√áńįMENTO ve BETON

- 1. 1 √áńįMENTO ve BETON TARńįHńį ńįnŇü. Y√ľk. M√ľh. Yasin Engin

- 2. 2 √áimento "√áimento" kelimesi, yontulmuŇü taŇü kńĪrńĪntńĪsńĪ anlamńĪndaki Latince "caementum" s√∂zc√ľńü√ľnden t√ľremiŇü, sonralarńĪ ‚ÄúbańülayńĪcńĪ‚ÄĚ anlamńĪnda kullanńĪlmaya baŇülamńĪŇütńĪr. ńįlk betonarme yapńĪnńĪn tarihi 1852 olmakla birlikte, yapńĪlarńĪn inŇüasńĪnda bańülayńĪcńĪ malzemelerin kullanńĪmńĪ √ßok eskilere dayanńĪr; bańülayńĪcńĪ madde olarak kullanńĪlan ilk madde kire√ßtir. √áimento tarihini bańülayńĪcńĪ malzemelerin ilk kullanńĪmńĪndan itibaren d√ľŇü√ľnmek gerekir. √á√ľnk√ľ y√ľzlerce yńĪllńĪk deneyim ve birikim g√ľn√ľm√ľzde kullandńĪńüńĪmńĪz ‚ÄúPortland √áimentosu‚ÄĚnun icat edilmesine yol a√ßmńĪŇütńĪr. www.betonvecimento.com

- 3. 3 BańülayńĪcńĪ Malzemeler Kirecin bańülayńĪcńĪ √∂zellińüinin insanlńĪk tarihinin erken d√∂nemlerinde keŇüfedildińüi s√∂ylenebilir. Eski MńĪsńĪr, KńĪbrńĪs, Girit ve Mezopotamya'nńĪn deńüiŇüik y√∂relerinde kirecin bir yapńĪ malzemesi olarak kullanńĪlmasńĪna ait √∂rneklere rastlanńĪlmńĪŇütńĪr. Eski YunanlńĪlar ve RomalńĪlar kireci hidrolik bańülayńĪcńĪ olarak kullanmńĪŇülardńĪr. M.√Ė. 70 - 25 yńĪllarńĪ arasńĪnda yaŇüamńĪŇü olan Mimar Vitruvius "On Architecture" (MimarlńĪk √úzerine) adlńĪ 10 ciltlik kitabńĪnda puzolan ve kire√ß karńĪŇüńĪmlarńĪnńĪn hidrolik √∂zelliklerinden bahsetmiŇü, nehir ve deniz kńĪyńĪsńĪnda yapńĪlacak olan yapńĪlarda kullanńĪlabilecek har√ß i√ßin karńĪŇüńĪm oranńĪ bile vermiŇütir(2 birim puzolan 1 birim kire√ß). www.betonvecimento.com

- 4. 4 Kronolojik olarak çimento tarihi

- 5. 5 M√Ė 8000‚Äôden √Ėnceki YńĪllar (Paleolitik √áańü) Killi topraklarńĪn bańülayńĪcńĪlńĪk potansiyeli farkedilmiŇü ve bu malzemeden d√∂neme uygun, iŇüe yarar basit aletler ve heykelcikler yapńĪlmńĪŇütńĪr. M√Ė 8000- M√Ė 4500 YńĪllarńĪ (Neolitik √áańü) AteŇüin bulunmasńĪyla al√ßńĪ ve kirecin bilin√ßli olarak √ľretilebilme y√∂ntemleri keŇüfedilmiŇütir. Skara Brae Neolitik K√∂y√ľ, ńįngiltere www.betonvecimento.com

- 6. 6 M√Ė 4500- M√Ė 300 YńĪllarńĪ M√Ė 4500‚Äôde Mezopotamya‚Äôdaki kent devletleri kurulmaya baŇüladńĪktan sonra bu devletlerde taŇü, ahŇüap gibi pek √ßok yapńĪ malzemesi kullanńĪlmńĪŇü, yaygńĪn olarak yararlanńĪlan malzemeler ise killi topraktan √ľretilen har√ßlar olmuŇütur. Tarihte, MńĪsńĪr Piramitleri, √áin Seddi ve deńüiŇüik zamanda yapńĪlan kalelerde o d√∂nemin medeniyetini simgeleyen bir√ßok deńüiŇüik bańülayńĪcńĪ madde kullanńĪlmńĪŇütńĪr. www.betonvecimento.com

