Milling cutting data_calculator_2012 (1)

1 like10,322 views

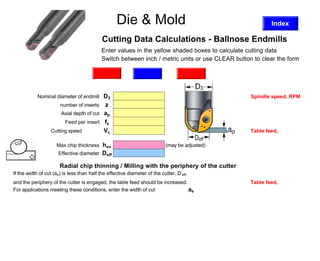

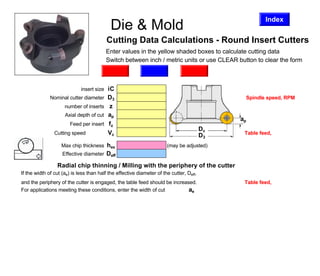

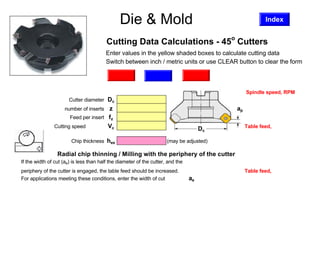

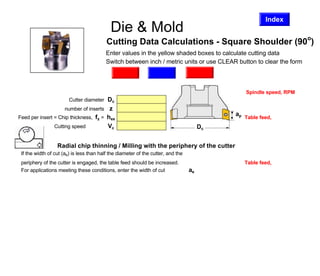

Acrobat Reader 4 is required to use the calculator tool on this document for cutting data calculations for various milling operations like ballnose end mills, round insert cutters, 45 degree facemills, and square shoulder milling. The document provides input fields for parameters like cutter diameter, spindle speed, feed rate, and depth of cut and performs calculations for optimal values.

1 of 5

Downloaded 18 times

Ad

Recommended

Week 1 mill 1

Week 1 mill 1Zaza Eureka

╠²

The document discusses milling processes and provides details about various milling techniques. It defines milling, describes up and down milling methods, and covers topics such as milling machines, cutters, operations, and factors that influence tool life. Examples of peripheral and face milling are illustrated.Cutting tools

Cutting toolsUniversity of engineering and technology taxila

╠²

The document provides an extensive overview of machining fundamentals, including types, operations, tool mechanics, and cutting conditions. It covers concepts such as chip removal, machining processes like turning, drilling, and milling, and highlights advantages and disadvantages of machining. Additionally, it details the theory of chip formation, cutting forces, power requirements, and methods to measure cutting temperatures in machining operations.Tool wear and tool Life

Tool wear and tool LifeDr. Bolleddu Venkateshwarlu

╠²

The document provides information about tool wear and tool life in machining processes. It discusses how tool wear occurs due to forces, temperature, and sliding action during cutting. The three main types of tool wear are flank wear, crater wear, and chipping. Flank wear is caused by abrasion from hard particles in the workpiece while crater wear results from high temperatures and diffusion at the tool-chip interface. Maintaining optimal cutting conditions and tool geometry can increase tool life. The document also covers tool materials, machinability factors, cutting fluids, machining forces, and lathe operations such as turning, facing, and threading.Theory of Metal Cutting

Theory of Metal CuttingKunduru Srinivasulu Reddy

╠²

The document discusses machining processes and cutting tools. It provides definitions of machining and cutting tools. It describes:

- The importance of machining processes in manufacturing precise parts.

- Objectives of machining like high material removal rate and surface finish, low tool and power costs.

- Classification of cutting tools based on how relative motion is provided between tool and workpiece.

- Key terms related to cutting tool geometry like rake angle, relief angle, and their influence on tool strength and chip removal.

- Mechanism of chip formation and different types of chips produced.Merchants circle-diagram

Merchants circle-diagramcpandiv

╠²

The document discusses cutting tool materials and Merchant's Circle Diagram (MCD) for calculating forces in machining. It provides information on 7 common cutting tool materials: high carbon steel, high speed steel, cast alloys, cemented carbides, coated carbides, ceramics, and diamonds. It also explains what MCD is and how it can be used graphically to calculate cutting, tangential, friction, normal, shear and normal shear forces from measured cutting forces. An example calculation using MCD is provided.Machining Process

Machining Process *noT yeT workinG! !M stilL studyinG*

╠²

This document discusses various machining processes used to produce complex shapes beyond simple round profiles. It describes milling operations like face milling and slab milling. Milling can produce parts with intricate shapes efficiently using computer numerical control (CNC) machines. Other shaping processes covered include broaching, sawing, and gear cutting. Broaching is well-suited for producing internal and external spline and gear teeth. Gears can be generated through hobbing, shaping, or fine-finished through grinding. The document explores the different machining methods, tools, and economics of producing complex geometries.Ipec manu scunit1

Ipec manu scunit1Manoj Yadav

╠²

1. The document discusses the theory of metal cutting, including the chip formation process, types of chips, tool angles, tool wear mechanisms, tool materials, and cutting fluids.

