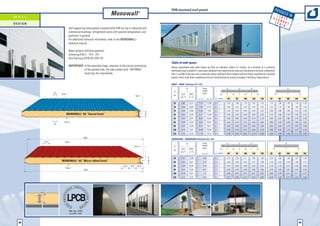

Monowall details

- 1. PUR-insulated wall panels PROD Monowall ? UCED I IN: WALL GE TALY RM SP ANY DESIGN AIN Self-supporting metal panels insulated with PUR for use in industrial and commercial buildings, refrigerated rooms with positive temperature, and partitions in general. For additional technical information, refer to the MONOWALL? technical manual. Major product technical approval: Zulassung Dibt Z - 10.4 - 241. Avis Tecnique CSTB AT-2/05-152 Table of safe spans IMPORTANT: In the assembly stage, attention to the correct positioning Values guaranteed with steel sheets as thick as indicated. Spans l in metres, as a function of a uniformly of the painted side: the side marked with ¡°INTERNAL¡± distributed load p (daN/m2), have been obtained from experimental data and calculated to provide a deflection must face the internalside. limit: f ¡Ü l/200 of the span and a minimum safety coefficient that complies with the UEAtc standards for insulated panels, which have been established and are implemented by primary European Certifying Organizations. steel - steel (thickness 0,4 + 0,4) K Panel p p p p weight 25 S kg/m2 Side 1 Kcal Watt l l l l Seal mm m2h ¡ãC m2 ¡ãC 0,4 + 0,4 0,6 + 0,6 p = (daN/m ) 2 60 80 100 120 150 60 80 100 120 150 25 0,66 0,77 7,70 11,08 l= 2,05 1,90 1,75 1,65 1,55 1,75 1,60 1,50 1,40 1,30 30 0,56 0,65 7,89 11,23 l= 2,60 2,45 2,30 2,05 1,85 2,25 2,10 1,90 1,80 1,65 35 0,48 0,56 8,08 1,46 l= 3,20 3,00 2,80 2,50 2,20 2,80 2,60 2,40 2,20 2,00 MONOWALL AC ¡°Staved finish¡± ? S 40 0,43 0,50 8,27 11,65 l= 3,40 3,20 3,00 2,80 2,50 3,10 2,90 2,70 2,50 2,20 50 0,35 0,41 8,65 12,03 l= 3,90 3,65 3,40 3,10 2,75 3,45 3,20 2,95 2,75 2,40 Side 2 60 0,29 0,34 9,03 12,41 l= 4,40 4,10 3,75 3,45 3,00 3,80 3,55 3,30 3,00 2,60 25 80 0,22 0,26 9,79 13,17 l= 5,20 4,65 4,25 3,90 3,35 4,50 4,00 3,70 3,35 2,90 100 0,18 0,21 10,59 13,99 l= 5,80 5,15 4,75 4,30 3,70 4,90 4,45 4,10 3,75 3,20 120 0,15 0,18 11,35 14,75 l= 6,40 5,70 5,25 4,75 4,05 5,50 4,90 4,50 4,10 3,50 1000 aluminium - aluminium (thickness 0,6 + 0,6) 62,5 Side 1 K Panel p p p p weight Seal S kg/m2 Kcal Watt l l l l mm m2h ¡ãC m2 ¡ãC 0,6 + 0,6 p = (daN/m2) 60 80 100 120 150 60 80 100 120 150 40 0,43 0,50 4,99 l= 2,75 2,39 2,11 1,90 1,66 2,34 2,06 1,84 1,67 1,49 MONOWALL? AC ¡°Micro-ribbed finish¡± S 50 0,35 0,41 5,37 l= 3,26 2,84 2,52 2,27 1,99 2,76 2,44 2,19 1,99 1,77 62,5 62,5 62,5 60 0,29 0,34 5,75 l= 3,74 3,26 2,90 2,62 2,32 3,16 2,79 2,51 2,29 2,04 Side 2 1020 80 0,22 0,26 6,51 l= 4,34 3,78 3,36 3,04 2,69 3,79 3,35 3,01 2,75 2,45 100 0,18 0,21 7,27 l= 4,86 4,24 3,77 3,41 3,02 4,30 3,79 3,41 3,11 2,77 120 0,15 0,18 8,03 l= 5,31 4,63 4,12 3,72 3,29 4,74 4,19 3,77 3,44 3,06 48 49