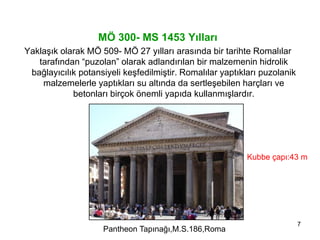

- 7. 7 M√Ė 300- MS 1453 YńĪllarńĪ YaklaŇüńĪk olarak M√Ė 509- M√Ė 27 yńĪllarńĪ arasńĪnda bir tarihte RomalńĪlar tarafńĪndan ‚Äúpuzolan‚ÄĚ olarak adlandńĪrńĪlan bir malzemenin hidrolik bańülayńĪcńĪlńĪk potansiyeli keŇüfedilmiŇütir. RomalńĪlar yaptńĪklarńĪ puzolanik malzemelerle yaptńĪklarńĪ su altńĪnda da sertleŇüebilen har√ßlarńĪ ve betonlarńĪ bir√ßok √∂nemli yapńĪda kullanmńĪŇülardńĪr. Pantheon TapńĪnańüńĪ,M.S.186,Roma Kubbe √ßapńĪ:43 m

- 8. 8 1453- 1690 YńĪllarńĪ Bizans ńįmparatorluńüu olarak anńĪlan Dońüu Roma ńįmparatorluńüu‚Äônun 1453 yńĪlńĪnda √ß√∂kmesinden sonra bańülayńĪcńĪlar ve betonla ilgili √∂nemli yenilikler yer almamńĪŇütńĪr. 1299 yńĪlńĪnda kurulmuŇü olan OsmanlńĪ Devleti‚Äônin daha sonraki d√∂nemlerinde √∂zellikle 1500‚Äôl√ľ yńĪllarda Mimar Sinan tarafńĪndan kullanńĪlan ‚ÄúHorasan HarcńĪ‚ÄĚ olarak adlandńĪrńĪlan malzemeden yararlanńĪlarak g√∂rkemli eserler yapńĪlmńĪŇütńĪr. ńį√ßkale Kilisesi, Bodrum 6.yySelimiye Camii,Edirne 16.yy www.betonvecimento.com

- 9. 9 1690- 1790 YńĪllarńĪ Plymouth LimanńĪ 1600‚Äôl√ľ yńĪllarda, demirlemek isteyen gemiler i√ßin en uygun liman olarak g√∂r√ľlmektedir. Ancak denizin i√ßerisinde yer alan Eddystone kayalńĪklarńĪ limana yaptńĪńüńĪ dalga ve alabora ile limana giriŇüi zorlaŇütńĪrmaktadńĪr. Su altńĪnda sertleŇüebilen har√ßlarńĪn kullanńĪmńĪ ile ńįngiltere‚Äôde, gemicilere kolaylńĪk sańülamasńĪ amacńĪyla John Smeaton tarafńĪndan yapńĪlan Eddystone Deniz Feneri yapńĪmńĪ 1757- 1759 yńĪllarńĪ arasńĪnda tamamlanmńĪŇütńĪr. Fener, denizaltńĪnda a√ßńĪlan deliklere, kurŇüun ile tutturulmuŇü olan demir √ßubuklara bańülńĪ ve toplam y√ľkseklińüi 36.6 m‚Äôdir.

