Non stranded ropes

- 1. N O N S T R A N D E D R O P E S PRESENTED BY VISHAL KUMAR DAS : 117MN0646

- 2. INTRODUCTION DEFINATION & CONSTRUCTION CLASSIFICATION APPLICATIONS IN MINES REFERENCES C O N T E N T S

- 3. In stricter senses, the term "wire rope" refers to a diameter larger than 3/8 inch (9.52 mm), with smaller gauges designated cable or cords. It is an important item of engineering material in mining and many other engineering industries. I N T R O D U C T I O N WIRE ROPE

- 4. TYPES : There are many classification of wire ropes based on different properties, but itâs broadly classified as: 1. Stranded Ropes 2. Non-stranded Ropes

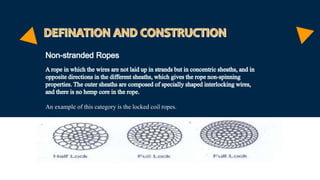

- 5. Wire Ropes Stranded Ropes A stranded rope is built up of strands and each strand consists of a number of concentrically twisted wires laid in the form of a helix round a central steel wire. Non-stranded Ropes In non-stranded rope, mainly the layers are coiled in a locked fashion and no such strands is there as in stranded ropes.

- 6. An example of this category is the locked coil ropes.

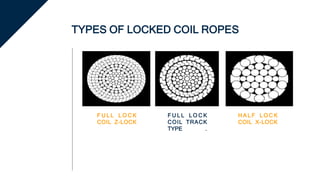

- 8. TYPES OF LOCKED COIL ROPES F U L L L O C K COIL Z-LOCK F U L L L O C K COIL TRACK TYPE . H A L F L O C K COIL X-LOCK

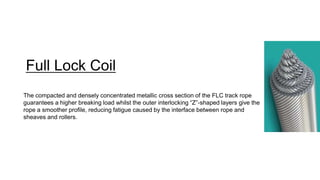

- 9. Full Lock Coil The compacted and densely concentrated metallic cross section of the FLC track rope guarantees a higher breaking load whilst the outer interlocking âZâ-shaped layers give the rope a smoother profile, reducing fatigue caused by the interface between rope and sheaves and rollers.

- 10. PROPERTIES . .

- 11. FEATURES Parallel core Sacrificial coating for corrosion resistance Diameter: 30 â 74mm MBL: 853 â 6906kN

- 12. Full Lock Coil, Z-Lock for deep shaft mining is a high strength, low stretch, stable, non-rotating rope. With its characteristic Z wires, designed to prevent unlocking, its smooth outer surface makes it highly compatible with sheave linings (drum and Koepe). Z-Lock ropes can be designed and manufactured to be compatible with specific drum grooves. FULL LOCK COIL Z-LOCK (A powerful, high strength rope for deep shaft mining applications.)

- 13. ADVANTAGES Precision engineering Rope is made to optimise performance and safety, enhance operating efficiencies, reduce costs and extend service life. High fatigue performance Engineered for overall performance, the tensile strength of FLCâs interlocking Z wires is key to this ropeâs superior fatigue resistance. Long service life With its characteristic steel Z wires, designed to prevent unlocking, the FLC Z-Lock has an exceptionally smooth outer surface making it highly compatible with sheave linings and resistant to friction, abrasion and fatigue Cost effective High ductility wires minimise the occurrence of internal wire breaks caused by dynamic stresses, improve performance and extend service life. .

- 14. PROPERTIES

- 15. FEATURES Diameter: 22 â 64mm MBL: 407 â 3996kN Rotation Resistance Stretch Resistant

- 16. The outer layer of interconnecting Z profile wires give the Full Lock Coil, Z- Lock rope an extremely smooth outer surface that is suitable for Koepe friction winders and drum winders. APPLICATIONS

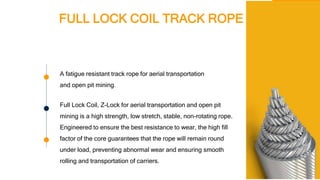

- 17. FULL LOCK COIL TRACK ROPE A fatigue resistant track rope for aerial transportation and open pit mining. Full Lock Coil, Z-Lock for aerial transportation and open pit mining is a high strength, low stretch, stable, non-rotating rope. Engineered to ensure the best resistance to wear, the high fill factor of the core guarantees that the rope will remain round under load, preventing abnormal wear and ensuring smooth rolling and transportation of carriers.

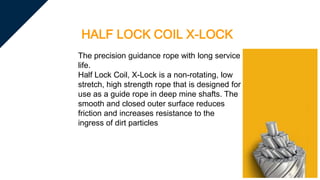

- 19. HALF LOCK COIL X-LOCK The precision guidance rope with long service life. Half Lock Coil, X-Lock is a non-rotating, low stretch, high strength rope that is designed for use as a guide rope in deep mine shafts. The smooth and closed outer surface reduces friction and increases resistance to the ingress of dirt particles

- 20. High service life HLC X-Lockâs unique structure, with interlocking X and O profile wires, provides a smooth outer surface that reduces friction and is resistant to the ingress of damaging dust and debris particles. Easy installation The non-rotating structure of HLC X-Lock make installation straightforward. Precision engineering Rope is made to optimise performance and operating efficiencies, reduce costs and extend service life. Cost effective High ductility wires minimise the occurrence of internal wire breaks, improving performance and extending service life. ADVANTAGES

- 21. SPECIFICATION: HALF LOCK X TYPE 40%

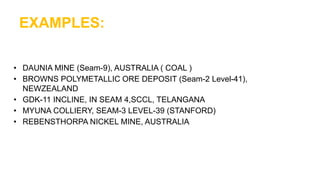

- 23. EXAMPLES: âĒ DAUNIA MINE (Seam-9), AUSTRALIA ( COAL ) âĒ BROWNS POLYMETALLIC ORE DEPOSIT (Seam-2 Level-41), NEWZEALAND âĒ GDK-11 INCLINE, IN SEAM 4,SCCL, TELANGANA âĒ MYUNA COLLIERY, SEAM-3 LEVEL-39 (STANFORD) âĒ REBENSTHORPA NICKEL MINE, AUSTRALIA

- 24. REFERENCES: âĒ https://www.mindat.org/glossary/locked_coil_rope âĒ Deshmukh D.J. (2019), Elements Of Mining Technology, Vol. 3, Denett Publications âĒ https://www.steelwirerope.com/WireRopes/Structural/fully-locked-coil-ropes.html âĒ https://barsandrods.arcelormittal.com/wiresolutions/wireropes/ âĒ https://en.wikipedia.org/wiki/Wire_rope

- 25. T H A N K S