Nano materials

- 2. INTRODUCTION In simple, any physical substance with structural dimensions between 1- 100nm can be defined as NANOMATERIAL âĒ Nano materials âNANOâ +âMATERIALSâ âdwarfâ=quantum

- 4. WHAT ARE NANOMATERIALS? ïNanomaterials: Materials possessing one or more dimensional features having length of order of a billionth of a metre. ï Simply ,1 inch = 2,54,00,000 nm. ïIf one marble =1 nm,1 m would be size of earth.

- 5. WHY NANOMATERIALS ARE CALLED SO? âĒ NANOSCALE: Border line between macro scale and quantum scale. ïķMACRO -------> NANO -------> QUANTUM > 100nm 1-100nm < 1nm

- 6. IMPORTANCE AND PROPERTIES ï1 nm = 1000 millionth of a metre. e.g.(1)Red blood cells = 7000 nm(approx.) (2)water molecule = 0.3 nm. ïAt Nanoscale , the properties of materials can be very different from those at larger scale.Such as (1)Optical (4) Melting (7)Bandgap (2)Catalysis (5) Conductivity (8)Surface area (3)Reactivity (6) Solubility (9)Mechanical properties

- 7. SIGNIFICANCE ïComposites made of nano particle become much stronger than predicted. e.g. grain size (10 nm)is 7 times harder and tougher than grain size (100 nm). ïThe properties of materials can be differentat nanoscale due to 2 main reason (1)Larger surface area chemically more reactive (2)Quantum effects begin to dominate the behaviour of matter at nano scale.

- 10. SYNTHESIS APPROACH OF NANOMATERIALS ï TOP DOWN METHOD: From bulk materials to nanomaterial.(MACRO to NANO scale) ï BOTTOM UP METHOD: From quantum material to nano material.(QUANTUM to NANO scale)

- 11. SYNTHESIS APPROACH OF NANOMATERIALS ï TOP DOWN (BULK to NANO) METHODS: 1. MECHANICAL GRINDING: (a)larger scale materials are grinded to nanoscale. 2. LITHOGRAPHY: (a)tiny chips from relatively large structure. ï BOTTOM UP (QUANTUM to NANO) METHODS: 1. SELF ASSEMBLY: (a) Desired Nanostructures are self assembled without any external manipulation. 2. POSITIONAL ASSEMBLY: (a)We can program to manipulate atom & molecule at will.

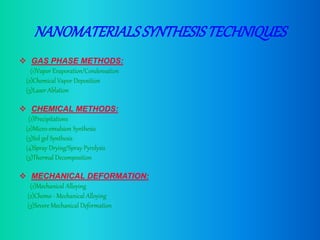

- 12. NANOMATERIALSSYNTHESISTECHNIQUES ïķ GAS PHASE METHODS: (1)Vapor Evaporation/Condensation (2)Chemical Vapor Deposition (3)Laser Ablation ïķ CHEMICAL METHODS: (1)Precipitations (2)Micro-emulsion Synthesis (3)Sol gel Synthesis (4)Spray Drying/Spray Pyrolysis (5)Thermal Decomposition ïķ MECHANICAL DEFORMATION: (1)Mechanical Alloying (2)Chemo - Mechanical Alloying (3)Severe Mechanical Deformation

- 13. DIFFERENCE BETWEEN TOP DOWN AND BOTTOM UP APPROACH Bottom â up Approach 1. QUANTUM to NANO. 2. It can be found from nature. 3. Higher precision accuracy. 4. No wastage of material. Top â down Approach 1. BULK to NANO. 2. It cannot be found from nature. 3. Lower precision accuracy. 4. Wastage of material occurs.

- 14. ANSWER IS : âBOTTOM UPâ 1. When object size is getting smaller in nanofabrication , bottom â up approach is an increasingly important complement to top â down techniques. 2. Bottom â up approach can be found from nature, where biological systems have exploited chemical forces to create structure for cells needed for life. Whereas , top â down approach is uncommon/rare in nature. 3. Limitations to top â down approach are surfaces & edges are not perfect as they are wrinkly or containing cavities , wastage of material & restriction to get smaller size.