- 10. 10 1790- 1800 YńĪllarńĪ ńįngiltere‚Äôde dońüal √ßimento √ľretilmeye ve kullanńĪlmaya baŇülanmńĪŇütńĪr. 1796 yńĪlńĪnda ńįngiliz James Parker tarafńĪndan ‚ÄúRoma √áimentosu‚ÄĚ veya ‚ÄúParker‚ÄôńĪn √áimentosu‚ÄĚ olarak adlandńĪrńĪlan dońüal √ßimento √ľretilmiŇütir. Hammaddesi Londra civarńĪnda veya ńįngiltere‚Äôde bulunan kalker taŇülarńĪdńĪr. O d√∂nemde b√ľy√ľk kanal ve liman yapńĪmlarńĪnda kullanńĪlmńĪŇütńĪr. AyrńĪca aynńĪ yńĪl, benzer bir hammadde ile ńįngiliz James Frost tarafńĪndan da ‚Äúńįngiliz √áimentosu‚ÄĚ veya ‚ÄúFrost‚Äôun √áimentosu‚ÄĚ olarak adlandńĪrńĪlan √ßimento √ľretilmiŇütir, ancak Roma √áimentosu kadar pop√ľler olmamńĪŇütńĪr. www.betonvecimento.com

- 11. 11 1800- 1824 YńĪllarńĪ FransńĪz Louis Vicat, hidrolik bańülayńĪcńĪ malzemelerin √ľretimine √∂nemli katkńĪlarda bulunmuŇü, √ľrettińüi hidrolik bańülayńĪcńĪyńĪ k√∂pr√ľ ve beton kanallarńĪnda kullanmńĪŇütńĪr. Hidrolik kirecin, kire√ß ve puzolan karńĪŇüńĪmńĪndan elde edilen bańülayńĪcńĪlarńĪn ve dońüal √ßimentonunu su altńĪnda sertleŇüebilme √∂zellińüini araŇütńĪrmńĪŇü, belirli oranda silika, al√ľmina ve kalsiyum oksitin birleŇütirilmesiyle sentetik hidrolik bańülayńĪcńĪ √ľretmiŇü ve bu √ßalńĪŇümalar bug√ľn kullanńĪlmakta olan portland √ßimentosu √ľretimine ńĪŇüńĪk tutmuŇütur. BańülayńĪcńĪ malzeme ve su karńĪŇüńĪmńĪndan oluŇüan hamurun priz s√ľresinin tayini i√ßin, g√ľn√ľm√ľzde de kullanńĪlan, bir deney y√∂ntemi bulmuŇütur.

- 12. 12 1824- 1850 YńĪllarńĪ 1824 yńĪlńĪnda ńįngiliz Joseph Aspdin, ‚Äúportland √ßimentosu‚ÄĚ olarak adlandńĪrdńĪńüńĪ bir √ßimento √ľretmiŇü ve patentini almńĪŇütńĪr. 1850 yńĪlńĪnda ńįngiliz Isaac Charles Johnson, Aspdin tarafńĪndan bulunan √ßimentoya benzer bir √ßimento √ľrettińüi i√ßin modern portland √ßimentosunun ilk √ľreticisi olarak tanńĪnmńĪŇütńĪr. Bunun √ľzerine ńįngiltere‚Äôde bir √ßok fabrika kurulmuŇütur. D√ľnyada ilk √ßimento fabrikasńĪ 1848 yńĪlńĪnda ńįngiltere‚Äôde kuruldu.

- 13. 13 1824- 1850 YńĪllarńĪ FransńĪz Jean-Louis Lambot beton i√ßinde ilk defa demir kullanarak ¬ę betonarme kayńĪk¬Ľ √ľretmiŇütir. 1850 yńĪlńĪnda ilk beton yol Avusturya‚Äôda yapńĪlmńĪŇütńĪr. www.betonvecimento.com

