Mineral

- 1. ĒĢÖļ▓ł : 20071726 20071710 ņØ┤ļ”ä : ņÜ░ņøÉņ×¼ Ļ╣ĆļŗżĒśä

- 3. ’é▓ ņ×æĒÆł ļ¬ģņ╣Ł : Mineral ’é▓ ņ×æĒÆł ņןļź┤ : ņś©ļØ╝ņØĖ ņŖłĒīģ Ļ▓īņ×ä ’é▓ ņ×æĒÆł Ļ░£ņÜö ’üĄ Top-View ĒśĢņŗØņ£╝ļĪ£ Ļ░äļŗ©ĒĢ£ ĒÖöļ®┤ ņŚ░ņČ£ ’üĄ REDĒīĆĻ│╝ GREENĒīĆ ļæÉĒīĆņ£╝ļĪ£ ļéśļłäņ¢┤ Ēéżļ│┤ļō£ņÖĆ ļ¦łņÜ░ņŖż ļÅÖņŗ£ ņĪ░ņ×æĒĢśņŚ¼ ņāüļīĆĒÄĖ ņ║É ļ”ŁĒä░ļź╝ ņō░ļ¤¼ļ£©ļ”¼Ļ│Ā ņāüļīĆļ░®ņØś Ļ▒░ņĀÉņØä ĒīīĻ┤┤ĒĢśļŖö Ļ▓āņØ┤ ļ¬®ņĀü

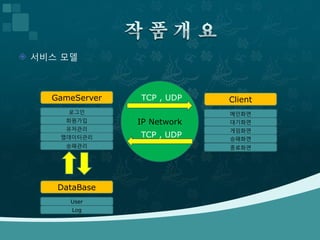

- 4. ’é▓ ņä£ļ╣äņŖż ļ¬©ļŹĖ GameServer TCP , UDP Client ļĪ£ĻĘĖņØĖ ļ®öņØĖĒÖöļ®┤ ĒÜīņøÉĻ░Ćņ×ģ IP Network ļīĆĻĖ░ĒÖöļ®┤ ņ£ĀņĀĆĻ┤Ćļ”¼ Ļ▓īņ×äĒÖöļ®┤ ļ¦ĄļŹ░ņØ┤Ēä░Ļ┤Ćļ”¼ TCP , UDP ņŖ╣Ēī©ĒÖöļ®┤ ņŖ╣Ēī©Ļ┤Ćļ”¼ ņóģļŻīĒÖöļ®┤ DataBase User Log

- 5. ’é▓ Ļ▓īņ×ä ņŗ£ļéśļ”¼ņśż ņ║Éļ”ŁĒä░ ļČĆĒÖ£ ļ®öņØĖĒÖöļ®┤ ņØ┤ļÅÖ Ļ│ĄĻ▓® ļ¼┤ĻĖ░ņäĀĒāØ Ļ▓īņ×äĒÖöļ®┤ Empty yes Ļ▒░ņĀÉņäĀĒāØ no ņןņĀä ņĀäņ▓┤ļ¦Ą ļ░śļ│Ą ņŻĮņØī

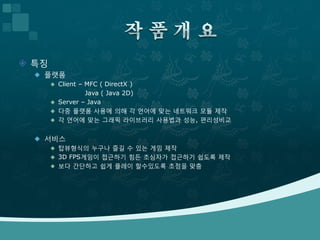

- 6. ’é▓ ĒŖ╣ņ¦Ģ ’üĄ Ēöīļ×½ĒÅ╝ ’üĄ Client ŌĆō MFC ( DirectX ) Java ( Java 2D) ’üĄ Server ŌĆō Java ’üĄ ļŗżņżæ Ēöīļ×½ĒÅ╝ ņé¼ņÜ®ņŚÉ ņØśĒĢ┤ Ļ░ü ņ¢Ėņ¢┤ņŚÉ ļ¦×ļŖö ļäżĒŖĖņøīĒü¼ ļ¬©ļōł ņĀ£ņ×æ ’üĄ Ļ░ü ņ¢Ėņ¢┤ņŚÉ ļ¦×ļŖö ĻĘĖļלĒöĮ ļØ╝ņØ┤ļĖīļ¤¼ļ”¼ ņé¼ņÜ®ļ▓ĢĻ│╝ ņä▒ļŖź, ĒÄĖļ”¼ņä▒ļ╣äĻĄÉ ’üĄ ņä£ļ╣äņŖż ’üĄ ĒāæļĘ░ĒśĢņŗØņØś ļłäĻĄ¼ļéś ņ”ÉĻĖĖ ņłś ņ׳ļŖö Ļ▓īņ×ä ņĀ£ņ×æ ’üĄ 3D FPSĻ▓īņ×äņØ┤ ņĀæĻĘ╝ĒĢśĻĖ░ ĒלļōĀ ņ┤łņŗ¼ņ×ÉĻ░Ć ņĀæĻĘ╝ĒĢśĻĖ░ ņēĮļÅäļĪØ ņĀ£ņ×æ ’üĄ ļ│┤ļŗż Ļ░äļŗ©ĒĢśĻ│Ā ņēĮĻ▓ī ĒöīļĀłņØ┤ ĒĢĀņłśņ׳ļÅäļĪØ ņ┤łņĀÉņØä ļ¦×ņČż

