Methanol plant

- 1. 1

- 3. Presentation index About Zagros petrochemical Introducing operational units Description the process of units Methanol applications and its market 3

- 4. . Zagros petrochemical co.  Start : 2000 (1379)  Location: Pars Special Economic Energy Zone  Area: 31 hectares  Start of production: 2006 Methanol 1.6 million tons per year (phase one)  Main Products: 1.6 million tons per year (phase two- 2008) 4

- 5.  Feed stock : natural gas from phases 1, 2 and 3 of the South Pars Gas Field  Utility Mobin co.  Licensor Lurgi co.  Tech Combined reforming  Purity 99.99 MeOH Ghadir Investment Co. (34%)  Shareholders: Alyaf Morvarid (18.8%) (Private equity) Pooshine Industrial (18.8%) and others … 5

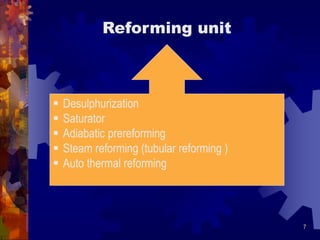

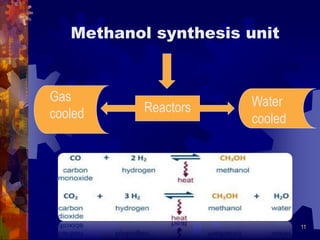

- 6. 1. Reforming unit 2. Steam and water distribution unit 3. Methanol synthesis unit 4. Hydrogen recovery unit 5. Distillation unit 6. Middle Storage tanks Unit 7. Pure methanol tanks unit 8. Water Treatment unit 9. Cooling water unit 10. Flare unit 11. Emergency electricity unit 12. Fire fighting water unit Introducing operational units 6

- 7. Reforming unit ÔÇß Desulphurization ÔÇß Saturator ÔÇß Adiabatic prereforming ÔÇß Steam reforming (tubular reforming ) ÔÇß Auto thermal reforming 7

- 8. ÔÇß Desulphurization: *since catalysts in the reforming section are extremely sensitive to Sulphur compounds. I. recycle hydrogen is added to the natural gas II. The natural gas feed is preheated in 2 exchanger III. Hydrogenation reactor conversion of organic Sulphur compounds to H2S Desulphurization reactor: H2S + ZnO ZnS + H2O 8

- 9. ÔÇß Saturator: saturation of natural gas with process condensate water ÔÇß Adiabatic pre reforming : ÔÇß Steam reforming : 9

- 10. Reactions: CH4 + H2O CO + 3H2 CO + H2O CO2 + H2 CH4 + CO2 2CO + 2H2O Auto thermal Reforming: ÔÉò Water flowing ÔÉò H.E 10

- 12. In end pfd of process 12

- 13. 13

- 14. 14