- 14. 14 1850- 1865 YńĪllarńĪ 1850‚Äôli yńĪllarńĪn baŇülarńĪnda Fransa, Bel√ßika ve Almanya‚Äôda ‚Äúportland √ßimentosu‚ÄĚ √ľreten fabrikalar kurulmuŇütur. Bu yńĪldan itibaren aynńĪ zamanda ‚Äúbetonarme malzeme‚ÄĚ kullanńĪmńĪ baŇülamńĪŇütńĪr. 1854 yńĪlńĪnda ńįngiliz William B. Wilkinson 2 katlńĪ ilk betonarme evi yapmńĪŇütńĪr. 1859 yńĪlńĪnda portland √ßimentosu ńįngiltere‚Äôde kanalizasyon inŇüaatinde ilk defa kullanńĪldńĪ. 1860‚ÄôlńĪ yńĪllarda y√ľksek fńĪrńĪn c√ľrufu gran√ľle hale getirilerek kullanńĪlmaya baŇülanmńĪŇütńĪr. 1865 yńĪlńĪnda Almanya‚Äôda bir fabrika ‚Äú√∂ńü√ľt√ľlm√ľŇü gran√ľle y√ľksek fńĪrńĪn c√ľrufu ve s√∂nd√ľr√ľlm√ľŇü kire√ß‚ÄĚ karńĪŇüńĪmńĪndan oluŇüan √ßimento √ľretmeye baŇülamńĪŇütńĪr. www.betonvecimento.com

- 15. 15 . 1868 yńĪlńĪnda ńįngiltere‚Äôden Amerikaya ilk portlan √ßimentosu ihracatńĪ yapńĪlmńĪŇütńĪr. 1871 yńĪlńĪnda ABD‚Äôli David O. Saylor tarafńĪndan ABD‚Äôde portland √ßimentosu √ľreten ilk fabrika kurulmuŇütur. 1887 yńĪlńĪnda ńįngiliz Frederick Ransome tarafńĪndan √ßimento fabrikalarńĪnda kullanńĪlmak √ľzere ilk ‚Äúd√∂ner fńĪrńĪn‚ÄĚ yapńĪlarak patent alńĪnmńĪŇütńĪr. 1890 yńĪlńĪnda √ßimento √ľretiminde al√ßńĪtaŇüńĪ kullanńĪlmaya baŇülanmńĪŇütńĪr. 1892 yńĪlńĪnda Almanya‚Äôda ve 1896 yńĪlńĪnda da ABD‚Äôde c√ľruflu √ßimento √ľretimine baŇülanmńĪŇütńĪr. 1898 yńĪlńĪnda bańülayńĪcńĪ malzemeler ve beton i√ßin temel deney y√∂ntemlerinin standartlaŇütńĪrńĪlmasńĪna da baŇülanńĪlmńĪŇütńĪr. 1865- 1900 YńĪllarńĪ www.betonvecimento.com

- 16. 16 1865- 1900 YńĪllarńĪ 1885 yńĪlńĪnda Earnest L. Ransom beton ve donatńĪ aderansńĪnńĪ artńĪrmak i√ßin kendi etrafńĪnda b√ľk√ľlm√ľŇü kare demir √ßubuk kullanmńĪŇütńĪr. 1887 yńĪlńĪnda FransńĪz Henri Le Chatelier portland √ßimentosu √ľretimi i√ßim oksit hesabńĪ geliŇütirmiŇütir. √áimento kimyasńĪnńĪ oluŇüturan temelleri atmńĪŇütńĪr. 1889 yńĪlńĪnda Gyozo Mihailich tarafńĪndan ilk betonarme k√∂pr√ľ Macaristan‚Äôda yapńĪlmńĪŇütńĪr. K√∂pr√ľ 5 metrelik iki a√ßńĪklńĪktan oluŇümaktadńĪr. 1890 yńĪlńĪndan Amerika‚Äôda √ßimento ve su arasńĪndaki reaksiyonda priz s√ľresini kontrol edebilmek i√ßin klinker ile birlikte al√ßńĪ beraber √∂ńü√ľt√ľlmeye baŇülanmńĪŇütńĪr. 1891 yńĪlńĪdan Amerika‚Äôda Ohio eyaletinde George Bartholomew tarafńĪndan ilk betonarme yol inŇüaa edilmiŇütir. Bu yol hala kullanńĪlmaktadńĪr. 1892 yńĪlńĪnda Francois Hennebique g√ľn√ľm√ľzde de kullanńĪlan betonarme sisteminin patentini almńĪŇütńĪr. Bu sayede bu tarihten itibaren betonarme yapńĪ inŇüaati d√ľnya √ßapńĪnda giderek artmńĪŇütńĪr. Beton Arme kelimesini ilk kullanandńĪr. 1897 yńĪlńĪnda Amerikan Ňüirketi Sears Holding kayńĪtlarńĪnda √ßimento ton fiyatńĪ yaklaŇüńĪk 10 $‚ÄôdńĪr. ńįthalat fiyatńĪ ise 17 $‚ÄôdńĪr. www.betonvecimento.com

