Norvatis by team 5 final

- 1. Should it Outsource its US Supply Chain? Team 5 Peter Francis Cullen, Robin Koo, Tracy Tan, Isabella Tan Lai Yuen

- 2. IEMBA 2015 Team 5 Novartis Global pharmaceutical leader with a âcare and cureâ mission

- 3. IEMBA 2015 Team 5 Novartis Novartis US âĒ Novartis Pharmaceuticals Corporation (NPC) âĒ R&D, manufacturing and marketing of patent-protected medicines and treatments for helping patients and improving patient care

- 4. IEMBA 2015 Team 5 Novartis

- 5. IEMBA 2015 Team 5 Novartis Agenda âĒ Brief Synopsis of the Case - Current Situation & Issues - Current Distribution Model âĒ The Problem Statement âĒ Case Analysis âĒ Recommendations âĒ Post Case-where are they today? âĒ Lessons Learned

- 6. IEMBA 2015 Team 5 Novartis Current Situation (2007) US Novartis manufactures 80% of their drugs in NY plant. Trucks product (40miles) to NJ Warehouse & DC. (Responsible for receiving, packing & preparing for shipping full range of Novartis pharmaceuticals to Wholesalers~ US$12bn in sales)

- 7. IEMBA 2015 Team 5 Novartis Current relationship with Wholesalers 3 National wholesalers handle 90% Novartis US shipments Wholesaler has a âbuy-and-hold approachâ â speculative buying. Reduced opportunity to do so leading to their discontent. Wholesalers also face challenges on customer side where powerful retail chains demanding higher price concessations Wholesalers response by imposing a distribution fee.

- 8. IEMBA 2015 Team 5 Novartis Current Issues (2007) Sustainability of Wholesale Distribution Model NJ Warehouse/ DC starting to deteriorate! Costly location Competitive Pressures Reduced Profit Margins Facilities Overcrowded Risk of single DC Limited Sophistication (IT/ EDI)

- 9. IEMBA 2015 Team 5 Novartis Current Supply Chain Novartis Suffern Plant East Hanover Centre Novartis Wholesaler Novartis Wholesaler Novartis Wholesaler Pack, Prepare, Deliver Receive & Store

- 10. IEMBA 2015 Team 5 Novartis The Problem Statement âĒ A Decision needs to be taken on whether to outsource supply chain to a 3rd Party Logistics Partner (3PL) âĒ How do we convince the board, CEO and internal management that outsourcing to Exel is the best option.

- 11. IEMBA 2015 Team 5 Novartis Agenda âĒ Brief Synopsis of the Case - Current Situation & Issues - Current Distribution Model âĒ The Problem Statement âĒ Case Analysis âĒ Recommendations âĒ Post Case-where are they today? âĒ Lessons Learned

- 12. IEMBA 2015 Team 5 Novartis Shipment visibility and inventory control important consideration for Norvatis

- 13. IEMBA 2015 Team 5 Novartis Case Analysis: Why outsource to EXEL? ïą They have a warehouse with an ideal combination of size, layout and location. ïą They can start distributing for Novartis immediately. Providing distribution flexibility. ïą Provide customer-centric initiatives which includes speciality and expedited deliveries. ïą Will add customer-specific electronic date interchange (EDI) mapping and disaster recovery plans for Novartis. ïą Exel optimizes warehouse and inventory management. ïą Will provide a security driven infrastructure to support such a large pharmaceutical company.

- 14. IEMBA 2015 Team 5 Novartis Inventory reduction to improve working capital Year Inventory T/O ratio Inventory no of days 2007 2.22 164 2008 2.03 180 Source: Novartis Annual Report Consolidated Group Ratios

- 15. IEMBA 2015 Team 5 Novartis Recommendations for Exel-McLaury: âĒ A 3PL that specializes in warehousing and transportation that can be extremely flexible. âĒ Supply chains are highly complex. âĒ Provide consolidation point/center near the Novartis HQ. âĒ Expertise in receiving, store, pack and prepare the pharmaceuticals for shipment to the wholesalers. âĒ Good size company whoâs size ensures that they will be able handle the demand. âĒ Pricing structure will save Novartis millions of dollars. âĒ Understanding of the pharmaceutical business and could take an even larger roles as needed.

