n-MOS Fabrication Process

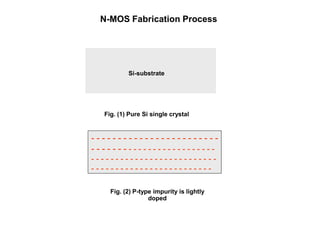

- 2. N-MOS Fabrication Process Fig. (1) Pure Si single crystal Si-substrate Fig. (2) P-type impurity is lightly doped - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

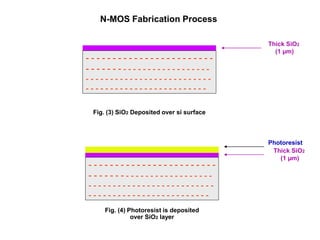

- 3. N-MOS Fabrication Process Fig. (3) SiO2 Deposited over si surface Fig. (4) Photoresist is deposited over SiO2 layer Thick SiO2 (1 µm) Photoresist Thick SiO2 (1 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

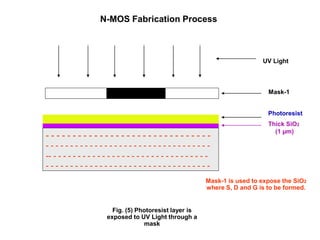

- 4. N-MOS Fabrication Process Fig. (5) Photoresist layer is exposed to UV Light through a mask Photoresist Thick SiO2 (1 µm) UV Light Mask-1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Mask-1 is used to expose the SiO2 where S, D and G is to be formed.

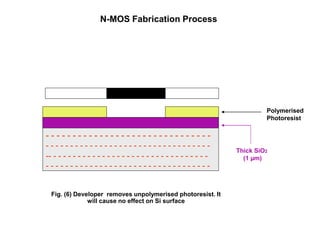

- 5. N-MOS Fabrication Process Fig. (6) Developer removes unpolymerised photoresist. It will cause no effect on Si surface Polymerised Photoresist Thick SiO2 (1 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- 6. N-MOS Fabrication Process Fig. (7) Etching [HF acid is used] will remove SiO2 layer which is in direct contact with etching solution Thick SiO2 (1 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- 7. N-MOS Fabrication Process Fig. (7) unpolymerised photoresist is also etched away [using H2SO4] Thick SiO2 (1 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

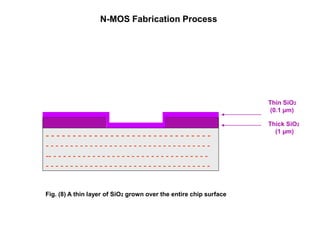

- 8. N-MOS Fabrication Process Fig. (8) A thin layer of SiO2 grown over the entire chip surface Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

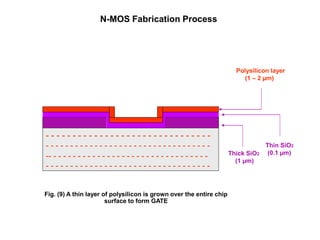

- 9. N-MOS Fabrication Process Fig. (9) A thin layer of polysilicon is grown over the entire chip surface to form GATE Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) Polysilicon layer (1 – 2 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

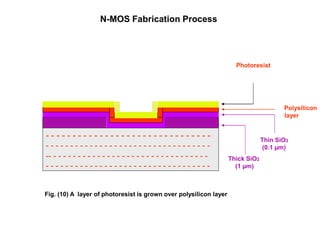

- 10. N-MOS Fabrication Process Fig. (10) A layer of photoresist is grown over polysilicon layer Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) Polysilicon layer Photoresist - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

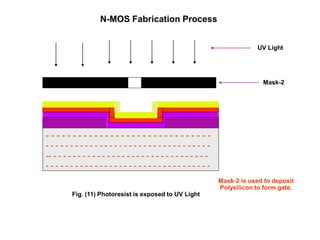

- 11. N-MOS Fabrication Process Fig. (11) Photoresist is exposed to UV Light UV Light Mask-2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Mask-2 is used to deposit Polysilicon to form gate.

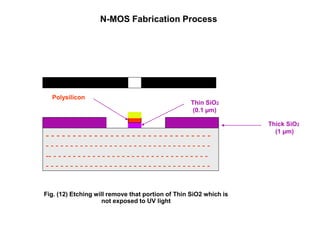

- 12. N-MOS Fabrication Process Fig. (12) Etching will remove that portion of Thin SiO2 which is not exposed to UV light Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) Polysilicon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

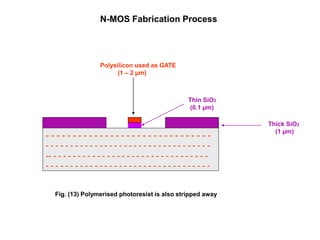

- 13. N-MOS Fabrication Process Fig. (13) Polymerised photoresist is also stripped away Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) Polysilicon used as GATE (1 – 2 µm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

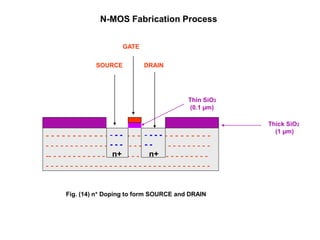

- 14. N-MOS Fabrication Process Fig. (14) n+ Doping to form SOURCE and DRAIN - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) Thin SiO2 (0.1 µm) GATE - - - - - - n+ - - - - - - n+ SOURCE DRAIN