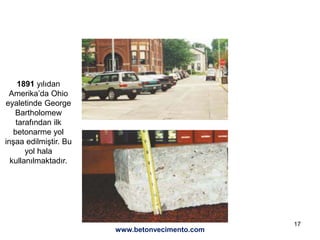

- 17. 17 www.betonvecimento.com 1891 yńĪlńĪdan Amerika‚Äôda Ohio eyaletinde George Bartholomew tarafńĪndan ilk betonarme yol inŇüaa edilmiŇütir. Bu yol hala kullanńĪlmaktadńĪr.

- 18. 18 1900- 1909 YńĪllarńĪ Bu yńĪllar arasńĪnda √ßimento √ľretimi ve betonarme ev yapńĪmńĪ konusunda Thomas Alva Edison‚Äôun √ßalńĪŇümalarńĪ olmuŇütur. 1908‚Äôde kendisine betonarme garaj yapan Edison, 1909 yńĪlńĪnda daha uzun bir d√∂ner fńĪrńĪn yaparak √ßimento kapasitesinin artmasńĪnńĪ sańülamńĪŇütńĪr. 1909 yńĪlńĪnda 11 adet betonarme ev yapmńĪŇü, bu giriŇüim ABD‚Äôde toplu konut yapńĪmńĪ i√ßin baŇülangńĪ√ß olmuŇütur. 1909‚Äôda da bu yapńĪlara uygun boya imal etmiŇütir. HazńĪr beton √ľretimi ilk kez 1903 yńĪlńĪnda Almanya‚Äôda baŇülamńĪŇü, J√ľrgen H. Margens bu anlamda patent almńĪŇütńĪr. www.betonvecimento.com

- 19. 19 1900- 1909 YńĪllarńĪ ńįlk betonarme g√∂kdelen amerika‚Äôda Ohio eyaletinde yapńĪlan Ingalls BinasńĪ‚ÄôdńĪr. Ransome betonarme teknińüi kullanńĪlmńĪŇütńĪr. AynńĪ yńĪl Sidney LimanńĪ‚Äônda ilk prekast beton elemanlar kullanńĪlmńĪŇütńĪr. 1907 yńĪlńĪnda J. H. Chubb tarafńĪndan ilk kez ¬ęg√∂r√ľn√ľr agrega y√ľzeyli beton¬Ľ uygulamasńĪ yapńĪlmńĪŇütńĪr. www.betonvecimento.com

- 20. 20 1911 √áimento teknolojisi T√ľrkiye'ye 50 yńĪl gecikme ile gelmiŇütir. T√ľrkiye'de ilk √ßimento fabrikasńĪ 1911 yńĪlńĪnda 20,000 ton/yńĪl kapasite ile ńįstanbul DarńĪca'da kurulmuŇütur. Cumhuriyetle birlikte √ľlkemizde yeni fabrikalar devreye girmiŇü, bir taraftan √ľretim artarken, dińüer taraftan artan √ßimento talebini karŇüńĪlamak √ľzere ithalat devam etmiŇütir. www.betonvecimento.com

- 21. 21 1911- 1920 YńĪllarńĪ 1911 yńĪlńĪnda ilk p√ľsk√ľrtme beton uygulamalarńĪ yapńĪlmaya baŇülanmńĪŇütńĪr. 1913 yńĪlńĪnda ilk beton pompasńĪ icat edilmiŇütir. 1914 yńĪlńĪnda ABD‚Äôli Stephen Stepanian hazńĪr betonun transmikser ile taŇüńĪnmasńĪna dair √ßalńĪŇümalarńĪna baŇülamńĪŇü, tasarladńĪńüńĪ transmikseri 1916 yńĪlńĪnda beton end√ľstrisine sunmuŇütur. 1918 yńĪlńĪnda ABD‚Äôli Duff A. Abrams, ‚Äúsu/√ßimento oranńĪ kanunu‚ÄĚ nu ortaya koymuŇütur. 1918 yńĪlńĪnda ilk buharlńĪ beton gemi Atlantus inŇüaa edilmiŇütir. AynńĪ yńĪl ayrńĪca beton kńĪvamńĪnńĪn tayininde ¬ę√ß√∂kme deney y√∂ntemi¬Ľ ilk kez uygulanmńĪŇütńĪr. www.betonvecimento.com