2. Key aspects covered include the orthogonal cutting model, factors that influence chip type like tool angles and speeds/feeds, how tool angles impact forces and tool life, and common tool materials like HSS and cemented carbides and their characteristics.

3. Cutting fluids are discussed as being important to reduce heat at the tool-work interface and lubricate the process to increase tool life and improve surface finish. Their properties and common types used are also summarized.Geometry of Milling cutter's and Twist drills

Geometry of Milling cutter's and Twist drillsN.I.T.T.T.R Chandigarh, Ministry of HRD, Govt. of India

╠²

This document discusses the geometry of plain milling cutters and twist drills. It describes the key features of milling cutters such as radial rake angle, radial relief angle, land, and lip angle. It also explains different types of milling operations including up milling, down milling, string milling, and gang milling. For twist drills, it outlines the drill point, twist drill nomenclature, and recommended drill geometries for different materials. Equations are provided for estimating drilling forces based on drill diameter and feed rate.Milling machines

Milling machinesAvinash Navin

╠²

This document discusses milling machines and their components and operations. It defines milling as a machining process that uses a rotating multi-tooth cutter to remove material from a workpiece as it travels along different axes relative to the workpiece. It describes the different types of milling machines, milling parameters such as cutting speed and feed, common milling operations including peripheral, face and end milling, and components like the worktable, saddle, knee, and head.Unit 1 Metal Cutting

Unit 1 Metal CuttingMechbytes

╠²

The document provides an overview of machining and metal cutting processes, detailing various methods of metal removal, including traditional and nontraditional techniques. It explains the importance of tool geometry, cutting parameters, and the mechanisms involved in chip formation, while highlighting the advantages and disadvantages of machining. Additionally, it classifies different cutting tools and their applications, as well as the significance of tool angles in improving machining efficiency and product quality.Milling

MillingAbdullah Dhaiban

╠²

The document discusses milling, which is a machining process that uses a rotating cutting tool to remove material from a workpiece. It describes different types of milling machines like column and knee machines, planer machines, and special machines. It also covers milling methods, cutter types, indexing heads, and thread milling. The main types of milling machines are column and knee machines, which can be horizontal, universal, or vertical, and planer machines, which are heavy-duty machines suited for production work.Single point cutting tool

Single point cutting toolsamayadtime

╠²

This document provides an overview of metal cutting processes on a center lathe. It discusses [1] the basic components and operation of a center lathe, [2] the types of single-point cutting tools used, [3] the theory behind metal cutting, and [4] important factors that influence tool life and cutting performance such as tool angles, cutting speed, feed, and use of cutting fluids. Safety procedures are also emphasized.Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECH

Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECHnaanmech123

╠²

This document provides information about milling machines and milling operations. It describes the major parts and differences between horizontal and vertical milling machines. Various milling operations like face milling, end milling and slot milling are explained along with principles of up and down milling. Different types of milling cutters are classified and their applications discussed. Specifications of milling machines like worktable size, movements in X, Y and Z directions and motor power are also covered.Milling machine.pptx

Milling machine.pptxAliRaza1767

╠²

Milling machines are versatile machines used for cutting metal. There are two main types - horizontal and vertical milling machines, distinguished by the orientation of the spindle. Milling machines can cut flat surfaces and irregular shapes using tools like end mills and face mills. They are widely used in manufacturing for machining parts and are capable of complex operations like gear cutting. The key parameters for milling are spindle speed, feed rate, depth of cut, and cutter rotation direction which must be optimized for efficient material removal.Lecture2 (1)

Lecture2 (1)Self Employed

╠²

The document provides an overview of machining technology. It discusses the theory of chip formation in metal machining, including the forces involved and the Merchant equation. It also covers power and energy relationships as well as cutting temperatures in machining processes. The key machining operations of turning, drilling, and milling are explained along with tooling and parameters like cutting speed, feed rate, and depth of cut.Milling and gear generation

Milling and gear generationDr. Bolleddu Venkateshwarlu

╠²

The document provides information on milling machines and gear generation. It discusses the different types of milling machines, milling processes like up and down milling, and milling cutters. The various milling operations like plain milling, face milling and gear cutting are explained. Indexing is described as the process of dividing the workpiece into equal parts and different indexing methods like simple indexing are covered. Gear types, gear forming, and mechanisms used for indexing like worm and worm gear are also summarized.Lecture 3 theory of metal cutting

Lecture 3 theory of metal cuttingVJTI Production

╠²

The document discusses theories of metal machining and chip formation. It describes how early theories like the theory of tear and theory of compression were later disproven. The generally accepted theory today is the theory of shear, which proposes that metal cutting occurs through shear along a plane at an angle to the cutting direction. The document also outlines the difficulties in studying metal cutting processes and how orthogonal cutting experiments were developed to simplify the analysis.Unit1

