msme project

- 1. GUIDED BY: DR. ARVIND TIWARI SUBMITTED BY: ADITYA TRIPATHI AND KUMAR GAURAV 12/14/2017 1

- 2. DEMONSTRATIVE MODEL These are taken from the demonstrative model available in the college. 12/14/2017 2

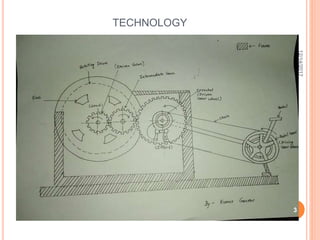

- 4. TECHNOLOGY Average pedal fore F1=156.5N Also, for 1.5 kg of cloths,F2=1.5*g =1.5*10N =150 Total pedal force, F=F1+F2 = 156.5+150 =306.5 =300N (approx.) Torque T=F*r = 300*0.25 =75N-m Power ,P =300 …………(power during cycling is between 250 to 500 W) P =2*Pi*Np*T/60 or, 300=2*pi*Np*75/60 or, Np=38.197rpm=38rpm (actual rpm produced by pedaling) In our demonstrative model , we have number of teeth on pedal gear,Tp=60 number of teeth on sprocket,Ts=30 Gear Ratio=Tp/Ts=60/30=2 Also,we know that Np*Tp = Ns*Ts or, 38*60=Ns*30 or,Ns=76 rpm 12/14/2017 4

- 5. TECHNOLOGY… The same rpm is transmitted to the compound gear G1,N1=76rpm Also, teeth on compound gear G1, T1=120 teeth on intermediate gear G2, T2 =90 teeth on small gear G3, T3=30 rpm of intermediate gear G2, N2*T2=N1*T1 or, N2*90=76*120 or, N2=101.33rpm rpm of small gear G3, N3*T3=N2*T2 or, N3*30=101.33*90 or, N3=304 rpm Hence , we get 304 rpm on the small gear shaft on which drum is mounted. N3/Ns=304/38 =8 times So , we get 8 times of input rpm on the output shaft. 12/14/2017 5

- 6. SOCIAL IMPACT ÔÇ¢ A pedal-powered washing machine would allow women to wash clothes faster and with less strain ÔÇ¢ It also emphasize on physical exercise of human body ÔÇ¢ The target population for the innovation will be the villagers of India because 35.5% of the population still live without access to electricity ÔÇ¢ Lesser maintenance required ÔÇ¢ Zero operating cost ÔÇ¢ Very effective in protecting the hands of washer men 12/14/2017 6

- 7. UNIQUENESS The horizontal axis pedal powered washing machine has following uniqueness like- 1.Minimized human effort in pedaling by applying gear and pinion arrangement. 2. Works without electricity so it can be an ideal machine for the people in the electricity deficient Indian villages. 3. Horizontal axis pedal washing machine consumes less power as compared to vertical axis washing machine. 4. It encourages pedaling which is a good physical exercise and keeps oneself fit. 12/14/2017 7

- 8. S. No. Items Likely Expenditure (Rs. in lakhs) 1 Technology development fee 2.00 2 Telephone, Fax, Computer facility, etc. 0.25 3 Machinery hiring or leasing from outside 1.00 4 Guidance fee for mentors/ handholding persons, etc. 2.00 5 Electricity, accommodation charges, etc. 1.00 Total 6.25 Funding Required from MSME 6.00 12/14/2017 8 Activity wise break-up of Project costing

- 9. Technology Development and Leasing Fee Details S.No. Items Quantity Approximate Cost in Lacs Total Cost in Lacs 1 Redesigning of commercially viable structure using AutoCAD and CATIA 1 0.5 0.5 2 Llight-weighted plastic and steel parts 1 0.2 0.2 3 Design of gear box system and shaft AutoCAD and SolidWorks 1 0.5 0.5 4 Gear box and shaft material 1 0.1 0.1 5 Fabrication and assembling N-x Unigraphics and CATIA 1 0.3 0.3 6 Analysis and testing ANSYS,PROE and lab testing 1 0.4 0.4 Total 2.00 12/14/2017 9

- 10. MACHINERY HIRING S.NUMBE R PARTICULARS APPROX. COST 1. Gear cutting machine 30,000 2. Casting and moulding equipments 30,000 3. Plastic processing machine(to make it leakage proof) 20,000 4. Shaping and planning machine for base development and finishing 20,000 TOTAL 1 lakh 12/14/2017 10