New Dadu Sugar Mills Limited

- 1. It was established in 1977 by Zulfiqar Ali Bhutto. Due to continuous and heavy production losses every year, Government decided to shut this unit in 1999. After 10 years In July 2008 it was purchased by Omni Group and made this plant one of the 2nd complete FCB plant in the world. Majority of sugar processing equipment are imported from FCB, France.Some of the majorprocessingequipments include3BoilerHouses,PowerHouse,ProcessHouse and a Mill House. WhenI visited, Isaw,howto make Sugarfrom Sugarcane.It has many processes tomake the Sugar.First Raw material walkthroughthe machine then putintocuttermachine make itsmall piecesof sugarcane. After that raw material go to grinder machine then make it sweet water or juice. Juice of sugarcane is boilinginlarge numberof boilertank.Infurtherprocess sweetwaterorjuice convertedintofinish good products such as; ’āś Turbinado Sugar ’āś Granulated Sugar ’āś Molasses ’āś Brown Sugar ’āś Powdered Sugar ’āś Bagasse Workersare assetsof an organization.Isurprise tosee their friendly environment, unity of each other. They are Host Hospitality in spite of some are uneducated. Because of, it is culture of Sindh to warm welcome totheirguests.There isworkersentryregistrationsystembutunfortunatelyPiyaroMillshasnŌĆÖt providedIDcards to theirworkers. A Piyaromillshastwodepartments,one isHRdepartment& otheris Finance department. There are three shifts for working; 1. 08:00 am to 04:00 pm 2. 04:00 pm to 12:00 am 3. 12:00 am to 08:00 am Hundreds of workers work in one shift. They are working on daily wages. Each worker gets 250 to 350 rupeesperday.There isone dispensaryroomunfortunatelythere isnodoctor only one Ambulance use inemergencytime &three dispensers,eachdispenserworkinone shift. A PiyaroMills hasnŌĆÖt any safety plansfor workers,mostof workersinjuredandlosttheirHands,Arms,legs duringwork. Sugarmillsruns onlywinterseason(10thJanuaryto 15th February). Unfortunately I came late and didn't see sugarcane but I sawwork inprocessof sugar. Waste brownpaste supplytoKarachi chocolate industriesformaking chocolates. Piyaro Sugar mills has own power plant, which is running by waste material powder or bagasse of sugarcane. Separate Energy Power plant supplying light to Piyaro Goth, Seeta village and Phulji Station.

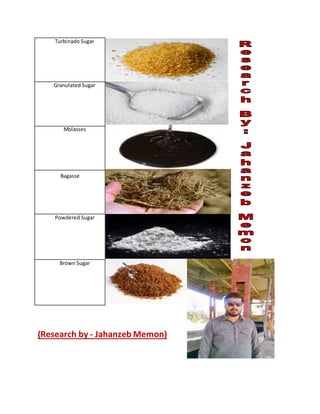

- 2. Turbinado Sugar Granulated Sugar Molasses Bagasse Powdered Sugar Brown Sugar (Research by - Jahanzeb Memon)