Microsoft word s13623-ds-scratch pad discolor-failure analysis report

- 1. FAILURE ANALYSIS REPORT FAILURE ANALYSIS REPORT CUSTOMER : DS DEVICE : NB Chip Checked®sVincent Wu Reported®sHarry Wang

- 2. FAILURE ANALYSIS REPORT Part 1 : Applicant Information Customer : DS Open date : 2012/07/10 Customer Ref. : S13623 Customer Part No. : NA Sales Thomas Hsiao Sample Qty : NA Device Type : NB Lot No. : NA Part No. : NA Lot Size : 57,938ea Date Code : NA Failure Rate : 5.8% Part 2 : 8D Report Content D1: ESTABLISH TEAMS Team Leader: Vincent Wu Members : SD/Thomas Hsiao, EPI/ Shay Wang, MFG/ Dylan Liu, QC/ Vincent Wu, FA/ Harry Wang D2: PROBLEM DESCRIPTION Defect PhenomenaŻ║ Scratch, Pad Discolor Ż║ Defect Occurred at Ż║ Ī÷ IQA Ī§ PQC Ī§ FQA Ī§ End User Customer DS found scratch, pad discolor issue in NB chips, and then intended to return 58K chips for rejecting. The rejected Tape lists are shown as below. D3: CONTAINMENT ACTIONS Tekcore will check the offered samples and find the root cause immediately. D4: ROOT CAUSE I. Pad Discolor : Due to customer had no provided the defective samples for further analyzing, so we check our warehouse products (NB) firstly.

- 3. FAILURE ANALYSIS REPORT 1. Through ICP etching process, the LED chip surface roughness will slightly different, which might affect the microscope by visual inspection, it will cause pad color differences. But this phenomenon wouldnĪ»t affect to LEDĪ» optical electrical characteristics. 2. Since TekcoreĪ» experience, if CCD (Charge Coupled Device) identification machines installed "Side Optical System", and trimmer machine parameter from the ring of light (Ring Light) with coaxial light (Coxial Light) can effectively improve the situation of chip identification.

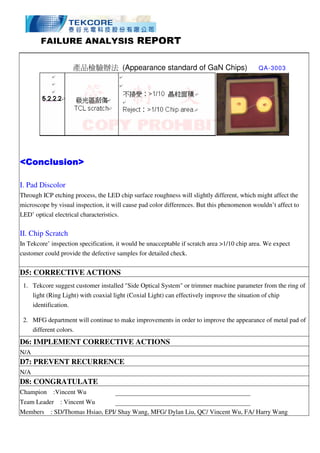

- 4. FAILURE ANALYSIS REPORT 3. Further, we took 3ea chip (picked from lead frame) to investigate in CCD identification machine, and trimmer machine parameter from ring (Ring Light) with coaxial light (Coxial Light). By the test results can be effective in improving the situation of chip identification. NB Chips Ring Light Intensity : 9% Coxial Light Intensity : 27% Ring Light Intensity : 34% Coxial Light Intensity : 33% II. Chip Scratch : In TekcoreĪ» inspection specification, it would be unacceptable if scratch area >1/10 chip area. We expect customer could provide the defective samples for detailed check.

- 5. FAILURE ANALYSIS REPORT «aŲĘÖz“×▐kĘ© (Appearance standard of GaN Chips) QA-3003 <Conclusion> I. Pad Discolor Through ICP etching process, the LED chip surface roughness will slightly different, which might affect the microscope by visual inspection, it will cause pad color differences. But this phenomenon wouldnĪ»t affect to LEDĪ» optical electrical characteristics. II. Chip Scratch In TekcoreĪ» inspection specification, it would be unacceptable if scratch area >1/10 chip area. We expect customer could provide the defective samples for detailed check. D5: CORRECTIVE ACTIONS 1. Tekcore suggest customer installed "Side Optical System" or trimmer machine parameter from the ring of light (Ring Light) with coaxial light (Coxial Light) can effectively improve the situation of chip identification. 2. MFG department will continue to make improvements in order to improve the appearance of metal pad of different colors. D6: IMPLEMENT CORRECTIVE ACTIONS N/A D7: PREVENT RECURRENCE N/A D8: CONGRATULATE Champion :Vincent Wu Team Leader : Vincent Wu Members : SD/Thomas Hsiao, EPI/ Shay Wang, MFG/ Dylan Liu, QC/ Vincent Wu, FA/ Harry Wang

- 6. FAILURE ANALYSIS REPORT Confirm and apply by customer ┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ) ┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ (┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ ┐═æ¶║×├¹ (Signature) : ╗ž║×╚šŲ┌ (Date) : CUSTOMER COMMENT (┐═æ¶ęŌęŖ ┐═æ¶ęŌęŖ) ┐═æ¶ęŌęŖ Ī§ ØMęŌ (Satisfaction) Ī§ ø]ėąęŌęŖ (No Comment) Ī§ ▓╗ØMęŌ (Dissatisfaction) ▓╗ØMęŌ└Ēė╔╝░ęŌęŖ(Dissatisfaction Reason and Suggestion)Ż║ šłņČ╩šĄĮ┤╦Ę▌ F.A. report ßß 7 ╚šā╚╗žĖ▓ęŌęŖŻ¼╚¶│¼▀^ 7 ╚š╬┤╗žĖ▓īóęĢ═¼─·═¼ęŌ ┤╦Ę▌ F.A. report ĮYšōĪŻ (Please reply this failure analysis report within 7 days, if no response more than 7 days we will deem that you agree the conclusion of failure analysis report.)

![FAILURE ANALYSIS REPORT

Confirm and apply by customer ┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ)

┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ

(┐═æ¶╗žĖ▓┤_šJ╝░ęŌęŖ

┐═æ¶║×├¹ (Signature) :

╗ž║×╚šŲ┌ (Date) :

CUSTOMER COMMENT (┐═æ¶ęŌęŖ ┐═æ¶ęŌęŖ)

┐═æ¶ęŌęŖ

Ī§ ØMęŌ (Satisfaction) Ī§ ø]ėąęŌęŖ (No Comment)

Ī§ ▓╗ØMęŌ (Dissatisfaction)

▓╗ØMęŌ└Ēė╔╝░ęŌęŖ(Dissatisfaction Reason and Suggestion)Ż║

šłņČ╩šĄĮ┤╦Ę▌ F.A. report ßß 7 ╚šā╚╗žĖ▓ęŌęŖŻ¼╚¶│¼▀^ 7 ╚š╬┤╗žĖ▓īóęĢ═¼─·═¼ęŌ

┤╦Ę▌ F.A. report ĮYšōĪŻ

(Please reply this failure analysis report within 7 days, if no response more than 7

days we will deem that you agree the conclusion of failure analysis report.)](https://image.slidesharecdn.com/microsoftword-s13623-ds-scratchpaddiscolor-failureanalysisreport-120716202253-phpapp02/85/Microsoft-word-s13623-ds-scratch-pad-discolor-failure-analysis-report-6-320.jpg)