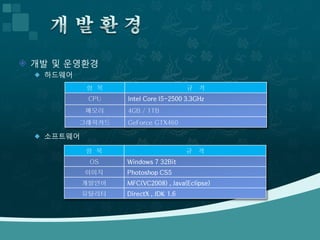

- 7. ’é▓ Ļ░£ļ░£ ļ░Å ņÜ┤ņśüĒÖśĻ▓Į ’üĄ ĒĢśļō£ņø©ņ¢┤ ĒĢŁ ļ¬® ĻĘ£ Ļ▓® CPU Intel Core I5-2500 3.3GHz ļ®öļ¬©ļ”¼ 4GB / 1TB ĻĘĖļלĒöĮņ╣┤ļō£ GeForce GTX460 ’üĄ ņåīĒöäĒŖĖņø©ņ¢┤ ĒĢŁ ļ¬® ĻĘ£ Ļ▓® OS Windows 7 32Bit ņØ┤ļ»Ėņ¦Ć Photoshop CS5 Ļ░£ļ░£ņ¢Ėņ¢┤ MFC(VC2008) , Java(Eclipse) ņ£ĀĒŗĖļ”¼Ēŗ░ DirectX , JDK 1.6

- 8. 1. ĒÖöļ®┤ņäżĻ│ä 2. UseCase Diagram 3. Ēü┤ļלņŖż

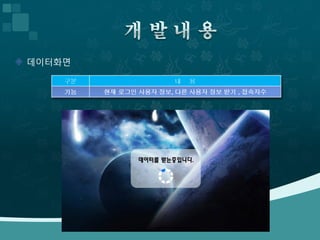

- 9. ’é▓ ļ®öņØĖĒÖöļ®┤ ĻĄ¼ļČä ļé┤ ņÜ® ĻĖ░ļŖź ļĪ£ĻĘĖņØĖ , ĒÜīņøÉĻ░Ćņ×ģ , ņóģļŻīĒĢśĻĖ░

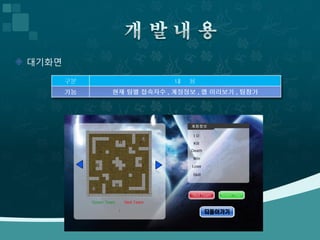

- 10. ’é▓ ĒÜīņøÉĻ░Ćņ×ģĒÖöļ®┤ ĻĄ¼ļČä ļé┤ ņÜ® ĻĖ░ļŖź ĒÜīņøÉĻ░Ćņ×ģ

- 11. ’é▓ ļŹ░ņØ┤Ēä░ĒÖöļ®┤ ĻĄ¼ļČä ļé┤ ņÜ® ĻĖ░ļŖź Ēśäņ×¼ ļĪ£ĻĘĖņØĖ ņé¼ņÜ®ņ×É ņĀĢļ│┤, ļŗżļźĖ ņé¼ņÜ®ņ×É ņĀĢļ│┤ ļ░øĻĖ░ , ņĀæņåŹņ×Éņłś

- 12. ’é▓ ļīĆĻĖ░ĒÖöļ®┤ ĻĄ¼ļČä ļé┤ ņÜ® ĻĖ░ļŖź Ēśäņ×¼ ĒīĆļ│ä ņĀæņåŹņ×Éņłś , Ļ│äņĀĢņĀĢļ│┤ , ļ¦Ą ļ»Ėļ”¼ļ│┤ĻĖ░ , ĒīĆņ░ĖĻ░Ć