Unit1naanmech123

╠²

This document discusses the theory and mechanics of metal cutting. It begins by defining metal cutting as removing unwanted material from a workpiece through cutting, abrasion, or non-traditional processes. It then covers the basics of orthogonal and oblique metal cutting, tool geometry including rake and relief angles, and different types of chips that can form. The document also discusses important considerations for metal cutting like cutting speed, feed rate, depth of cut, and tool materials commonly used including high-speed steel, cemented carbides, and ceramics.Pp mills

Pp millsMaxy2001

╠²

Milling machines use rotating cutters to produce flat surfaces on workpieces. Operators must take safety precautions when using milling machines due to the rotating cutters. Milling machines come in vertical and horizontal styles. Workholding devices like vices and dividing heads are used to securely hold and position workpieces for milling. Cutters must be properly mounted and the correct feed rate applied based on the work material and cutter type. A variety of techniques can be used to position the cutter accurately for the initial cut. Milling operations include drilling, boring, cutting steps and slots. Workpieces should be checked during and after milling to ensure quality.Ch 7 milling

Ch 7 millingNandan Choudhary

╠²

Milling is a machining process that uses a rotating cutting tool called a milling cutter to remove material from a workpiece. Milling cutters come in various types for different purposes like flat surfaces, slots, threads, gears, etc. There are two types of milling: up milling where the cutter moves against the workpiece feed and down milling where they move together. Down milling provides better surface finish and tool life. Milling machines are classified based on their purpose, configuration, orientation, and level of automation. Milling cutters are also classified based on their geometry and how they machine specific features. Key parameters like cutting speed, feed rate, and depth of cut determine the material removal rateMilling cutter

Milling cutterAlbert Candor

╠²

Milling cutters are cutting tools used to remove material from workpieces in milling machines. They have cutting edges and flutes to remove chips of material. Common milling cutter types include end mills, face mills, and inserted tooth cutters. Milling cutters come in various geometries and are made of materials like high-speed steel or carbide depending on the application. Cutting parameters like spindle speed, feed rate, depth of cut, and surface cutting speed determine how efficiently a milling cutter removes material from a workpiece.Machine tools

Machine toolsUbaid Shah

╠²

The document provides a comprehensive overview of machine tools, categorizing them based on various criteria such as axis direction, purpose, automation level, size, precision, spindle count, and automation type. It discusses specific types of machines, including lathes, shapers, and drilling machines, along with the basic operations performed on each type. Additionally, the document details the grinding process, types of grinding wheels, and the various grinding machines, along with their specifications and uses.Ipec milling

Ipec millingManoj Yadav

╠²

The document discusses milling machine processes and operations. It describes how milling works by progressively removing material from a workpiece as it is fed into a rotating cutting tool. Milling can be used for high material removal rates and is well-suited for mass production. There are different types of milling cutters and milling operations depending on the shape and direction of material removal, such as peripheral milling and face milling. The document also covers milling machine classifications, components, workholding devices, and dividing heads used for indexing parts.Lecture 1 metal cutting and machine tools unit i

Lecture 1 metal cutting and machine tools unit iSerajul Haque

╠²

The document discusses the objectives and modules of a course on metal cutting and machine tools. The objectives include studying material removal processes, learning about lathes, milling machines, drilling, broaching, and gear cutting, and gaining knowledge of CNC machine tools and advanced machining methods. The modules cover theory of metal cutting, lathes, reciprocating machines, milling, drilling/broaching/gear cutting, finishing processes, and CNC/modern machining. Key aspects of metal cutting discussed are the geometry of single point cutting tools, chip formation, forces, tool wear, and cutting fluids.Theory of metal cutting

Theory of metal cuttingSahebrao Deshmukh

╠²

This document discusses the theory of metal cutting. It covers topics such as tool geometry, chip formation, types of chips, tool wear, cutting fluids, and tool material selection. It describes the two main types of metal cutting processes as orthogonal and oblique cutting. Orthogonal cutting involves two forces while oblique cutting involves three forces. Chip formation occurs through shear deformation of the work material. The main types of chips are continuous, discontinuous, continuous with BUE, and serrated. Continuous chips form under conditions like small chip thickness and high cutting speed, while discontinuous chips occur when machining brittle materials.Machining Processes and Metrology

Machining Processes and MetrologyDr. Bolleddu Venkateshwarlu

╠²

This document provides information about the Machining Processes and Metrology course taught by Dr. B. Venkateshwarlu at VIT University. The course covers topics related to mechanics of metal cutting including chip formation, cutting forces, tool materials, and tool wear. Evaluation will include assignments, tests, seminars, and projects. The first module focuses on metal cutting processes and mechanics including types of chips, chip formation mechanisms, orthogonal and oblique cutting, and machining forces.Milling Machine

