirement ŌĆó By industrial standards = ؤöؤÉؤÄØÆÄؤæ ؤÉØ¤Ä ØÆÄؤæ ØÆÄؤæØÆéØÆŖØÆō/ØÆÄØÆŖØÆÅ = ؤæؤŠØÆÄؤæ ØÆéØÆŖØÆō/ØÆÄØÆŖØÆÅ

- 14. SLUDGE GENERATION ŌĆó Daily Sludge Generation =ØæāØæźØæć,ØæēØæåØæå = ØæŗØæć├ŚØæē ØæåØæģØæć = 8000Øæö ØæÜ3 ├Ś620ØæÜ3 30 = 165.33 ØæśØæö/ØææØæÄØæ” ŌĆó Daily Slurry Generation (98% Moisture) = 8266.5 kg/day. ŌĆó If we are going to use screw press for dewatering = 2 tons/day (Maximum).

- 15. INFLUENT PARAMETERS Parameter Unit Value Condensate Flow rate m3/hr 11 Biological Oxygen Demand (BOD5) mg/l 500-600 Chemical Oxygen Demand (COD) mg/l 3000-6000 Total Dissolved Solids (TDS) mg/l 160-210 Electrical Conductivity at 25 oC ╬╝S/cm 300-320 Oil and grease mg/l 6-20 Dissolved Phosphates (as P) mg/l 4.5-5.5 Total Kjedahl Nitrogen ( as N) mg/l 140-160 Ammonical Nitrogen (as N) mg/l 60-75 Sulphide (as S) mg/l 6-7.6 Copper (as Cu) mg/l 0.015-0.025 Iron (as Fe) mg/l 0.6-0.9 Zinc (as Zn) mg/l 0.05-1.00 pH 3-3.2

- 16. EXPECTED TREATED WATER QUALITY Parameter Unit Maximum desired value Total Suspended Solids (TDS) mg/l Max. 50 pH at ambient temperature - 6.5-8.5 Biochemical Oxygen Demand mg/l 30 Phenolic compounds (as C6H5OH) mg/l 1 Oil & Grease mg/l 6-20 Chemical Oxygen Demand (COD) mg/l 250 Dissolved phosphates (as P) mg/l 5 Total Kjedahl Nitrogen (as N) mg/l 140-160 Ammonical Nitrogen (as N) mg/l 50 Sulfide (as S) mg/l 2 Iron (Fe) mg/l 3 Copper (Cu) mg/l 3 Zinc (Zn) mg/l 2 Color Wavelength range Yellow range (436nm) Red range (525 nm) Blue range (620 nm) Max. absorption coefficient 7m-1 5m-1 3m-1

- 17. MBR SPECIFICATIONS MBR SPECIFCATION (Flat Sheet)

- 18. Our Services Installation Operation Startup Support