mssm

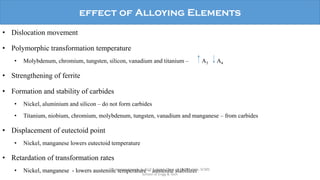

- 1. effect of Alloying Elements • Dislocation movement • Polymorphic transformation temperature • Molybdenum, chromium, tungsten, silicon, vanadium and titanium – A3 A4 • Strengthening of ferrite • Formation and stability of carbides • Nickel, aluminium and silicon – do not form carbides • Titanium, niobium, chromium, molybdenum, tungsten, vanadium and manganese – from carbides • Displacement of eutectoid point • Nickel, manganese lowers eutectoid temperature • Retardation of transformation rates • Nickel, manganese - lowers austenitic temperature – austenite stabilizer Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 2. effect of Alloying Elements • Lowering of critical cooling rates • Improvement in corrosion resistance • Aluminium- forms aluminium oxide – prevent corrosion • Chromium – 13% • Influence on grain growth • Chromium – grain growth • Nickel, vanadium – grain refiners Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 3. • Properties of composite materials depends on characteristics of reinforcements • Concentration • Shape • Size • Distribution • Orientation Composite Materials Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 4. Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 5. • Particle Reinforced composites • Large particle reinforced composites • Dispersion strengthened composites • Fibre reinforced composites • Continuous fibre reinforced composites • Discontinuous fibre reinforced composites Classification based on Reinforcement Geometry Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 6. • Particle size - 1-50µm • Concentration – 15-40% by volume • Particulate phase is harder and stiffer than matrix • Particle phase restrain the movement of matrix phase • Matrix phase transfer the load to the particles • Mechanical properties increases with increasing particle content • Even distribution • Examples • WC in MMC • Carbon black in rubber Large particle reinforced composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 7. • Particle size <0.1µm • Volume fraction – 5-15% • Particles- metallic, non-metallic • Examples – carbides, oxides and borides • Matrix is the load bearing phase • Dispersions prevent the motion of dislocations • High strength at elevated temperatures and extended time Dispersion strengthened composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 8. • Fibre – length =100Xdiameter • Small diameter fibre is stronger than larger diameter fibre • Types • Whiskers ((large length-diameter ratio) • Fibres (Dia – 5-10µm) • Wires • Properties of composites affected by – type, Volume fraction and orientation of fibre • Critical length Lc = 1mm(20 to 150 times of fibre dia) • Classifications • Continuous – L >15Lc • Discontinuous – l=Lc to 15Lc Fibre reinforced composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 9. • Binds and holds the reinforcing medium • Acts as medium through which the external loads are transferred • Matrix separates the fibres from each other • Matrix protects the fibres form surface damage • Matrix withstand heat, cold, electrical resistance, chemical attack Roles of Matrix Phase Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 10. • Classifications • Thermosetting plastics • Thermo plastics • Properties • Low density • High specific strength • High specific stiffness • Easy fabrication • Low cost Polymer matrix composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 11. • Glass Fibre Reinforced Polymer Composites (GFRP) • Diameter – 3-20 µm • High strength but not suitable for structural applications (Not stiff & Rigid) • Automotive bodies, marine bodies, storage containers, industrial floorings, plastic pipes • Carbon Fibre Reinforced Composites ( CFRP) • Carbon fibre properties - High strength at elevated temperatures • Not affected by moisture • 4-10 µm • Aerospace structural components, rocket motor cases • Composite properties – High strength, stiffness, wear and impact resistance • Aramid Fibre Reinforced Polymer Composites • Polyamide – high strength • Kevlar and Normex • Applications – Bullet proof vests, , automotive brakes, clutch linings, tyres Polymer matrix composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 12. • Withstand high temperature than polymers • Metal is reinforced to increase specific strength, abrasion resistance, creep resistance etc., • Metal matrix – aluminium, magnesium, titanium and their alloys • Reinforcements – particulates, fibres and whiskers • Concentration – 10-60% • Reinforcements – SiC, Boron Carbide, Aluminium oxide • Applications – Automobile and aerospace Metal matrix composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 13. • High melting point and good resistance to oxidation • Brittle, low tensile strength and impact strength • Reinforcements – Zro2, SiC • Applications – Aircraft turbine engines, cutting tool inserts Ceramic Matrix Composites Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 14. • Air craft and aerospace • Automotive applications • Marine applications • Sporting goods • Biomaterials Applications of Composite materials Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 15. • The term ceramic – originates from the greek word kermikos(means burnt stuff) • The properties are achieved by “firing” process. • It is formed as a combination of metallic and non metallic elements. • Properties:- high hardness, high brittleness, high MP, chemical inertness, electrical insulation. • Reason for properties:-presence of strong ionic and covalent bonds • Ceramic material has more than one type of bonds in them. • Metallic ions (cations) are +ve ly charged, non metallic (anoins) are –ve ly charged. • Ratio rc ra is known as radius ratio. • Co-ordination number is the number of nearest ions for a specific ion. Ceramics Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 16. • AX type • Equal number of cations (A)and anions (X) • Different crystal structures • NaCl, MgO,FeO • AmXp type • M not equal to p • CaF2,Zro2 • AmBnXp • More than one type of cations • BaTio3,SrZno3 Fe Al2o3 Crystal structure Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 17. • Glasses • Clay products • Refractories • Abrasives • Cements • Advanced ceramics Applications Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 18. • Liquid cools without crystallization • Supercooled liquid • Brittle, transparent, chemically inert • Basic ingredients – silica sand. Other elements – CaCO3, Na2CO3,CaO,Na2O • Construction and engineering applications • Glass fibres – insulation, reinforcing elements • Automobile glasses – sandwich of tough plastic between glasses Glass Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 19. • Non-crystalline glass subjected to high temperature treatment →crystalline material • Fine grained polycrystalline material • Cooling rate should be lesser than critical cooling rate • Characteristics • High mechanical strength • Low coefficient of thermal expansion • High temperature resistance • Good bio compatibility • Ease of fabrication • Application – table ware, electrical insulators Glass ceramics Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 20. • Clay ceramics • Raw material – clay • Bricks, tiles • Whiteware – become white at high temperature firing • Refractory ceramics • Furnace lining • Classification – fireclay(silica and alumina), silica, basic(magnesia) and special refractories(alumina, silica,magnesia,beryllia, zirconia) • Abrasives • Grind /cut away soft materials • Silicon carbide, tungsten carbide, aluminium oxide and silica sand • Cements • Advanced ceramics – PZT Ceramics –Applications Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech

- 21. • High strength and creep strength at elevated temperatures • Classification • Nickel based (Haste alloy, nichrome, kanthol,udimet and Inconel) • Cobalt based (Stellite, hayness and vitallium) • Iron based (Incoloy) • Solid solution strengthening, precipitation hardening and dispersion hardening • Applications • Aerospace • Industrial gas turbine blades • Engine valves Super alloys Dr. Jenson Joseph. E, Prof & Head, Dept of Automobile, SCMS School of Engg & Tech