Milling MachineDhyey Shukla

╠²

This document discusses the vertical milling machine. It begins by listing the objectives of describing the main parts of a ram-type vertical milling machine and explaining how to select cutting speeds, feeds, and depth of cut. It then explains the parts of a ram-type vertical milling machine and how to align the vertical head and vise. The document provides information on various milling operations and cutter types including end mills. It concludes by outlining the procedure for accurately machining a block square and parallel and drilling holes to location using a vertical milling machine.Knee and column milling machines

Knee and column milling machinesGokulanand Padhmanabhan

╠²

This document summarizes different types of milling machines and milling processes. It discusses column and knee milling machines, which are commonly used for small shop work. It also describes different milling processes like peripheral milling, up milling, down milling, and face milling. Key factors that influence these milling processes like cutter geometry, lead angle, and rake angle are explained. Guidelines for milling operations to minimize vibrations and ensure rigidity are also provided.Cutters

Cuttersangelochintu

╠²

This document provides specifications for various types of milling cutters, including:

1) Cylindrical milling cutters for flat surface milling with various diameters and lengths.

2) High power cylindrical cutters for heavy cuts with larger diameters and lengths.

3) Helical cylindrical cutters for heavy surfacing with various diameters, lengths, and helix angles.

4) Straight and staggered tooth side and face cutters for milling slots and surfaces with various diameters, widths, and tooth configurations.CS Unitec Beveling Machine

CS Unitec Beveling MachineCS Unitec

╠²

The EKF multi-purpose beveling machine efficiently bevels, deburrs, and chamfers edges of various materials including steel and plastics at angles of 30┬░ and 45┬░. It is equipped with three milling head options and a fine adjustment feature for precise control, making it ideal for applications in moldmaking, boiler construction, and mechanical engineering. The machine is portable, with specifications including a motor power of 13.5 amps and cutting speed of 3000 sfpm.More Related Content

What's hot (20)

Milling machines

Milling machinesAvinash Navin

╠²

This document discusses milling machines and their components and operations. It defines milling as a machining process that uses a rotating multi-tooth cutter to remove material from a workpiece as it travels along different axes relative to the workpiece. It describes the different types of milling machines, milling parameters such as cutting speed and feed, common milling operations including peripheral, face and end milling, and components like the worktable, saddle, knee, and head.Unit 1 Metal Cutting

Unit 1 Metal CuttingMechbytes

╠²

The document provides an overview of machining and metal cutting processes, detailing various methods of metal removal, including traditional and nontraditional techniques. It explains the importance of tool geometry, cutting parameters, and the mechanisms involved in chip formation, while highlighting the advantages and disadvantages of machining. Additionally, it classifies different cutting tools and their applications, as well as the significance of tool angles in improving machining efficiency and product quality.Milling

MillingAbdullah Dhaiban

╠²

The document discusses milling, which is a machining process that uses a rotating cutting tool to remove material from a workpiece. It describes different types of milling machines like column and knee machines, planer machines, and special machines. It also covers milling methods, cutter types, indexing heads, and thread milling. The main types of milling machines are column and knee machines, which can be horizontal, universal, or vertical, and planer machines, which are heavy-duty machines suited for production work.Single point cutting tool

Single point cutting toolsamayadtime

╠²

This document provides an overview of metal cutting processes on a center lathe. It discusses [1] the basic components and operation of a center lathe, [2] the types of single-point cutting tools used, [3] the theory behind metal cutting, and [4] important factors that influence tool life and cutting performance such as tool angles, cutting speed, feed, and use of cutting fluids. Safety procedures are also emphasized.Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECH

Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECHnaanmech123

╠²

This document provides information about milling machines and milling operations. It describes the major parts and differences between horizontal and vertical milling machines. Various milling operations like face milling, end milling and slot milling are explained along with principles of up and down milling. Different types of milling cutters are classified and their applications discussed. Specifications of milling machines like worktable size, movements in X, Y and Z directions and motor power are also covered.Milling machine.pptx

Milling machine.pptxAliRaza1767

╠²

Milling machines are versatile machines used for cutting metal. There are two main types - horizontal and vertical milling machines, distinguished by the orientation of the spindle. Milling machines can cut flat surfaces and irregular shapes using tools like end mills and face mills. They are widely used in manufacturing for machining parts and are capable of complex operations like gear cutting. The key parameters for milling are spindle speed, feed rate, depth of cut, and cutter rotation direction which must be optimized for efficient material removal.Lecture2 (1)

Lecture2 (1)Self Employed

╠²

The document provides an overview of machining technology. It discusses the theory of chip formation in metal machining, including the forces involved and the Merchant equation. It also covers power and energy relationships as well as cutting temperatures in machining processes. The key machining operations of turning, drilling, and milling are explained along with tooling and parameters like cutting speed, feed rate, and depth of cut.Milling and gear generation