- 16. IEMBA 2015 Team 5 Novartis New Supply Chain Novartis Suffern Plant DC, Mechanicsburg Novartis Wholesaler Novartis Wholesaler Novartis Wholesaler Pack, Prepare, Deliver Receive & Store

- 17. IEMBA 2015 Team 5 Novartis Additional Recommendations for 3PL-Team 5: âĒ Direct system integration (e.g. IT, cross functional) âĒ Transparency âĒ Business continuity plan (BCP) âĒ Inventory management and control âĒ Safety and security âĒ Proficient inventory management âĒ Hybrid distribution âĒ Product packaging âĒ Parallel run to ensure risks are minimized âĒ Change management

- 18. IEMBA 2015 Team 5 Novartis Agenda âĒ Brief Synopsis of the Case - Current Situation & Issues - Current Distribution Model âĒ The Problem Statement âĒ Case Analysis âĒ Recommendations âĒ Post Case-where are they today? âĒ Lessons Learned

- 19. IEMBA 2015 Team 5 Novartis Enhanced supply chain flexibility with Exel âĒ Enhanced disaster recovery & business continuity âĒ Improved security and tracking âĒ Leveraged IT, labor and global resources âĒ Improved working capital â reduced inventory âĒ Better efficiency with shipment consolidation âĒ Novartis earned âSupplier of the Yearâ award from McKesson Source: Exel website

- 20. IEMBA 2015 Team 5 Novartis During the next 5 years, we aim to optimize our production network by creating manufacturing centres of excellence. We are looking to improve our network utilization to around 80% by 2015, from approximately 50% today. Also scaling up procurement organization, and our target is to deliver sustainable savings between 6% and 8% per year 2010 Annual Report Joseph Jimenez CEO

- 21. IEMBA 2015 Team 5 Novartis Business strategy to be more focused, more profitable and grow faster Source: June 2014 Analyst Briefing

- 22. IEMBA 2015 Team 5 Novartis Driving margin increase and accelerating cash flow Many SCM related initiatives e.g. SRM, lean manufacturing, offshoring, etc Beyond 3PL Source: June 2014 Analyst Briefing

- 23. SCM initiatives â enablers for margin growth IEMBA 2015 Team 5 Novartis Source: June 2014 Analyst Briefing

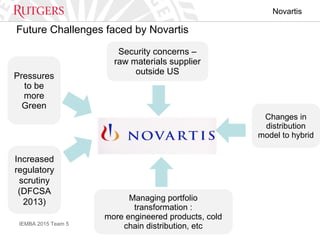

- 24. IEMBA 2015 Team 5 Novartis Security concerns â raw materials supplier outside US Managing portfolio transformation : more engineered products, cold chain distribution, etc Pressures to be more Green Changes in distribution model to hybrid Future Challenges faced by Novartis Increased regulatory scrutiny (DFCSA 2013)

- 25. IEMBA 2015 Team 5 Novartis Agenda âĒ Brief Synopsis of the Case - Current Situation & Issues - Current Distribution Model âĒ The Problem Statement âĒ Case Analysis âĒ Recommendations âĒ Post Case-where are they today? âĒ Lessons Learned

- 26. IEMBA 2015 Team 5 Novartis Lessons Learned âĒ Focus on core strength - R&D and manufacturing âĒ SCM strategies â an important enabler for Novartis margin growth âĒ Market forces amplify the impetus to consider outsourcing âĒ Pharma industry is facing an increasing list of challenges that requires greater supply chain capabilities and flexibility âĒ Effective communication is essential for successful implementation

- 27. IEMBA 2015 Team 5 Novartis

Editor's Notes

- #27: Outsourcing logistics activities that are transactional, operational and repetitive in nature