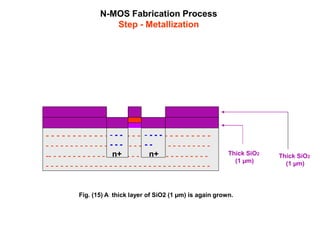

- 15. N-MOS Fabrication Process Step - Metallization Fig. (15) A thick layer of SiO2 (1 µm) is again grown. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm)

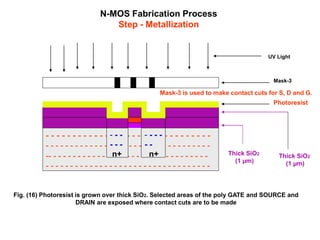

- 16. N-MOS Fabrication Process Step - Metallization Fig. (16) Photoresist is grown over thick SiO2. Selected areas of the poly GATE and SOURCE and DRAIN are exposed where contact cuts are to be made - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Photoresist Mask-3 UV Light Mask-3 is used to make contact cuts for S, D and G.

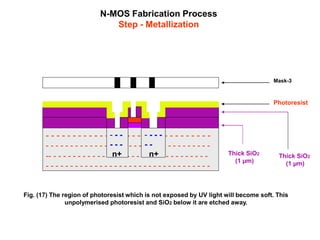

- 17. N-MOS Fabrication Process Step - Metallization Fig. (17) The region of photoresist which is not exposed by UV light will become soft. This unpolymerised photoresist and SiO2 below it are etched away. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Photoresist Mask-3

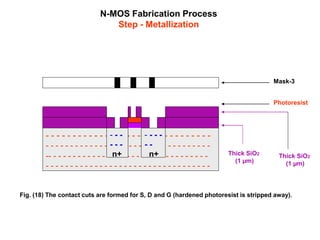

- 18. N-MOS Fabrication Process Step - Metallization Fig. (18) The contact cuts are formed for S, D and G (hardened photoresist is stripped away). - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Photoresist Mask-3

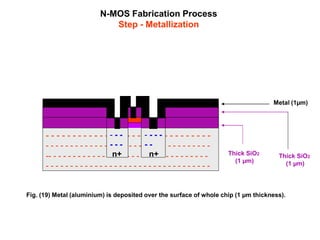

- 19. N-MOS Fabrication Process Step - Metallization Fig. (19) Metal (aluminium) is deposited over the surface of whole chip (1 µm thickness). - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Metal (1µm)

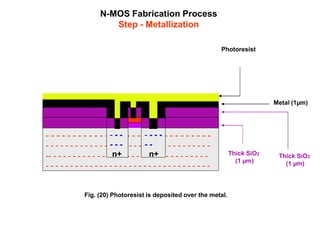

- 20. N-MOS Fabrication Process Step - Metallization Fig. (20) Photoresist is deposited over the metal. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Metal (1µm) Photoresist

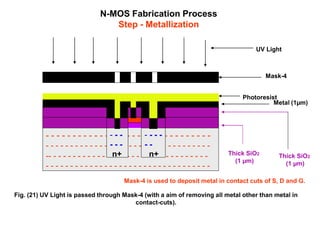

- 21. N-MOS Fabrication Process Step - Metallization Fig. (21) UV Light is passed through Mask-4 (with a aim of removing all metal other than metal in contact-cuts). - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Metal (1µm) Photoresist UV Light Mask-4 Mask-4 is used to deposit metal in contact cuts of S, D and G.

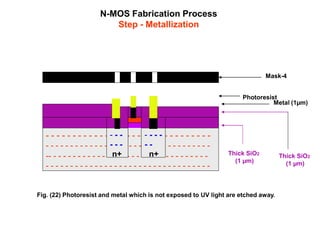

- 22. N-MOS Fabrication Process Step - Metallization Fig. (22) Photoresist and metal which is not exposed to UV light are etched away. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Thick SiO2 (1 µm) - - - - - - n+ - - - - - - n+ Thick SiO2 (1 µm) Metal (1µm) Photoresist Mask-4

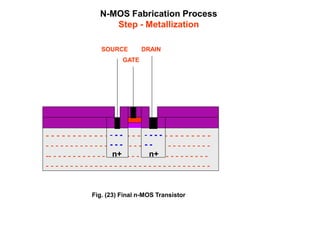

- 23. N-MOS Fabrication Process Step - Metallization Fig. (23) Final n-MOS Transistor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - n+ - - - - - - n+ SOURCE DRAIN GATE

![N-MOS Fabrication Process

Fig. (7) Etching [HF acid is used] will remove SiO2 layer

which is in direct contact with etching solution

Thick SiO2

(1 µm)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

-- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -](https://image.slidesharecdn.com/c5a8af5a-02be-45a8-b68e-97105a189a80-151114161252-lva1-app6892/85/n-MOS-Fabrication-Process-6-320.jpg)

![N-MOS Fabrication Process

Fig. (7) unpolymerised photoresist is also etched away

[using H2SO4]

Thick SiO2

(1 µm)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

-- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -](https://image.slidesharecdn.com/c5a8af5a-02be-45a8-b68e-97105a189a80-151114161252-lva1-app6892/85/n-MOS-Fabrication-Process-7-320.jpg)