Milling and gear generationDr. Bolleddu Venkateshwarlu

╠²

The document provides information on milling machines and gear generation. It discusses the different types of milling machines, milling processes like up and down milling, and milling cutters. The various milling operations like plain milling, face milling and gear cutting are explained. Indexing is described as the process of dividing the workpiece into equal parts and different indexing methods like simple indexing are covered. Gear types, gear forming, and mechanisms used for indexing like worm and worm gear are also summarized.Lecture 3 theory of metal cutting

Lecture 3 theory of metal cuttingVJTI Production

╠²

The document discusses theories of metal machining and chip formation. It describes how early theories like the theory of tear and theory of compression were later disproven. The generally accepted theory today is the theory of shear, which proposes that metal cutting occurs through shear along a plane at an angle to the cutting direction. The document also outlines the difficulties in studying metal cutting processes and how orthogonal cutting experiments were developed to simplify the analysis.Unit1

Unit1naanmech123

╠²

This document discusses the theory and mechanics of metal cutting. It begins by defining metal cutting as removing unwanted material from a workpiece through cutting, abrasion, or non-traditional processes. It then covers the basics of orthogonal and oblique metal cutting, tool geometry including rake and relief angles, and different types of chips that can form. The document also discusses important considerations for metal cutting like cutting speed, feed rate, depth of cut, and tool materials commonly used including high-speed steel, cemented carbides, and ceramics.Pp mills

Pp millsMaxy2001

╠²

Milling machines use rotating cutters to produce flat surfaces on workpieces. Operators must take safety precautions when using milling machines due to the rotating cutters. Milling machines come in vertical and horizontal styles. Workholding devices like vices and dividing heads are used to securely hold and position workpieces for milling. Cutters must be properly mounted and the correct feed rate applied based on the work material and cutter type. A variety of techniques can be used to position the cutter accurately for the initial cut. Milling operations include drilling, boring, cutting steps and slots. Workpieces should be checked during and after milling to ensure quality.Ch 7 milling

Ch 7 millingNandan Choudhary

╠²

Milling is a machining process that uses a rotating cutting tool called a milling cutter to remove material from a workpiece. Milling cutters come in various types for different purposes like flat surfaces, slots, threads, gears, etc. There are two types of milling: up milling where the cutter moves against the workpiece feed and down milling where they move together. Down milling provides better surface finish and tool life. Milling machines are classified based on their purpose, configuration, orientation, and level of automation. Milling cutters are also classified based on their geometry and how they machine specific features. Key parameters like cutting speed, feed rate, and depth of cut determine the material removal rateMilling cutter

Milling cutterAlbert Candor

╠²

Milling cutters are cutting tools used to remove material from workpieces in milling machines. They have cutting edges and flutes to remove chips of material. Common milling cutter types include end mills, face mills, and inserted tooth cutters. Milling cutters come in various geometries and are made of materials like high-speed steel or carbide depending on the application. Cutting parameters like spindle speed, feed rate, depth of cut, and surface cutting speed determine how efficiently a milling cutter removes material from a workpiece.Machine tools

Machine toolsUbaid Shah

╠²

The document provides a comprehensive overview of machine tools, categorizing them based on various criteria such as axis direction, purpose, automation level, size, precision, spindle count, and automation type. It discusses specific types of machines, including lathes, shapers, and drilling machines, along with the basic operations performed on each type. Additionally, the document details the grinding process, types of grinding wheels, and the various grinding machines, along with their specifications and uses.Ipec milling

Ipec millingManoj Yadav

╠²

The document discusses milling machine processes and operations. It describes how milling works by progressively removing material from a workpiece as it is fed into a rotating cutting tool. Milling can be used for high material removal rates and is well-suited for mass production. There are different types of milling cutters and milling operations depending on the shape and direction of material removal, such as peripheral milling and face milling. The document also covers milling machine classifications, components, workholding devices, and dividing heads used for indexing parts.Lecture 1 metal cutting and machine tools unit i

Lecture 1 metal cutting and machine tools unit iSerajul Haque

╠²

The document discusses the objectives and modules of a course on metal cutting and machine tools. The objectives include studying material removal processes, learning about lathes, milling machines, drilling, broaching, and gear cutting, and gaining knowledge of CNC machine tools and advanced machining methods. The modules cover theory of metal cutting, lathes, reciprocating machines, milling, drilling/broaching/gear cutting, finishing processes, and CNC/modern machining. Key aspects of metal cutting discussed are the geometry of single point cutting tools, chip formation, forces, tool wear, and cutting fluids.Theory of metal cutting

Theory of metal cuttingSahebrao Deshmukh

╠²

This document discusses the theory of metal cutting. It covers topics such as tool geometry, chip formation, types of chips, tool wear, cutting fluids, and tool material selection. It describes the two main types of metal cutting processes as orthogonal and oblique cutting. Orthogonal cutting involves two forces while oblique cutting involves three forces. Chip formation occurs through shear deformation of the work material. The main types of chips are continuous, discontinuous, continuous with BUE, and serrated. Continuous chips form under conditions like small chip thickness and high cutting speed, while discontinuous chips occur when machining brittle materials.Machining Processes and Metrology

