NOVOCHEM ENGINEERING INDIA LLP

- 1. NOVOCHEM ENGINEERING INDIA LLP.Plot no-4,KH no-22/14/2 Pochanpur Extn. B-Block Dwarka, New Delhi-110077. www.srdchemicals.in DETERGENT POWDER & DETERGENT BAR MACHINERY. .

- 3. RIBBON MIXTURE WE MANUFACTRE DIFFERENT SIZE OF RIBBON MIXTURE , 100KG PER BATCH. 200KG PER BATCH 300KG PER BATCH 400KG PER BATCH 500KG PER BATCH 700KG PER BATCH 1000KG PER BATCH MACHINES ARE AVILABLE IN STAINLESS STEEL 304 AND IN MILD STEEL.

- 4. RIBBON BLENDER BLADE WE HAVE AN UNIQUE TECHNOLOGY IN WHICH OUR BLADES ARE WORKING SIMALTANEOUSLY IN TWO DIFFERENT DIRECTION AT ONCE AND IN SAME DIRECTION AFTER SOME TIME , THIS SYSTEM OF MOVEMENT MAKE THE POWDER MIX PROPERLY. WE USE HEAVY SHAFT THICK BLADES. This is a Ribbon Blender Mixer Machine, Mainly used to Blend all the additives to be used in Detergent Powder. It also performs a function of adding Color & Perfume in Powder.

- 5. RIBBON MIXTURE WE USE HELICAL GEAR BOX IN OUR RIBBON MIXTURE. THESE HEAVYDUTY GEAR BOX ARE FOR BETTER MOVEMENT AND ROTATION OF MACHINE. BRANDED MOTOR AND HELICAL GEAR BOXES MAKES OUR MACHINE 100% FULL PROOF TECHNOLOGICALY .

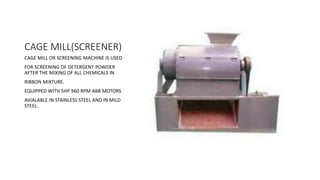

- 6. CAGE MILL(SCREENER) CAGE MILL OR SCREENING MACHINE IS USED FOR SCREENING OF DETERGENT POWDER AFTER THE MIXING OF ALL CHEMICALS IN RIBBON MIXTURE. EQUIPPED WITH 5HP 960 RPM ABB MOTORS AVIALABLE IN STAINLESS STEEL AND IN MILD STEEL.

- 7. BUCKET CONVYER BUCKET CONVYER USED FOR THE SHIPMENT OF DETERGENT POWDER FROM RIBBON MIXTURE TO CAGE MIL OR FROM CAGE MILL TO DOSSIER.HEIGHT IS 20 FEET TALL.

- 8. SCREW CONVYER SCREW CONVYER IS USE FOR THE MOVEMENT OF DETERGENT POWDER FROM FLOOR TO AUTOMATIC PACKING MACHINE.

- 9. Detergent bar machine. SIGMA MIXTURE Sigma MIXTURE is used for the manufacturing of detergent bar as well dish wash Bar and Dish wash Tub. Bottom discharge, feeding hopper IF REQUIRE , 20 HP electric motor and HELICAL gear box, twin blade heavy Duty sigma mixer for mixing detergent cake mass with other chemicals. We use heavy z arm blades for the mixing of clay along with the other related chemicals.

- 11. Duplex Single Worm Vacuum Plodder with Worm Reducer Gear Boxes :- The Duplex Single Worm Vacuum Plodder is suitable to carry out the Refining & Extrusion of Laundry /Toilet Soap Noodles & Bar. . The Components of Plodder are:- 1.Extrution Barrels : Extrusion Barrels are made of Seamless Grade Tubes. Outer Double Jacket is fitted for cooling of the Plodder, by a forced water flow circulation. The outside Water circuit is Pre Mounted. 2. Extrusion Worms : Worm are casted. This Worm is Highly Glossy Polished. Being a low weight it will consume lesser electric power & higher extrusion rate. The worm is supported by the Spider Wheels with Teflon Bushes. 3.Bearing Housing Unit or Thrust Unit : In this Unit Thrust Bearings are installed outside the Gear Boxes in an Independent Group, with the combination, Three (3) Bearings witch are fitted in sequence with Lubrication Ports. 4.Refining Head & Extrusion Head: Hinged Round Hole Drilled Plate duly fitted with Rotary Knife System that ensures the best Refining & Cutting of the Noodles to Standard Size. Same as Extrusion Head to Extrude final Bar

Editor's Notes

- .