- 13. ’é▓ Ļ▓īņ×äĒÖöļ®┤ ĻĄ¼ļČä ļé┤ ņÜ® ĻĖ░ļŖź Ļ▓īņ×ä ĒöīļĀłņØ┤ , Ēśäņ×¼ Ļ▓īņ×äņĀæņåŹņ×É ĒÖĢņØĖ , ĒāĆĻ▓®ņŻ╝ĻĖ░

- 14. ’é▓ UseCase Diagram Stream <<Include>> UDP <<Extend>> <<Extend>> UDP CSocket Client Server TCP <<Extend>> <<Extend>> TCP MFC Graphic <<Include>> <<Include>> Image <<Include>> Sprite Java2D DirectX

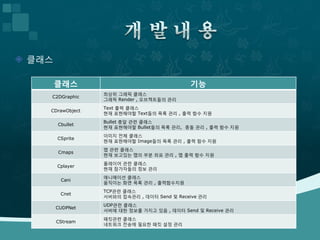

- 15. ’é▓ Ēü┤ļלņŖż Client C2DGraphic CDrawObject CBullet CSprite CMaps CPlayer CAni CUDPNet CNet

- 16. ’é▓ Ēü┤ļלņŖż Ēü┤ļלņŖż ĻĖ░ļŖź ņĄ£ņāüņ£ä ĻĘĖļלĒöĮ Ēü┤ļלņŖż C2DGraphic ĻĘĖļלĒöĮ Render , ņśżļĖīņĀØĒŖĖļōżņØś Ļ┤Ćļ”¼ Text ņČ£ļĀź Ēü┤ļלņŖż CDrawObject Ēśäņ×¼ Ēæ£ĒśäĒĢ┤ņĢ╝ĒĢĀ TextļōżņØś ļ¬®ļĪØ Ļ┤Ćļ”¼ , ņČ£ļĀź ĒĢ©ņłś ņ¦ĆņøÉ Bullet ņ┤ØņĢī Ļ┤ĆļĀ© Ēü┤ļלņŖż Cbullet Ēśäņ×¼ Ēæ£ĒśäĒĢ┤ņĢ╝ĒĢĀ BulletļōżņØś ļ¬®ļĪØ Ļ┤Ćļ”¼, ņČ®ļÅī Ļ┤Ćļ”¼ , ņČ£ļĀź ĒĢ©ņłś ņ¦ĆņøÉ ņØ┤ļ»Ėņ¦Ć ņĀäņ▓┤ Ēü┤ļלņŖż CSprite Ēśäņ×¼ Ēæ£ĒśäĒĢ┤ņĢ╝ĒĢĀ ImageļōżņØś ļ¬®ļĪØ Ļ┤Ćļ”¼ , ņČ£ļĀź ĒĢ©ņłś ņ¦ĆņøÉ ļ¦Ą Ļ┤ĆļĀ© Ēü┤ļלņŖż Cmaps Ēśäņ×¼ ļ│┤Ļ│Āņ׳ļŖö ļ¦ĄņØś ļČĆļČä ņóīĒæ£ Ļ┤Ćļ”¼ , ļ¦Ą ņČ£ļĀź ĒĢ©ņłś ņ¦ĆņøÉ ĒöīļĀłņØ┤ņ¢┤ Ļ┤ĆļĀ© Ēü┤ļלņŖż Cplayer Ēśäņ×¼ ņ░ĖĻ░Ćņ×ÉļōżņØś ņĀĢļ│┤ Ļ┤Ćļ”¼ ņĢĀļŗłļ®öņØ┤ņģś Ēü┤ļלņŖż Cani ņøĆņ¦üņØ┤ļŖö ĒÖöļ®┤ ļ¬®ļĪØ Ļ┤Ćļ”¼ , ņČ£ļĀźĒĢ©ņłśņ¦ĆņøÉ TCPĻ┤ĆļĀ© Ēü┤ļלņŖż Cnet ņä£ļ▓äņÖĆņØś ņĀæņåŹĻ┤Ćļ”¼ , ļŹ░ņØ┤Ēä░ Send ļ░Å Receive Ļ┤Ćļ”¼ UDPĻ┤ĆļĀ© Ēü┤ļלņŖż CUDPNet ņä£ļ▓äņŚÉ ļīĆĒĢ£ ņĀĢļ│┤ļź╝ Ļ░Ćņ¦ĆĻ│Ā ņ׳ņØī , ļŹ░ņØ┤Ēä░ Send ļ░Å Receive Ļ┤Ćļ”¼ Ēī©ĒéĘĻ┤ĆļĀ© Ēü┤ļלņŖż CStream ļäżĒŖĖņøīĒü¼ ņĀäņåĪņŚÉ ĒĢäņÜöĒĢ£ Ēī©ĒéĘ ņäżņĀĢ Ļ┤Ćļ”¼