Machining Processes and MetrologyDr. Bolleddu Venkateshwarlu

╠²

This document provides information about the Machining Processes and Metrology course taught by Dr. B. Venkateshwarlu at VIT University. The course covers topics related to mechanics of metal cutting including chip formation, cutting forces, tool materials, and tool wear. Evaluation will include assignments, tests, seminars, and projects. The first module focuses on metal cutting processes and mechanics including types of chips, chip formation mechanisms, orthogonal and oblique cutting, and machining forces.Milling Machine

Milling MachineDhyey Shukla

╠²

This document discusses the vertical milling machine. It begins by listing the objectives of describing the main parts of a ram-type vertical milling machine and explaining how to select cutting speeds, feeds, and depth of cut. It then explains the parts of a ram-type vertical milling machine and how to align the vertical head and vise. The document provides information on various milling operations and cutter types including end mills. It concludes by outlining the procedure for accurately machining a block square and parallel and drilling holes to location using a vertical milling machine.Knee and column milling machines

Knee and column milling machinesGokulanand Padhmanabhan

╠²

This document summarizes different types of milling machines and milling processes. It discusses column and knee milling machines, which are commonly used for small shop work. It also describes different milling processes like peripheral milling, up milling, down milling, and face milling. Key factors that influence these milling processes like cutter geometry, lead angle, and rake angle are explained. Guidelines for milling operations to minimize vibrations and ensure rigidity are also provided.Similar to Milling cutting data_calculator_2012 (1) (20)

Cutters

Cuttersangelochintu

╠²

This document provides specifications for various types of milling cutters, including:

1) Cylindrical milling cutters for flat surface milling with various diameters and lengths.

2) High power cylindrical cutters for heavy cuts with larger diameters and lengths.

3) Helical cylindrical cutters for heavy surfacing with various diameters, lengths, and helix angles.

4) Straight and staggered tooth side and face cutters for milling slots and surfaces with various diameters, widths, and tooth configurations.CS Unitec Beveling Machine

CS Unitec Beveling MachineCS Unitec

╠²

The EKF multi-purpose beveling machine efficiently bevels, deburrs, and chamfers edges of various materials including steel and plastics at angles of 30┬░ and 45┬░. It is equipped with three milling head options and a fine adjustment feature for precise control, making it ideal for applications in moldmaking, boiler construction, and mechanical engineering. The machine is portable, with specifications including a motor power of 13.5 amps and cutting speed of 3000 sfpm.CS Unitec Annular Cutters Catalog

CS Unitec Annular Cutters CatalogCS Unitec

╠²

Annular cutters can drill burr-free holes faster than twist drills without predrilling or stepdrilling. They have precision-ground flutes for efficient chip clearance. The document describes the benefits of annular cutters made by CS Unitec, including their double-action tooth geometry that cuts, splits, and ejects chips efficiently. It provides details on their high-speed steel and armor-plated models, such as available sizes and specifications.Catlogue

Catloguesachindesai055

╠²

This document provides technical specifications for three machine tools:

1. A centering and plunge facing machine with capabilities up to 1000/1500/2000mm job length, 60mm facing diameter, and 9.2HP total power.

2. A face milling and centering machine with capabilities up to 1000/1500/2000/2500mm job length, 160mm facing diameter, and 17.2HP total power.

3. A vertical pull type broaching machine with pulling capacities up to 3000/6000/9000kg, broach slide strokes up to 600/900/1200/1500mm, and total power up to 10.5/15.5/20.5HP.6 threadmilling

6 threadmillingVJTI Production

╠²

1. Thread milling is a method of producing threads using a milling cutter that can move in helical paths to cut threads.

2. Selecting the proper thread milling cutter for the application from the product selector will provide cutting data and an optimized CNC program.

3. Thread milling offers advantages over conventional threading like smaller chips, tolerance adjustments via calculations, longer tool life, and suitability for most materials.Hand tools

Hand toolsVladislav Vatamaniuc

╠²

This document summarizes various hand tools from Moore & Wright Engineers including engineers squares, sliding T-squares, precision engineers squares, and calipers. The squares are made from hardened steel or stainless steel and have precise tolerances. The calipers come in spring joint or firm joint styles and various sizes, with leg lengths ranging from 125mm to 150mm.non traditional machining

non traditional machiningKhalid Sheikh

╠²

This document summarizes key concepts in traditional machining processes. It discusses chip formation, types of chips, tool geometry including rake angle, tool wear, cutting parameters such as depth of cut and step over distance, recommended feeds and speeds, factors that affect machinability, and power and force calculations. Examples are provided to demonstrate how to estimate cutting speeds, feeds, and power requirements for different machining operations and materials.Wt5912 2012 u2-w3