- 22. 22 1920- 1930 YńĪllarńĪ 1928 yńĪlńĪnda FransńĪz Eugene Freyssinet, y√ľksek dayanńĪmlńĪ √ßelik ve beton kullanarak √∂ngermeli beton yapńĪmńĪnńĪ geliŇütirmiŇütir. 1929 yńĪlńĪnda ńįsve√ßli Axel Eriksson, y√ľksek basńĪn√ßlńĪ buhar k√ľr√ľ uygulayarak ‚Äúgaz beton‚ÄĚ √ľretmiŇütir. 1930 yńĪlńĪnda hava s√ľr√ľkleyici katkńĪ kullanńĪlmaya baŇülanmńĪŇütńĪr. 1926 yńĪlńĪnda Ankara‚Äôda ikinci √ßimento fabrikasńĪ kuruldu. www.betonvecimento.com

- 23. 23 1930- 1950 YńĪllarńĪ 1930‚Äôlu yńĪllarńĪn baŇüńĪnda termik santrallerde kullanńĪlan pulverize k√∂m√ľr√ľ yan √ľr√ľn√ľ olan u√ßucu k√ľl√ľn puzolanik √∂zellikleri araŇütńĪrńĪlmńĪŇü ve 1937 yńĪlńĪnda bu malzeme beton yapńĪmńĪnda kullanńĪlmaya baŇülanmńĪŇütńĪr.1930‚Äôlu yńĪllarda yerine yerleŇütirilen taze betonun sńĪkńĪŇütńĪrńĪlmasńĪ iŇüleminde vibrasyon uygulanmasńĪna, 1933 yńĪlńĪnda betonun pompa g√ľc√ľ kullanńĪlarak taŇüńĪnmasńĪna, 1935 yńĪlńĪnda da bazńĪ betonlarńĪn donma- √ß√∂z√ľlme olaylarńĪnda dayanńĪklńĪlńĪńüńĪnńĪn i√ßerisine s√ľr√ľklenen hava kabarcńĪklarńĪna bańülńĪ olduńüunun anlaŇüńĪlmasńĪndan sonra beton yapńĪmńĪnda hava s√ľr√ľkleyici malzemelerin kullanńĪma baŇülanmńĪŇütńĪr. 1948 yńĪlńĪnda Ernst Schmidth ‚ÄúBeton √áekici‚ÄĚ adńĪnda, beton basńĪn√ß dayanńĪmńĪnńĪn hasarsńĪz bulunmasńĪnńĪ sańülayan bir alet geliŇütirmiŇütir. 1930'da Kartal ve Zeytinburnu'nda √ßimento fabrikalarńĪ kurulmuŇütur. Devlet ilk √ßimento fabrikasńĪnńĪ 1943 yńĪlńĪnda Sivas'ta a√ßmńĪŇütńĪr. www.betonvecimento.com