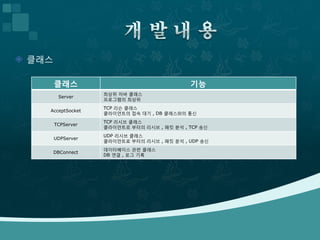

- 17. ’é▓ Ēü┤ļלņŖż Server Server AcceptSocket DBConnect TCPServer UDPServer PullingMsg BufferStream

- 18. ’é▓ Ēü┤ļלņŖż Ēü┤ļלņŖż ĻĖ░ļŖź ņĄ£ņāüņ£ä ņ×Éļ░ö Ēü┤ļלņŖż Server ĒöäļĪ£ĻĘĖļשņØś ņĄ£ņāüņ£ä TCP ļ”¼ņŖ© Ēü┤ļלņŖż AcceptSocket Ēü┤ļØ╝ņØ┤ņ¢ĖĒŖĖņØś ņĀæņåŹ ļīĆĻĖ░ , DB Ēü┤ļלņŖżņÖĆņØś ĒåĄņŗĀ TCP ļ”¼ņŗ£ļĖī Ēü┤ļלņŖż TCPServer Ēü┤ļØ╝ņØ┤ņ¢ĖĒŖĖļĪ£ ļČĆĒä░ņØś ļ”¼ņŗ£ļĖī , Ēī©ĒéĘ ļČäņäØ , TCP ņåĪņŗĀ UDP ļ”¼ņŗ£ļĖī Ēü┤ļלņŖż UDPServer Ēü┤ļØ╝ņØ┤ņ¢ĖĒŖĖļĪ£ ļČĆĒä░ņØś ļ”¼ņŗ£ļĖī , Ēī©ĒéĘ ļČäņäØ , UDP ņåĪņŗĀ ļŹ░ņØ┤Ēä░ļ▓ĀņØ┤ņŖż Ļ┤ĆļĀ© Ēü┤ļלņŖż DBConnect DB ņŚ░Ļ▓░ , ļĪ£ĻĘĖ ĻĖ░ļĪØ

- 19. ’é▓Ļ▓░ļĪĀ ’üĄ ņÜ░ņøÉņ×¼ ’üĄ ĒĢ£ļŗ¼ļé©ņ¦ō ņāØĻ░üĒĢśĻ│Ā ĒöäļĪ£ĻĘĖļלļ░ŹĒĢ£ Ļ▓░Ļ│╝Ļ░Ć ņĀ£ļīĆļĪ£ ļÉ£ ņÖäņä▒ļ│Ėņ£╝ļĪ£ ļéśņśżņ¦Ć ņĢŖņĢäņä£ ņĢäņēĮņ¦Ćļ¦ī ĻĘĖļÅÖņĢł ņĢīņĢäļ│┤Ļ│Ā Ļ│ĄļČĆĒĢ£ Ļ│╝ņĀĢņØĆ ņÖäņä▒ļ│Ė ņØ┤ņāüņØś ĒÜ©Ļ│╝ļź╝ ļāłļŗżĻ│Ā ņāØĻ░üĒĢ® ļŗłļŗż. ņØ┤ļ▓ł Ļ│Ąļ¬©ņĀä ņżĆļ╣äņżæņŚÉ ņØĄĒ×ī ĻĖ░ņłĀļōż ņżæ ĒŖ╣Ē׳ ļäżĒŖĖņøīĒü¼ ļČĆļČäĻ│╝ ĒöäļĪ£ĻĘĖļשņØś ņŖżļĀłļō£ , ĻĘĖļ”¼Ļ│Ā ņ×Éļ░öņÖĆ CĻ░äņØś ņóĆļŹö ņ×ÉņäĖĒĢ£ ņ¢Ėņ¢┤ļ╣äĻĄÉ, ļśÉ ĒĢśļéś ņāØĻ░üņÖĖļĪ£ ņ╗┤Ēō©Ēä░ Ļ░Ć ņŚäņ▓ŁļéśĻ▓ī ļ╣Āļź┤ļŗżļŖö ņé¼ņŗżņØä ļŗżņŗ£ ĒĢ£ļ▓ł ņØĖņŗØĒĢśĻ▓ī ļÉśņŚłņŖĄļŗłļŗż.