Wt5912 2012 u2-w3JOE LYSTER

╠²

This document provides information about machine anatomy and construction, specifically regarding surface planers, thicknessers, and rip/panel saws. It discusses the parts, design, functions, processes, safety, use, and maintenance of these machines. The sections cover topics like cutter block design, knife geometry, chip formation, risk assessment, and blade configurations. The goal is to educate students about the components and operation of various woodworking machinery.ES Trim Winder

ES Trim WinderEURO SERVICE A/S

╠²

The ES Trim Winder is a versatile and portable machine designed for winding various trim materials such as PE, PVC, and textiles. It features adjustable speed and tension, quick roll removal, and a strong industrial build suitable for core and core-less applications. Technical specifications vary across models, accommodating different winding requirements, and options for customization are available.Technical a milling circular

Technical a milling circularFortinoHiplitoAstudi

╠²

This document discusses circular milling techniques. It provides information on:

1. Approaching and leaving contours in a circular motion to avoid dwell marks and achieve better circularity.

2. How the feed rate at the cutting edge is higher than the feed rate at the center of the tool for circular milling.

3. Factors that determine the maximum plunge angle for circular milling, including tool diameter and type of insert used.ANALYSES OF CHIPS FORMED IN PLANO MILLER AND HORIZONTAL BORING MACHINES .

ANALYSES OF CHIPS FORMED IN PLANO MILLER AND HORIZONTAL BORING MACHINES .Suraj Patwal

╠²

The document analyzes chips formed in plano millers and boring machines, detailing specifications such as table sizes, spindle RPMs, and lead angles for different machines. It discusses the effects of cutter diameter and depth of cut on chip formation, tool life, and the importance of using appropriate cutting techniques and fluids. The observations highlight the relationship between feed rate, depth of cut, and chip characteristics, emphasizing the risks of excessive vibrations and heat generation in milling processes.9902200016 wnt catalogue 2016 06 circular and thread milling

9902200016 wnt catalogue 2016 06 circular and thread millingAbel Ferreira de Brito

╠²

This document provides information on various types of drilling, threading, turning, and milling tools including:

1) HSS and solid carbide drilling, tapping, threading, turning, and milling cutters.

2) Milling cutters with indexable carbide inserts for circular milling, threading, and other operations.

3) Details on toolholders, materials examples, cutting data, and an article number index for selecting the appropriate tool.Me2258 lm

Me2258 lmSamuel Christy

╠²

1) The document provides instructions for completing various machining exercises using different machines like the lathe, milling machine, drilling machine, shaping machine, and capstan lathe.

2) The exercises include measuring shear angle, machining internal keyways, surface grinding, assembling bolts and nuts, assembling dies and punches, assembling flange couplings, and machining spur gears and hexagons.

3) Detailed procedures are provided for setting up and operating the machines to machine workpieces to the required dimensions, including calculating necessary values, marking dimensions, fixing and securing workpieces, and checking final results.Torno A20 vii

Torno A20 viiammeee

╠²

This document summarizes a cost effective CNC automatic lathe for complex machining. The A20 Type VII model contains 5 axes, 4 rotary tools, and a sub-spindle for exceptional productivity. It features streamlined control for fast, smooth movements to reduce cycle times. The machine provides user friendly operation with a pivoting panel and large capacity coolant tank.CS Unitec P1 Portable Magnetic Drills

CS Unitec P1 Portable Magnetic DrillsCS Unitec

╠²

This document provides information about the P1 portable magnetic drill. It can drill holes up to 1-3/8 inches in diameter using annular cutters or twist drills. The drill features a 10 amp motor, weighs 26.5 pounds, and has a 4 inch stroke length. It comes equipped with safety features and accessories like a carrying case, lubrication pump, and safety strap. Optional accessories allow it to function as a standard drill press as well.Seminario Vibrazioni in Lavorazione

Seminario Vibrazioni in LavorazioneMarco Leonesio

╠²

Integrated analysis of machine tools and cutting processes from research to market. The document discusses (1) machine tool specifications for heavy machining, (2) objectives of virtual prototyping machine tools, and (3) an integrated modeling approach that combines structure, control, and cutting process modeling. Ongoing research aims to refine models of chatter stability, process damping, and grinding processes to improve virtual prototyping predictions and enable more efficient design of high-performance machine tools.App145 en inspection-adhesive-beading-termination-strip

App145 en inspection-adhesive-beading-termination-stripISATECK

╠²

The document describes using a scanCONTROL 2810 laser profile sensor to inspect the application of adhesive beading on termination strips in vehicle manufacturing. The sensor measures the height, width, and position of the adhesive relative to the strip to ensure dimensional requirements are met. It analyzes the profile directly in the controller and provides output if tolerances are exceeded. The complete independent system allows for high-speed inspection of the critical stripping process.TE-DM57A-8H8.3