- 24. 24 1950- 1960 YńĪllarńĪ 1950‚Äôli yńĪllarda √∂ńü√ľt√ľlm√ľŇü gran√ľle y√ľksek fńĪrńĪn c√ľrufu beton yapńĪmńĪnda kullanńĪlmaya baŇülanmńĪŇütńĪr. Silis dumanńĪ ilk kez 1952 yńĪlńĪnda bir t√ľnel yapńĪmńĪnda, betonda katkńĪ malzemesi olarak kullanńĪlmńĪŇütńĪr. 1957 yńĪlńĪnda T√ľrkiye √áimento M√ľstahsilleri Birlińüi kurulmuŇütur. 1958 yńĪlńĪnda ABD‚Äôde genleŇüen √ßimento √ľretimi ger√ßekleŇütirilmiŇütir. 1950 yńĪlńĪnda kiŇüi baŇüńĪna √ßimento t√ľketimi 25 kg. olmuŇütur. 1950 yńĪlńĪndan sonra 23.10.1953'te T√ľrkiye √áimento Sanayii T.A.Ňě.'nin (√áńįSAN) kuruluŇüu ile hńĪzlńĪ bir geliŇüme d√∂nemi baŇülamńĪŇütńĪr.

- 26. 26 1824: Portland √áimentosu, ńįNGńįLTERE 1862: C√ľruflu √ßimento, ALMANYA 1901: Demir portland‚Äď1907 den sonra y√ľksek fńĪrńĪn- √ßimentosu, ALMANYA 1901: Sulfata dayanńĪklńĪ √ßimento, ALMANYA 1912: Erken Y√ľksek dayanńĪmlńĪ √ßimento, AVUSTURYA 1912: Ferrari √ßimentosu (Sulfata dayanńĪklńĪ √ßimento), ńįTALYA 1931: Beyaz √ßimento, ALMANYA 1955: Derin yapńĪ √ßimentosu, SOVYETLER BńįRLńįńěńį 1968: Regulated Set Cement (Jet cement), ABD 1970: Jet cement, JAPONYA www.betonvecimento.com

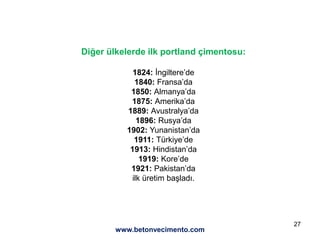

- 27. 27 Dińüer √ľlkelerde ilk portland √ßimentosu: 1824: ńįngiltere‚Äôde 1840: Fransa‚Äôda 1850: Almanya‚Äôda 1875: Amerika‚Äôda 1889: Avustralya‚Äôda 1896: Rusya‚Äôda 1902: Yunanistan‚Äôda 1911: T√ľrkiye‚Äôde 1913: Hindistan‚Äôda 1919: Kore‚Äôde 1921: Pakistan‚Äôda ilk √ľretim baŇüladńĪ. www.betonvecimento.com

- 28. 28 T√ľrkiye‚Äôde: 1906: Beyońülu/ńįstanbul‚Äôda bulunan Saint Antuan kilisesi T√ľrkiye‚Äôdeki ilk betonarme uygulamasńĪdńĪr. ńįstanbul dońüumlu ńįtalyan mimar Giulio MONGERI tarafńĪndan yapńĪlmńĪŇütńĪr. D√ľnyanńĪn da ilk betonarme kilisesi olduńüu sanńĪlmaktadńĪr. 1918: T√ľrkiye‚Äônin ilk √ßok katlńĪ betonarme yapńĪsńĪ L√Ęleli/ńįstanbul‚Äôdaki Crawne Plaza Otel binasńĪdńĪr. Mimar Kemalettin (Kemaleddin) Bey‚Äôin eseridir. 1918- 1922 arasńĪnda inŇüa edilmiŇütir, eski adńĪ Tayyare ApartmanlarńĪ idi. 4 adet olan bu Apartmanlar aynńĪ zamanda T√ľrkiye‚Äônin ilk toplu konutlarńĪdńĪr. 1924‚Äď1929 yńĪllarńĪ arasńĪnda inŇüa edilen, ńįzmir‚Äôin (eski) itfaiye binasńĪ Ňüehrin ilk betonarme yapńĪsńĪdńĪr. 1925 yńĪlńĪnda ilk betonarme k√∂pr√ľ Menderes nehri √ľzerinde inŇüa edildi . (?) Malatya belediye binasńĪ Ňüehrin ilk betonarme yapńĪsńĪdńĪr. 1939: ŇěanlńĪurfa KńĪz Meslek Lisesi Ňüehrin ilk betonarme binasńĪdńĪr. www.betonvecimento.com