TE-DM57A-8H8.3microbuzzer

╠²

The document outlines the specifications for a speaker, detailing its electrical, acoustic characteristics, and physical dimensions. Key features include a rated input power of 2.0W, a maximum input power of 2.5W, and a resonance frequency of 300┬▒20% Hz. It also specifies operating and storage temperature ranges, as well as frequency response measurements.IEEE SWTW 2012 Road to 450 mm Semiconductor Wafers - Ira Feldman li2

IEEE SWTW 2012 Road to 450 mm Semiconductor Wafers - Ira Feldman li2Ira Feldman

╠²

The document discusses the transition to 450 mm semiconductor wafers, outlining the technical and economic challenges associated with this shift, including increased costs and equipment requirements. It emphasizes multiple solutions for research and development, as well as short and long-term strategies to enhance ROI while addressing the significant financial considerations. Overall, the need for careful planning and innovation to successfully navigate this transition is highlighted.TE-DM57A-8H8.3

TE-DM57A-8H8.3microbuzzer

╠²

The document provides specifications for a speaker, detailing its dimensions, electrical and acoustic characteristics including impedance, power ratings, resonance frequency, and sound pressure level. It also includes operational and storage temperature ranges, as well as material information indicating that the speaker is produced by Tianer Technology Co., Ltd. The design includes specific dimensional tolerances and project details.Ad

Milling cutting data_calculator_2012 (1)

- 1. Acrobat Reader 4 is Die andMold Die & Mould required for calculator to work Cutting Data Calculations Ballnose endmills Round insert cutters 45 degree Facemilling Square Shoulder Milling

- 2. Die and Mold Die & Mould Index Cutting Data Calculations - Ballnose Endmills Enter values in the yellow shaded boxes to calculate cutting data Switch between inch / metric units or use CLEAR button to clear the form Inch CLEAR Metric metric Nominal diameter of endmill D3 Spindle speed, RPM number of inserts z Axial depth of cut ap Feed per insert fz Cutting speed (m/min) Vc Table feed, mm/min Max chip thickness hex (may be adjusted) Effective diameter Deff Radial chip thinning / Milling with the periphery of the cutter If the width of cut (ae) is less than half the effective diameter of the cutter, D eff, and the periphery of the cutter is engaged, the table feed should be increased. Table feed, mm/min For applications meeting these conditions, enter the width of cut ae

- 3. Dieand Mould Die & Mold Index Cutting Data Calculations - Round Insert Cutters Enter values in the yellow shaded boxes to calculate cutting data Switch between inch / metric units or use CLEAR button to clear the form Inch CLEAR Metric inch insert size iC .375 Nominal cutter diameter D3 1.250 Spindle speed, RPM number of inserts z 2 8343.923921515736 Axial depth of cut ap 0.060 ap Feed per insert fz 0.03 Dc Cutting speed (ft/min) Vc 2512 Table feed, inches/min D3 500.63543529094414 Max chip thickness hex (may be adjusted) 0.02199636333578803 Deff Effective diameter 1.1499545416973505 Radial chip thinning / Milling with the periphery of the cutter If the width of cut (ae) is less than half the effective diameter of the cutter, Deff, and the periphery of the cutter is engaged, the table feed should be increased. Table feed, inches/min For applications meeting these conditions, enter the width of cut ae .6250 500.63543529094414

- 4. Die & Mold Die and Mould Index Cutting Data Calculations - 45o Cutters Enter values in the yellow shaded boxes to calculate cutting data Switch between inch / metric units or use CLEAR button to clear the form Inch CLEAR Metric metric Spindle speed, RPM Cutter diameter Dc number of inserts z ap Feed per insert fz Cutting speed (m/min) Vc Table feed, mm/min Dc Chip thickness hex (may be adjusted) Radial chip thinning / Milling with the periphery of the cutter If the width of cut (ae) is less than half the diameter of the cutter, and the periphery of the cutter is engaged, the table feed should be increased. Table feed, mm/min For applications meeting these conditions, enter the width of cut ae

- 5. Die & Mold Index Die and Mould Cutting Data Calculations - Square Shoulder (90o) Enter values in the yellow shaded boxes to calculate cutting data Switch between inch / metric units or use CLEAR button to clear the form Inch CLEAR Metric inch Spindle speed, RPM Cutter diameter Dc 2 572.9577951308232 number of inserts z 5 ap Table feed, Feed per insert = Chip thickness, fz = hex .007 inches/min Cutting speed (ft/min) Vc 300 Dc 20.053522829578814 Radial chip thinning / Milling with the periphery of the cutter If the width of cut (ae) is less than half the diameter of the cutter, and the periphery of the cutter is engaged, the table feed should be increased. Table feed, inches/min For applications meeting these conditions, enter the width of cut ae .5 23.15581360771527